Patents

Literature

200results about "Screening processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

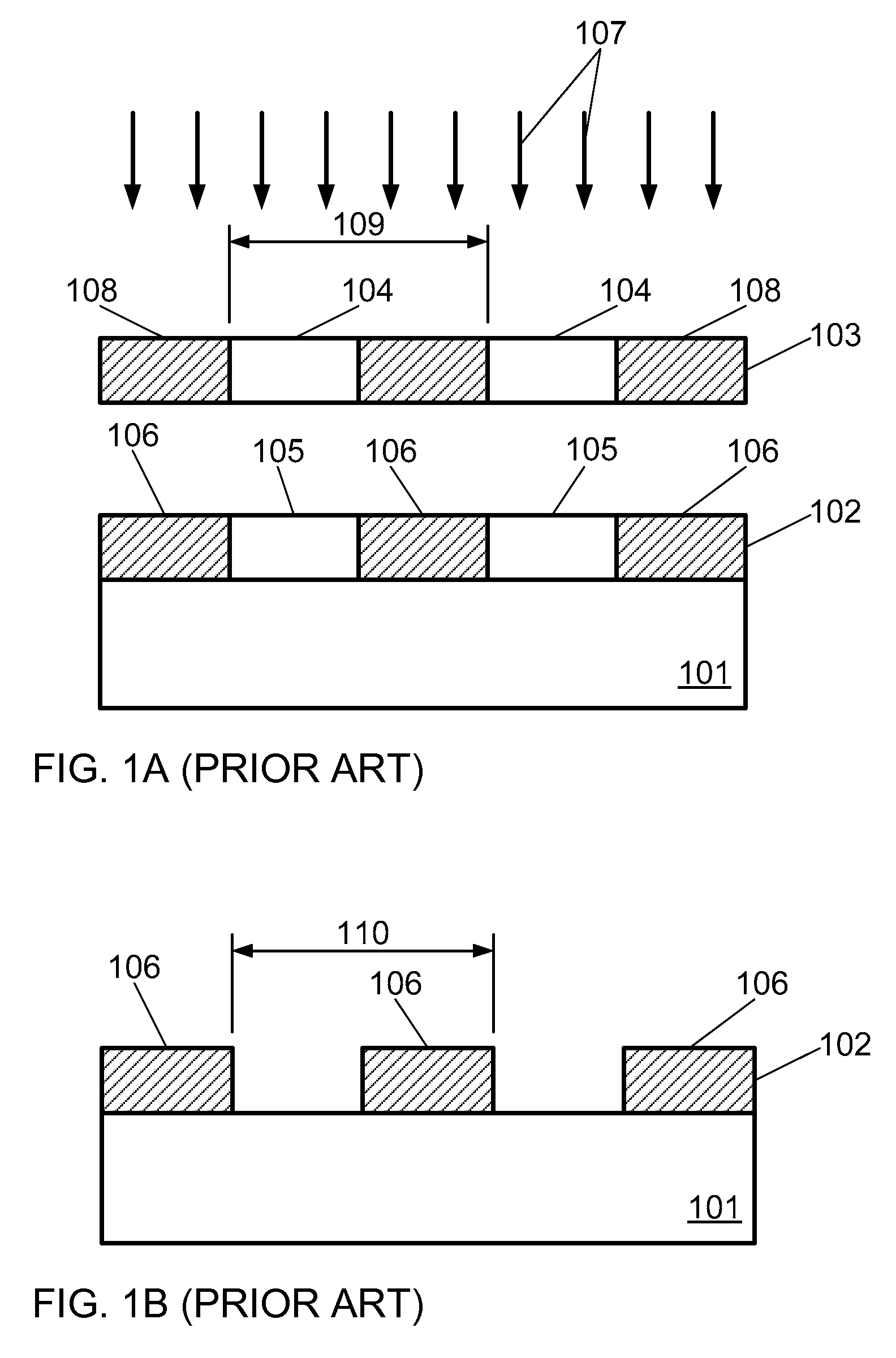

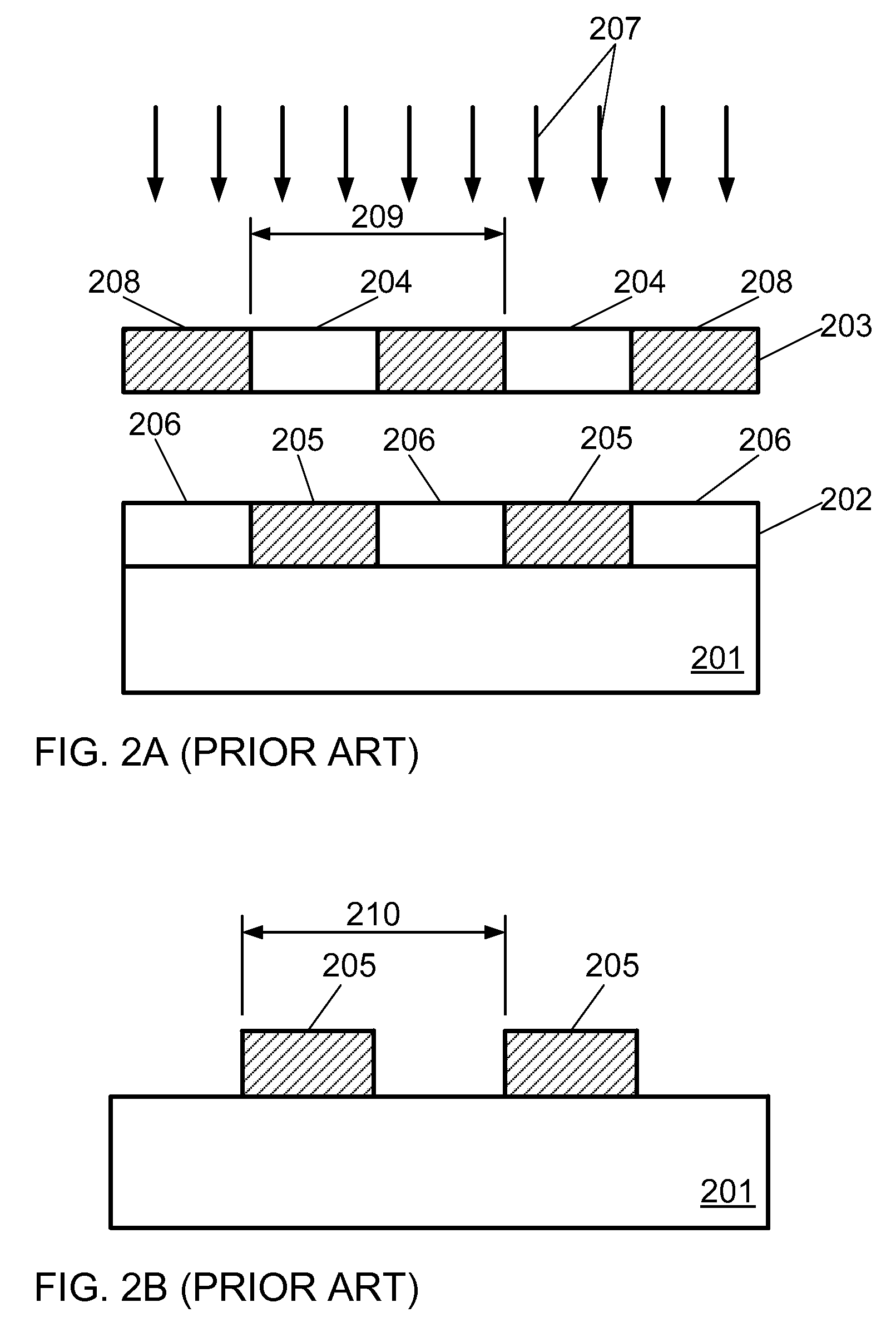

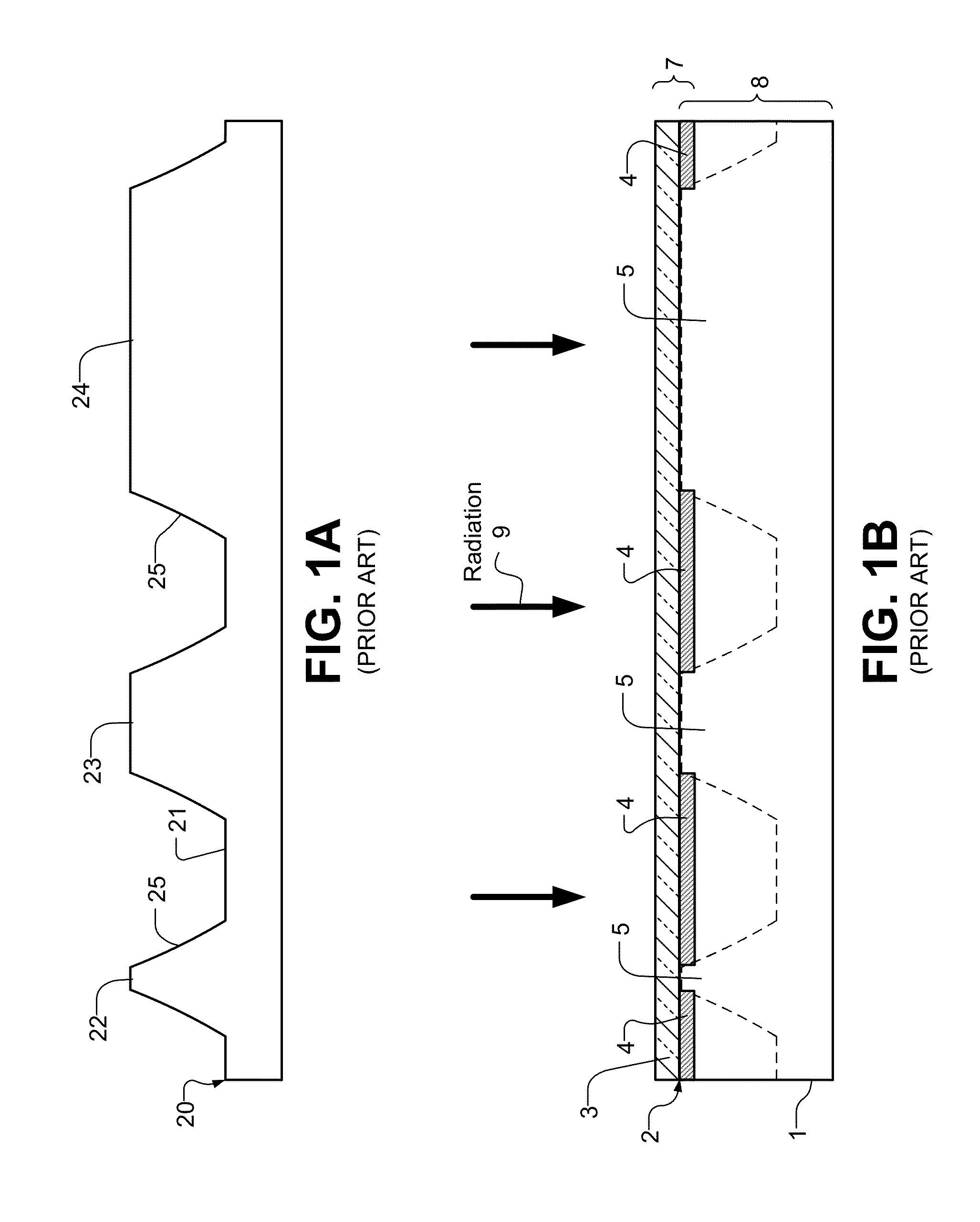

Generating mask patterns for alternating phase-shift mask lithography

InactiveUS6993741B2Photosensitive materialsSemiconductor/solid-state device manufacturingResistEngineering

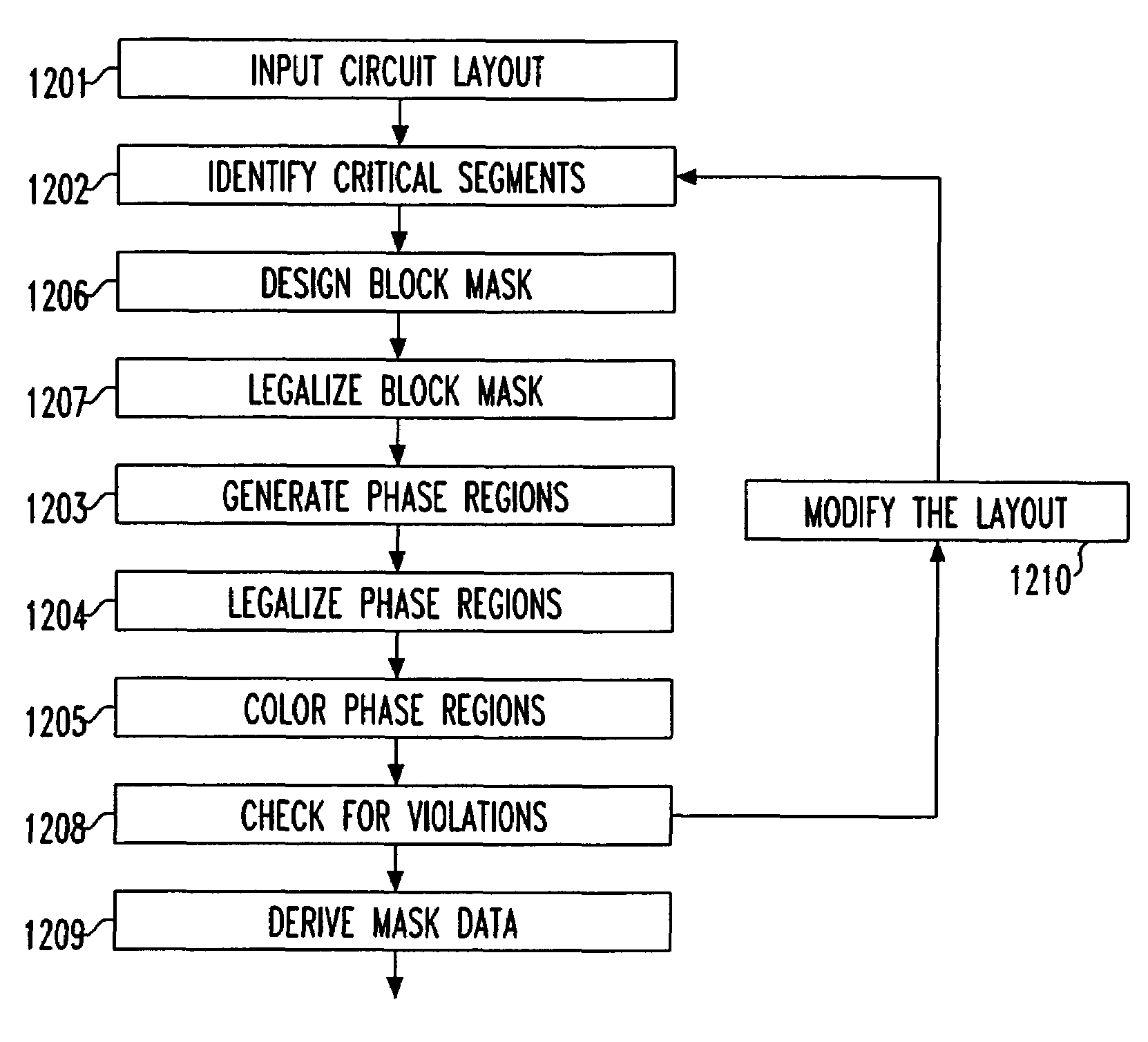

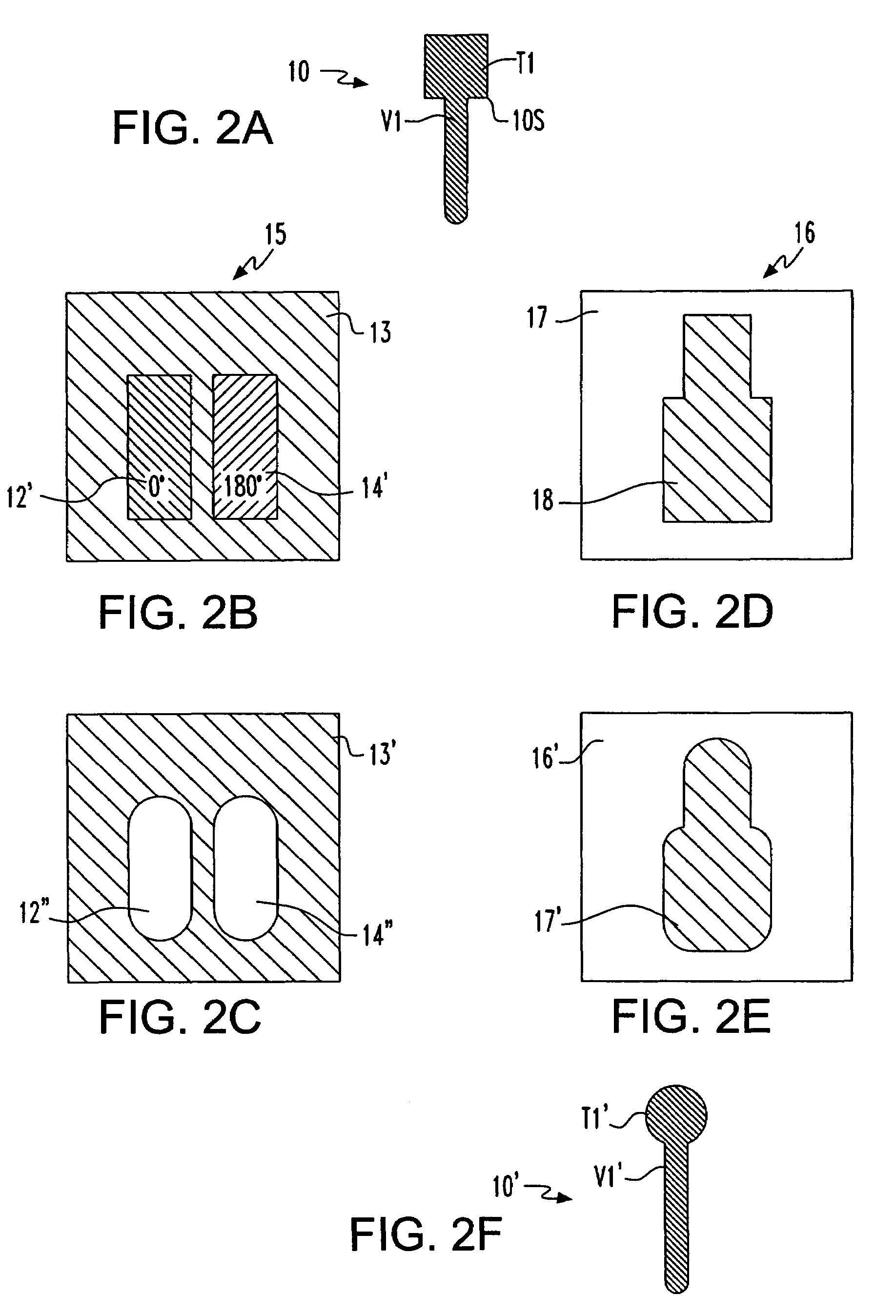

A method of generating patterns of a pair of photomasks from a data set defining a circuit layout to be provided on a substrate includes identifying critical segments of the circuit layout to be provided on the substrate. Block mask patterns are generated and then legalized based on the identified critical segments. Thereafter, phase mask patterns are generated, legalized and colored. The legalized block mask patterns and the legalized phase mask patterns that have been colored define features of a block mask and an alternating phase shift mask, respectively, for use in a dual exposure method for patterning features in a resist layer of a substrate.

