A transport robot based on universal joints

A technology of universal joints and robots, applied in the field of robots, can solve the problems of increasing the number of motors, complex structures, and inability to meet the functional requirements of robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

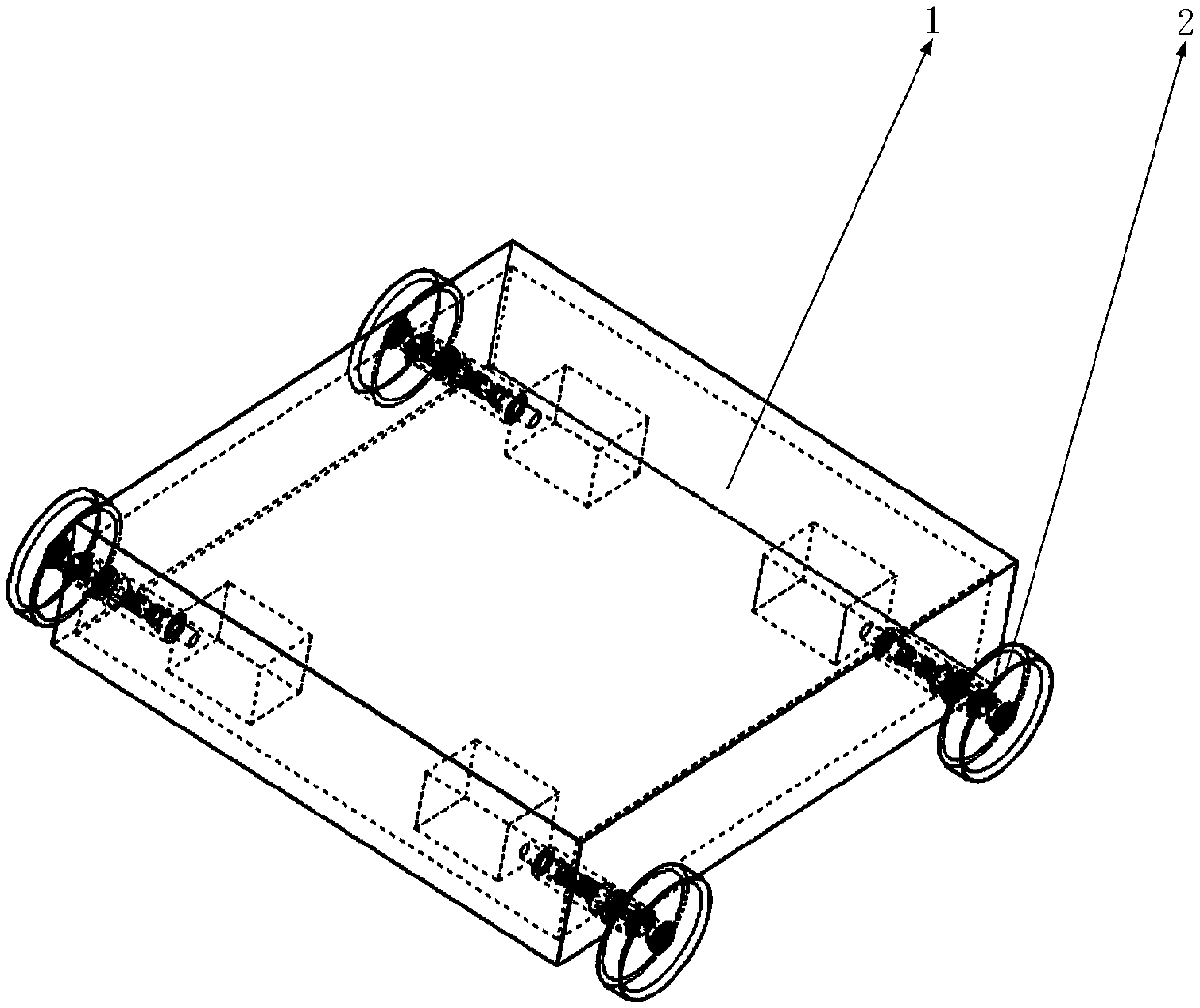

