Automotive chair headrest foaming product production device

A technology for car seats and production equipment, applied in the field of machinery, can solve problems such as inability to achieve precise positioning of stations, long waiting time for stations, and slow production tempo, so as to reduce labor consumption, save floor space, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

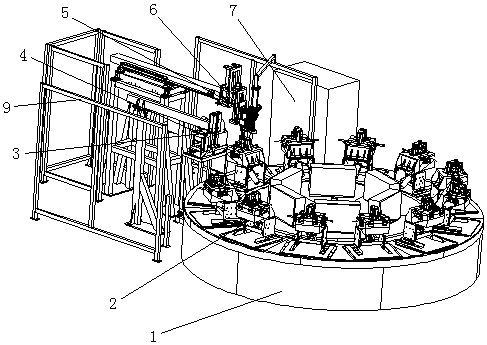

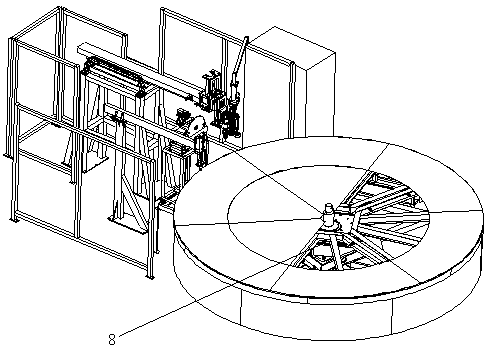

[0013] The following is a further detailed description of the automobile seat headrest foam product production device of the present invention in conjunction with the accompanying drawings.

[0014] Such as figure 1 , figure 2 As shown, the blowing mechanism 3, the pneumatic manipulator 5 and the cleaning mechanism 4 of the automobile seat headrest foam product production device of the present invention are all installed on the support 9 and controlled by the electric cabinet 7. The turntable body 1 is rotated clockwise by the indexing table 8 and controlled by the electric cabinet 7. In the original state, the mold 2 is opened, the headrest cover is manually put into the mold 2, the sprue sleeve is placed, and the mold 2 is transferred to the blowing mechanism At 3 o'clock, the turntable stops, and the blowing mechanism 3 blows air on the opposite side; when the mold 2 turns to the position of the pneumatic manipulator 5, the turntable stops, and the pneumatic manipulator 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com