Owner:GLOBALFOUNDRIES INC

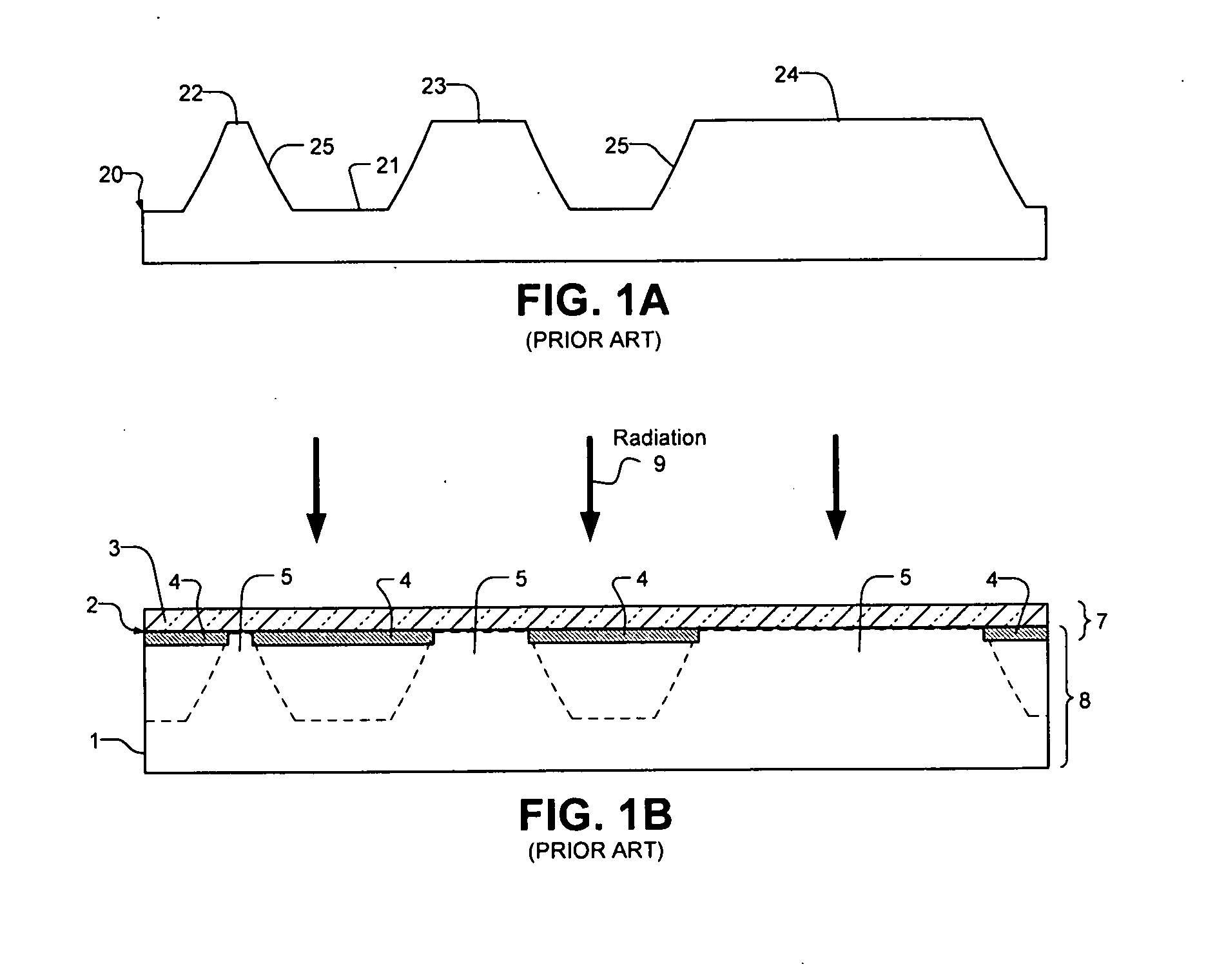

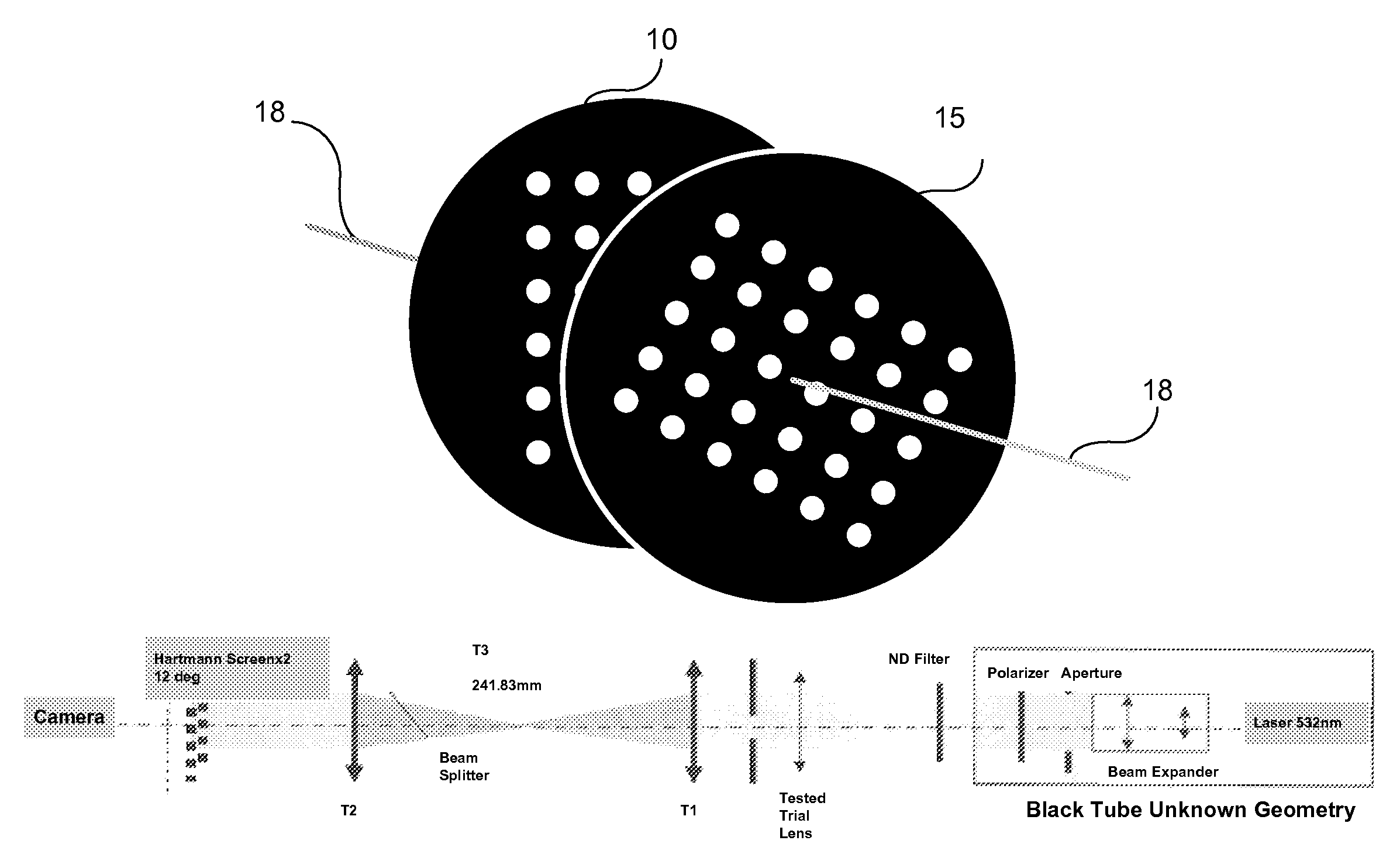

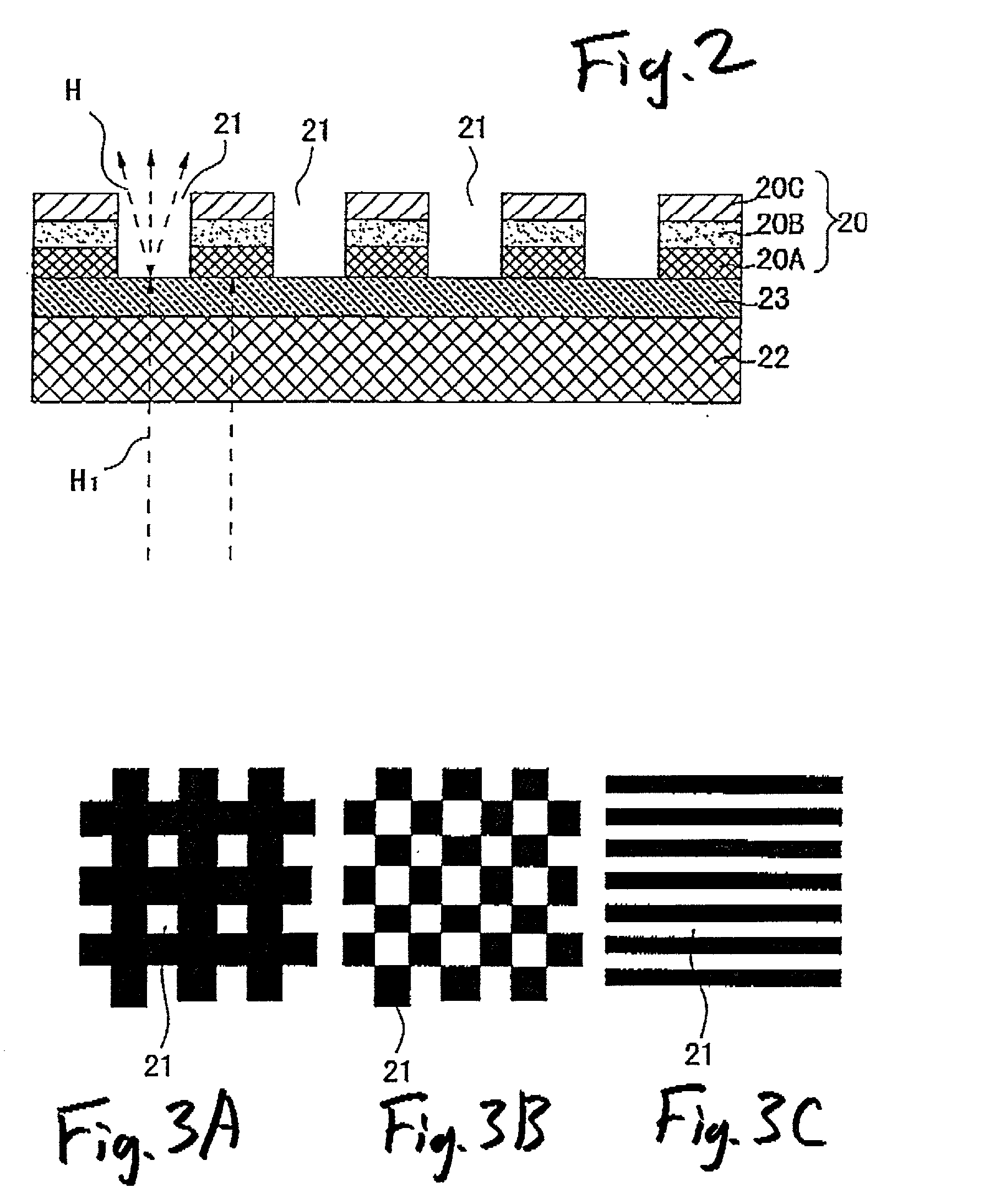

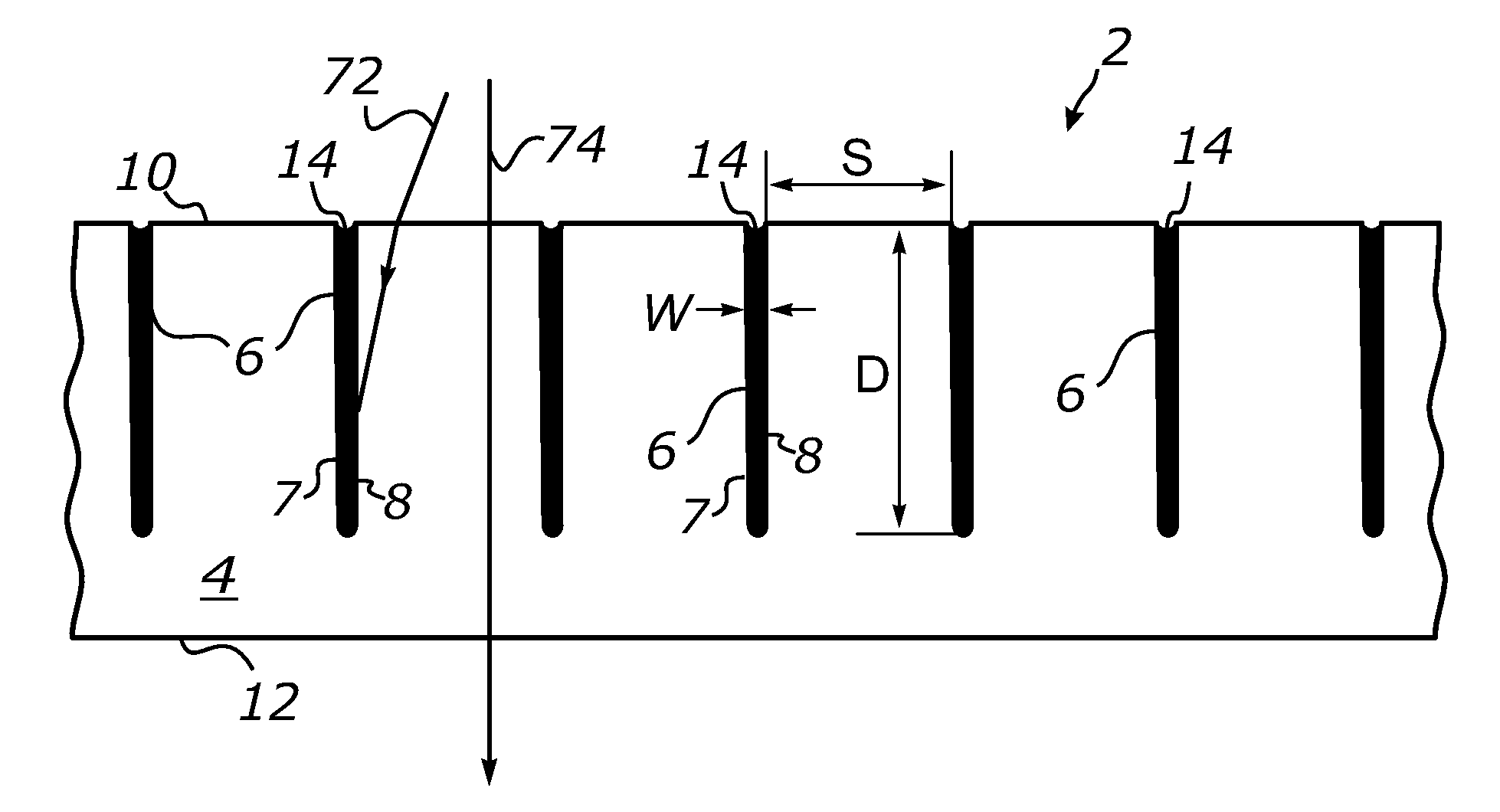

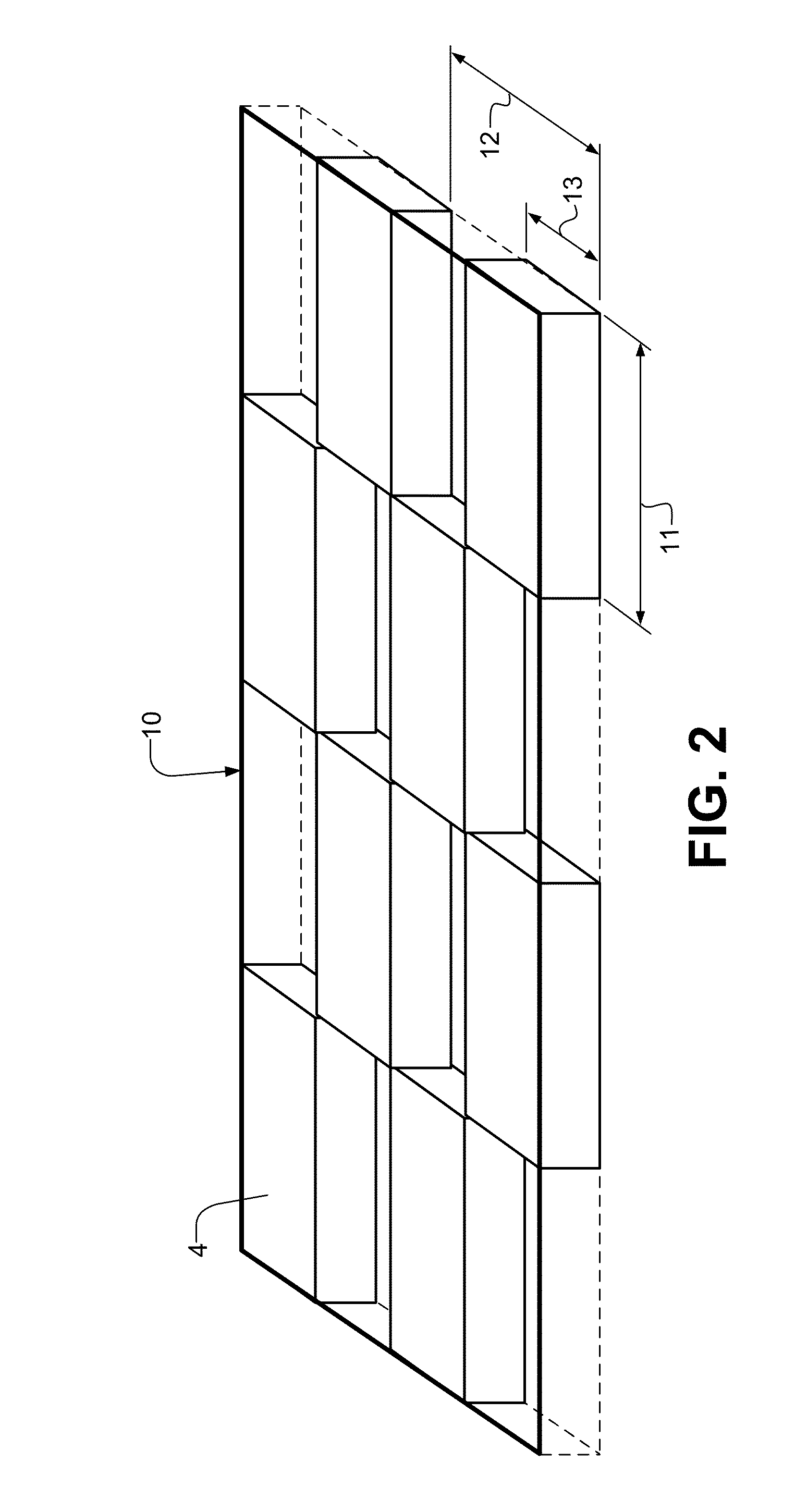

Enhanced relief printing plate

ActiveUS20100143841A1Improve accuracyOptimization rangePhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringImage area

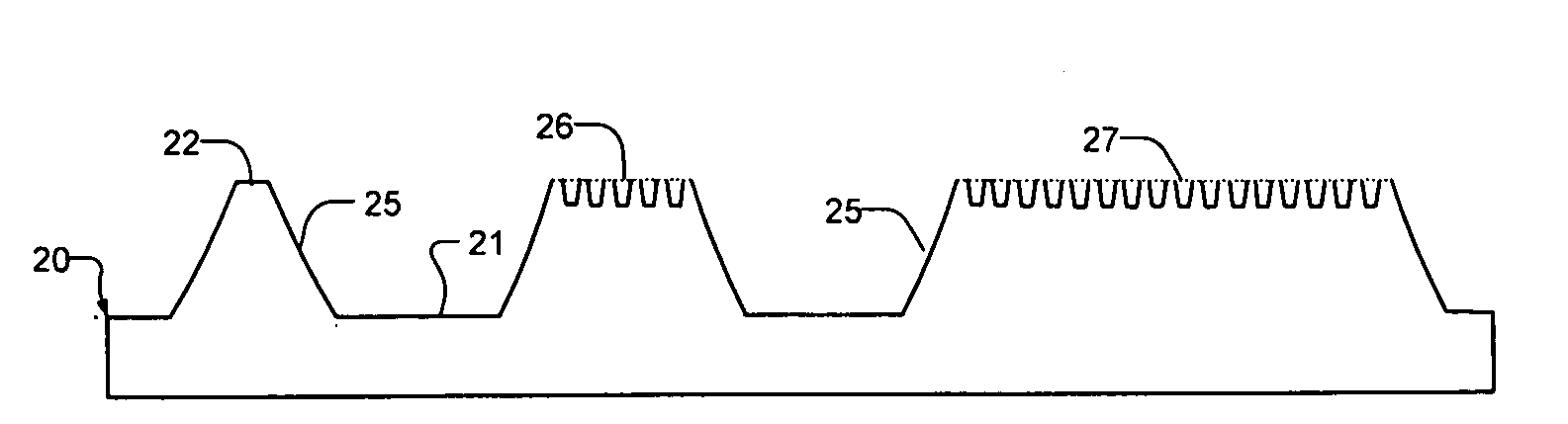

An improved relief printing plate and method for producing said plate is disclosed. Substantially all sizes of relief features resolve a fixed pattern which improves print quality. The pattern is applied to image areas in halftone data used to produce an image mask that is subsequently used to convert a plate precursor into a relief plate. The accuracy, ink density and tonal response of printed images corresponding to relief features that include the pattern are comparable or better than relief features produced without the pattern.

Owner:MIRACLON CORP

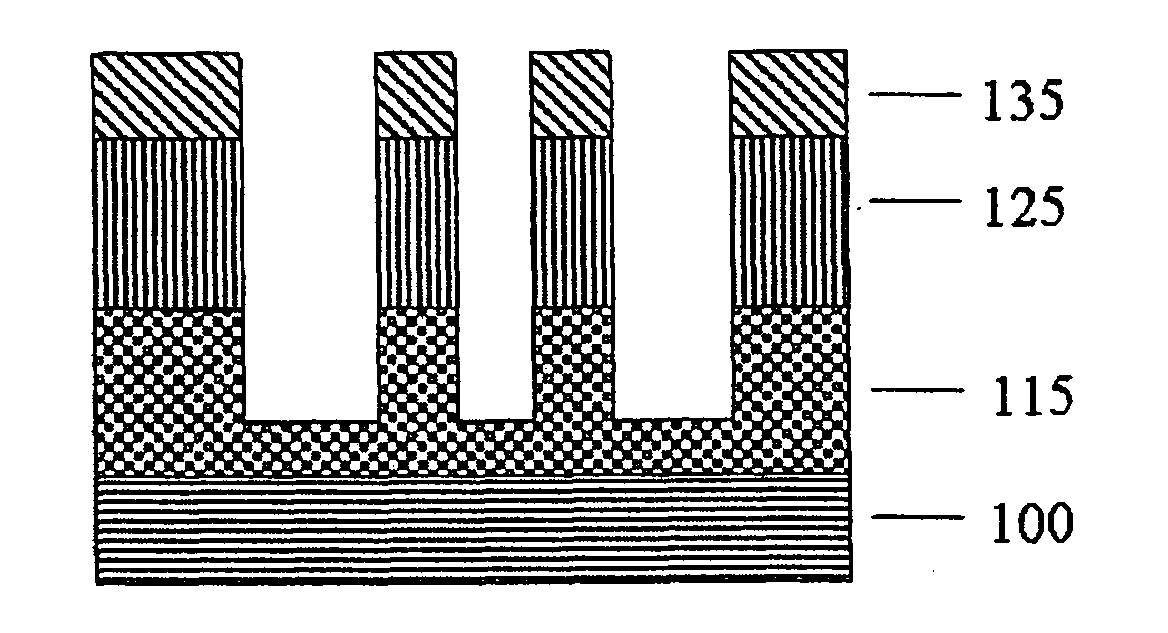

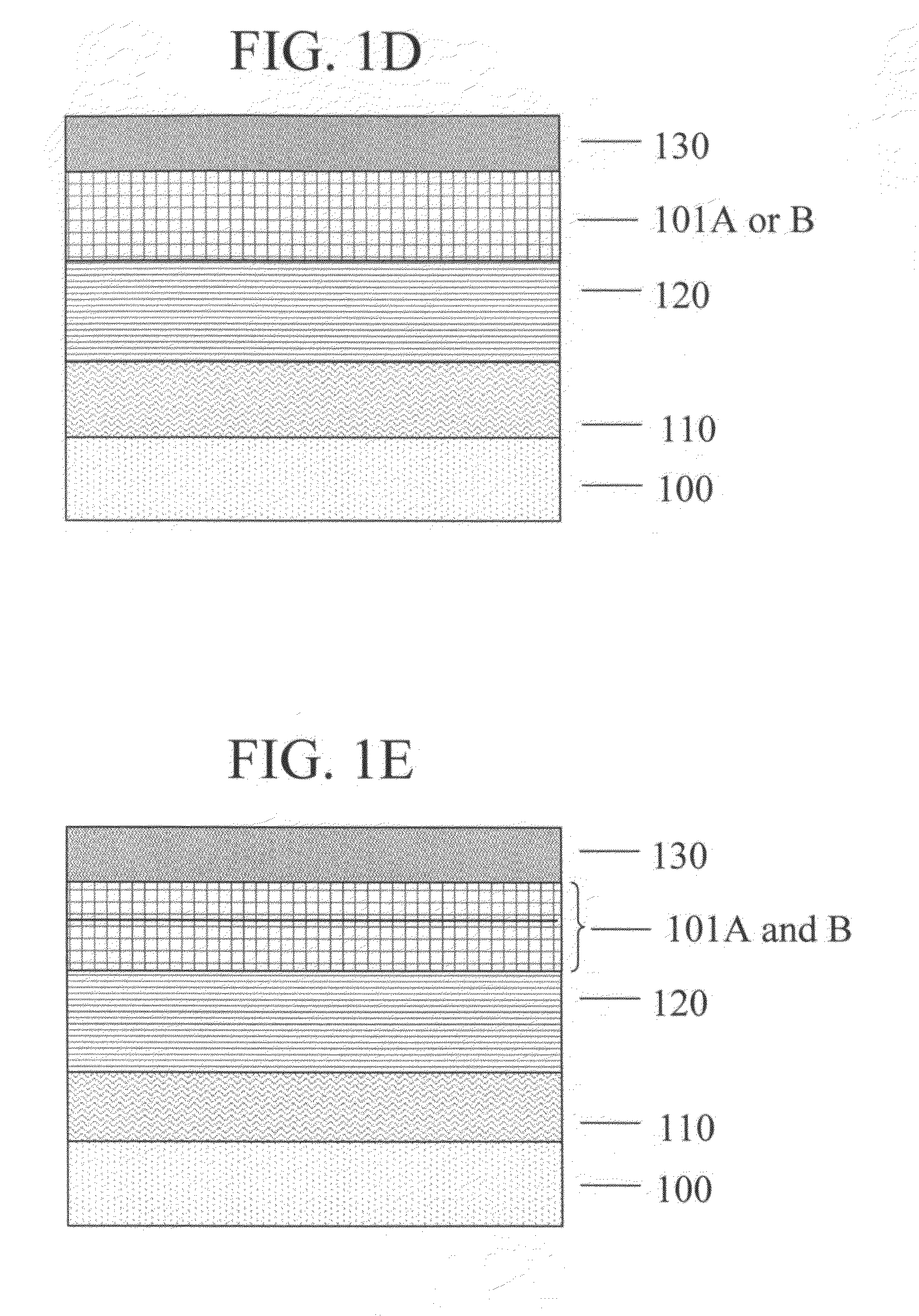

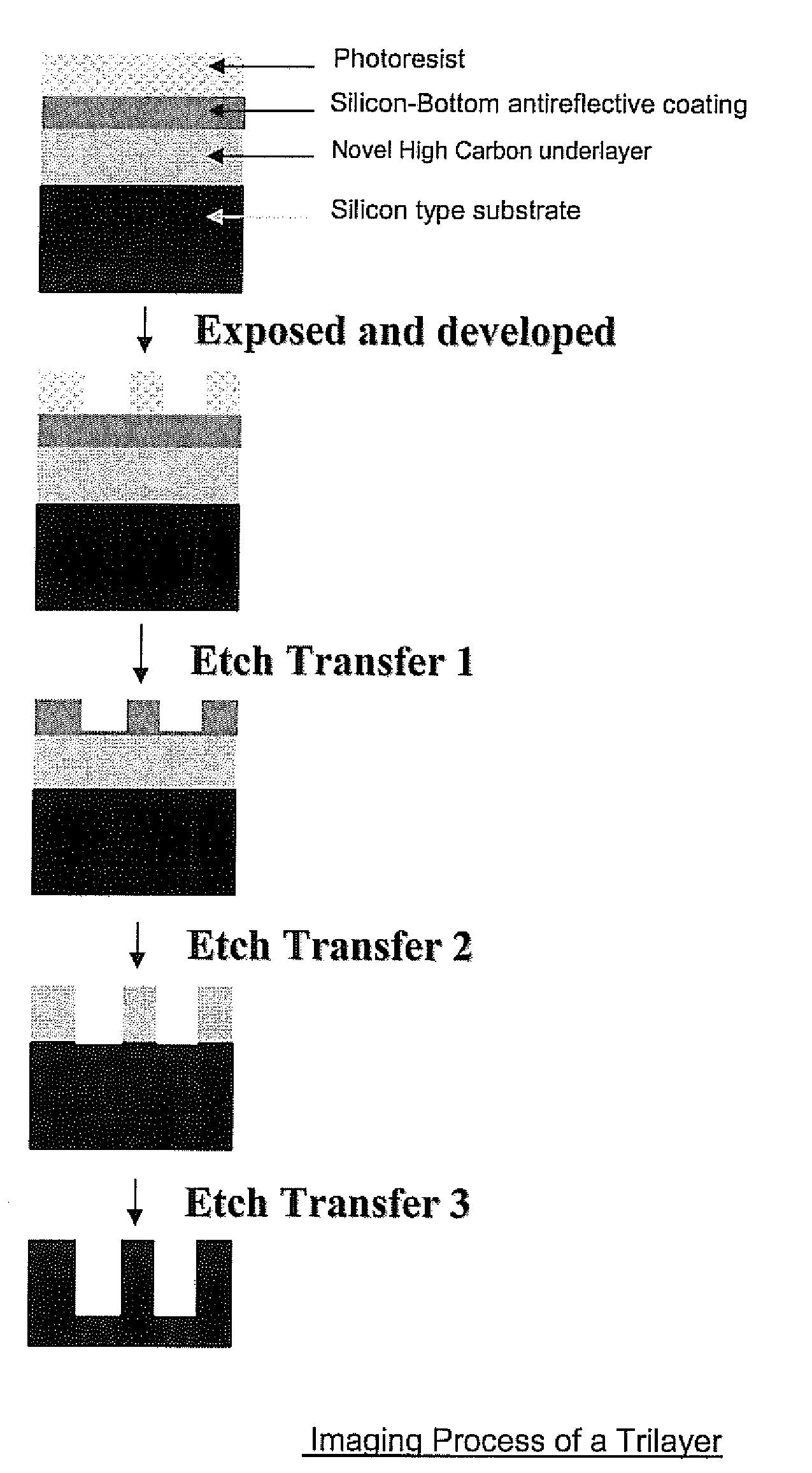

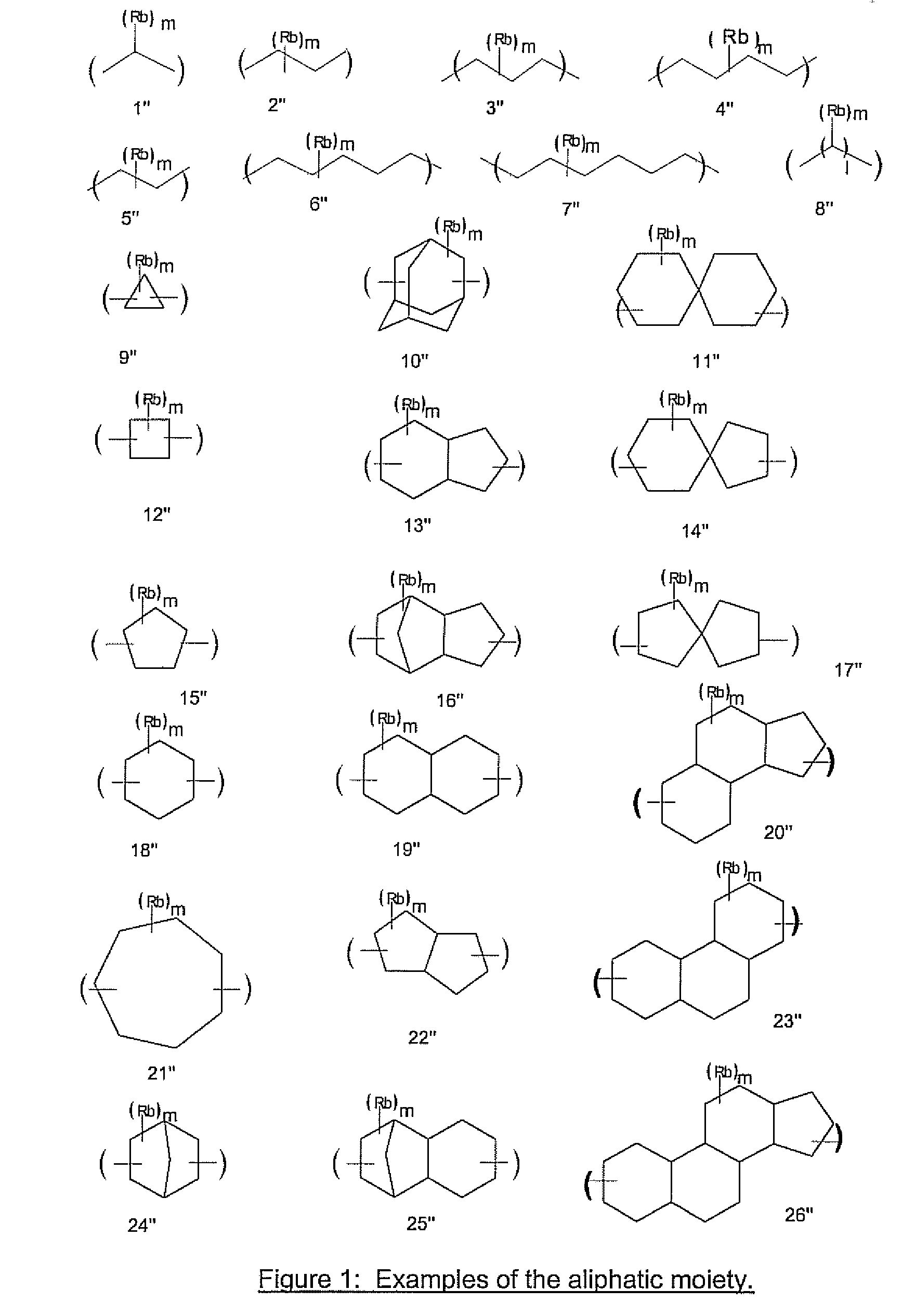

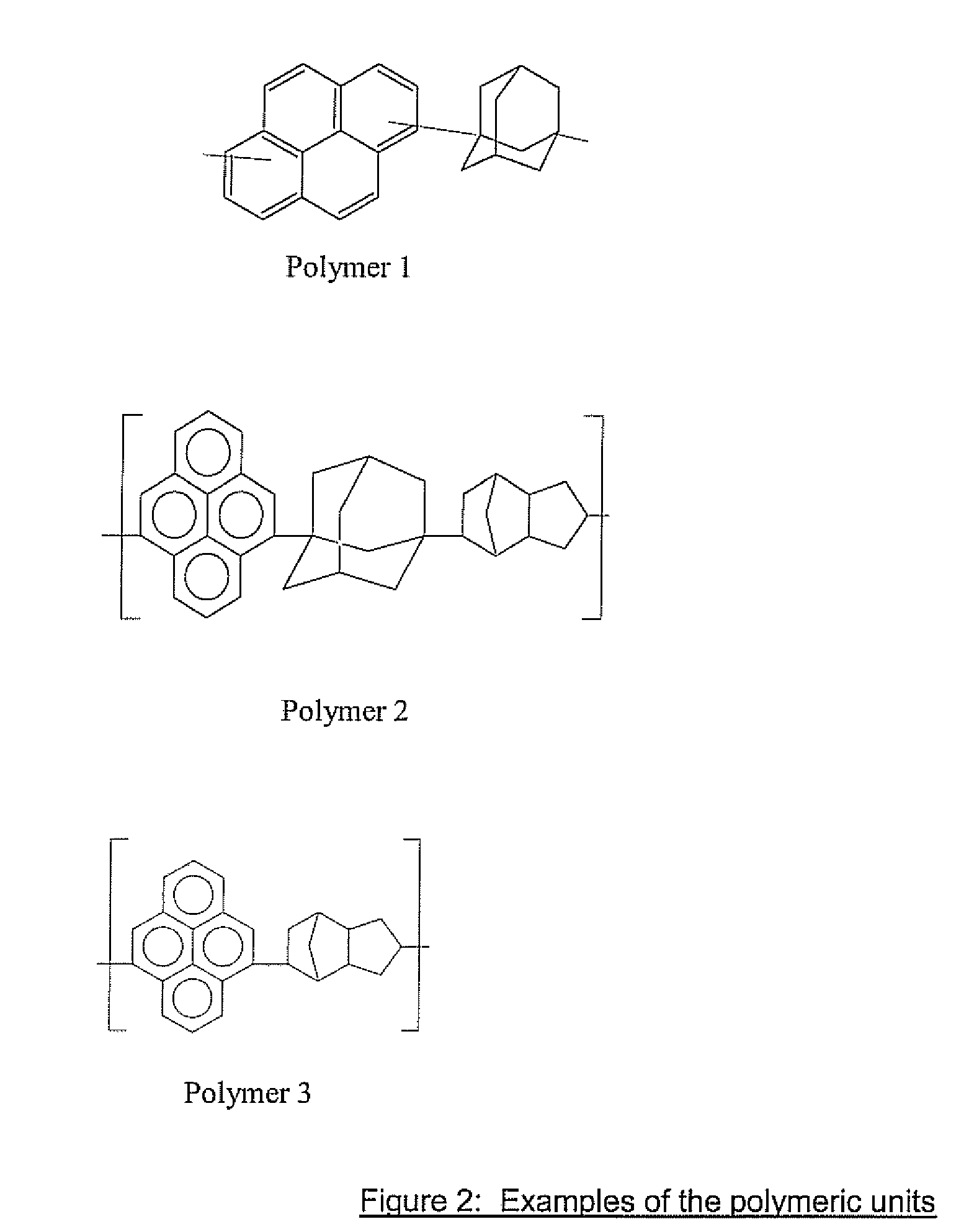

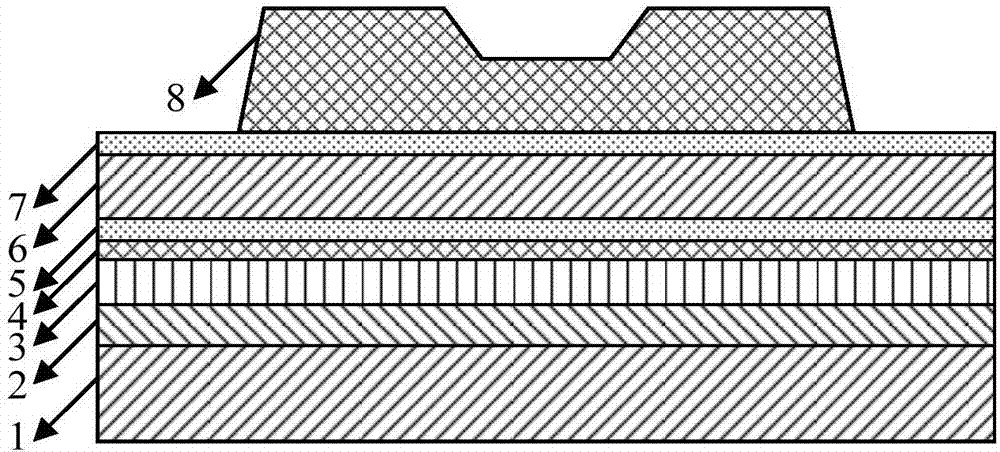

Polymer having antireflective properties and high carbon content, hardmask composition including the same, and process for forming a patterned material layer

