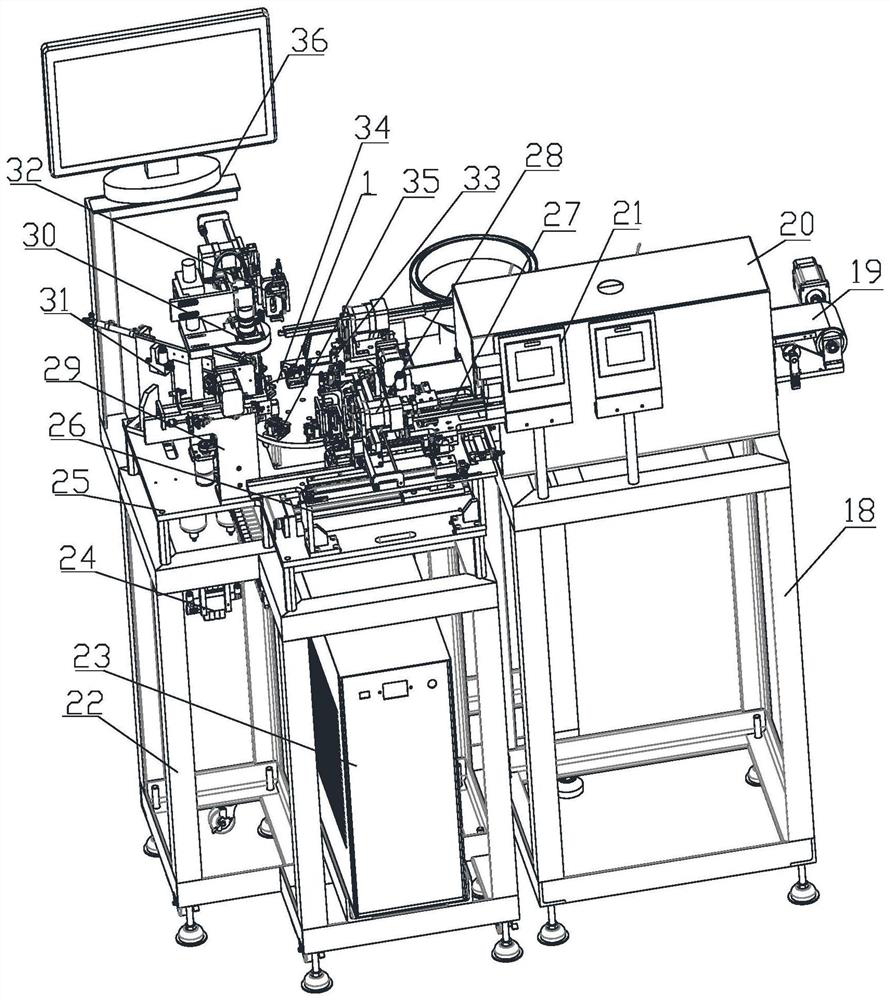

Production line for automatic assembly and bonding of surface inductor cores

A technology of automatic assembly and surface inductance, which is applied in the manufacture of inductors/transformers/magnets, circuits, and magnetic cores. It can solve the problems of poor ring core height consistency, inconsistent assembly errors, and low product qualification rate, and achieve firm terminal blocks. , low production cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The point sticking tin drip glue that the present invention adopts, according to mass percentage, by the tin powder of 60%-70%, the silver powder of 10%-20%, the resin of 0.7%-1.2%, the acetone of 1.5%-2%, 0.55% Acetate, 8%-15% rosin (selected as FS113A) and 5%-6.25% water are mixed at room temperature. After fusion, it cannot be exposed to the air, otherwise precipitation will occur. The resin particles are 1um-3um, the tin powder particles are 3um-50um, and the silver powder particles are 0.3um-3um. The soldering temperature of the spot-stick tin drop glue is 150°C-300°C, and the soldering time is less than 2s. It is pre-stirred for 5 minutes before operation, and then stirred synchronously with the operation.

[0024] The upper, lower, left, and right positions in the following text descriptions are subject to the figures shown in the respective drawings, and the actual installation positions can be deduced by analogy.

