Automotive drum type braking device grinding and renovating method

A brake device and drum-type technology, applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve problems such as machine damage, chatter, traffic accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

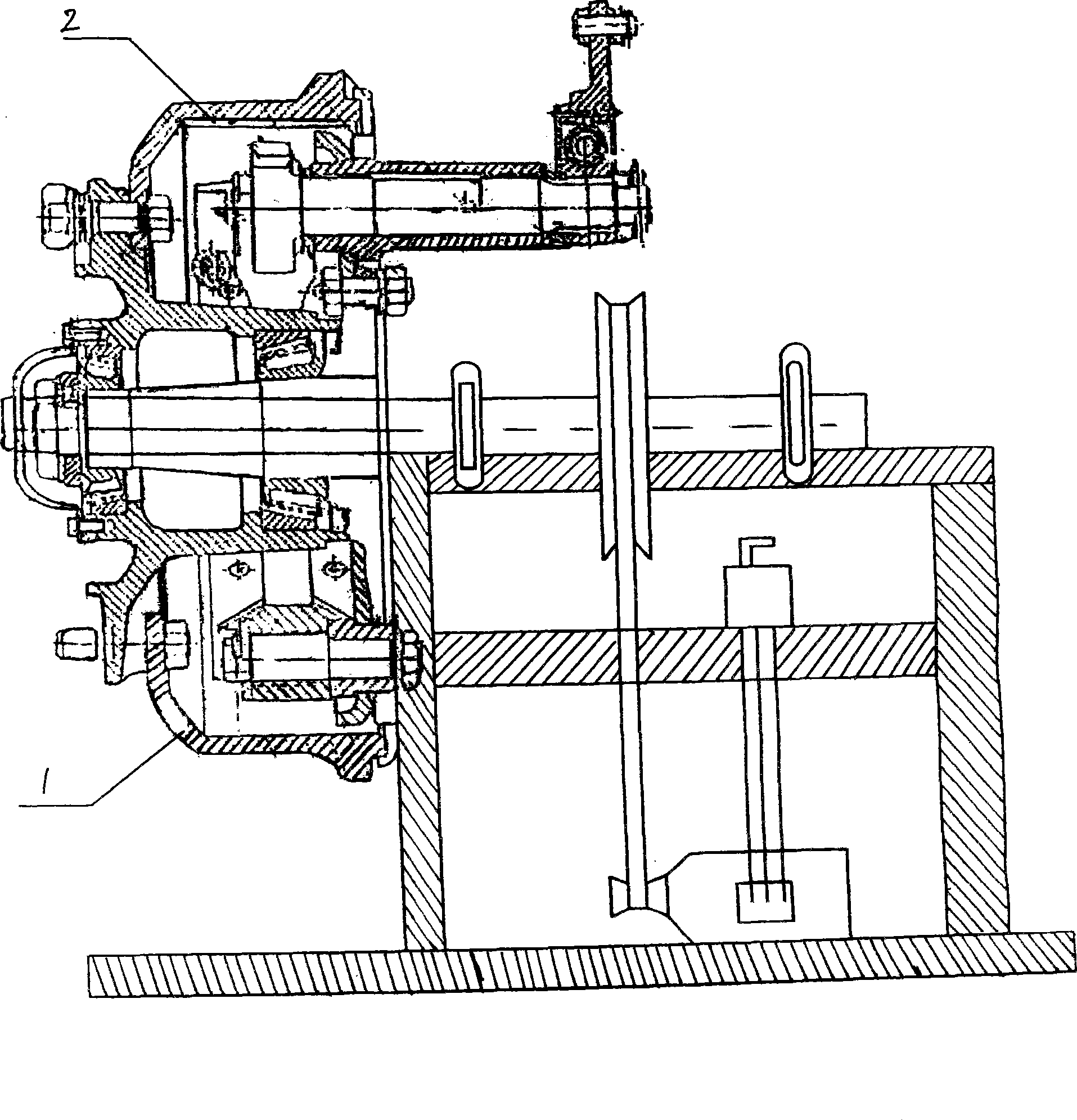

[0015] 1. Build a pair of car brake fixtures that are exactly the same as the car brake device; the difference is that the brake pads 2 and the hub can rotate forward or reverse like the normal operation of the car; immediately take it off or clamp it, and clamp it.