ActiveUS20080160461A1High carbon contentPhotosensitive materialsPhotoprinting processesOrganic solventPolymer science

An antireflective hardmask composition includes an organic solvent, an initiator, and at least one polymer represented by Formulae A, B, or C:

Owner:CHEIL IND INC

Antireflective Coating Composition Comprising Fused Aromatic Rings

The present invention relates to an organic spin coatable antireflective coating composition comprising a polymer comprising at least one unit with 3 or more fused aromatic rings in the backbone of the polymer and at least one unit with an aliphatic moeity in the backbone of the polymer. The invention further relates to a process for imaging the present composition.

Owner:MERCK PATENT GMBH

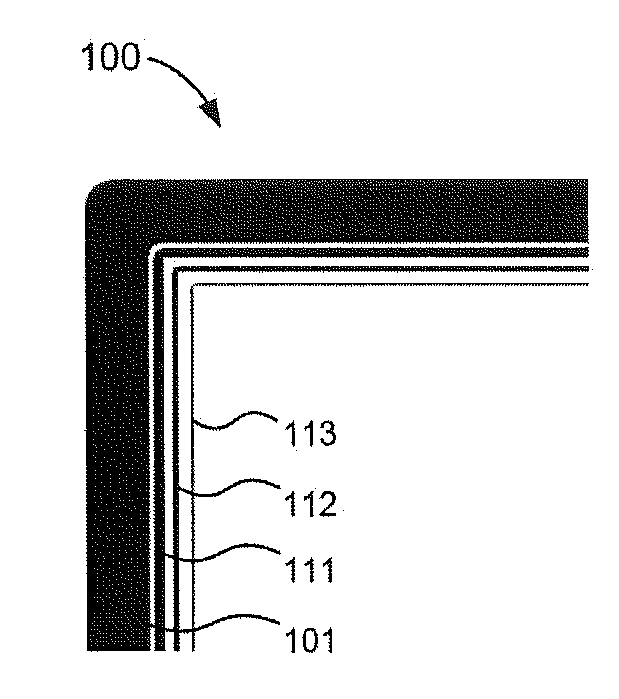

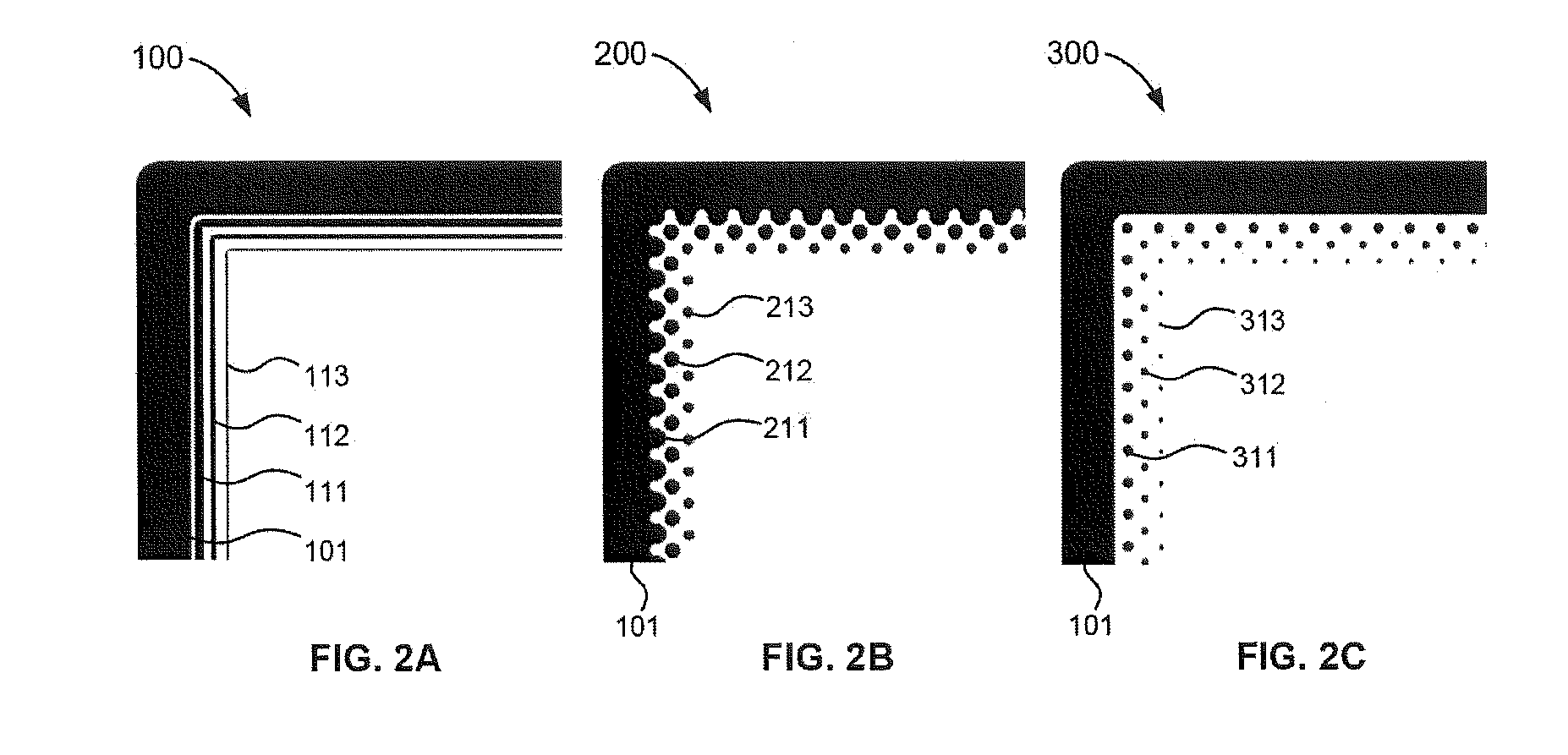

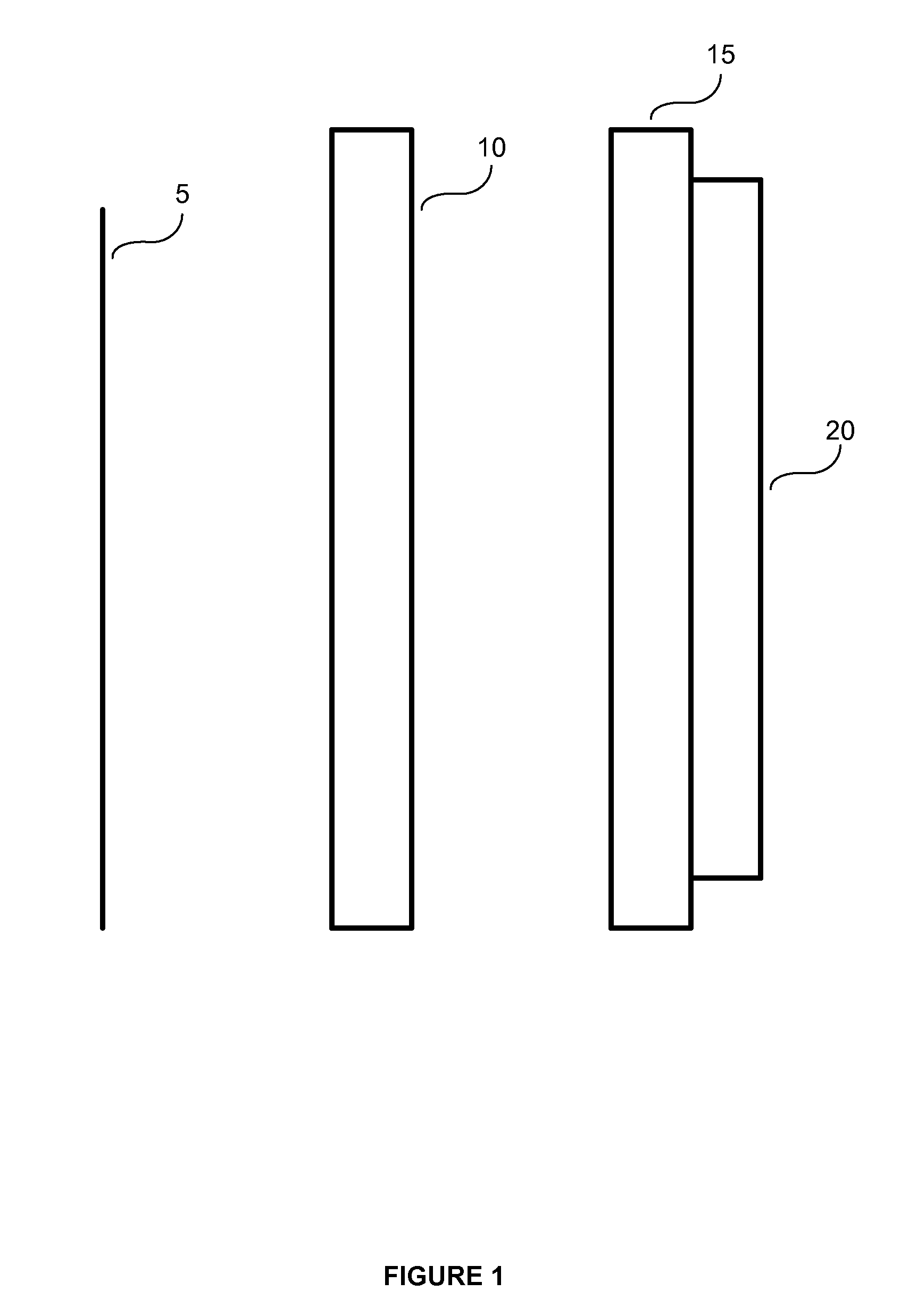

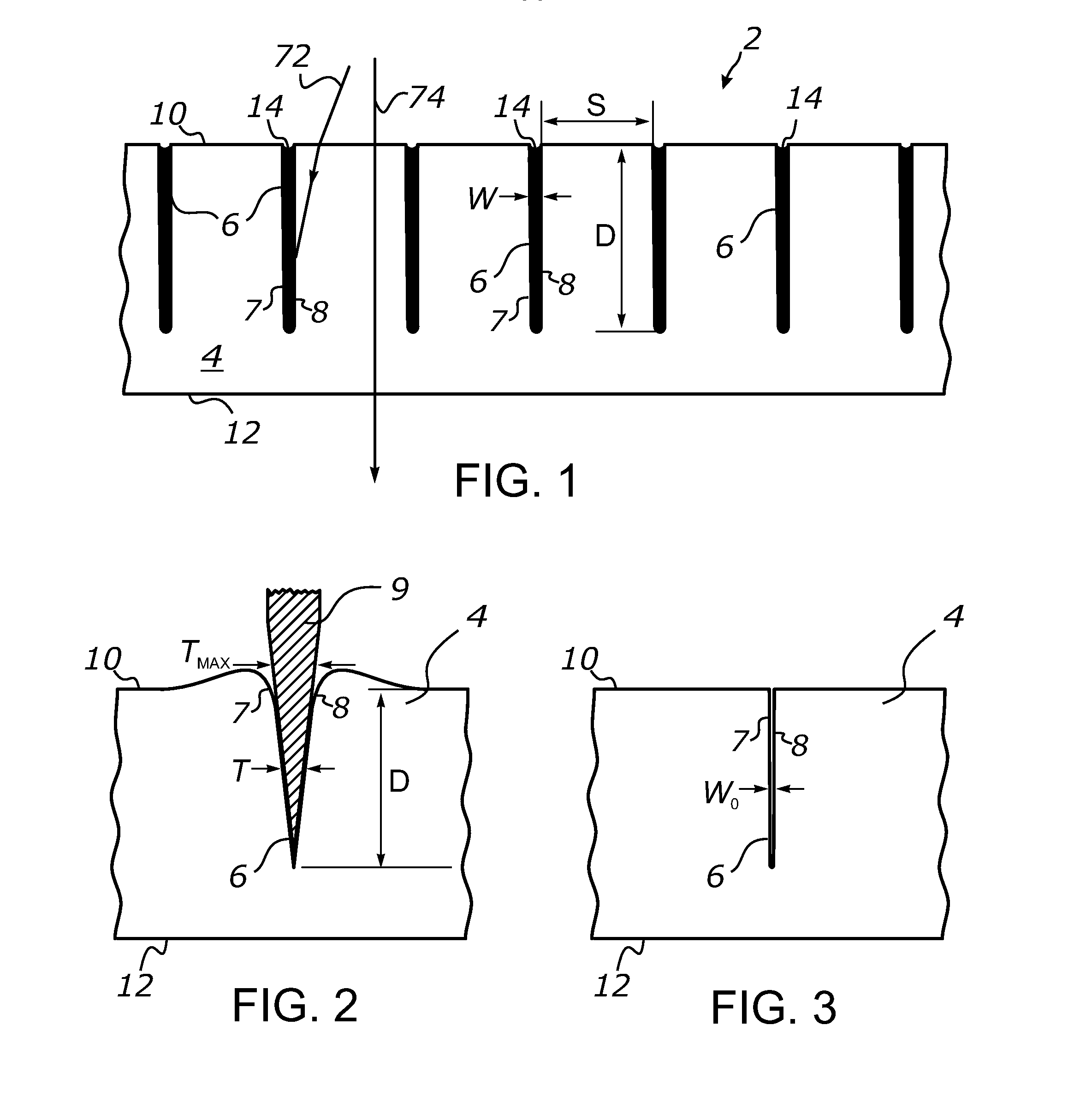

Patterned obscuration lines for electrochromic devices

InactiveUS20130258436A1Lessen visualLessen actual impactScreening processesGlass/slag layered productsEngineeringMaterials science

An electrochromic device is provided. The device may be inserted within a frame. The device may include a substrate, an electrochromic coating, and a patterned layer. The electrochromic coating may overlie a portion of the substrate within a visible region of the substrate. The electrochromic coating may have an outer edge that is spaced from an outer boundary of the visible region of the substrate. The outer edge of the electrochromic coating and the outer boundary of the visible region may define a working region. The patterned layer may be deposited within the working region. The patterned layer may include a plurality of spaced apart shapes.

Owner:SAGE ELECTROCHROMICS

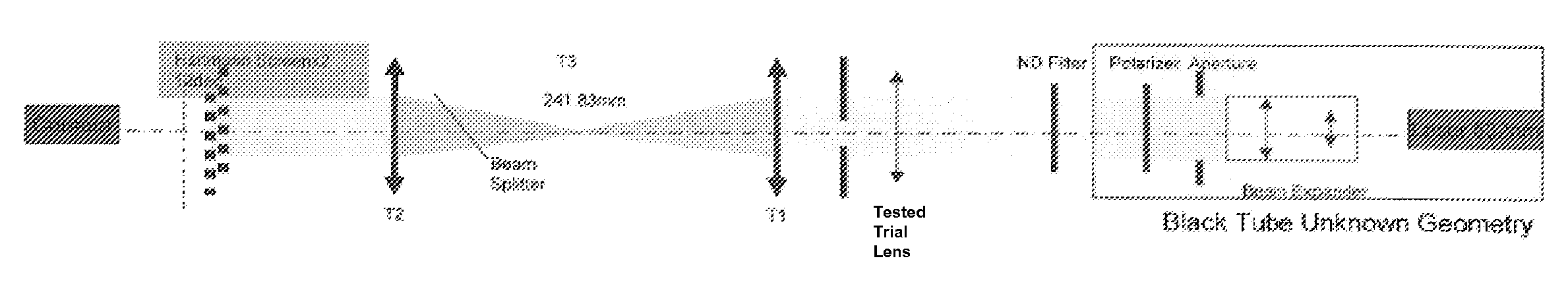

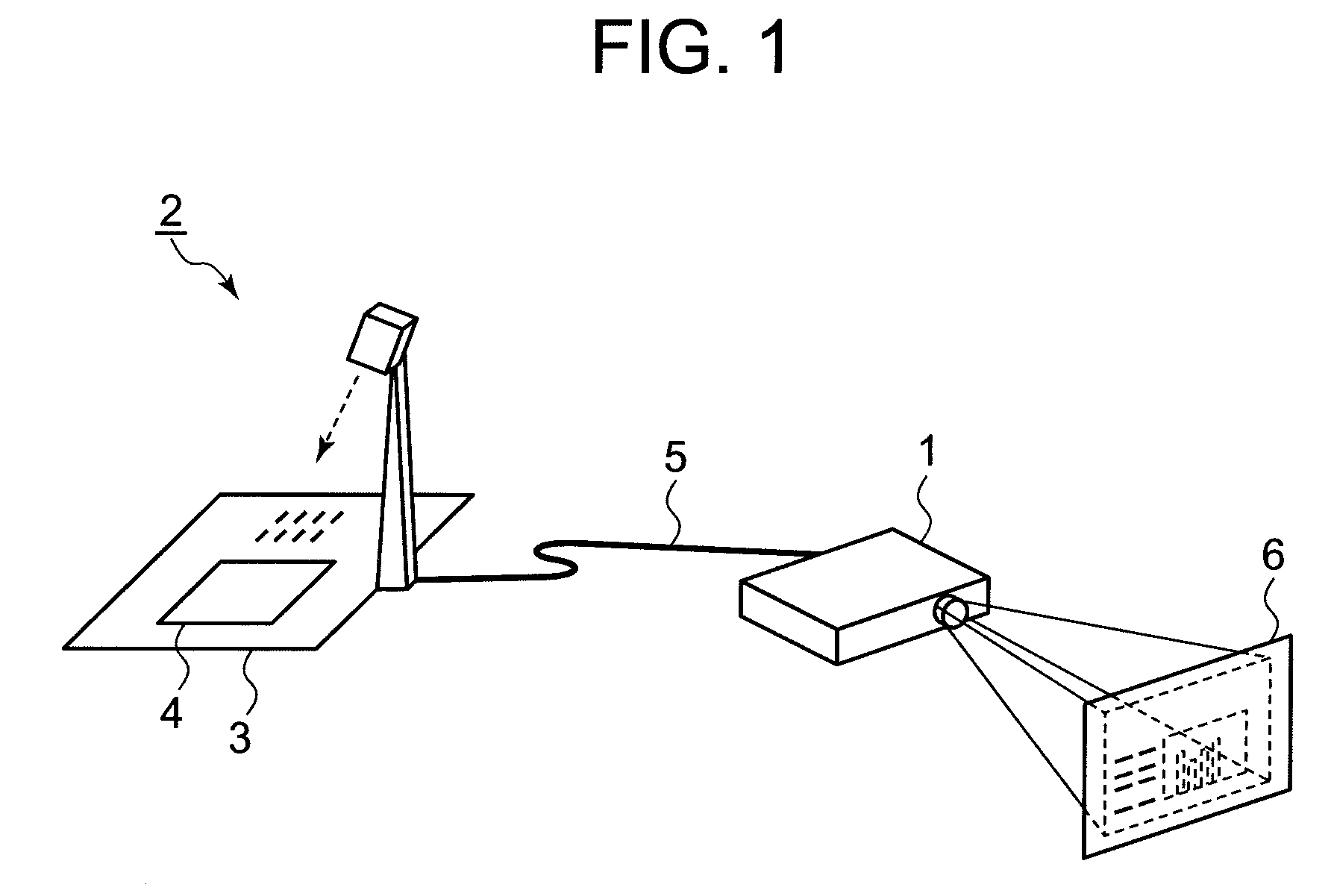

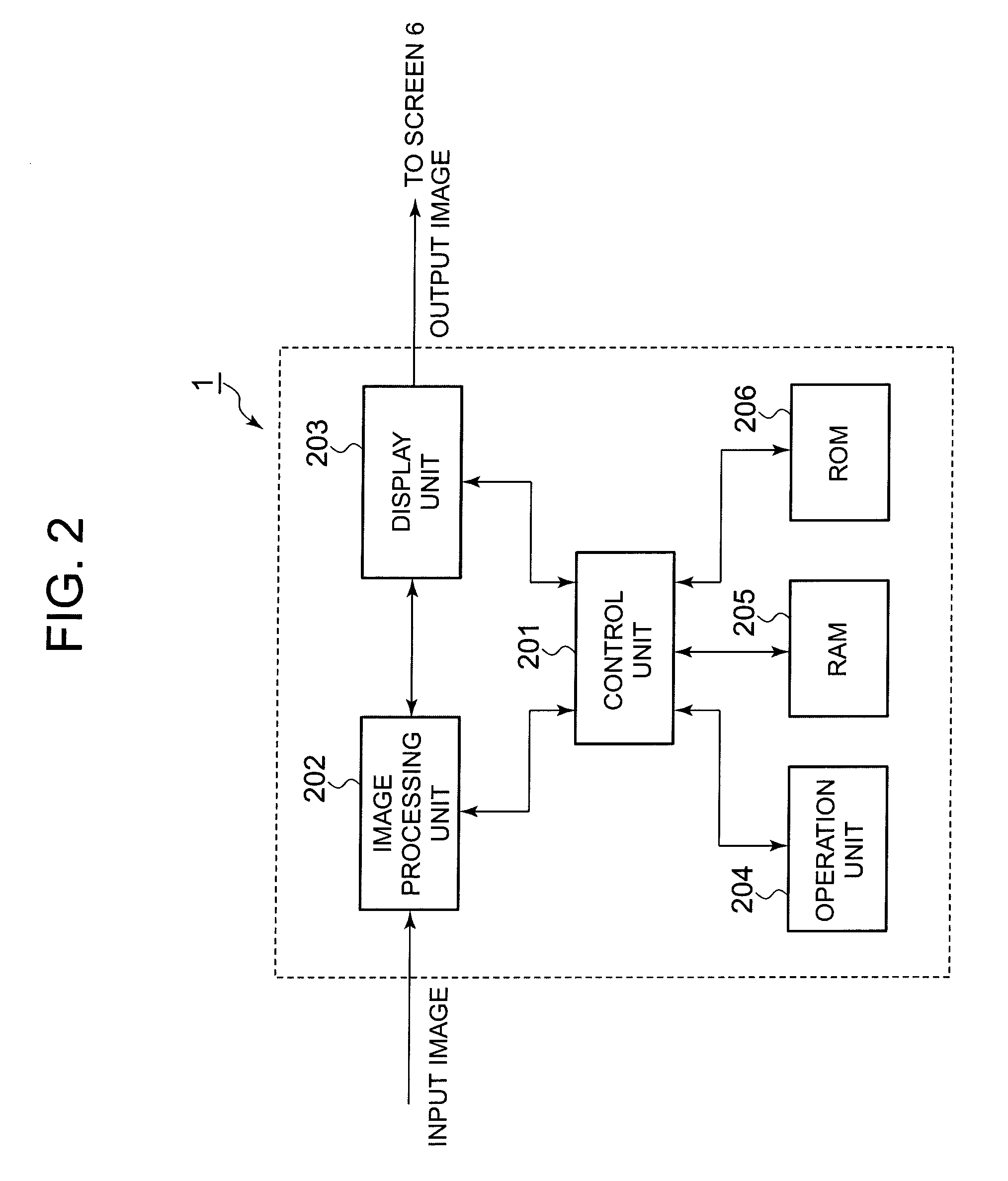

Projection apparatus, projection method, and computer program

Light emitted from a lamp enters a color wheel having a region for allowing a predetermined color to pass therethrough, is reflected on a mirror, and enters a DMD. After this, the light is reflected by the DMD and enters a color sensor, which then detects the color of the transmitting light. A projection apparatus automatically synchronizes the control on the rotation of the color wheel and the control on the proceeding direction of the transmitting light by the DMD, based on a color time-division pattern of the transmitting light detected by the color sensor.

