A connection flange assembly device

A flange combination and flange technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., to achieve the same effect of gap or misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

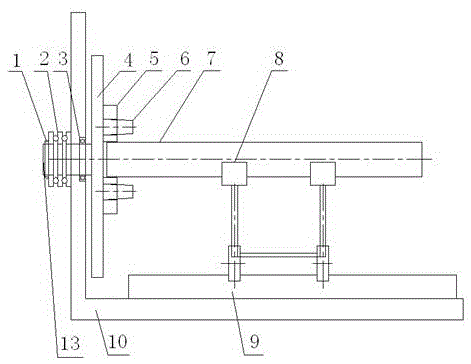

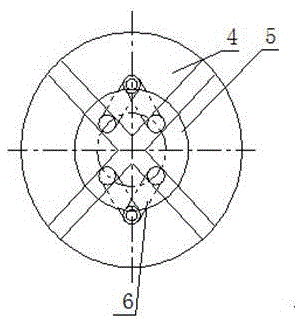

[0029] In the installation process of skid-mounted devices, there are usually small batches and small-diameter pipe flanges of the same pipe diameter paired. At present, the matching between the connecting pipe and the flange is often based on manual matching. The efficiency of manual matching is low, and it is greatly affected by human factors. The consistency of the connecting gap between the connecting pipe and the It is difficult to guarantee the alignment and misalignment with the flange. In order to solve the defects of the manual assembly method, reduce the influence of human factors, improve the quality and efficiency of the connection flange assembly, realize the semi-automation of the assembly construction, and meet the construction requirements, this embodiment provides a connection flange assembly device. The takeover flange pairing device is mainly composed of L-shaped operating platform 10, fixed support 11, rail 9, flange fixing 4, flange 5, rotating shaft 13, ...

Embodiment 2

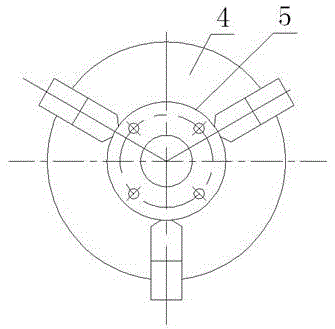

[0040] The flange fixing part 4 described in this embodiment is a three-jaw chuck, such as Figure 4 As shown, there is no pin shaft linkage mechanism 6 and cross groove structure on the three-jaw chuck. The rapid positioning of the workpiece flange 5 and the connecting pipe 7 is realized through the three-jaw chuck. Wherein the three claws on the three-jaw chuck fix the flange 5 through the outer diameter of the flange 5, which is mainly used for the combination of the flange 5 and the connecting pipe 7 with a smaller outer diameter. Refer to Embodiment 1 for the fitting device and usage method of connecting flanges in this implementation.

Embodiment 3

[0042] In order to further illustrate the beneficial effects of the connection flange assembly device of the present invention, this embodiment provides a manual assembly method and a time-consuming comparative experiment using the connection flange assembly device of the present invention.

[0043] In this embodiment, statistics are made on the time-consuming of groups of 10 DN40 sockets. Among them, the manual pairing method requires the cooperation of two riveters and welders during the pairing construction; when using the joint flange pairing device of the present invention, only one welder is required to operate. See Table 1 for the time-consuming statistical results of the manual pairing method, and see Table 2 for the time-consuming statistical results of using the connecting flange assembly device of the present invention. It can be seen from Table 1 that the total time-consuming of manual pairing is 35 minutes. It can be seen from Table 2 that it takes 11 minutes to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com