Integrated frame longitudinal beam connecting support

A connecting bracket and integrated technology, applied in the direction of vehicle components, the upper structure of the truck, the upper structure, etc., can solve the problems of low integration, the fixing of the front and lower protective beams is not firm, etc. Mechanical strength and component assembly efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

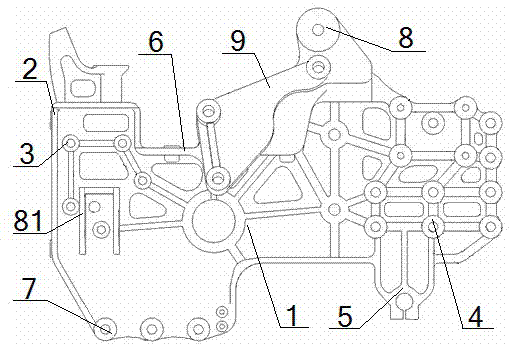

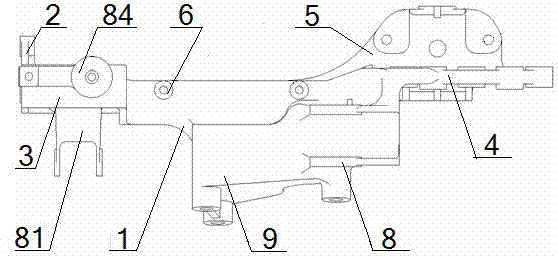

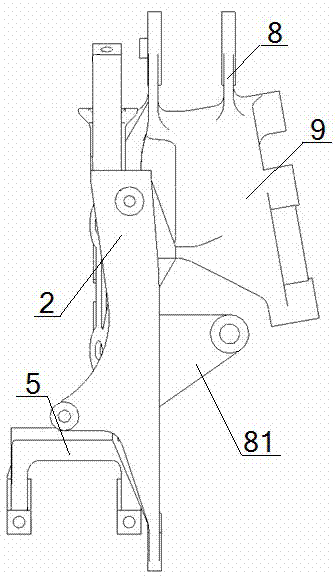

[0048] see figure 1 – Figure 6 , an integrated vehicle frame longitudinal beam connection bracket, including a base body 1 and a bumper mounting part 2, a beam assembly mounting part 3, a frame fixing part 4 and a leaf spring fixing part 5 arranged on the base body 1, and the bumper mounting part The back of the part 2 is fixedly connected to the front end of the frame fixing part 4 through the beam assembly installation part 3, and the bottom of the frame fixing part 4 is fixedly connected to the side part of the leaf spring fixing part 5; 3 and the frame fixing part 4 are provided with a recessed water tank installation part 6 and a cab front suspension turning arm installation part 8, and the lower side of the beam assembly installation part 3 is fixedly connected with a front lower protective support fixing part 7, The side part of the crossbeam assembly installation part 3 is fixedly connected with the front suspension shock absorber installation bracket 81; 5. The rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com