Owner:CASIO COMPUTER CO LTD

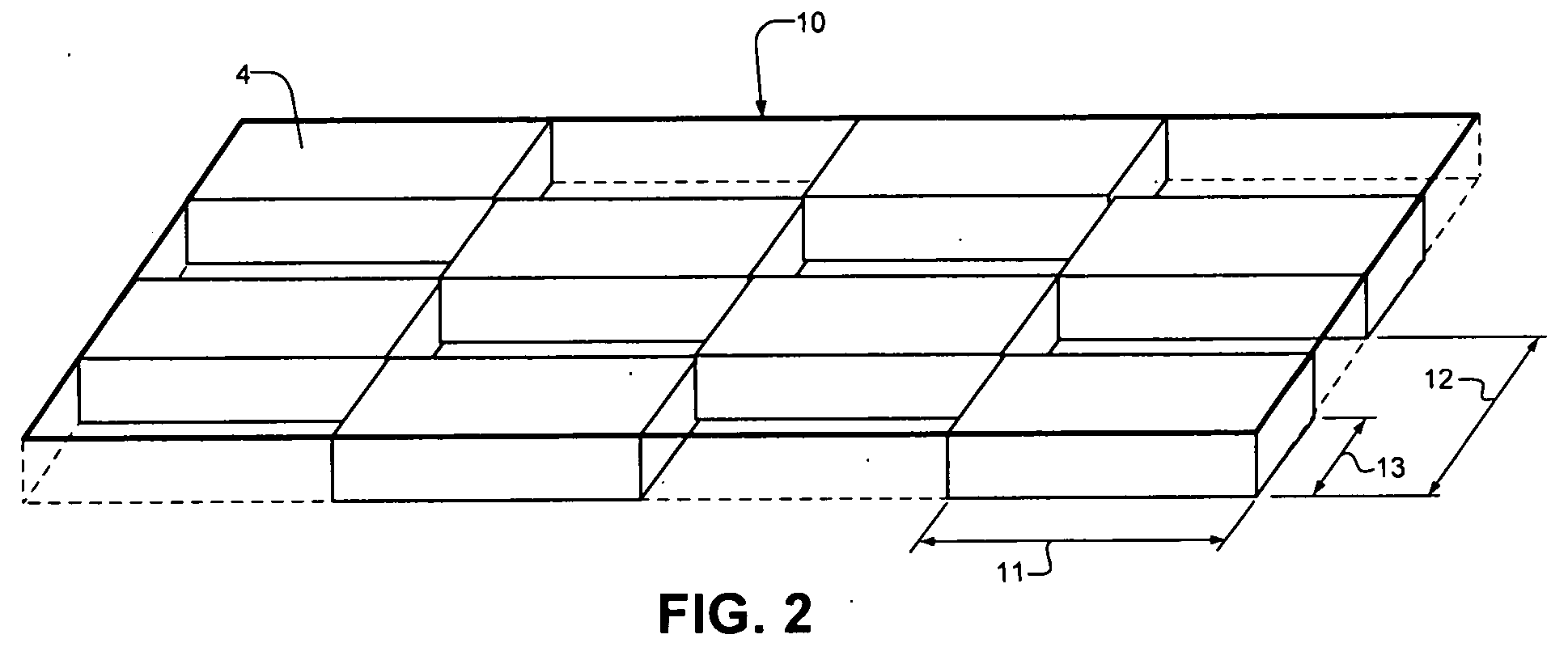

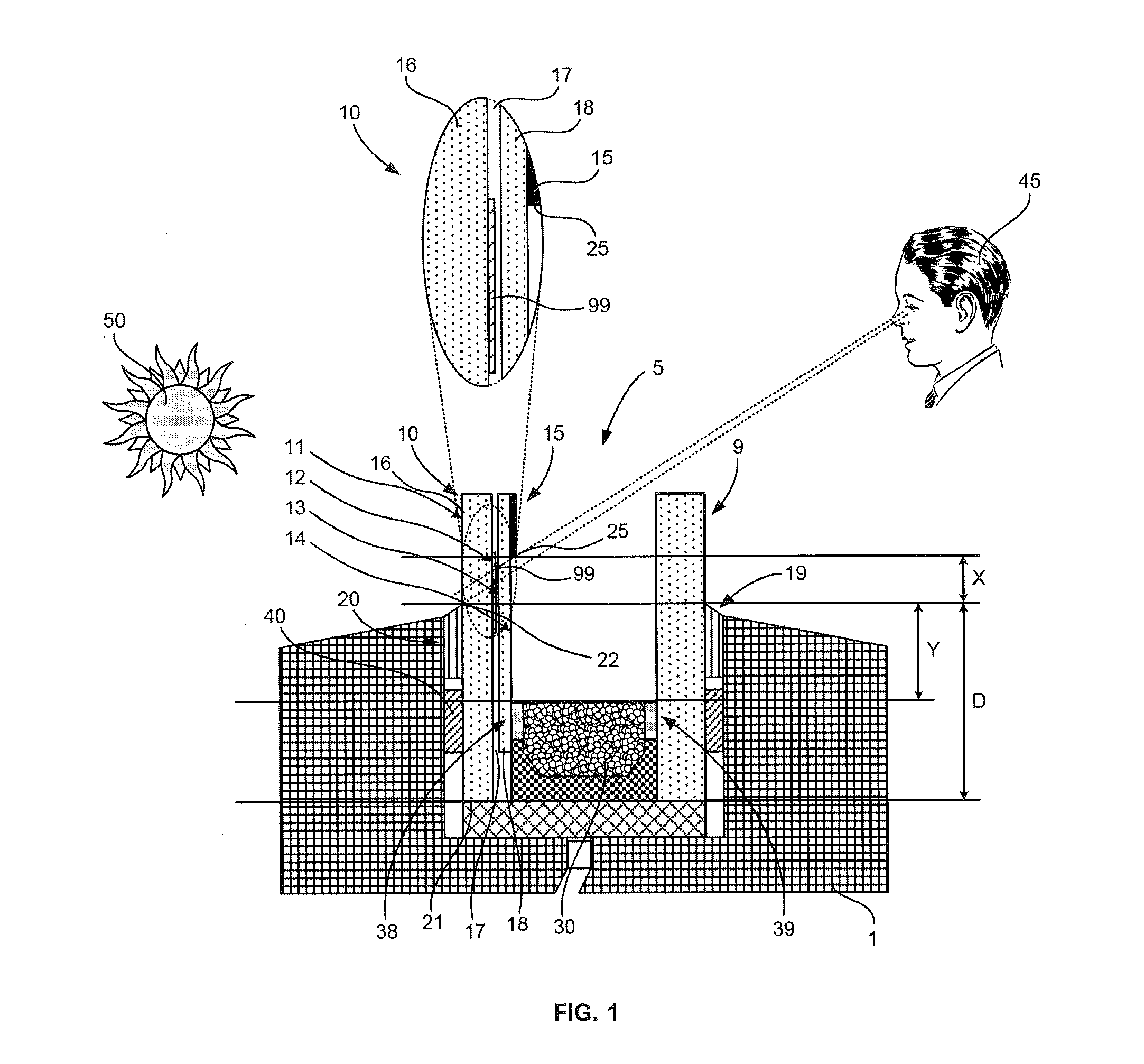

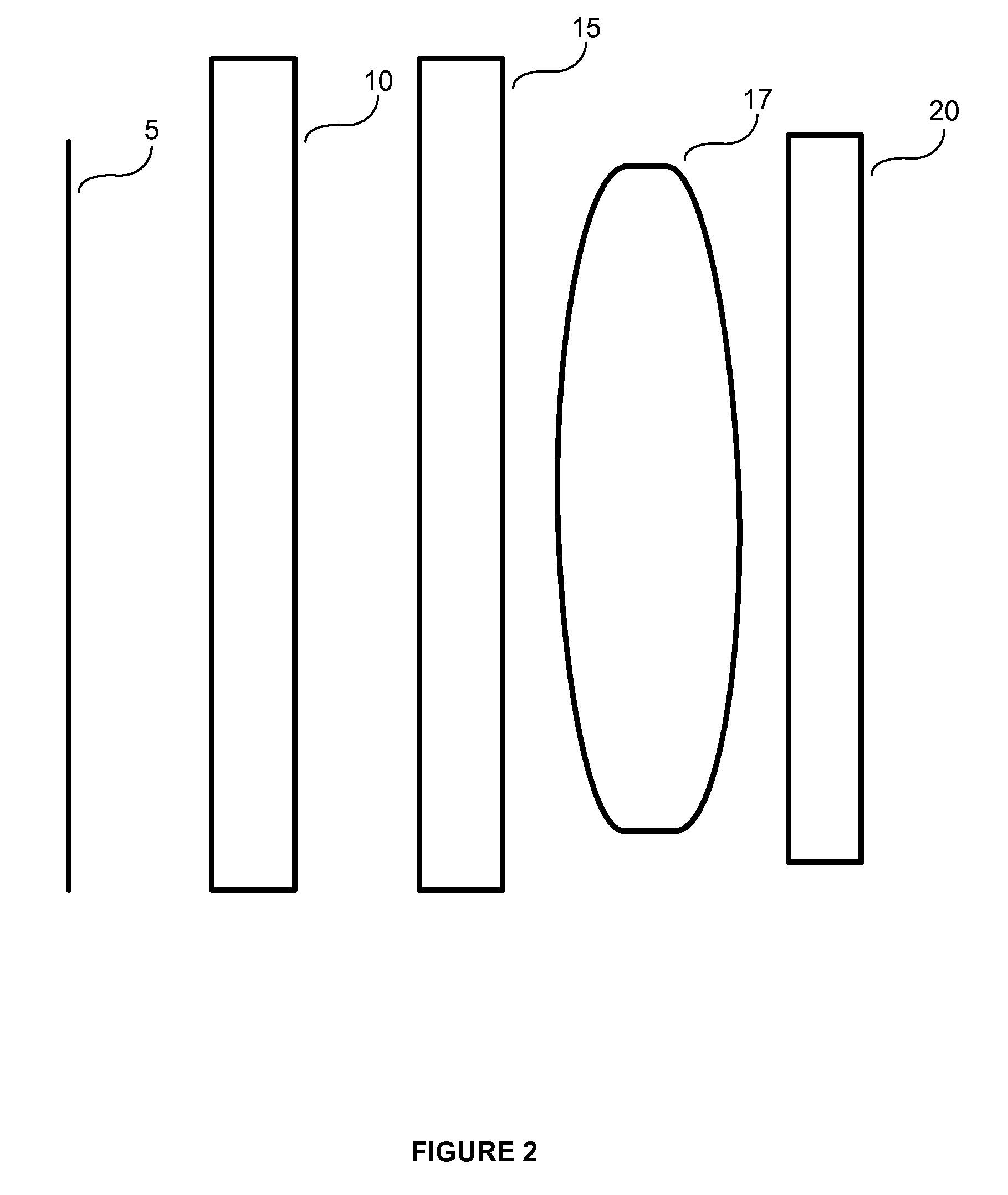

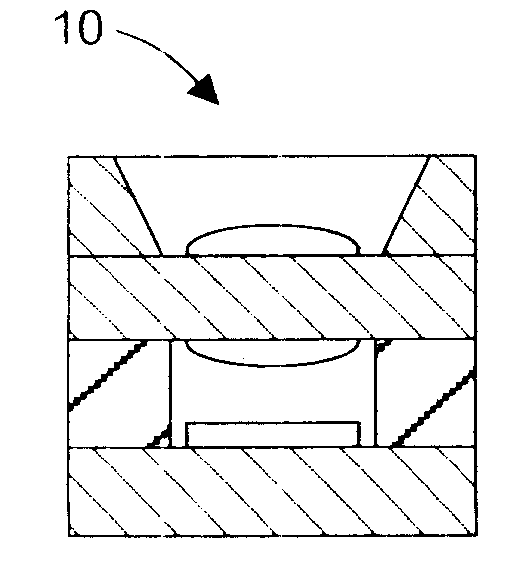

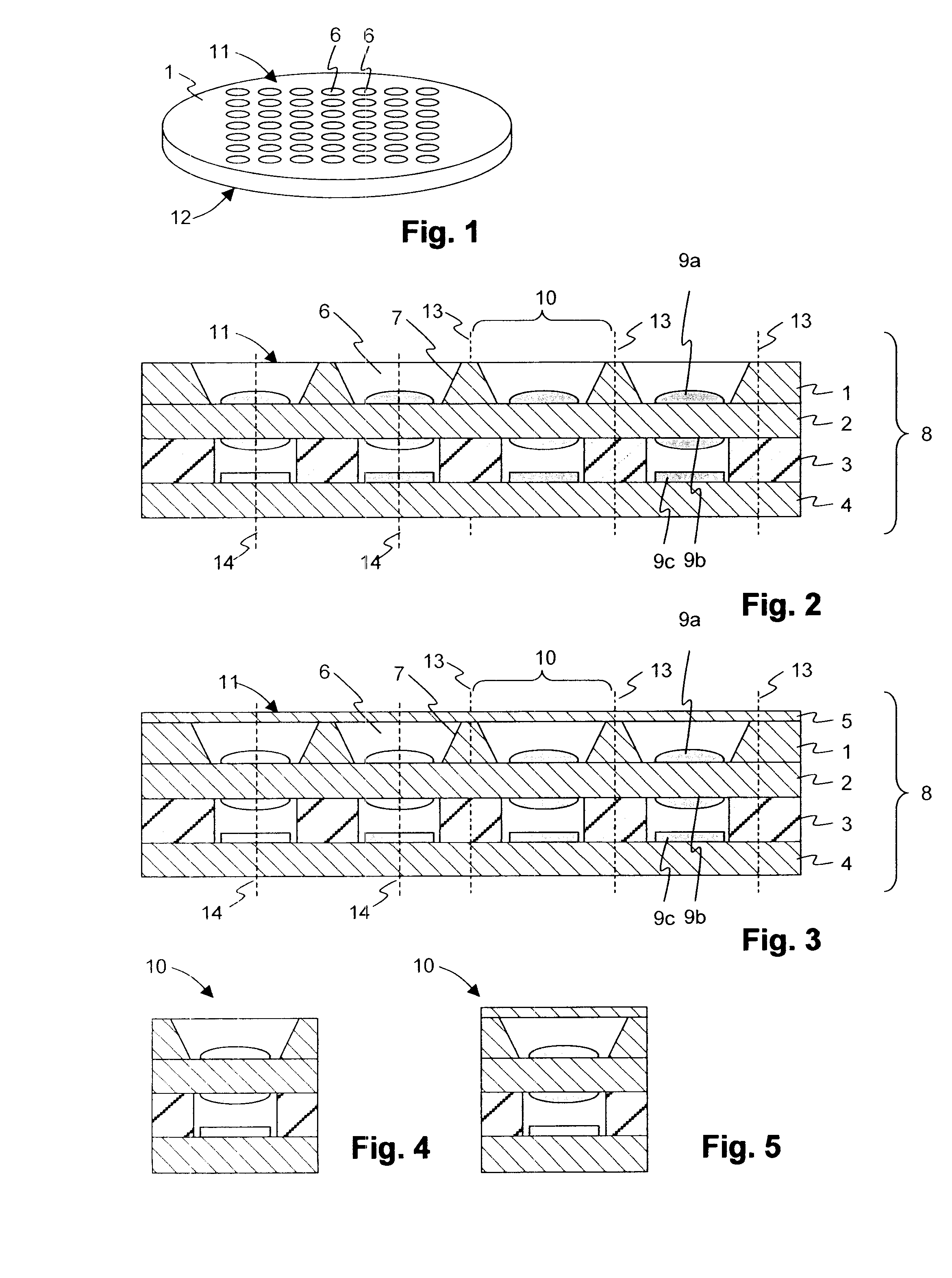

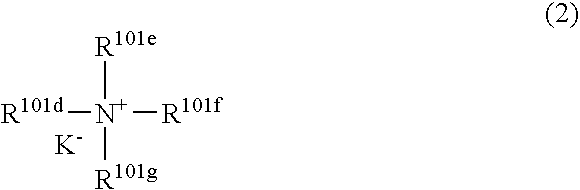

Wafer stack, integrated optical device and method for fabricating the same

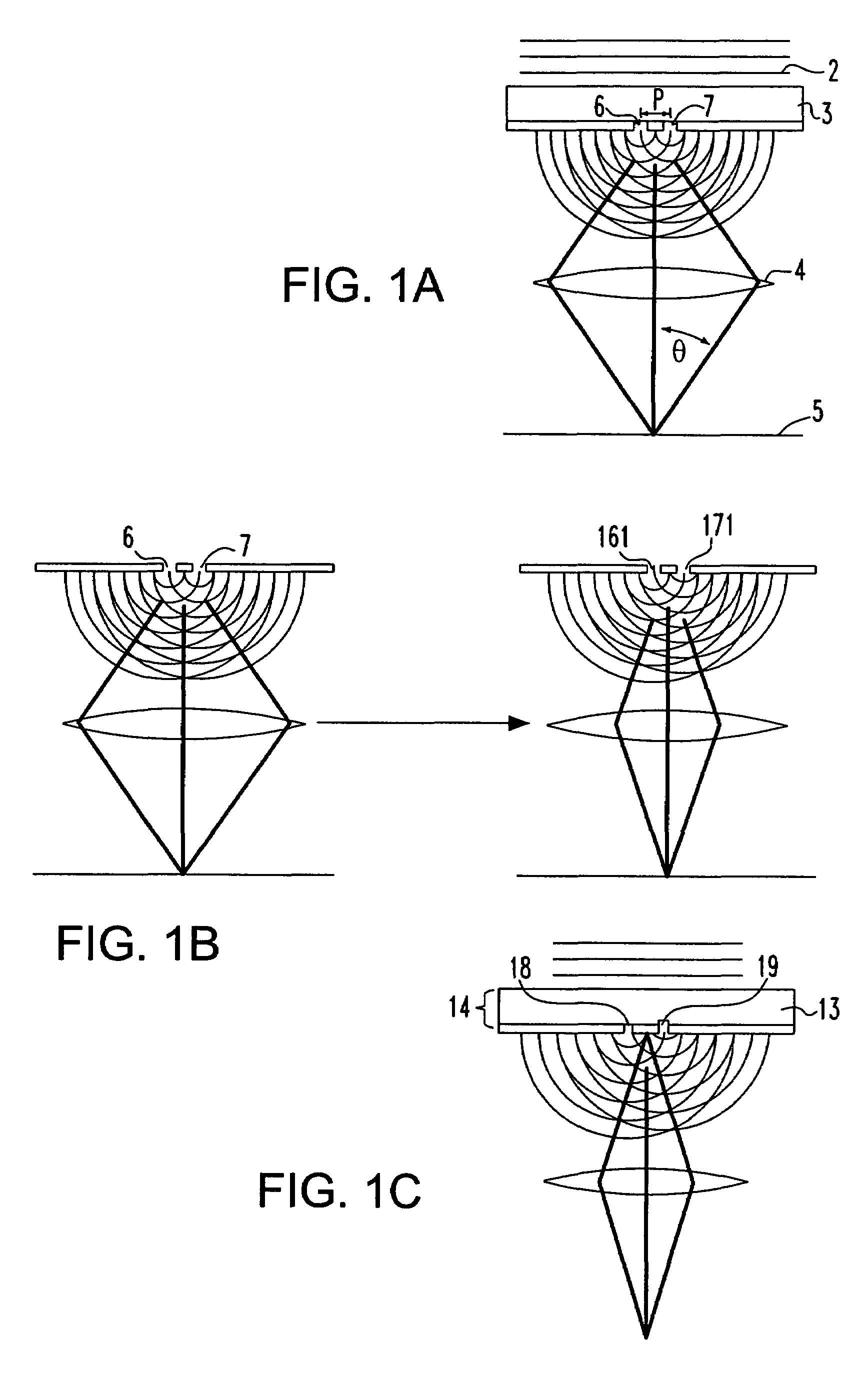

In a method for fabricating an integrated optical device by creating a wafer stack by stacking at least a top wafer carrying as functional elements a plurality of lenses on at least one further wafer including further functional elements, and separating the wafer stack into a plurality of integrated optical devices, wherein corresponding functional elements of the top and further wafer are aligned with each other and define a plurality of main optical axes, a method for providing a sunshade plate as part of an integrated optical device (10), including the steps of: providing a sunshade plate having a plurality of through holes, the through holes being arranged to correspond to the arrangement of the functional elements on the top wafer; and stacking the sunshade plate on the top wafer, with the through holes being aligned with said main optical axes.

Owner:AMS SENSORS SINGAPORE PTE LTD

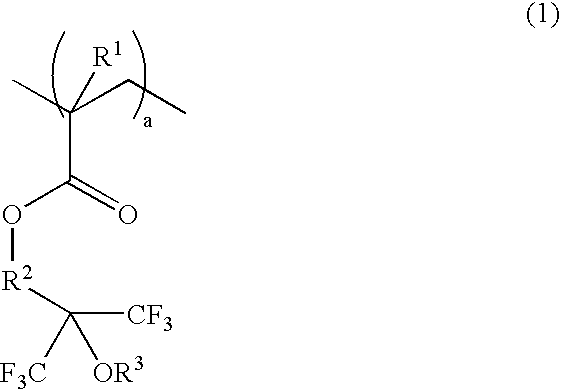

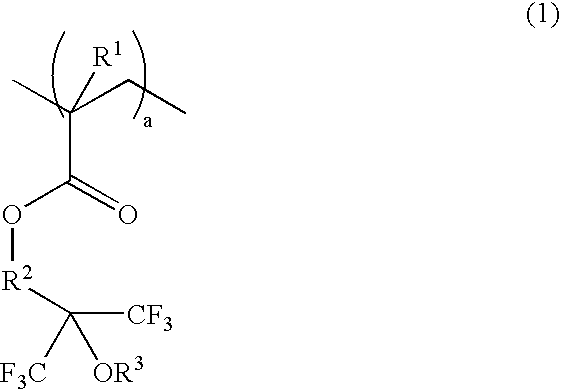

Resist lower layer film composition and patterning process using the same

ActiveUS20080227037A1Etching speed is fastShorten the time periodPhotosensitive materialsPhotoprinting processesResistPolymer

Owner:SHIN ETSU CHEM IND CO LTD

Screen print lattice-point printing process

ActiveCN1743951ALow costSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusScreen printingElectrical and Electronics engineering

A silk screen printing technology, which contains making film, making silk screen printing board, printing and optical solidifying, said invention features adopting screen point printing to make film, printing area adopting 45-65 % screen point percent, 50-80 screen line and 45 or 90 degree mesh angle.

Owner:广西真龙彩印包装有限公司

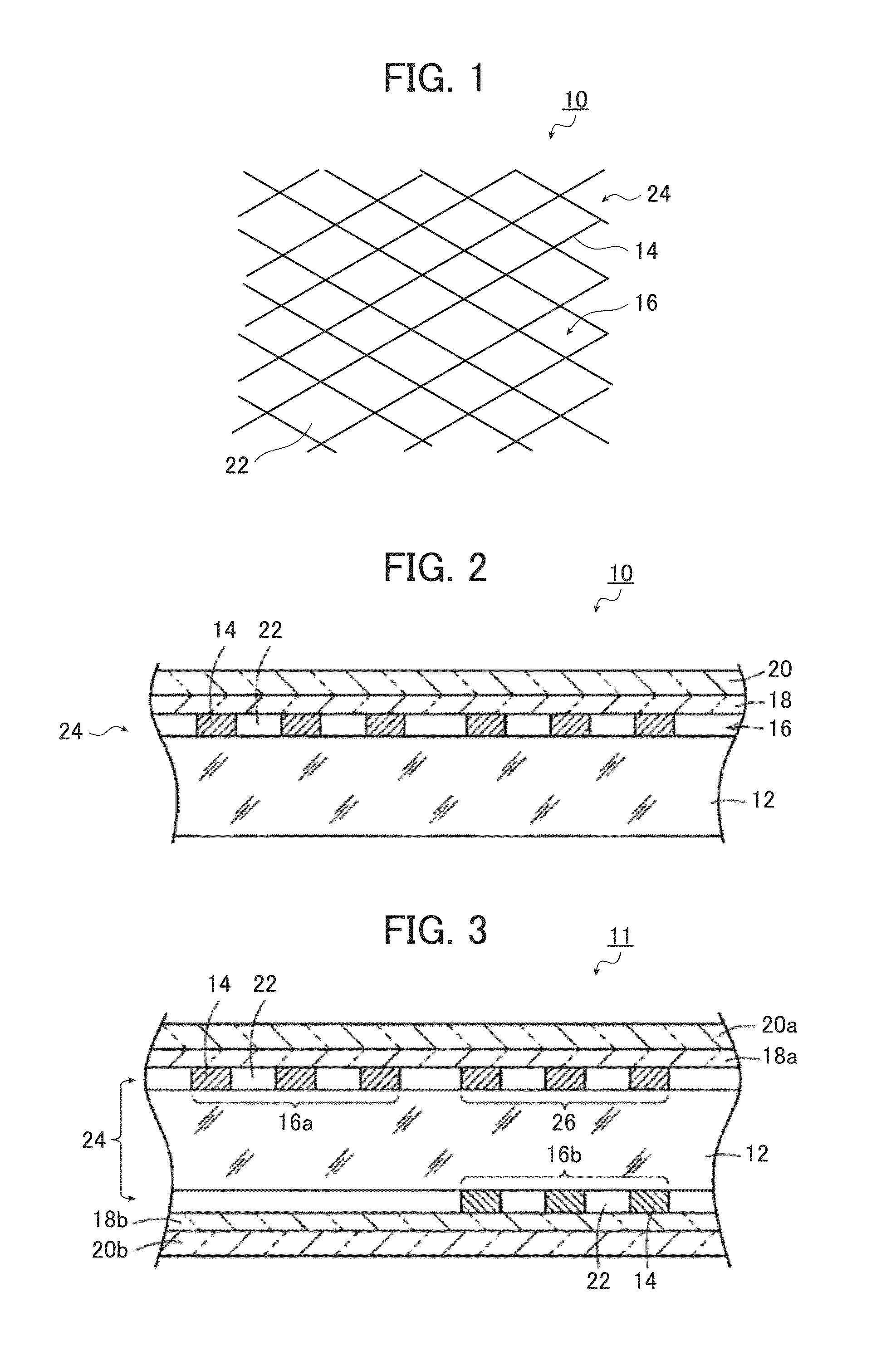

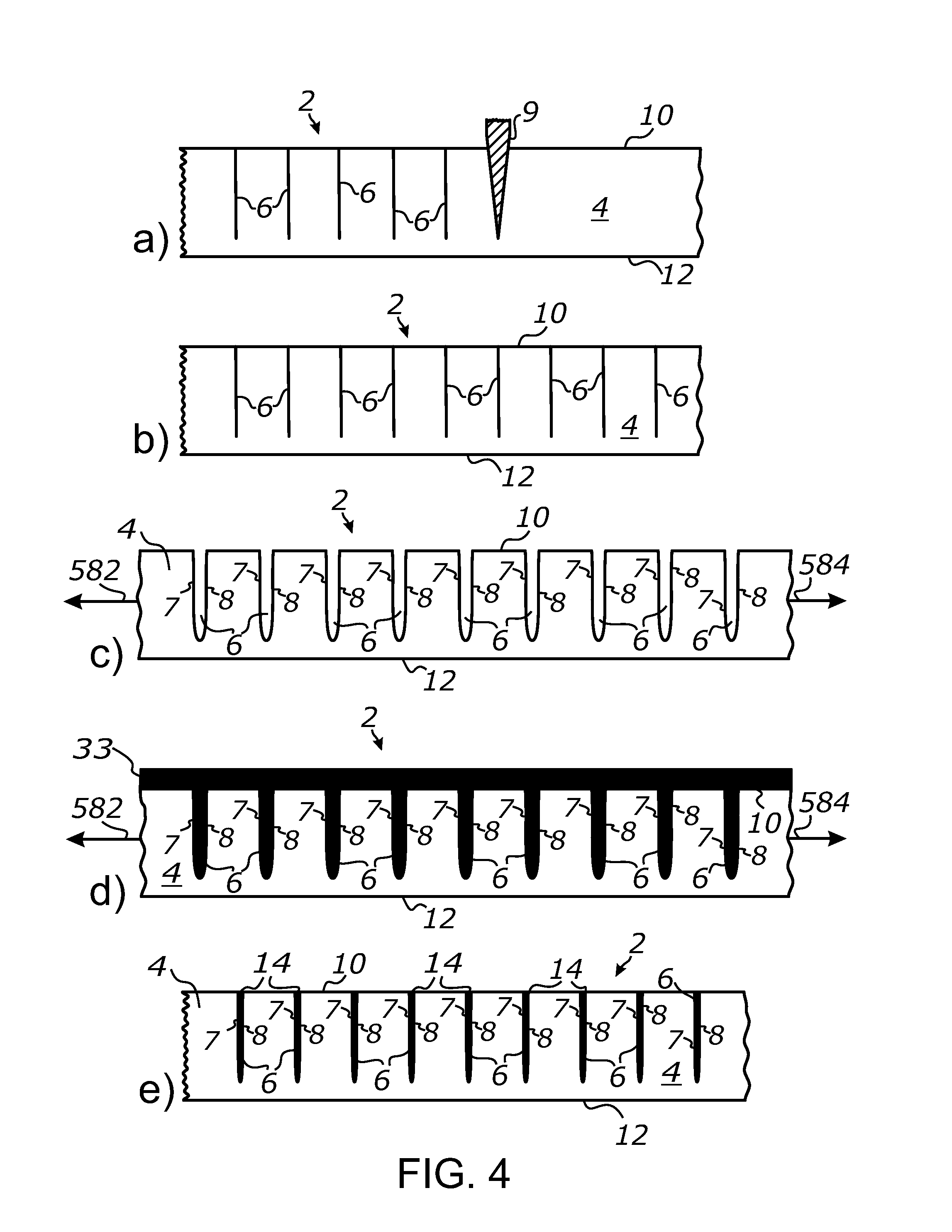

Method for Improving Print Performance of Flexographic Printing Elements

ActiveUS20130017493A1Improve printing qualityDensity of ink thus increaseSemiconductor/solid-state device manufacturingScreening processesComputer scienceOxygen barrier

A method of making a relief image printing element having a relief pattern comprising a plurality of relief dots, wherein the photocurable printing blank comprises a backing layer having at least one photocurable layer disposed thereon and a masking layer on the at least one photocurable layer is provided. The method comprising the steps of: a) selectively ablating the masking layer to create an overall image in the masking layer, such that the overall image comprises a sub-image, comprising a pattern of cells, in it; b) applying an oxygen barrier layer on top of the masking layer; c) exposing the printing element to actinic radiation through the oxygen barrier layer and the masking layer to selectively crosslink and cure the at least one photocurable layer, thereby creating the relief image therein and a textured surface on the printing element; and d) developing the printing blank by removing the barrier layer and the uncured portions of the photocurable layer to reveal the relief image. The method results in printing plate having improved print performance for optimal printing and a higher achievable solid ink density.