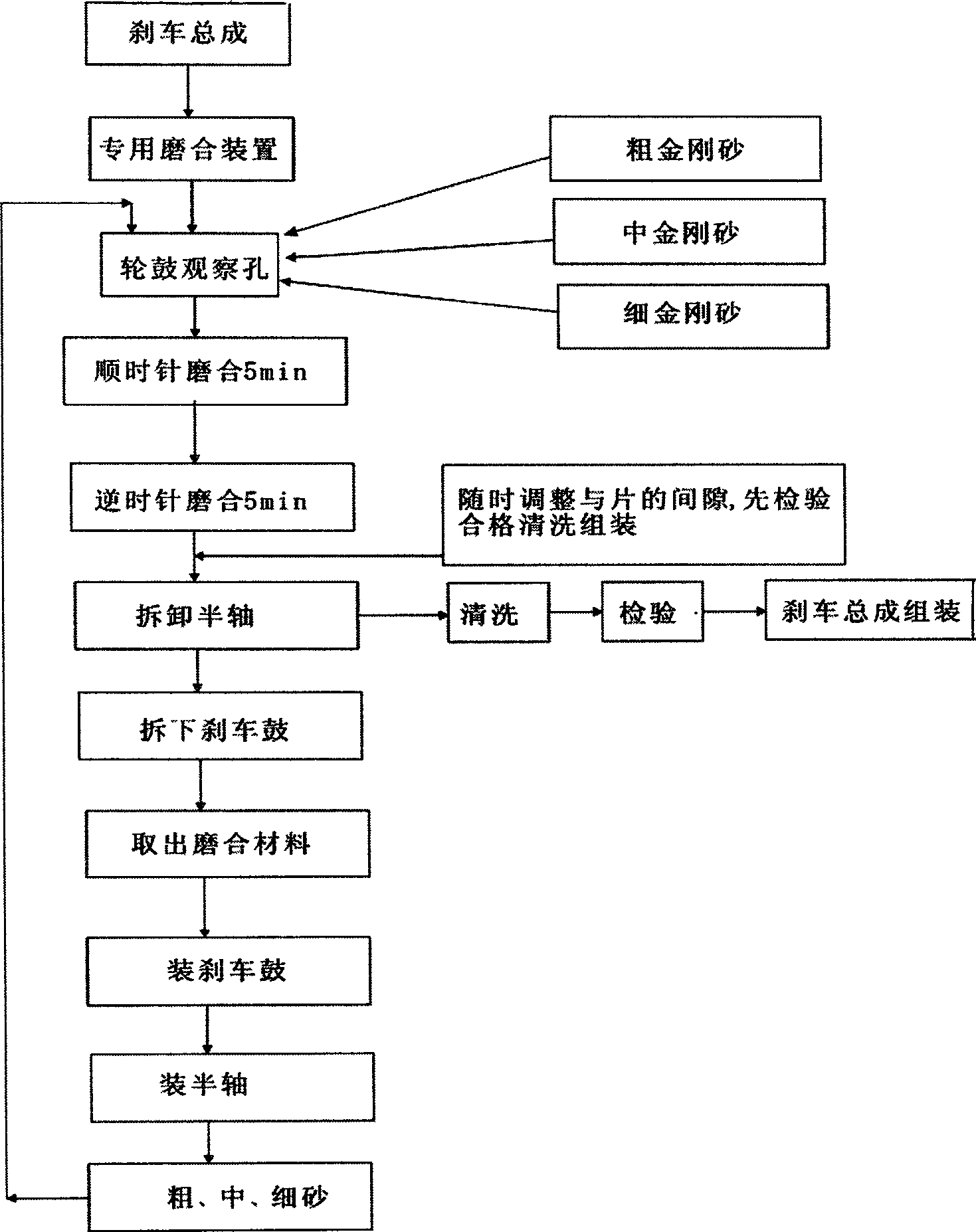

[0016] 2. Round or coarse grinding process;

[0017] For brakes and brake drums (sand foundry parts) that have not undergone the rounding process, or for brake drums that have been damaged by use, the concentric circle formed by the inner circle and the outer circle of the brake friction pad will definitely be damaged. Such repairs require More processes:

[0018] The first process is relatively difficult or the amount of milling or rough grinding is relatively large, so that the blank of the brake drum can be obtained.

[0019] 3. Coarse, medium and fine grinding process;

[0020] The specific methods of coarse, medium and fine grinding processes are as follows;

[0021] The specific methods of coarse, medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com