A laser cutting machine

A laser cutting machine and auxiliary workbench technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of inability to realize the positioning accuracy of the cutting box, increase the after-sales maintenance cost of enterprises, and increase the maintenance rate of equipment manufacturers and other problems, to achieve the effect of simple structure, elimination of front and rear jitter, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

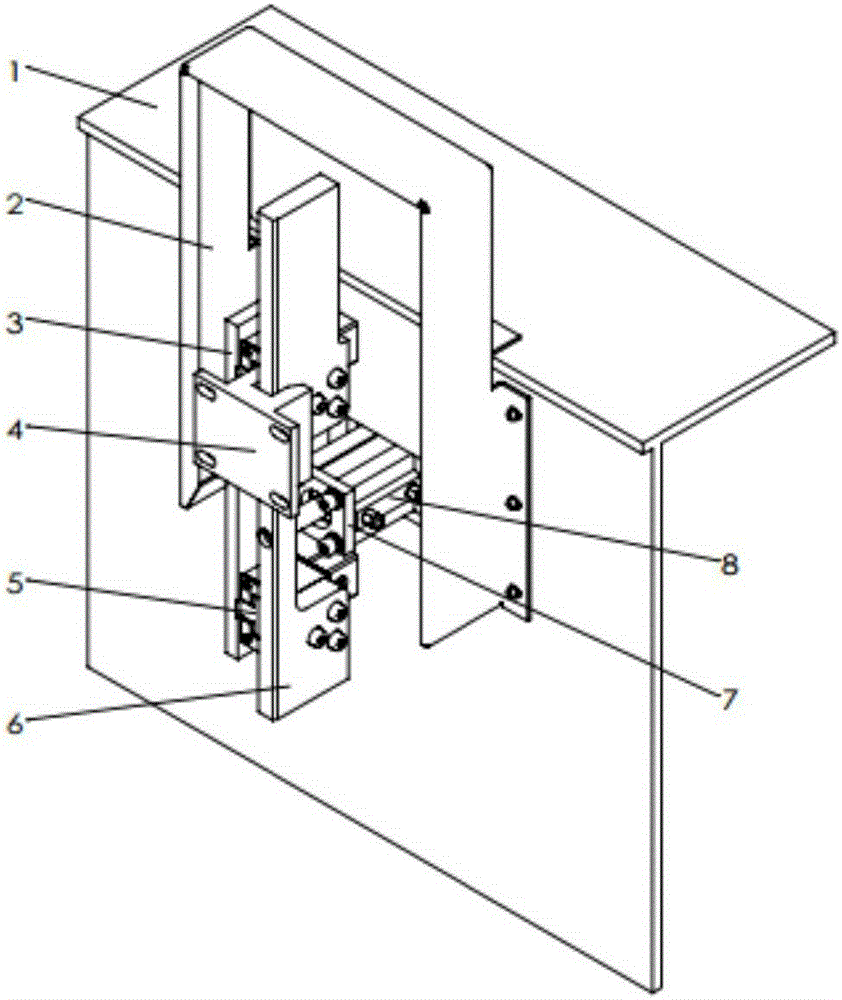

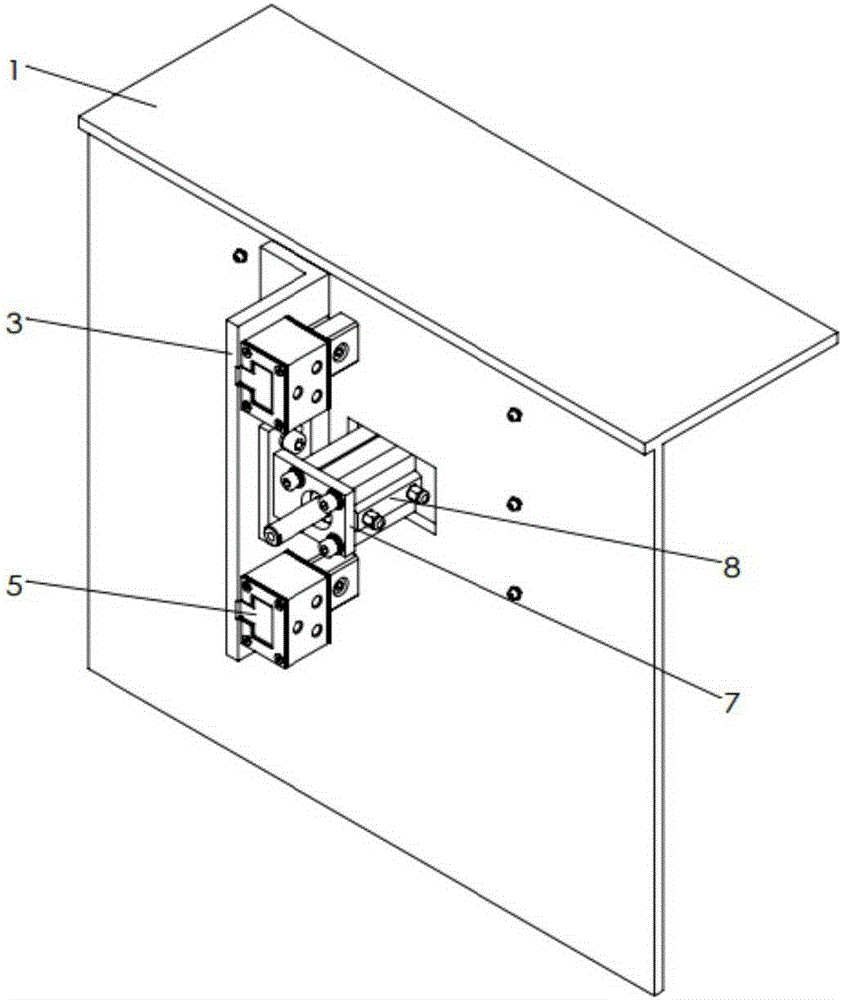

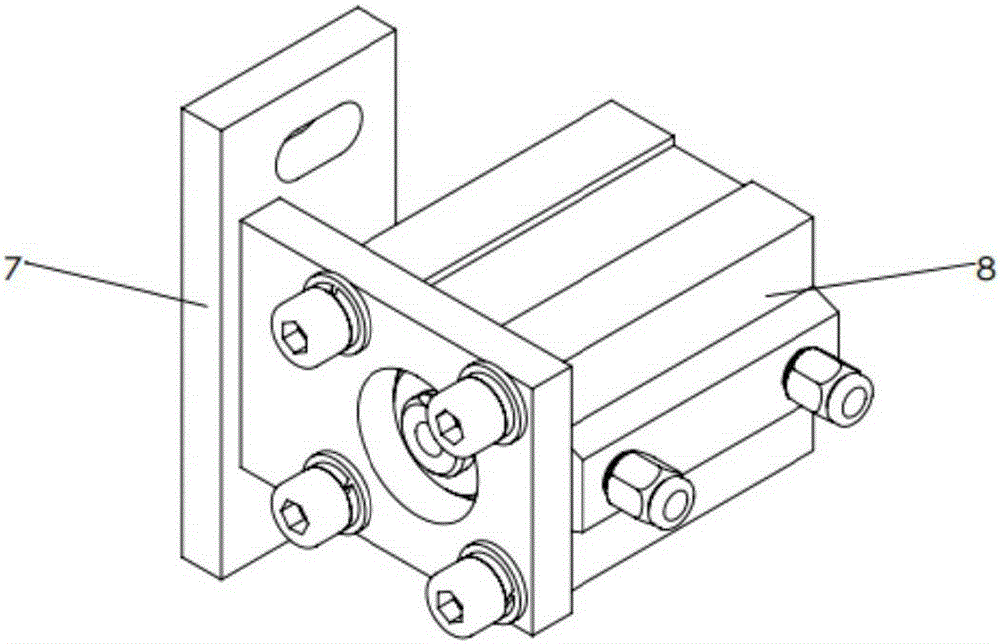

[0032] like Figure 1a and Figure 1b As shown, the present embodiment discloses a laser cutting machine, which includes a cutting box 18 and an auxiliary workbench 1. A side positioning device is provided between the cutting box 18 and the auxiliary workbench 1; the side positioning device is mainly composed of The guide rail slider pair 5 on the 3, the positioning plate 6, the cylinder support frame 7 and the cylinder 8, the positioning block 4 installed on the cutting box and the throttle valve 14, the two-position five-way reversing valve 15, and the muffler 16 , push-in connector 17, pneumatic control system 9 formed by trachea (omitted and not drawn). The protective cover 2 can protect the device, and can also provide safety protection for operating workers. The positioning device has a simple structure and a small overall size, and can be directly installed on the auxiliary workbench 1 of a numerically controlled laser cutting machine tool after being assembled.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com