Owner:MACDERMID PRINTING SOLUTIONS

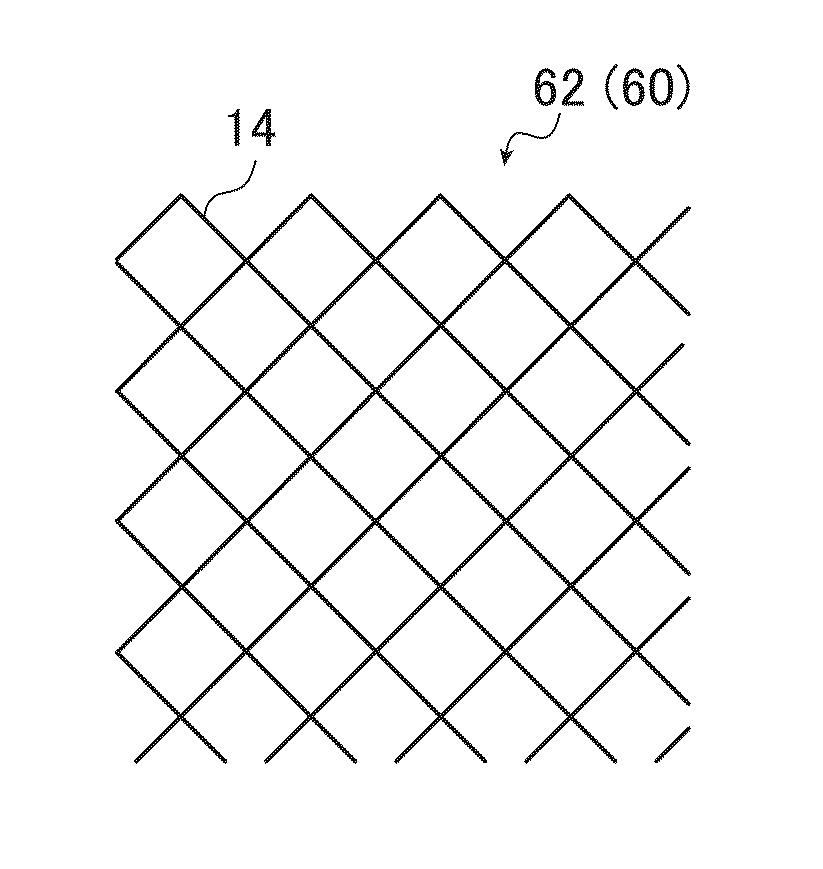

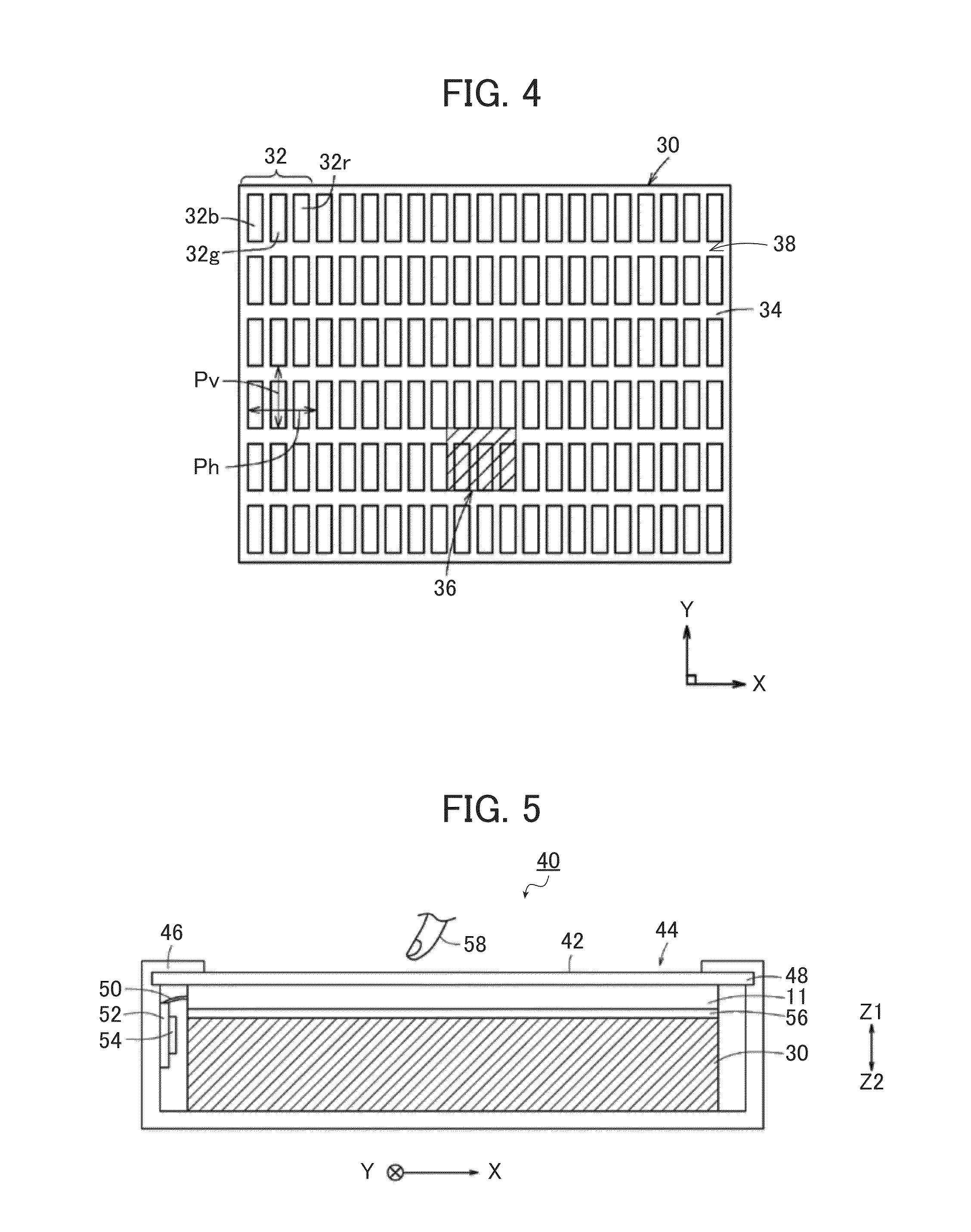

Conductive film, display device equipped with same, and method for determining pattern of conductive film

InactiveUS20150015979A1InhibitionIncrease awarenessConductive layers on insulating-supportsMagnetic/electric field screeningVisibilityDisplay device

The conductive film has a wiring pattern which, with respect to the frequencies and intensities of moire obtained by applying a human visual response characteristic to the frequency information and intensity information of moire calculated from peak frequencies and peak intensities of the two-dimensional Fourier spectrums of the transmittance image data of the wiring pattern and the transmittance image data of a pixel array pattern, causes the sum of intensities of moire each corresponding to frequencies of moire falling within a frequency range predetermined depending on the visual response characteristic to be less than or equal to a predetermined value. The conductive film allows suppression of moire and significant improvement in visibility.

Owner:FUJIFILM CORP

Bragg reflector

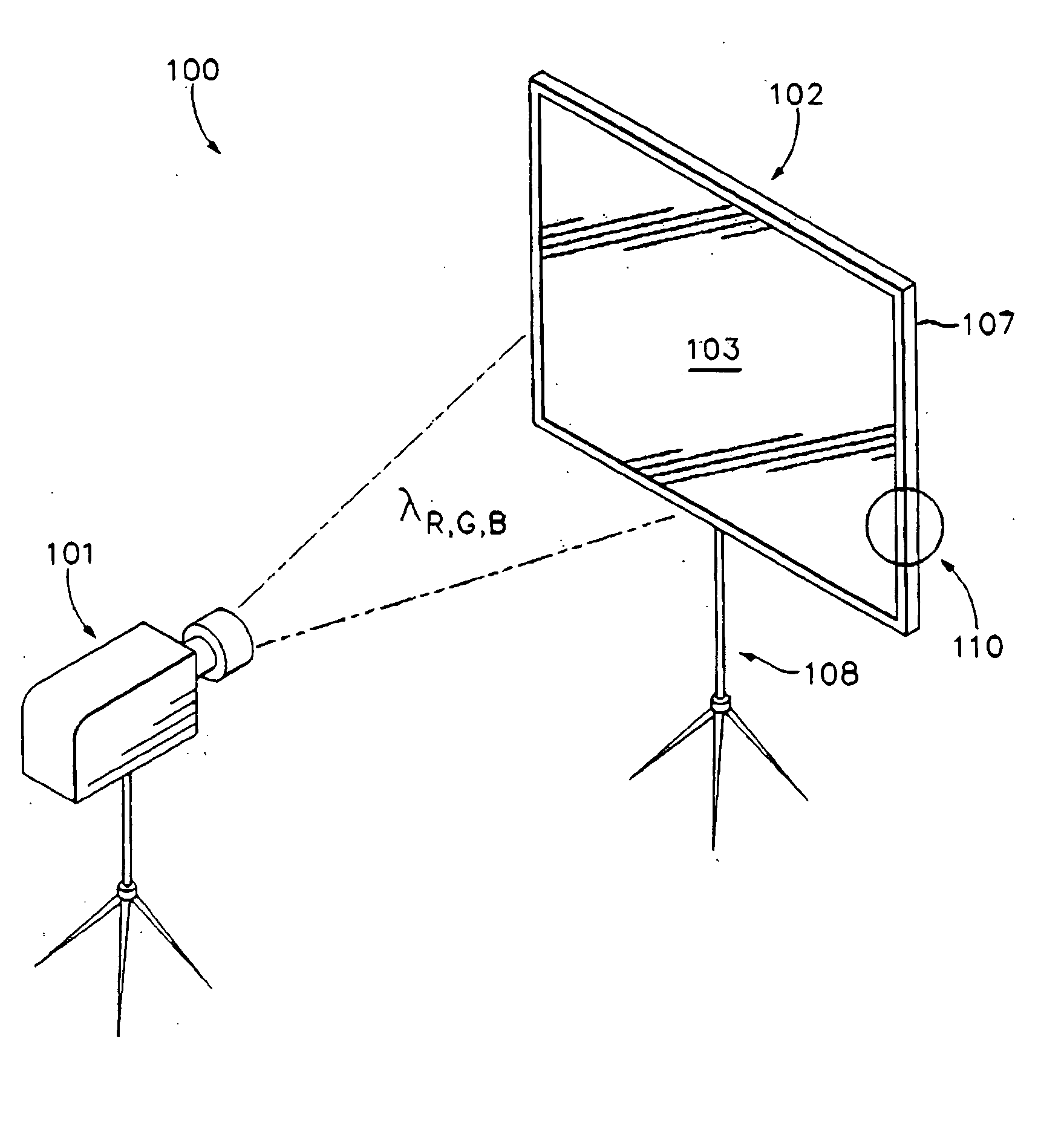

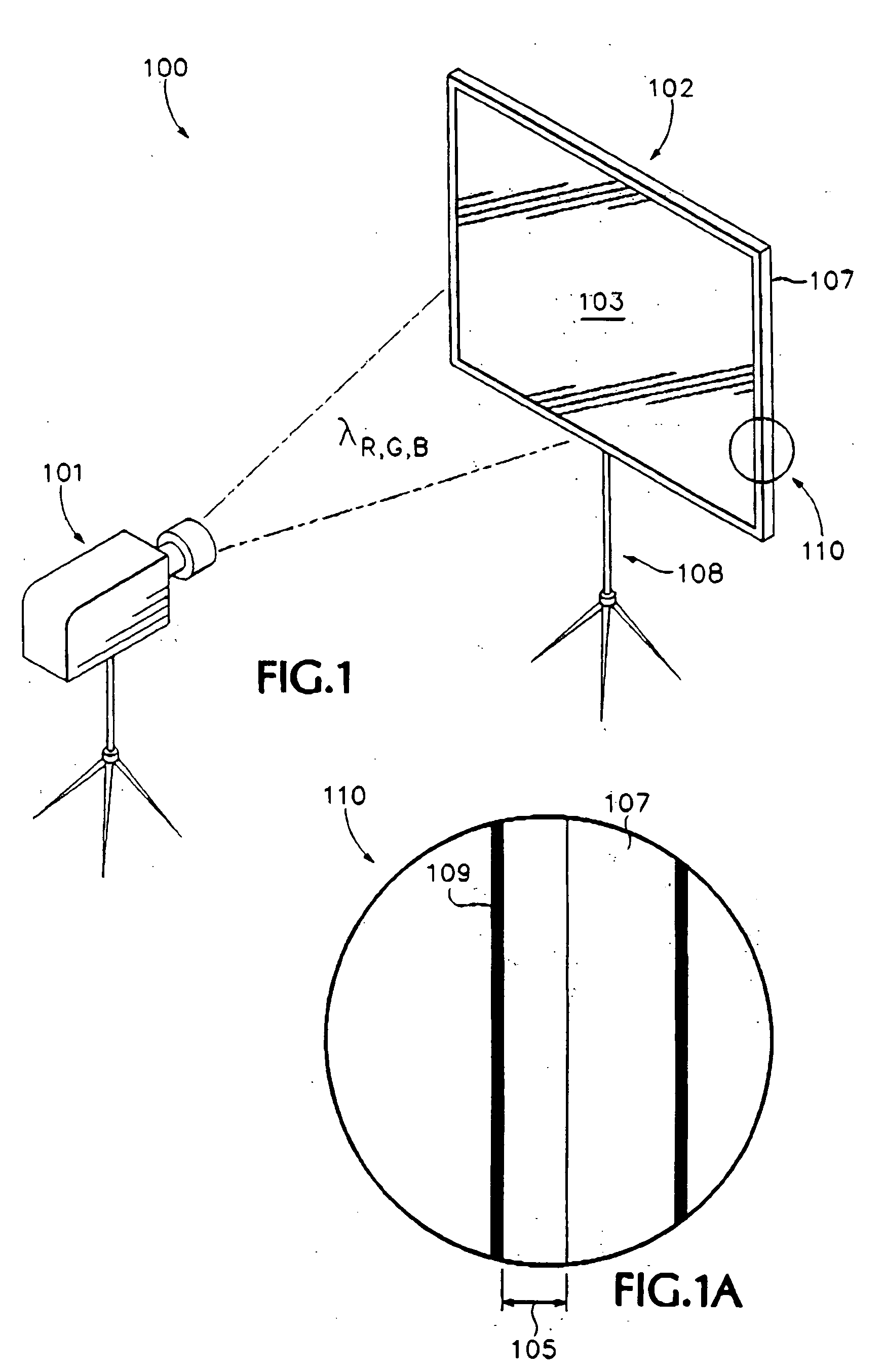

A reflector comprises a core and a first dielectric mirror formed over at least a portion of the core to reflect light having a preselected wavelength. The reflector may comprise a plurality of dielectric mirrors formed concentrically over the first dielectric mirror to reflect light having the preselected wavelength. The multiple dielectric mirrors may have different diffraction indices. A layer of such reflectors deposited onto the reflective surface of a projection screen may enhance the reflective selectivity of the screen to the preselected wavelength. Reflectors formed to reflect different wavelengths may be deposited onto the reflective surface to enhance selectivity to the different wavelengths and minimize reflection of ambient light.

Owner:HEWLETT PACKARD DEV CO LP

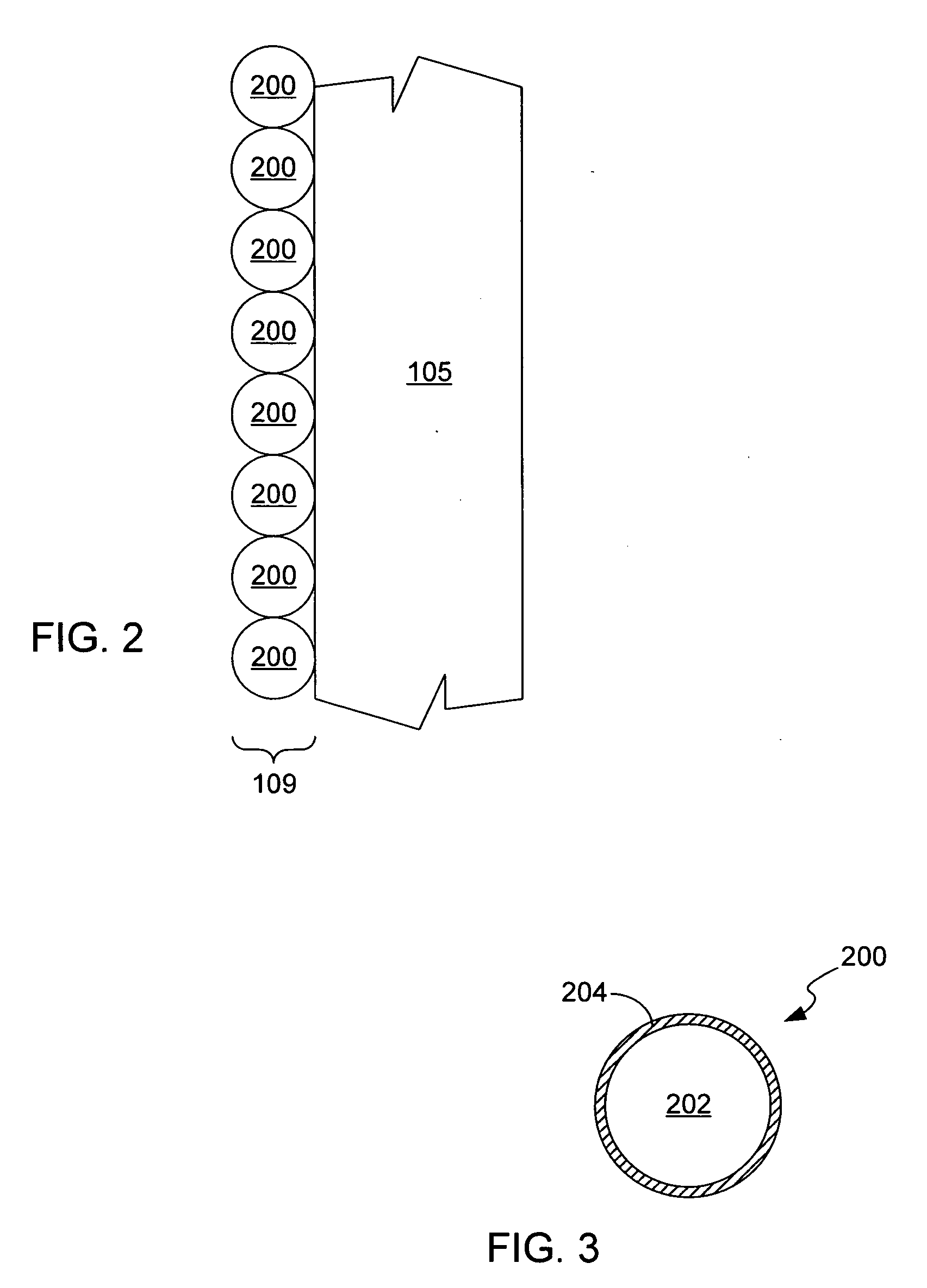

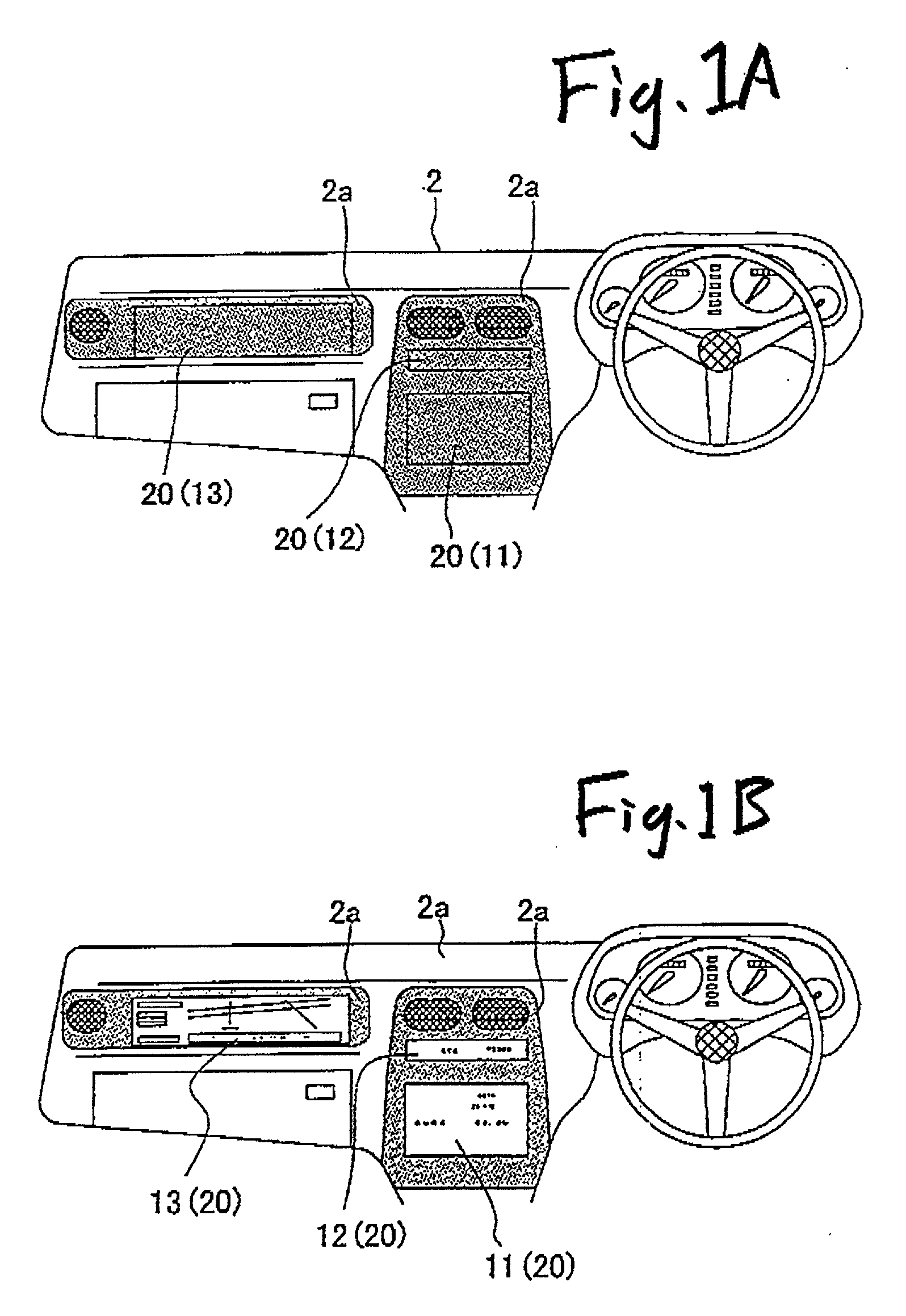

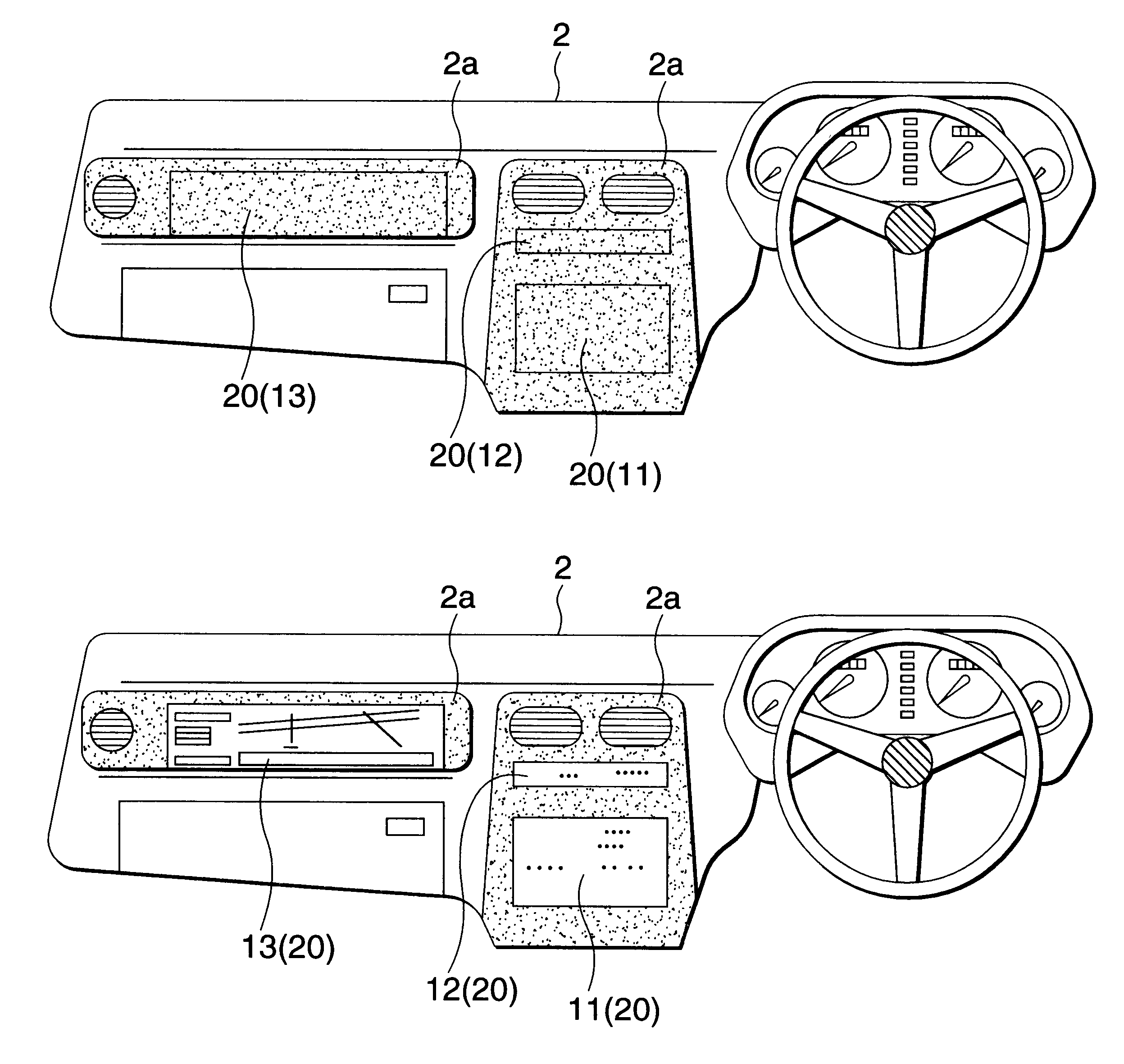

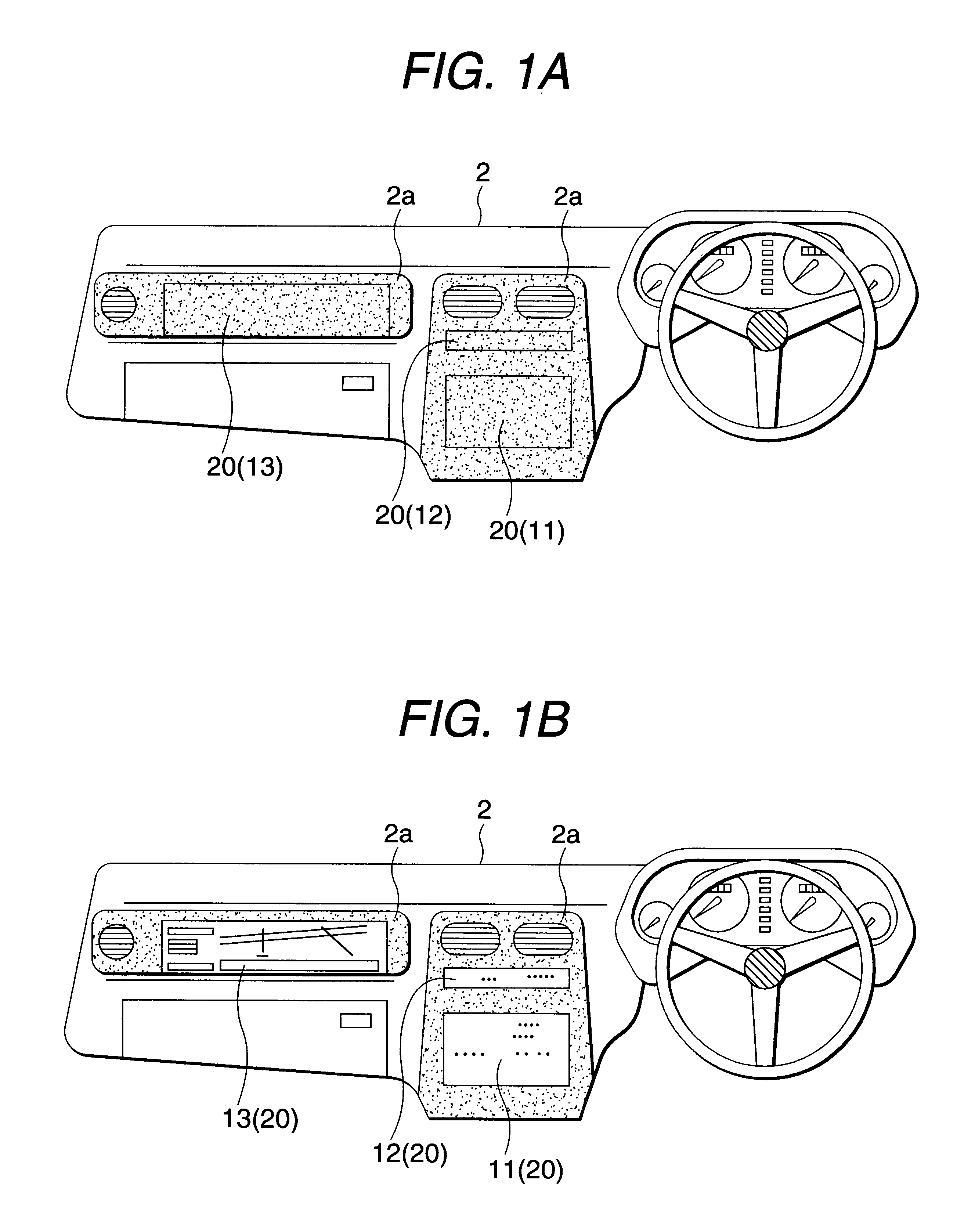

Display device

InactiveUS20020054440A1Tone can be prevented from sinkingReduced sensationMeasurement apparatus componentsStatic indicating devicesEffect lightDisplay device