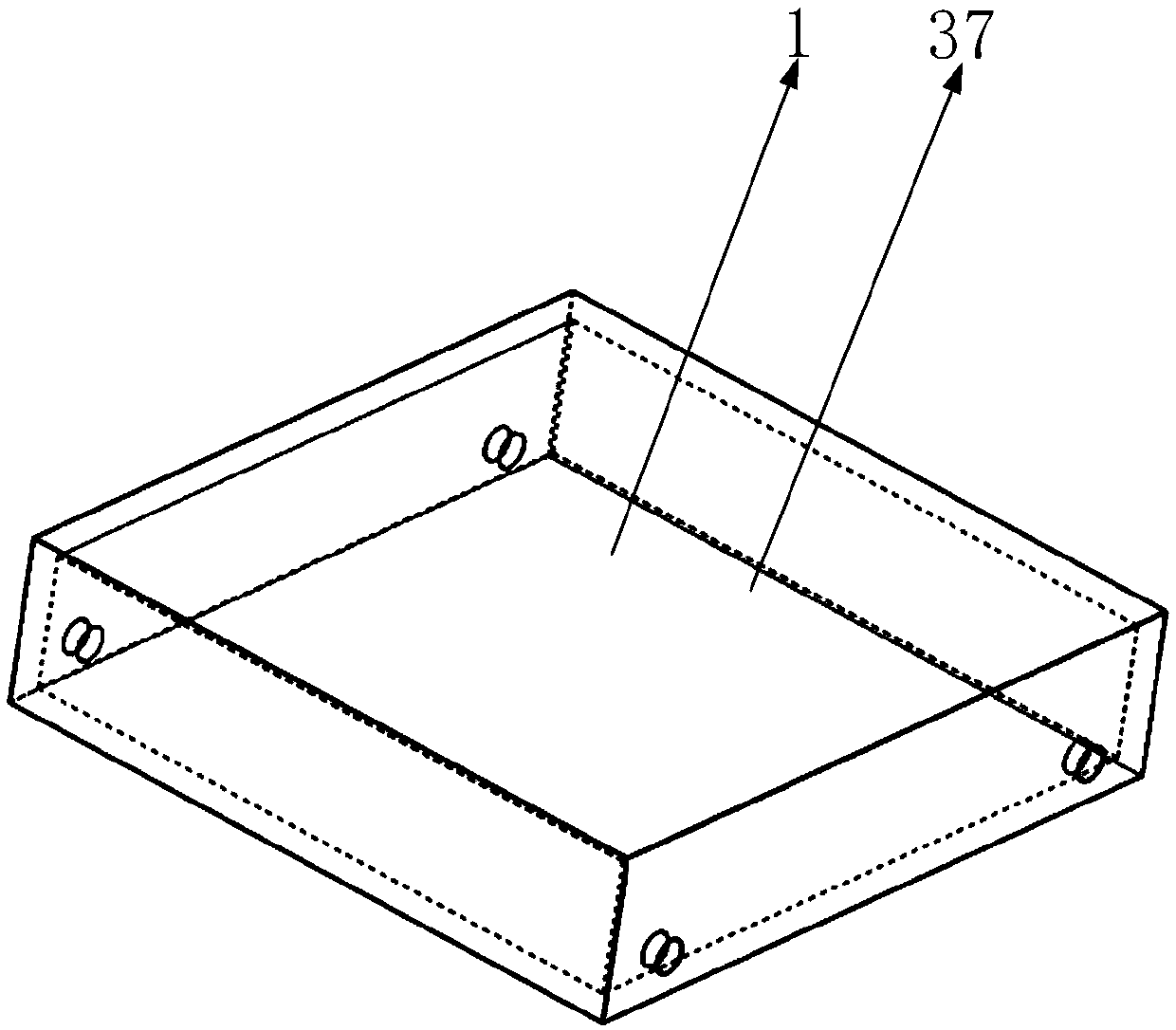

[0040] Such as figure 1 As shown, it includes a vehicle body 1 and a driving wheel unit 2, wherein four driving wheel units 2 are symmetrically installed on both sides of the vehicle body 1 in pairs, and two driving wheel units 2 on one side are located at both ends of the vehicle body 1 .