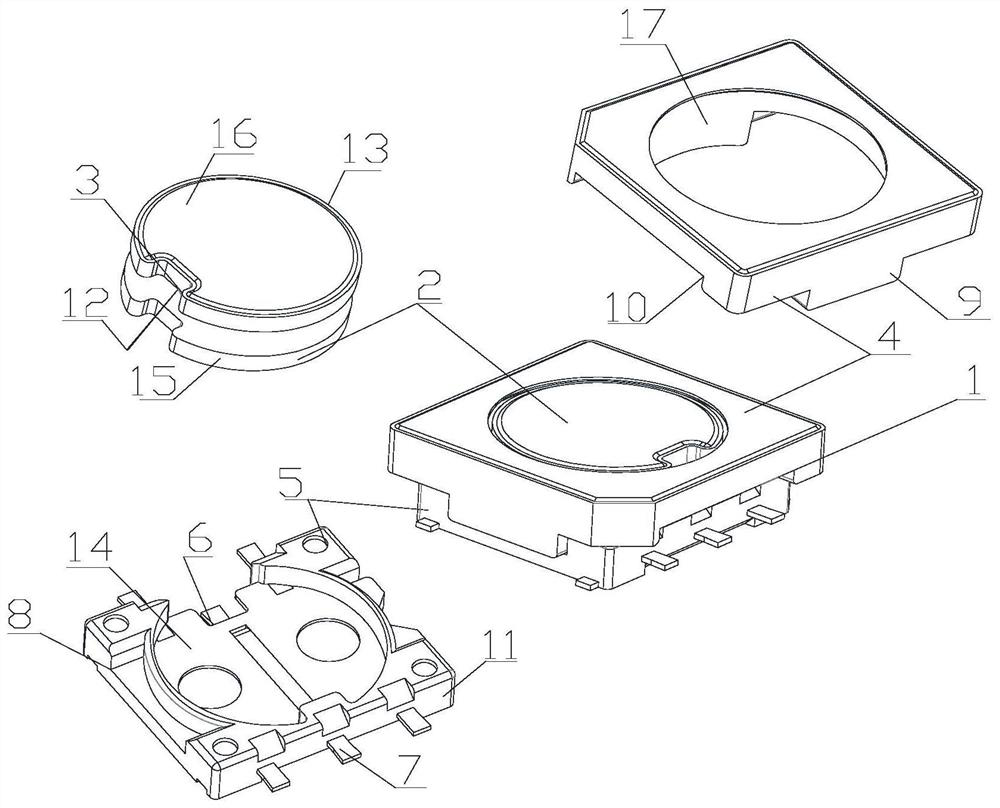

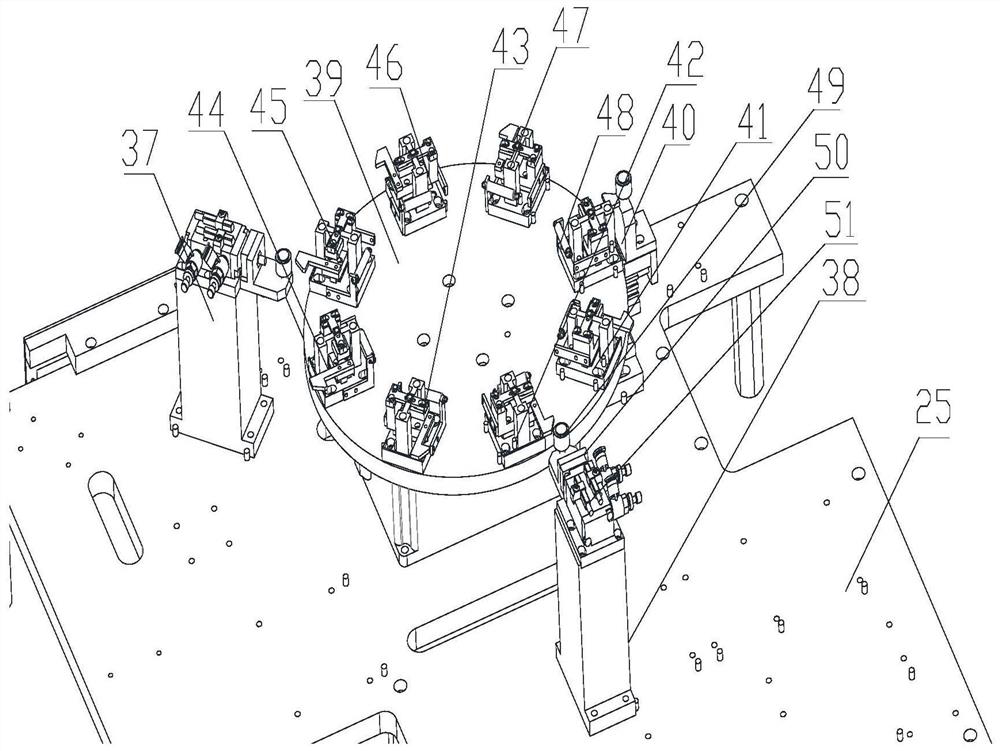

[0025] refer to figure 2, the structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com