In a vehicle display device having displays (11, 12, 13) fitted in a grained panel (2a) of an instrument panel (2) of a vehicle and serving to emit a display light to an outside during lighting, a front face of each of the displays is covered with a screen (20) having a grained pattern which is provided with a large number of minute holes capable of transmitting the display light. Consequently, a screen can be seen through the minute holes of the screen when the display is turned on, while the display is hidden by the grained screen (20) when the display is turned off. Therefore, the whole portion including the part having the display fitted therein is unified to be grained.

Owner:YAZAKI CORP

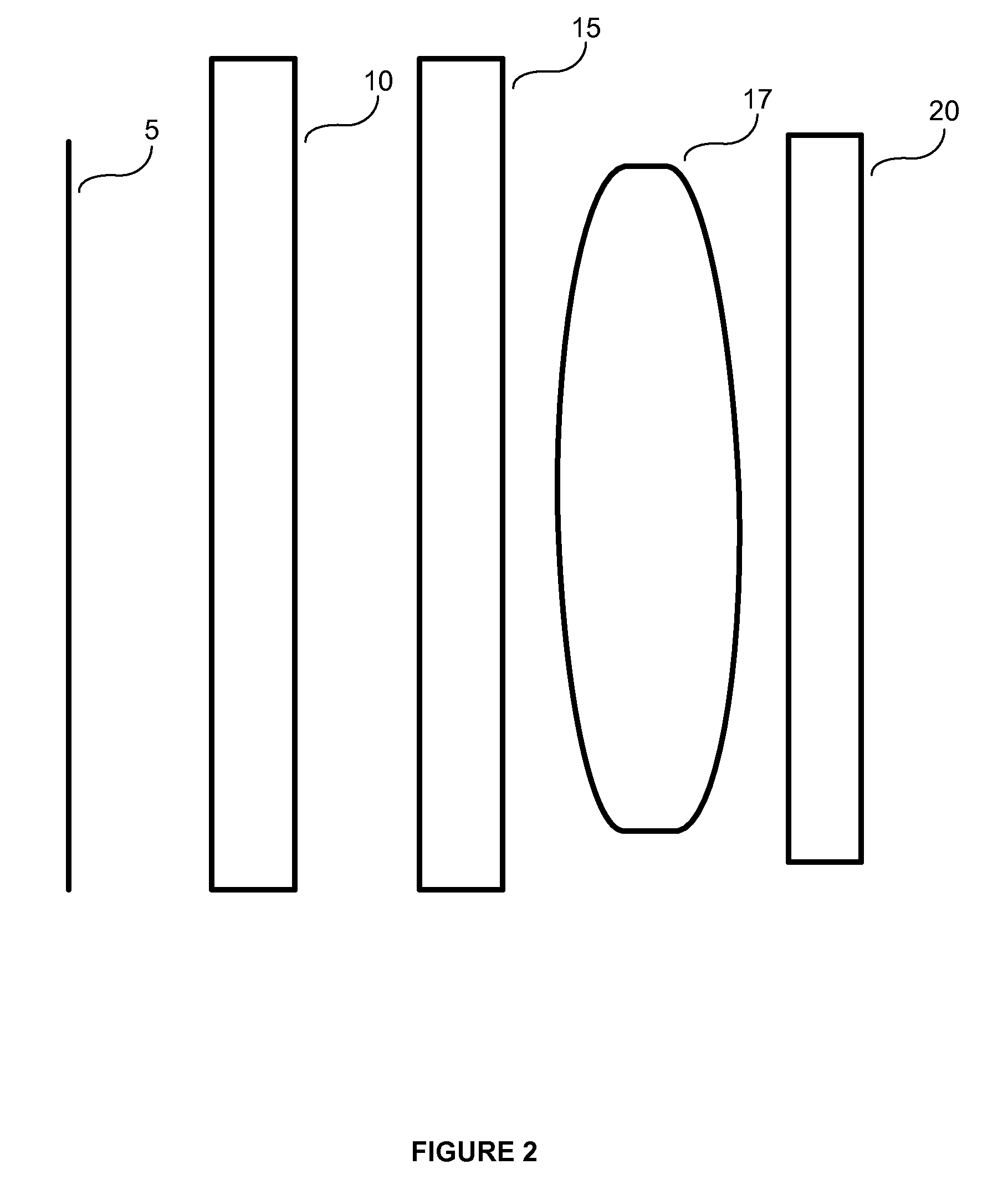

Angular selective light control sheeting and method of making the same

InactiveUS20160124126A1Improve structural propertiesScreening processesOptical elementsEngineeringPlastic film

An angular selective light control sheeting and a method of making the same are disclosed. The light control sheeting includes a layer of an optically clear elastic material which has a series of parallel slits formed by means of surface slitting with a sharp object such as a razor or blade. Each slit is filled with an opaque material which prevents light transmission through the slit walls. The method includes a step of slitting of an elastic, optically transmissive plastic sheet with a blade and forming at least one array of substantially parallel linear slits in a surface of the sheet, a step of stretching the sheet in a direction perpendicular to the linear slits, and a step of introducing an opaque material into the interior of the slits.

Owner:VASYLYEV SERGIY

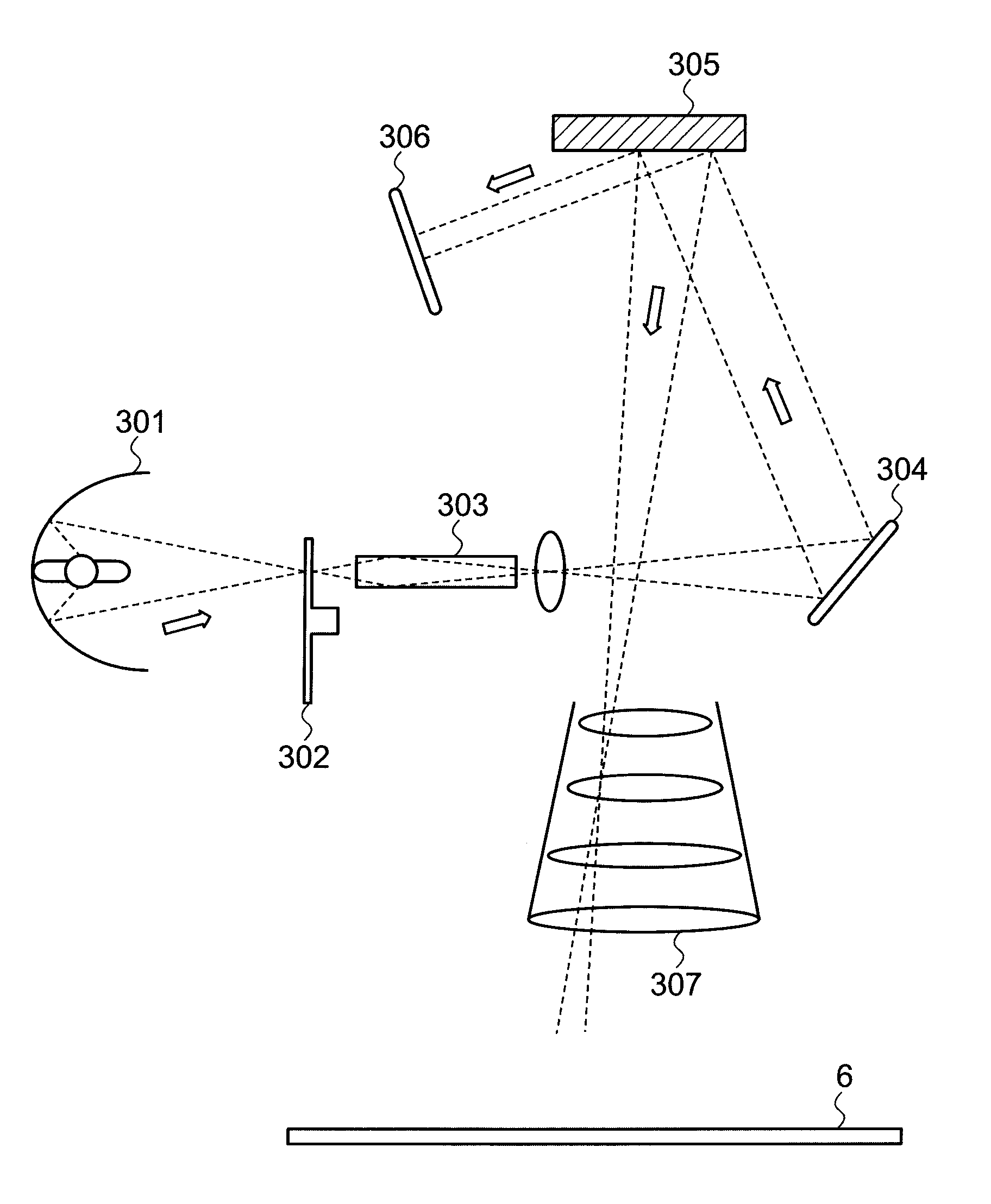

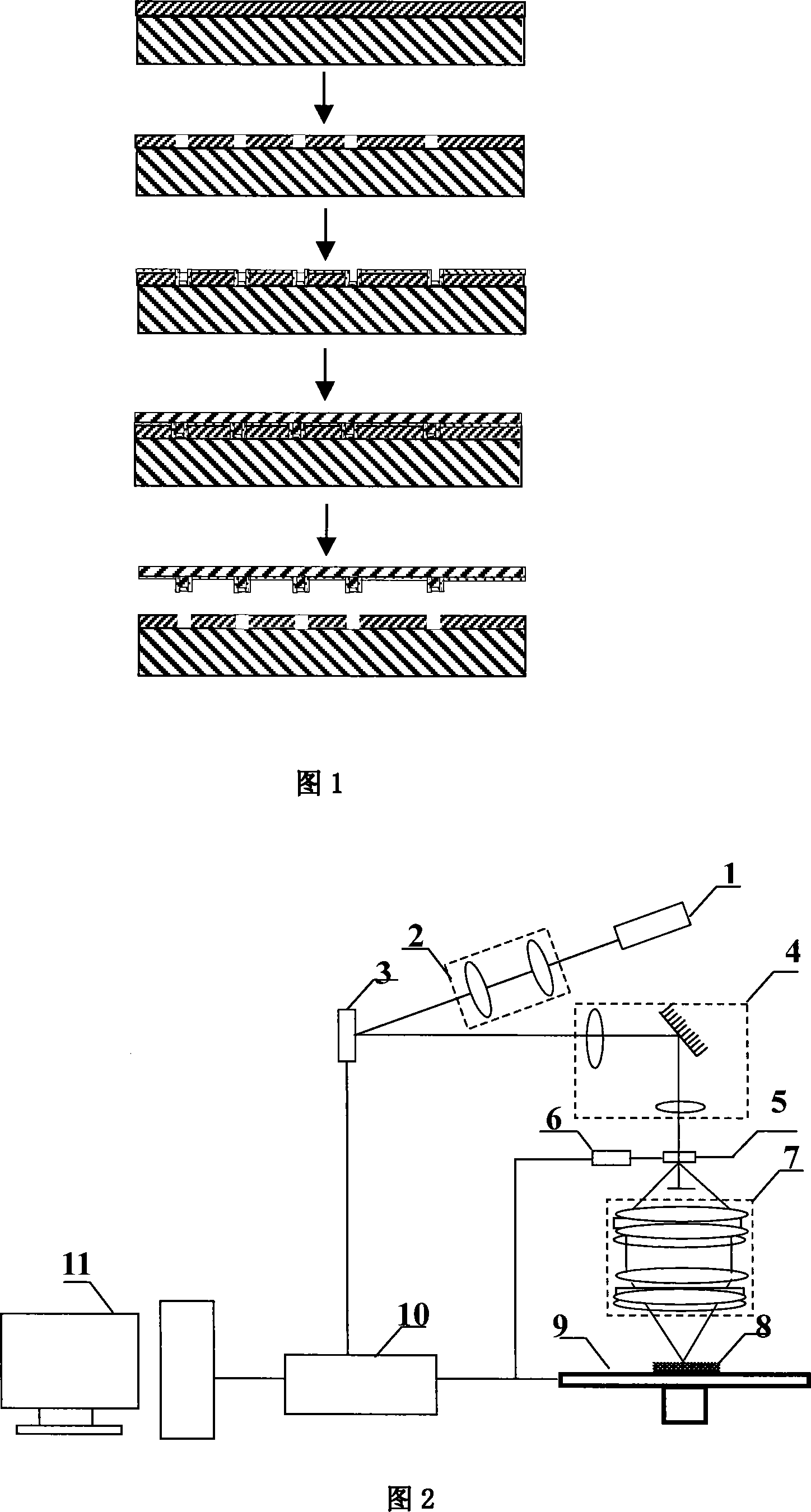

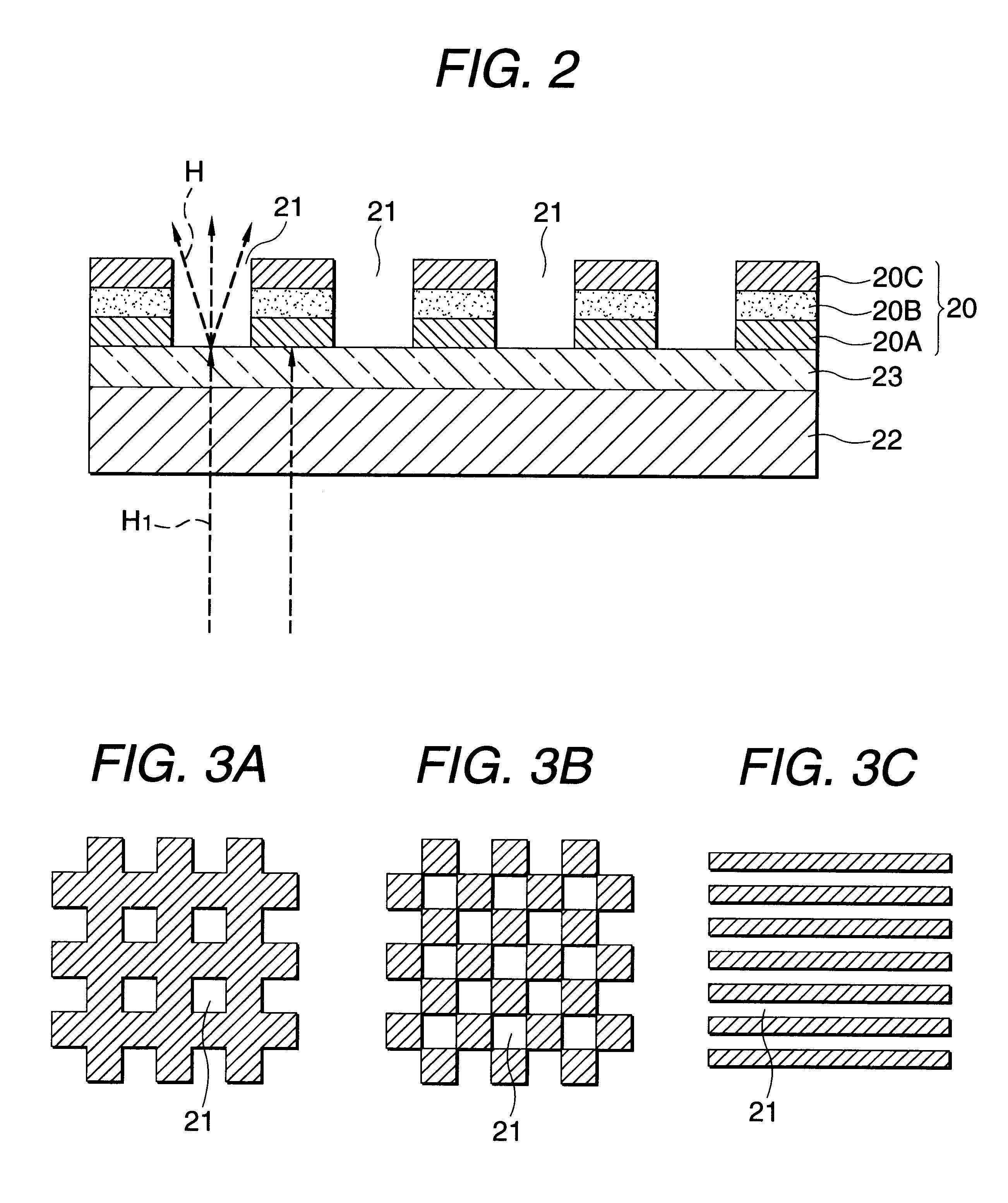

Backlight module accurate light guide thin film core production method

ActiveCN101216663AEliminate the influence of uneven dot qualityEliminate the effects of uneven qualityLaser detailsPhotomechanical apparatusEtchingLight guide

The invention discloses a method for manufacturing a precise photoconductive film cavity of backlight modules, which is characterized in that: an ultraviolet laser beam is reflected on a digital micro mirror after being expanded and collimated, the digital micro mirror is controlled according to the shape of a light guide network to be produced, and reflected light etches the light guide network on the surface of an ultraviolet photoresist dry plate via a projection optical system with 4F light paths; the relative positions of the reflected light and the photoresist dry plate are changed in turn to complete the etching of each needed light guide network; and the etched photoresist dry plate is electroformed after the process of surface metallization, so as to obtain the needed light guide film cavity. By inputting the shape of the light guide network via the digital micro mirror and etching the light guide network on the photoresist dry plate directly via the ultraviolet laser, the invention can evaluate the network design and provide sample products in a rapid manner, and improve the manufacturing quality of the cavity; at the same time, the invention is propitious to the manufacture of large-sized light guide plates.

Owner:YANCHENG NICROTEK CO LTD

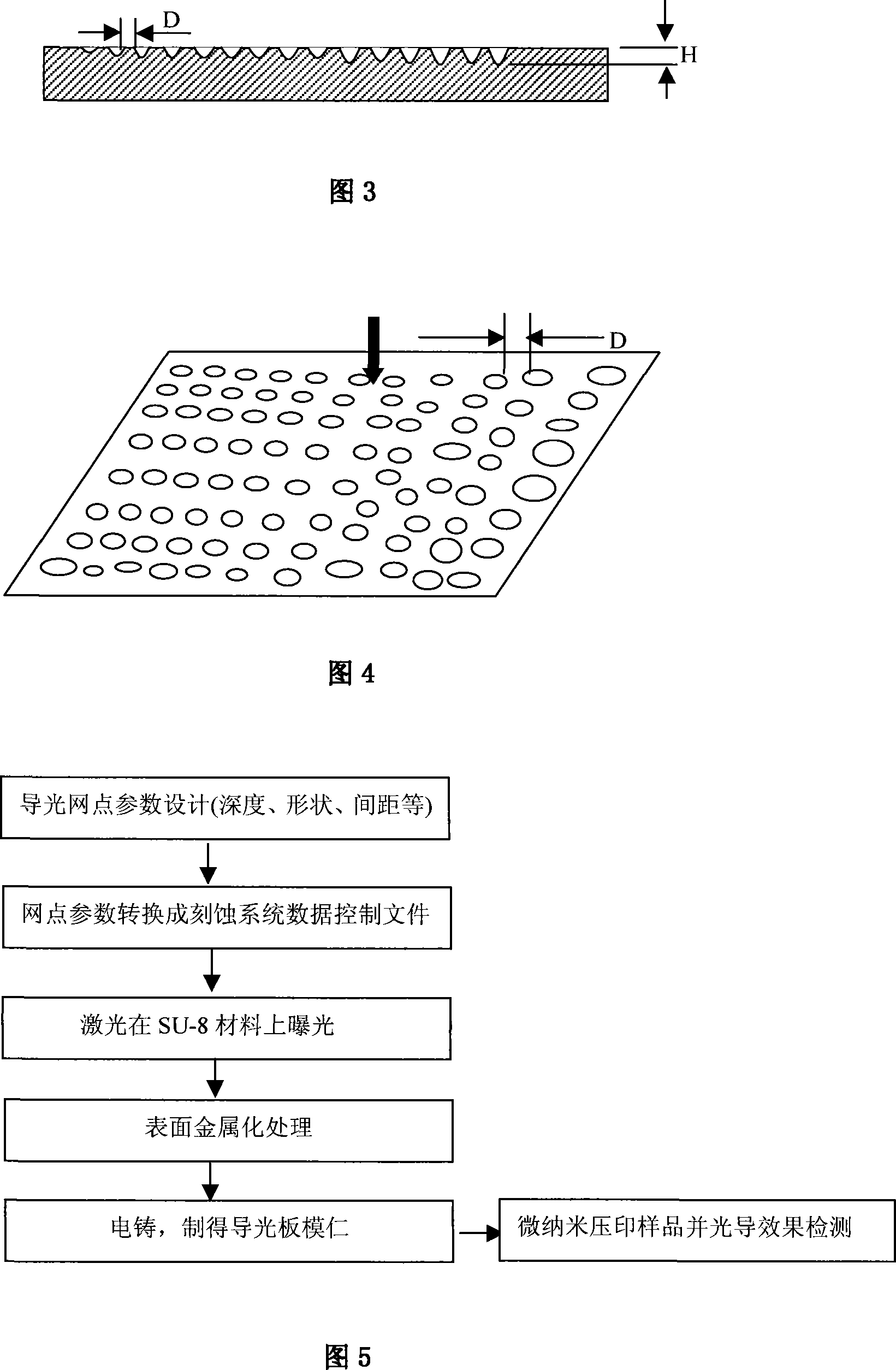

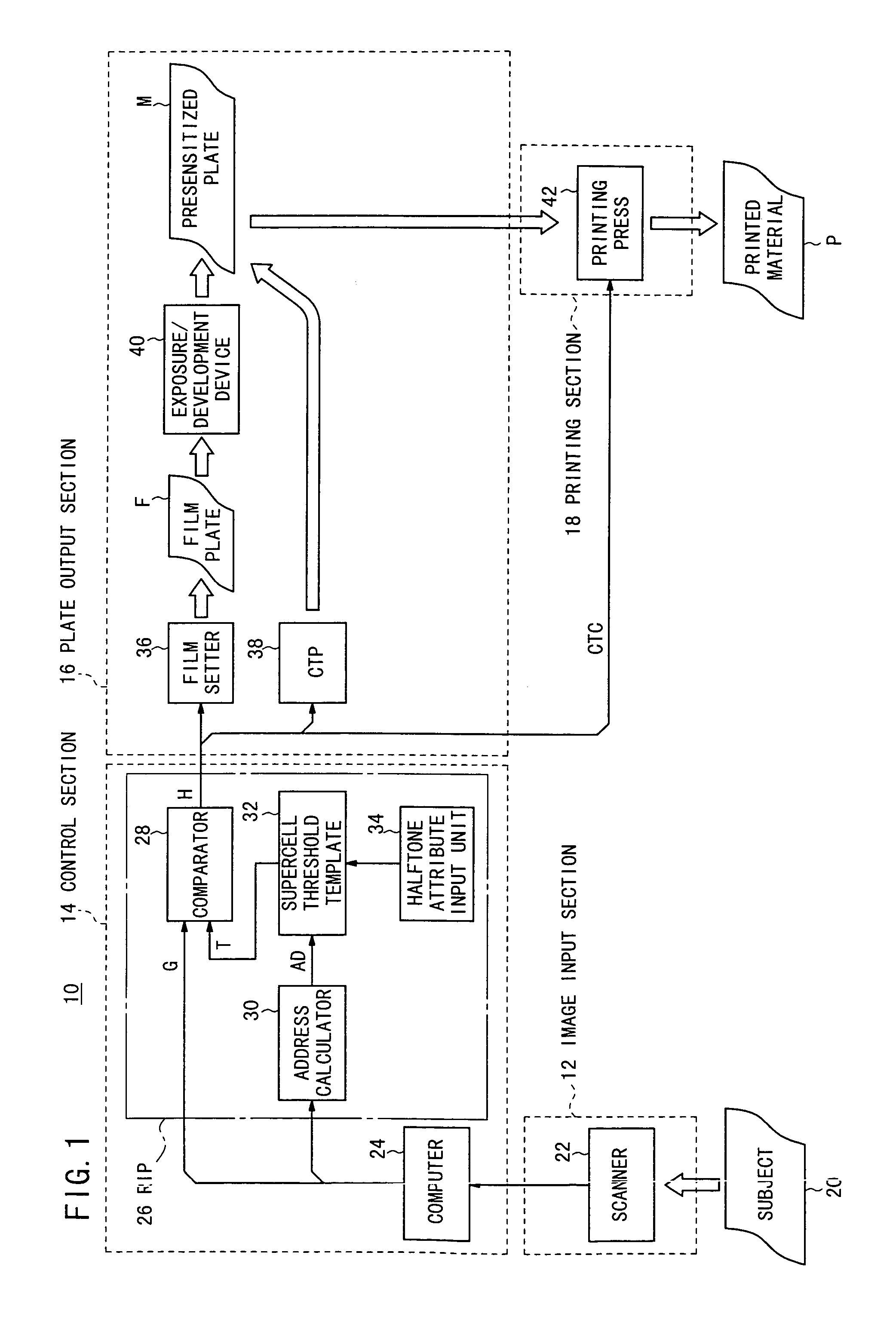

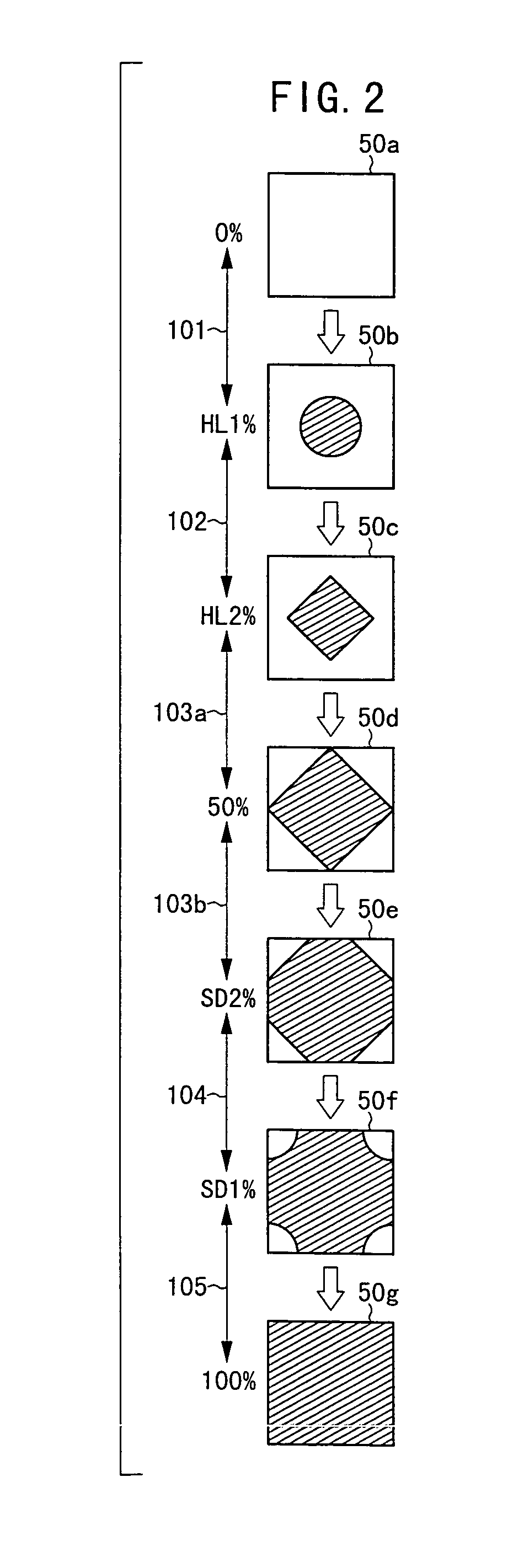

Method of tone reproduction with halftone dots, apparatus for outputting halftone plate, halftone plate, and printed material