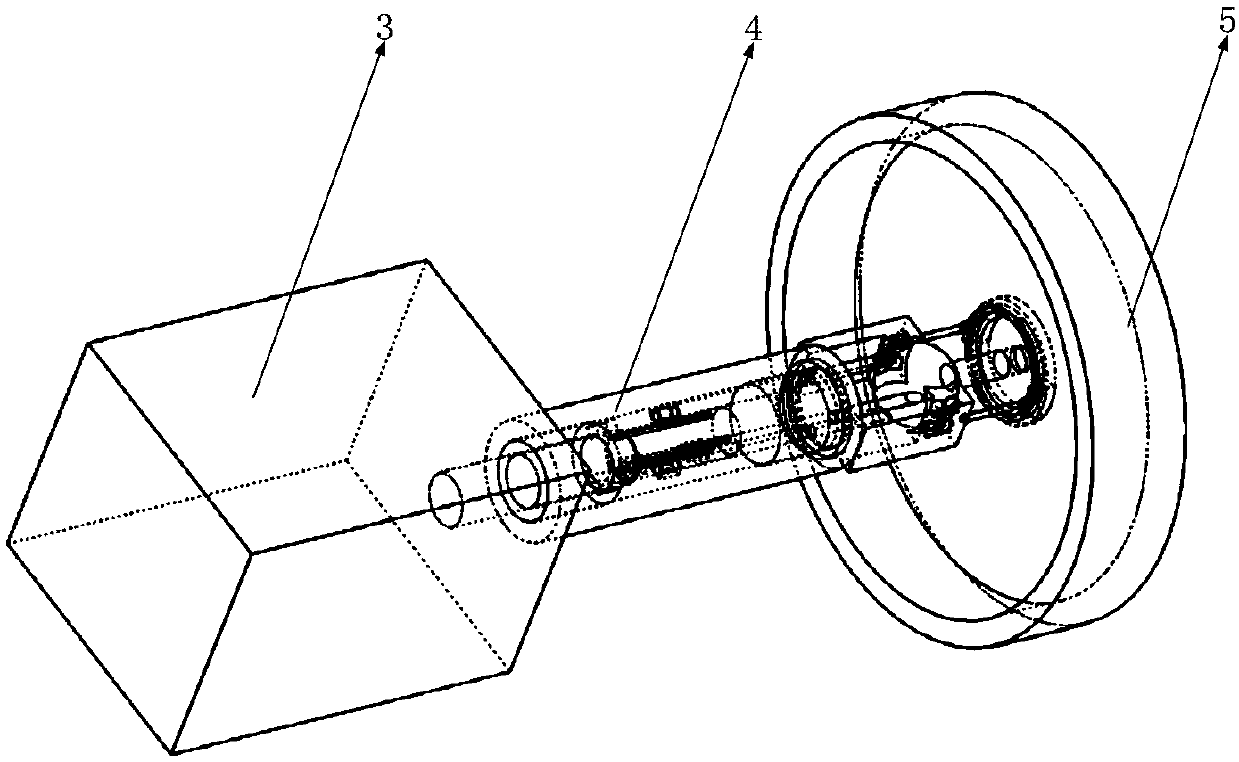

[0041] Such as figure 1 , 2 , 22, the above-mentioned drive wheel unit 2 includes a motor 3, a second permanent magnet 38, a third permanent magnet 39, a second electromagnet 40, a third electromagnet 41, a second spring 42, a third spring 43, a second Wire rope 44, third wire rope 45, fixed sleeve 4, wheel 5, transmission shaft 6, T-shaped guide groove 8, axle sleeve 10, electromagnet, permanent magnet, first wire rope 13, support plate 14, through hole 15, ring groove 16. Spring, T-shaped guide block 18, support block 19, transmission ball 20, connecting rod 21, wheel shaft 22, T-shaped slider 23, transmission circular plate 24, spherical surface 25, first ball hinge shaft 26, support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com