InactiveUS6970273B1Eliminating tone jumpSmoother tone reproductionScreening processesVisual presentationTone reproductionComputer science

Tone jumps are eliminated in all areas ranging from a highlight area through an intermediate tone area to a shadow area for thereby achieving a smoother tone reproduction. Halftone dots are grown in a circular shape from a halftone percentage of 0% to a first highlight percentage. Halftone dots are grown while changing from the circular shape to a square shape from the first highlight percentage to a second highlight percentage greater than the first highlight percentage. Halftone dots are grown in a square shape from the second highlight percentage to a second shadow percentage. Halftone dots are grown while changing from the square shape to a circular shape from the second shadow percentage to a first shadow percentage greater than the second shadow percentage. Halftone dots are grown in a circular shape from the first shadow percentage to a percentage of 100%. The dots stick well to the print sheet in the highlight area and clearly define inter-dot spaces in the shadow area, and no tone jumps occur in the vicinity of the halftone percentages of 50% and 78.5%.

Owner:FUJIFILM HLDG CORP +1

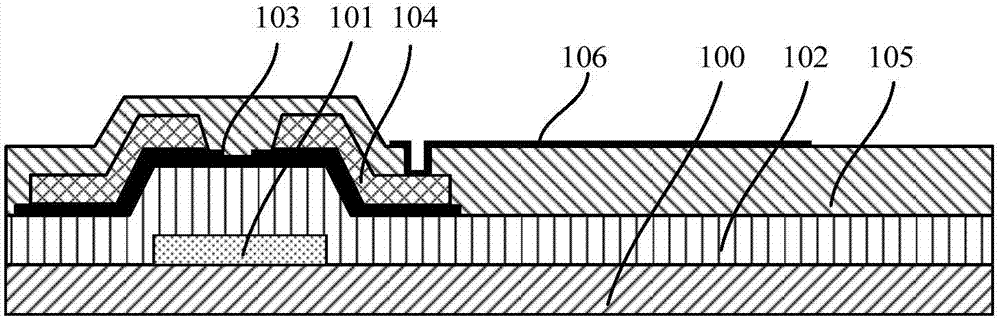

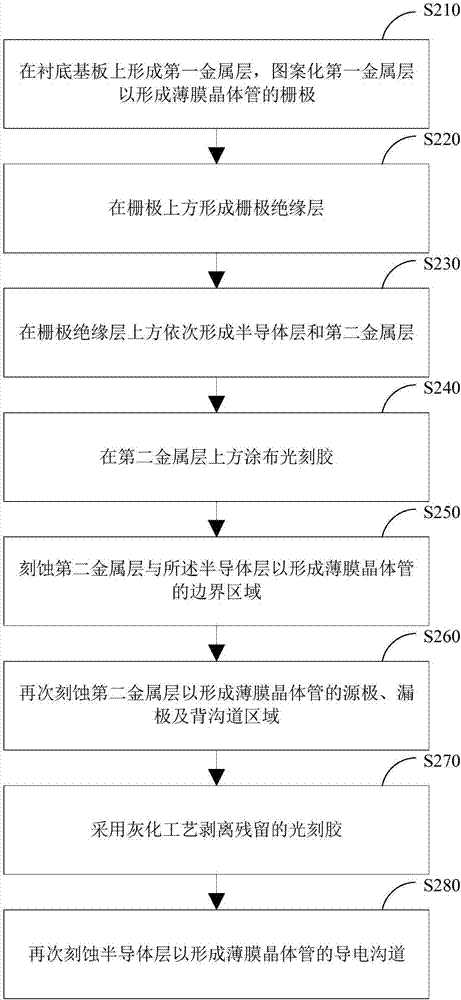

Method for making thin film transistor

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

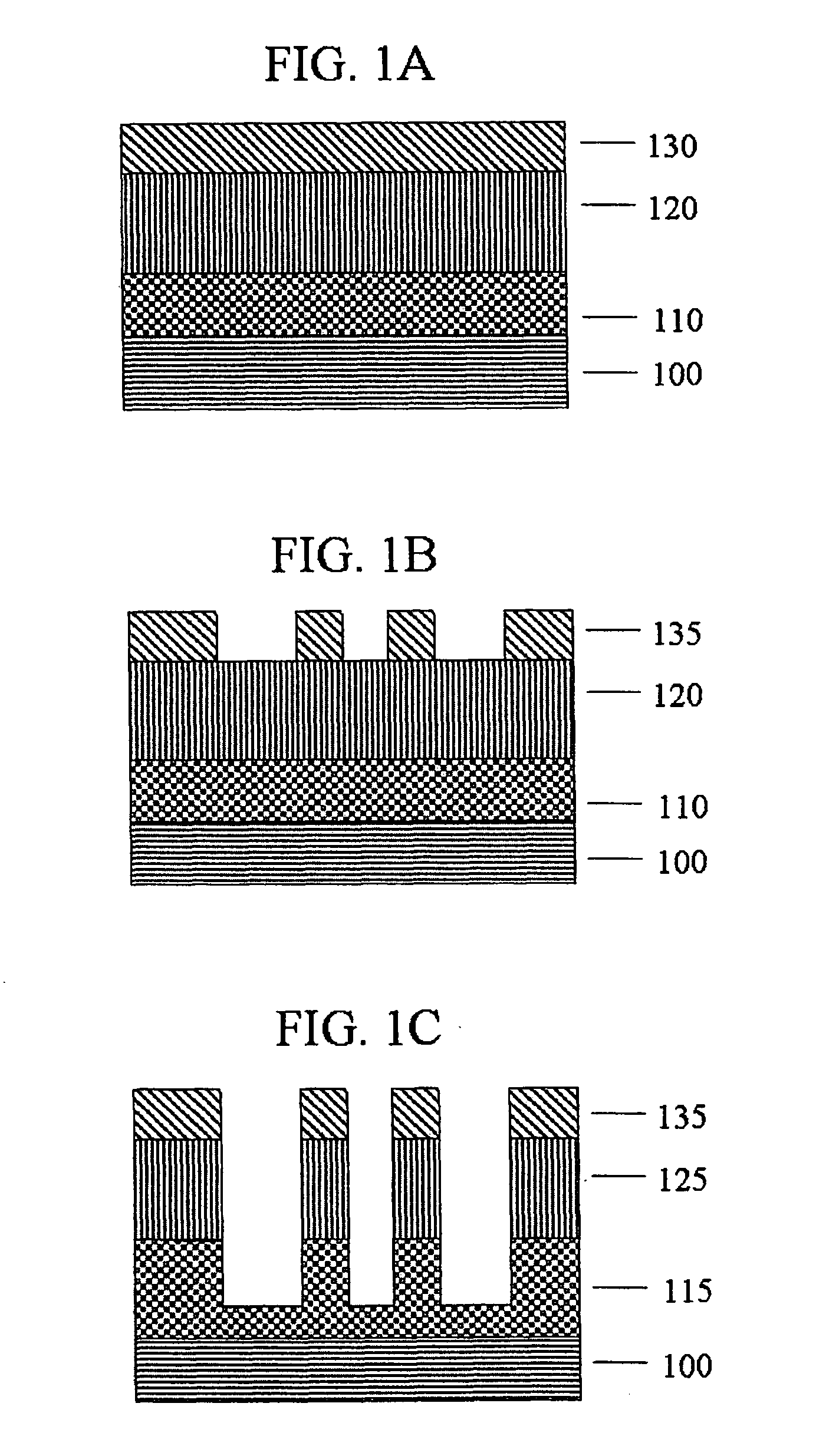

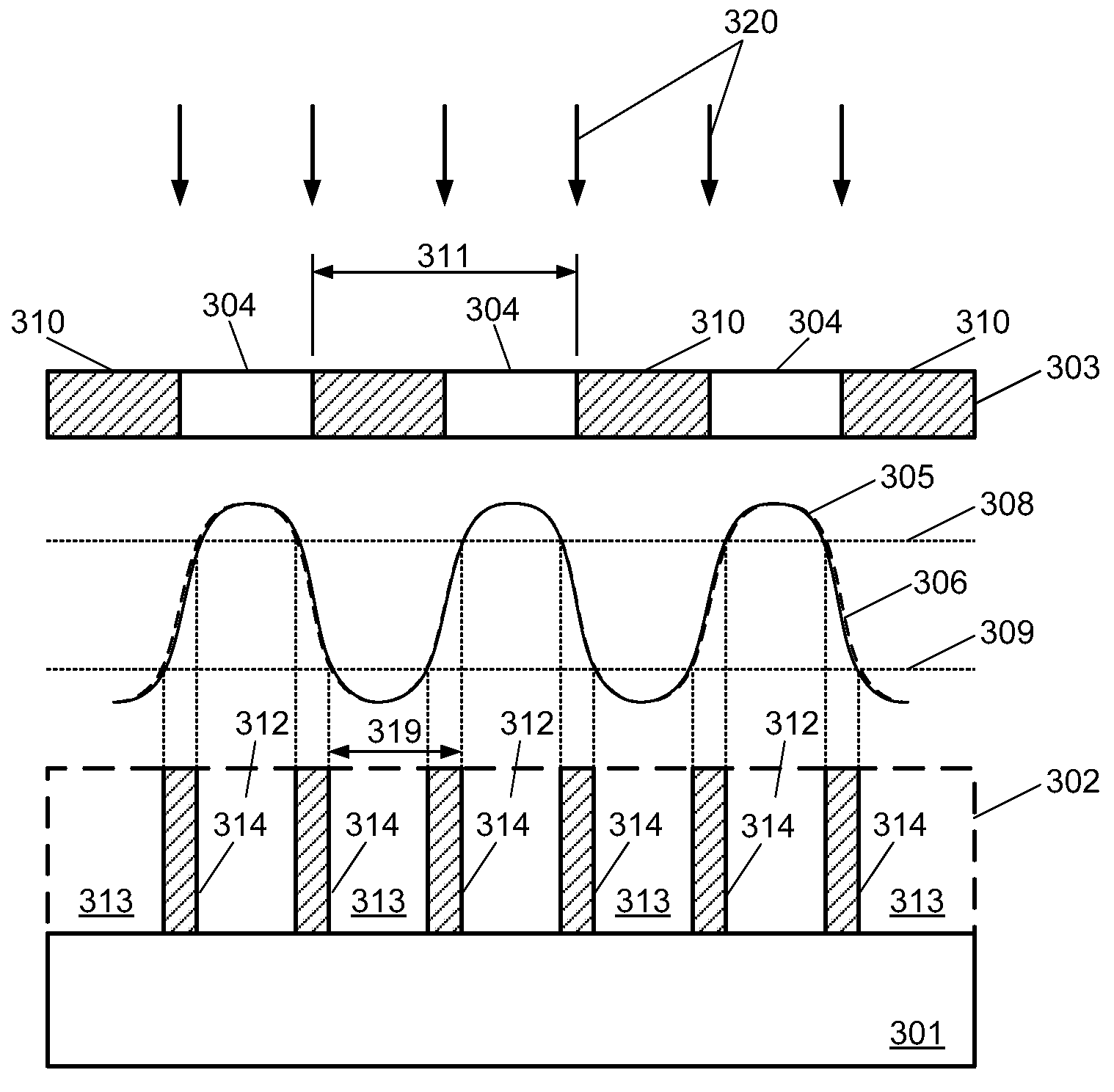

Method for creating gray-scale features for dual tone development processes

InactiveUS20100068654A1Easy to useSemiconductor/solid-state device manufacturingScreening processesColor toneResist

A method of patterning a substrate using a dual-tone development process is described. The patterning method comprises forming a layer of radiation-sensitive material on a substrate, wherein the layer of radiation-sensitive material comprises a dual tone resist. Thereafter, the patterning method comprises performing one or more exposures of the layer of radiation-sensitive material to one or more patterns of radiation, wherein at least one of the one or more exposures comprises using a mask having a dual-tone mask pattern region configured for printing dual tone features and a half-tone mask pattern region configured for printing half-tone features. Furthermore, the half-tone mask pattern region is optimized for use with the dual tone resist.

Owner:TOKYO ELECTRON LTD

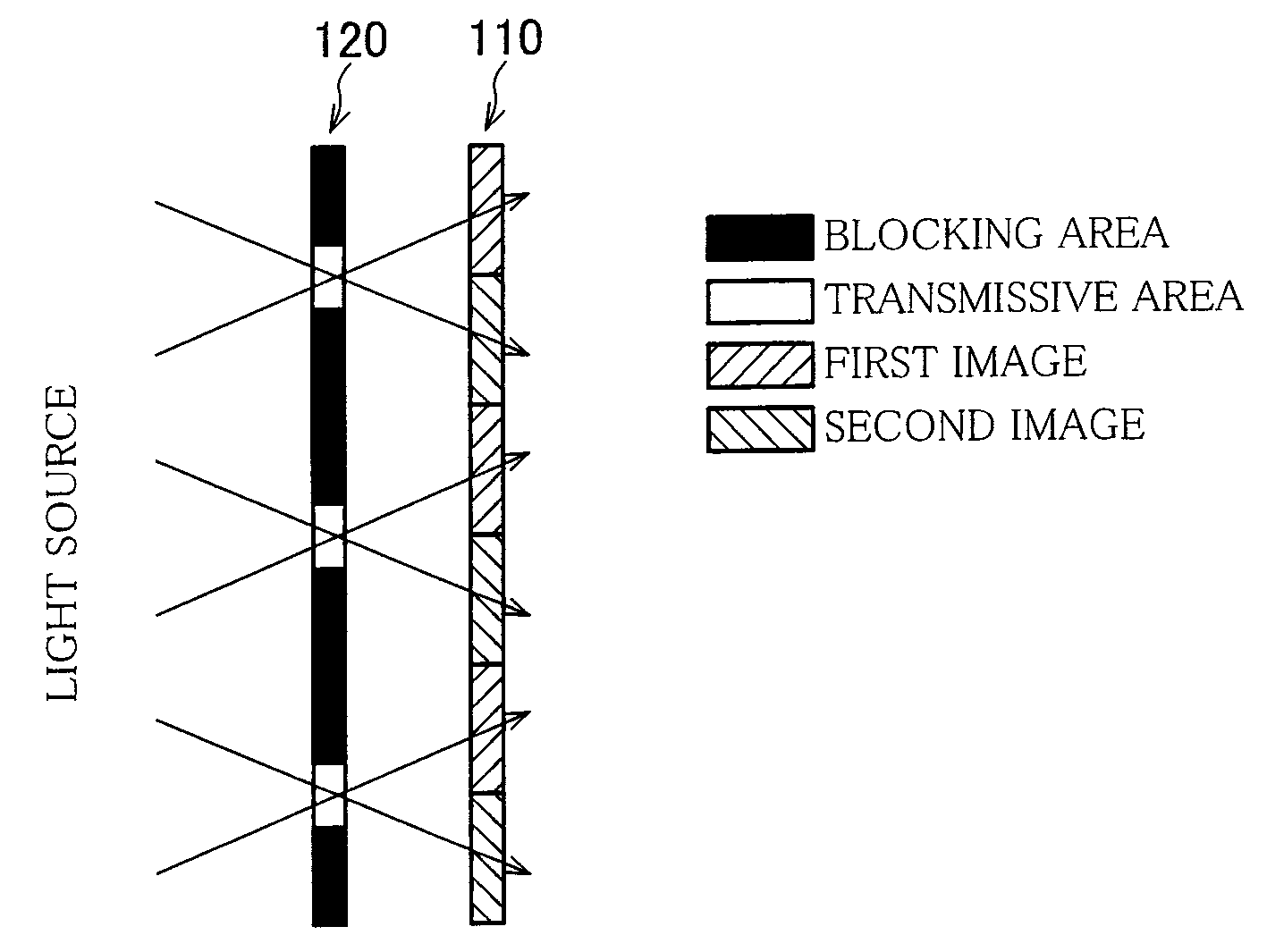

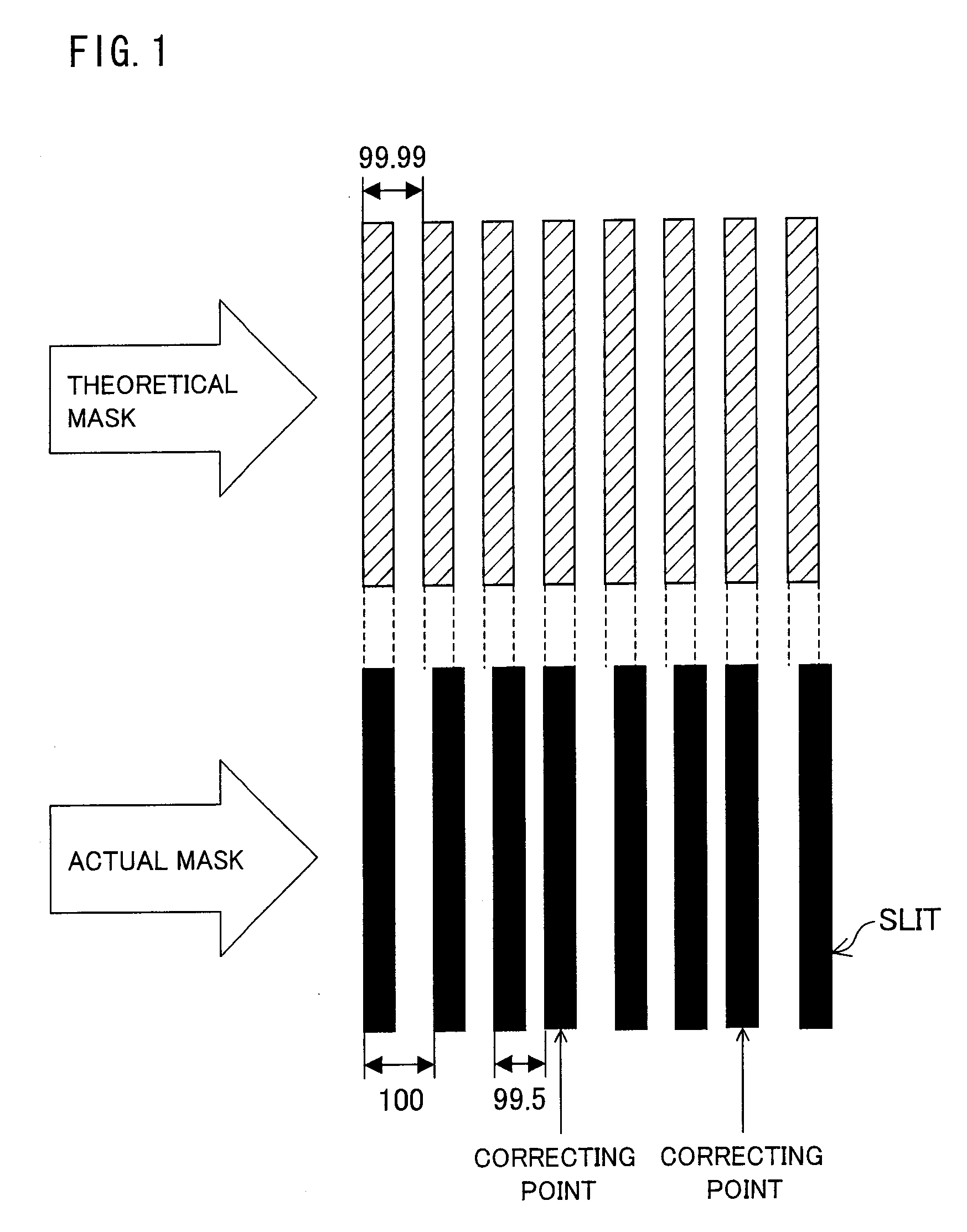

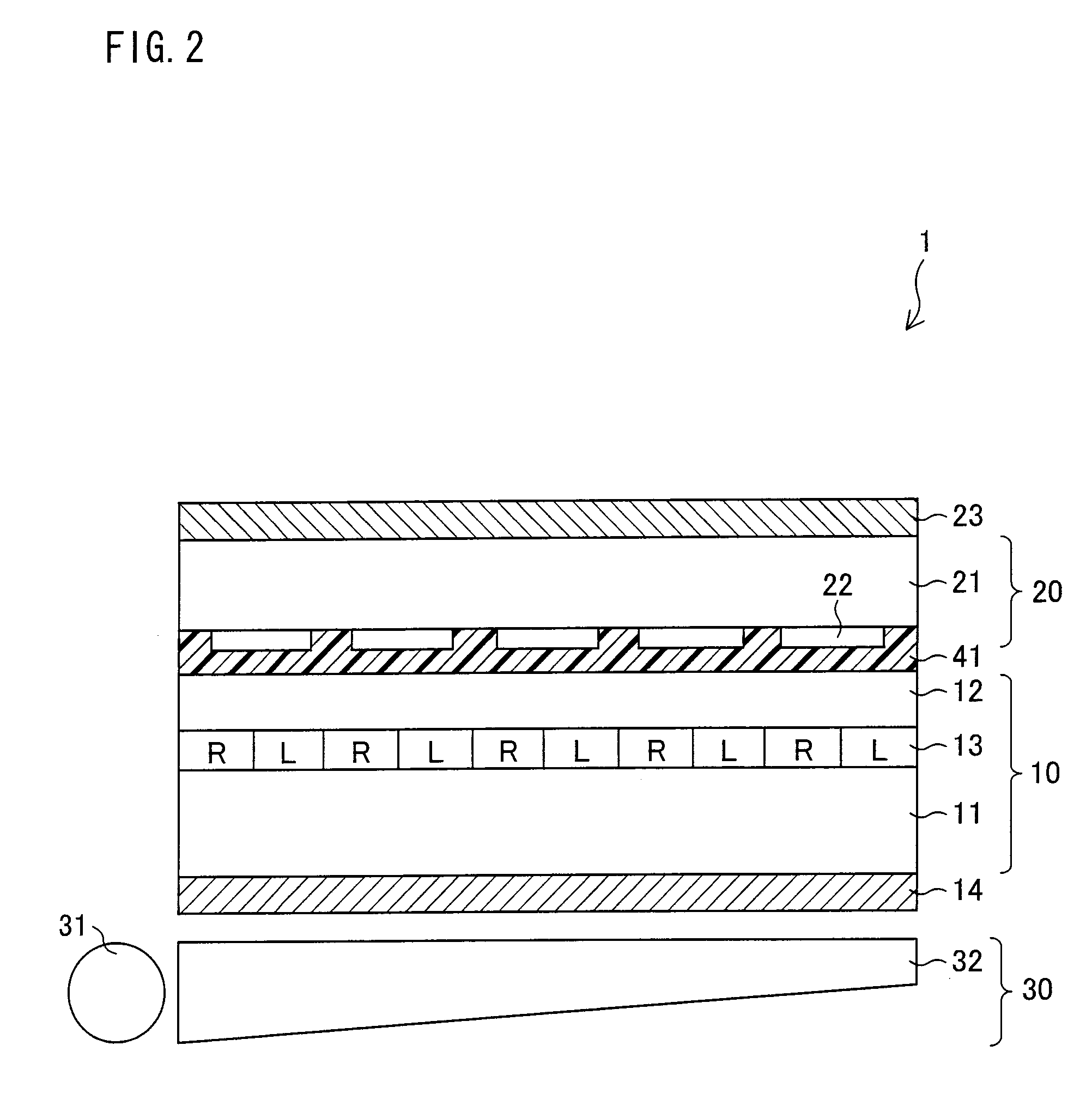

Parallax barrier, multiple display device and parallax barrier manufacturing method

InactiveUS20090080099A1Increase awarenessConvenient and accurateScreening processesPhotomechanical exposure apparatusVisibilityLithographic artist

A parallax barrier is manufactured by forming a light-blocking layer by patterning a metal layer or a resin layer on a barrier glass in a photolithography step. On a mask used in the photolithography step, some pitches between slits are different, the slits corresponding to portions whereupon the light-blocking layers are to be formed. In addition, on the mask, first pitches (for instance, 100) and second pitches (for instance 99.5), which can be actually formed with accuracy, are formed in a cycle, and the average of such pitches can be accord with a theoretical pitch distance (for instance, 99.99). Thus, in the parallax barrier to be used for a multiple display device, visibility of the entire screen can be improved, and the parallax barrier which can be manufactured by using the mask lithography technology having a limited accuracy, and a method for manufacturing such parallax barrier are provided.

Owner:SHARP KK

Enhanced relief printing plate

ActiveUS8399177B2Improve accuracyOptimization rangePhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringImage area

Owner:MIRACLON CORP

Display device

InactiveUS6765546B2Tone can be prevented from sinkingReduced sensationMeasurement apparatus componentsStatic indicating devicesDisplay deviceEffect light

In a vehicle display device having displays fitted in a grained panel of an instrument panel of a vehicle and serving to emit a display light to an outside during lighting, a front face of each of the displays is covered with a screen having a grained pattern which is provided with a large number of minute holes capable of transmitting the display light. Consequently, a screen can be seen through the minute holes of the screen when the display is turned on, while the display is hidden by the grained screen when the display is turned off. Therefore, the whole portion including the part having the display fitted therein is unified to be grained.

Owner:YAZAKI CORP

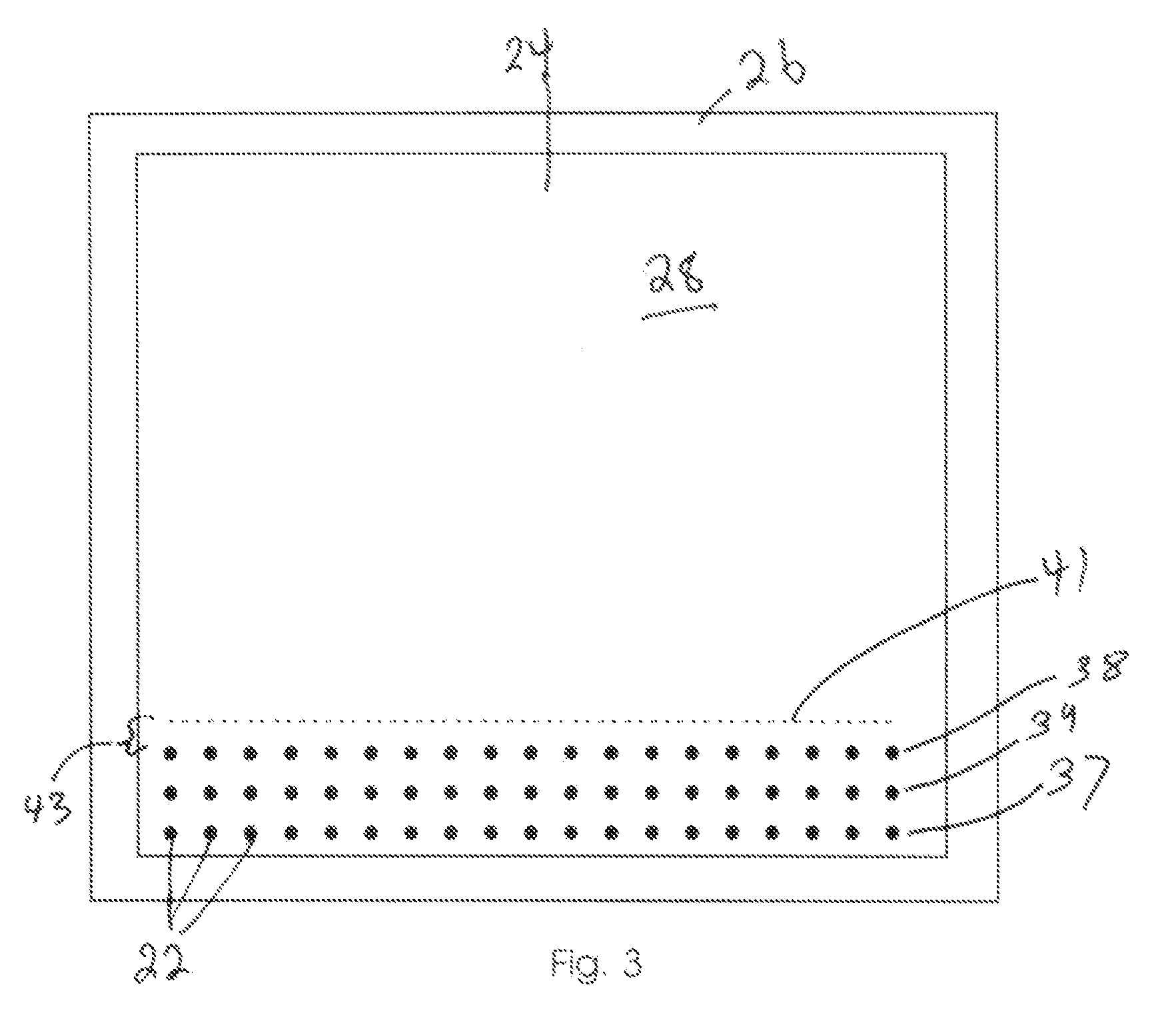

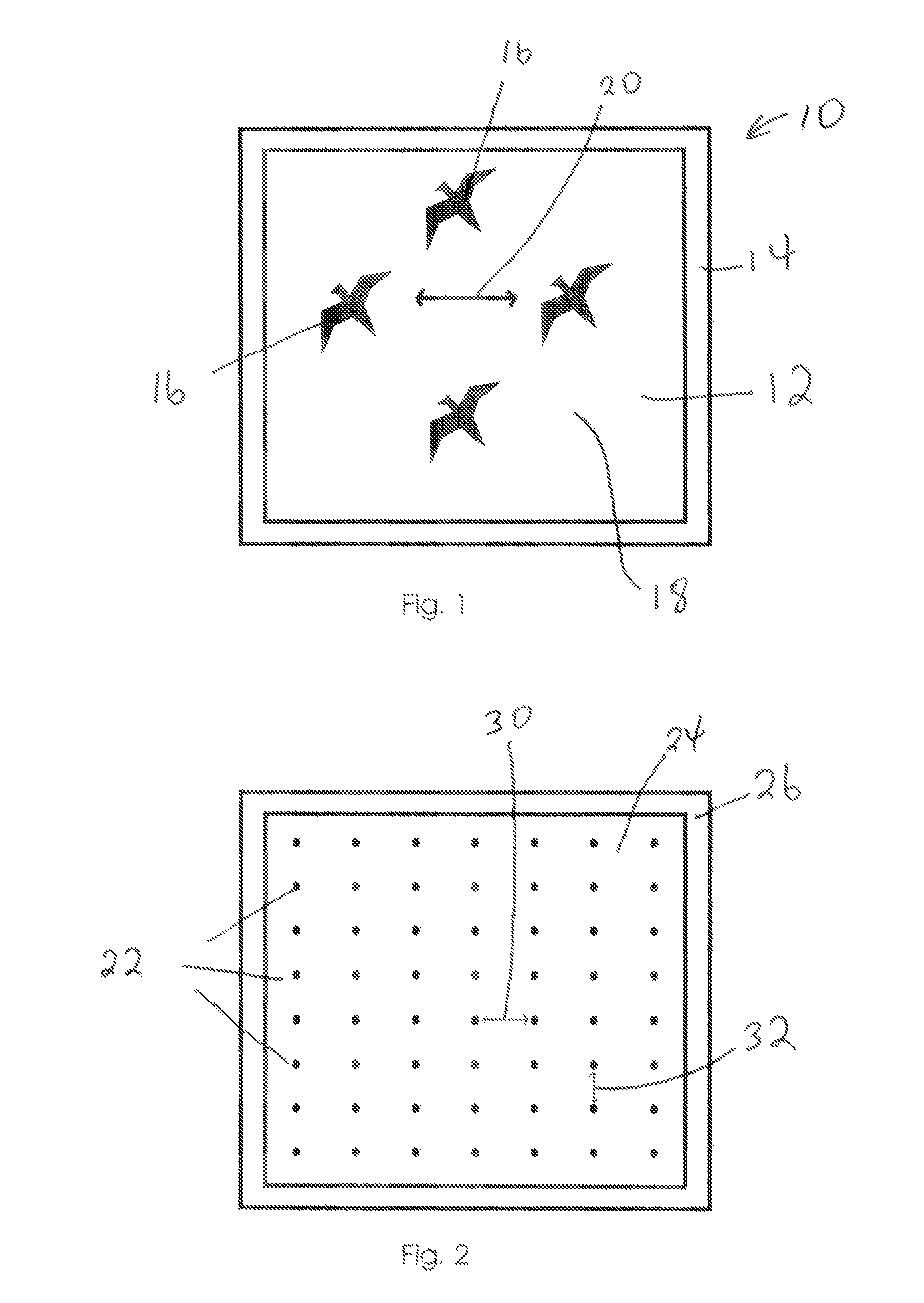

Bird Collision Avoidance Treatment for Exterior Glass

InactiveUS20130003208A1Prevent bird collisionDecorative surface effectsScreening processesEngineeringVertical distance

There is disclosed a glass treatment for treating exterior glass to prevent bird collisions with the glass. The treatment consists of a plurality of visible markings applied to an exterior surface of the glass, the plurality of markings extending substantially across the entire exterior surface. The markings are separated from each other by a vertical distance not exceeding 2.5 inches and by a horizontal distance not exceeding 4.5 inches. The markings occupy no more than 15% of the exterior surface of the glass.

Owner:ALSIP ROBERT +3

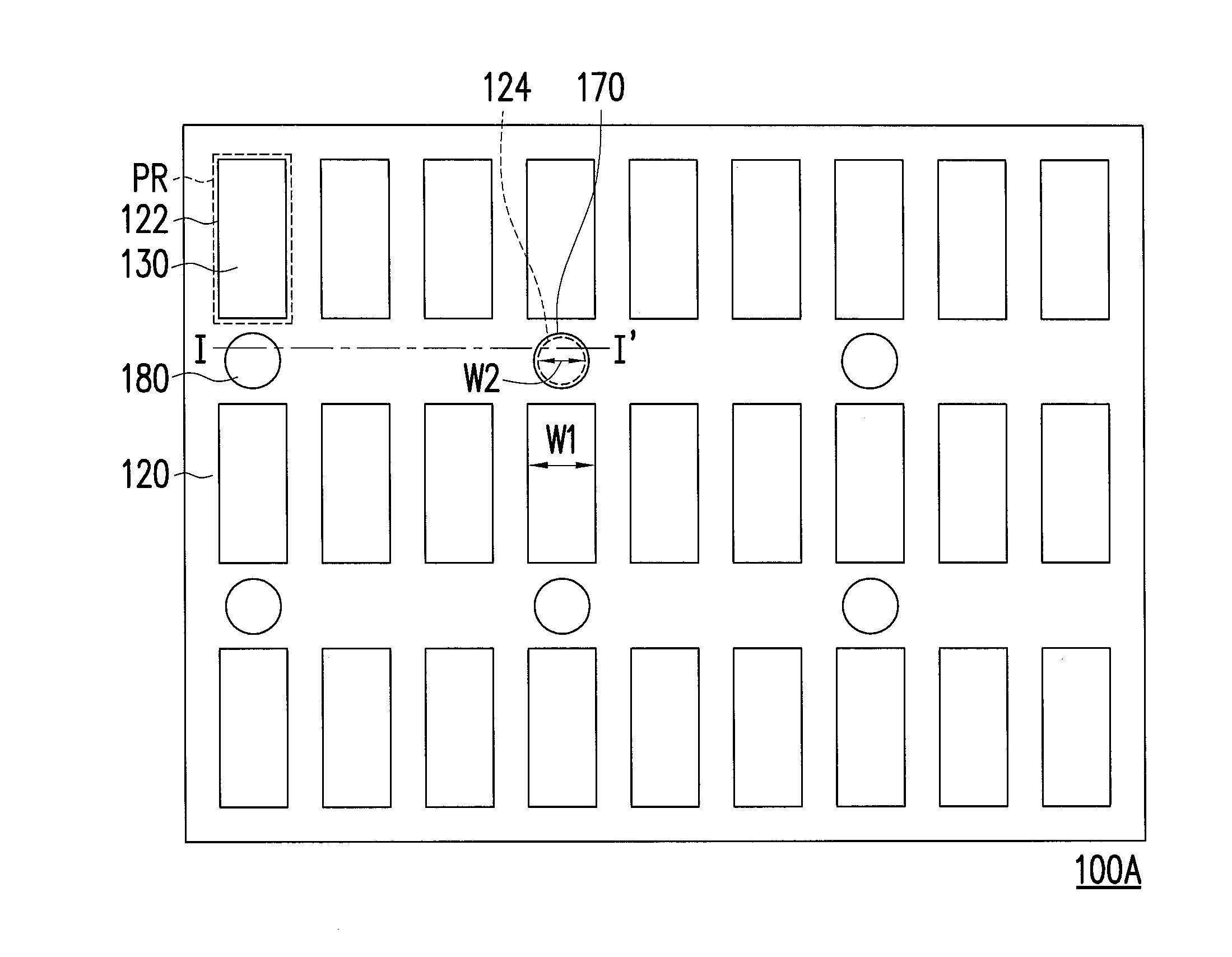

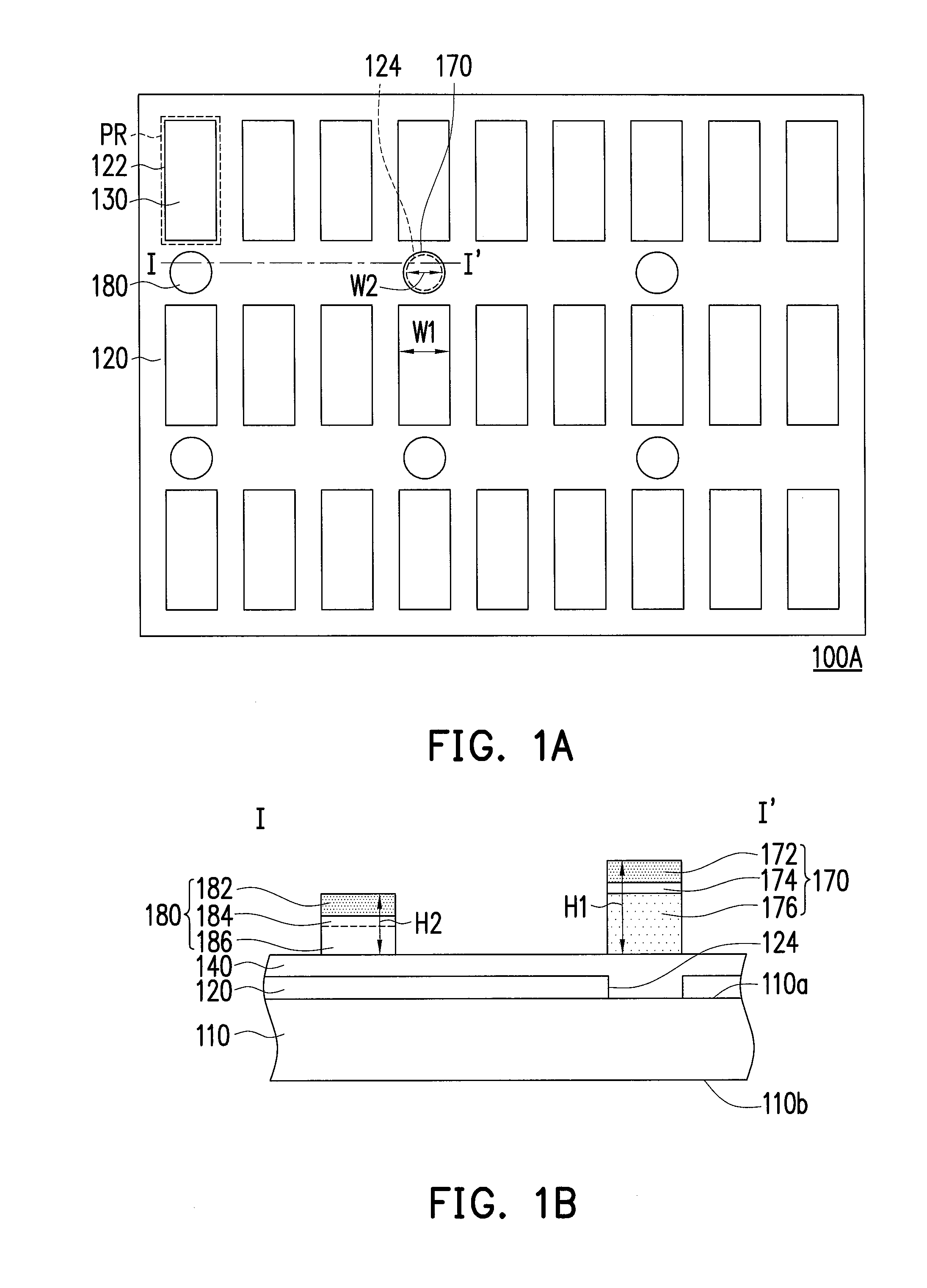

Device substrate and fabricating method thereof

ActiveUS20150293279A1Strong control abilityIncrease the differenceOptical filtersScreening processesEngineering

A device substrate and a fabricating method thereof are provided. The device substrate includes a substrate and a patterned light-shielding layer. The patterned light-shielding layer having a plurality of pixel openings and a plurality of first exposure openings is disposed on the substrate, and an area and / or shape of one of the first exposure openings is different from an area and / or shape of one of the pixel openings.

Owner:AU OPTRONICS CORP

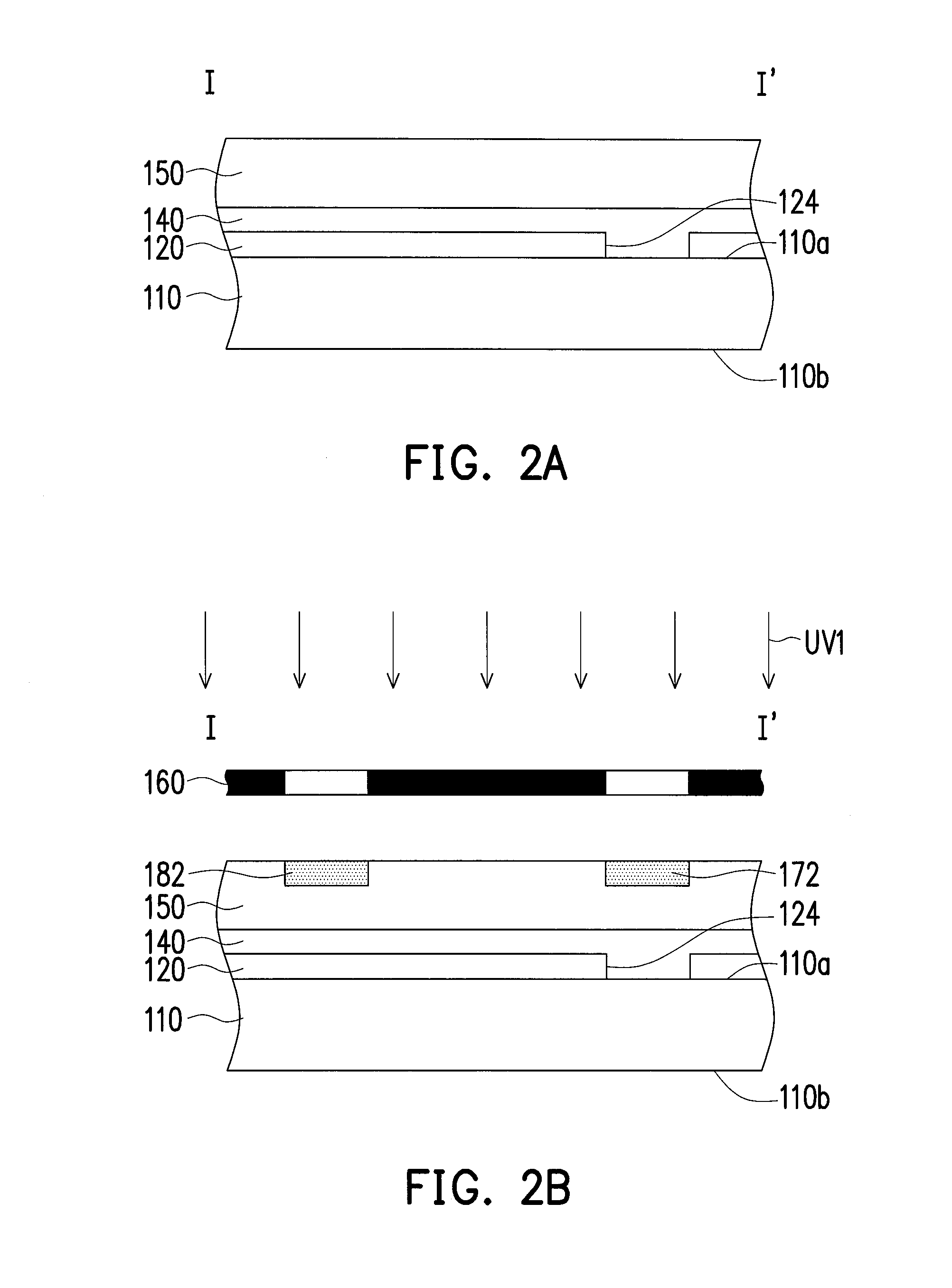

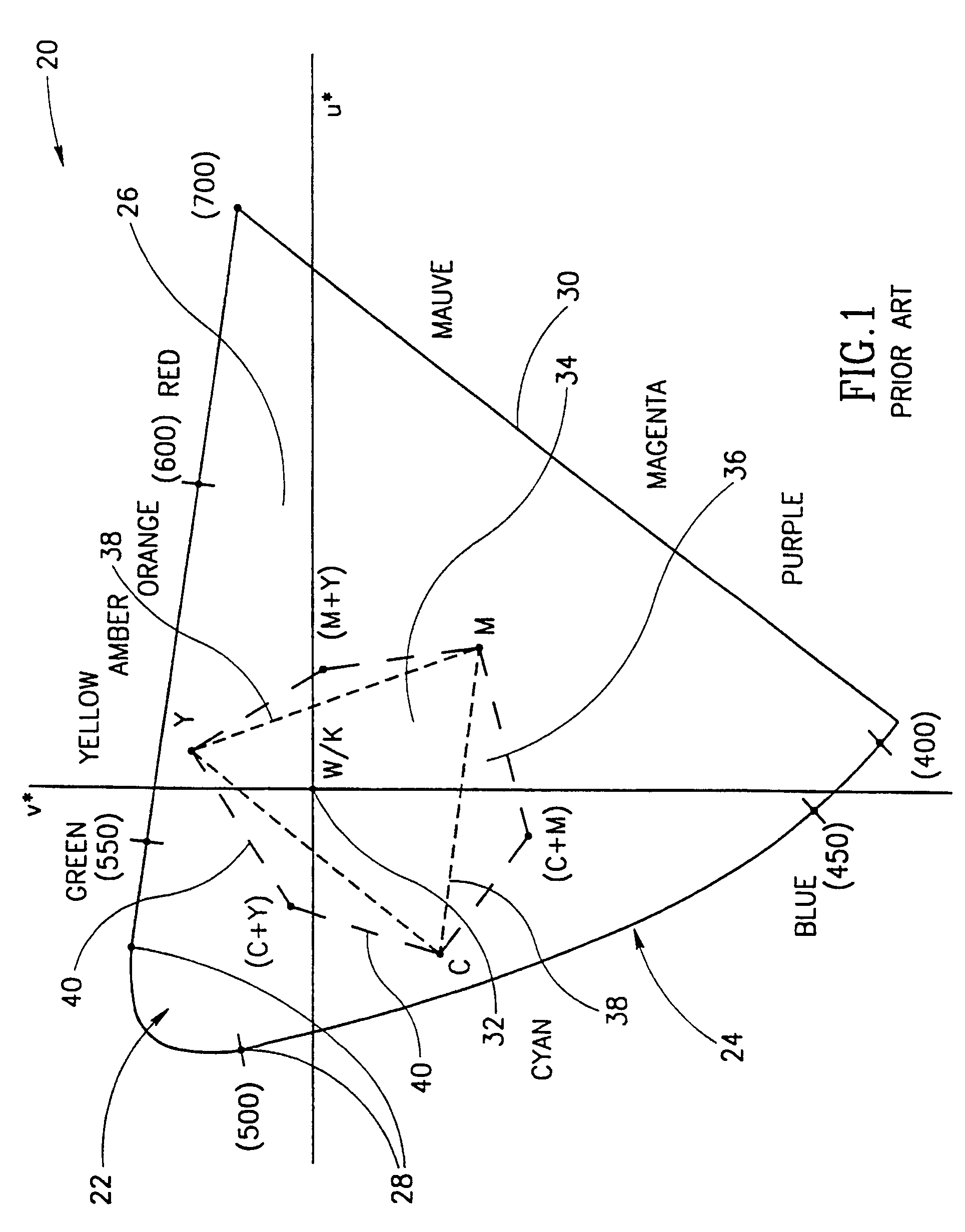

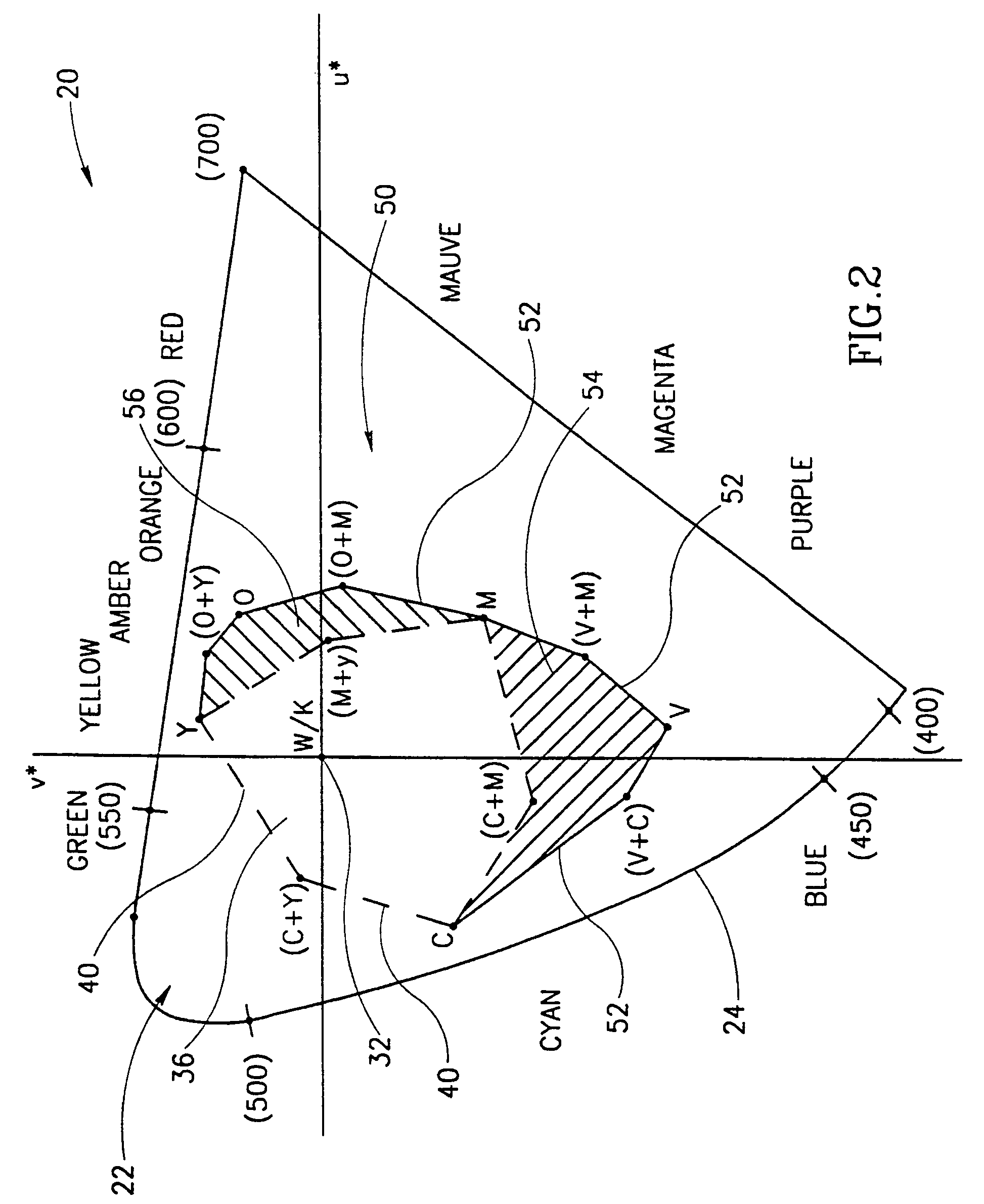

Expanded color space

InactiveUS7027191B1Reduce moiréMitigate moiré patternsScreening processesVisual presentationColor printingHue

A process for color printing an image with angled half tone screens and a colorant set that includes Cyan, Magenta, Yellow and Black colorants and at least one other colorant having a hue angle intermediate the hue angles of Cyan and Magenta.

Owner:HEWLETT PACKARD INDIGO BV

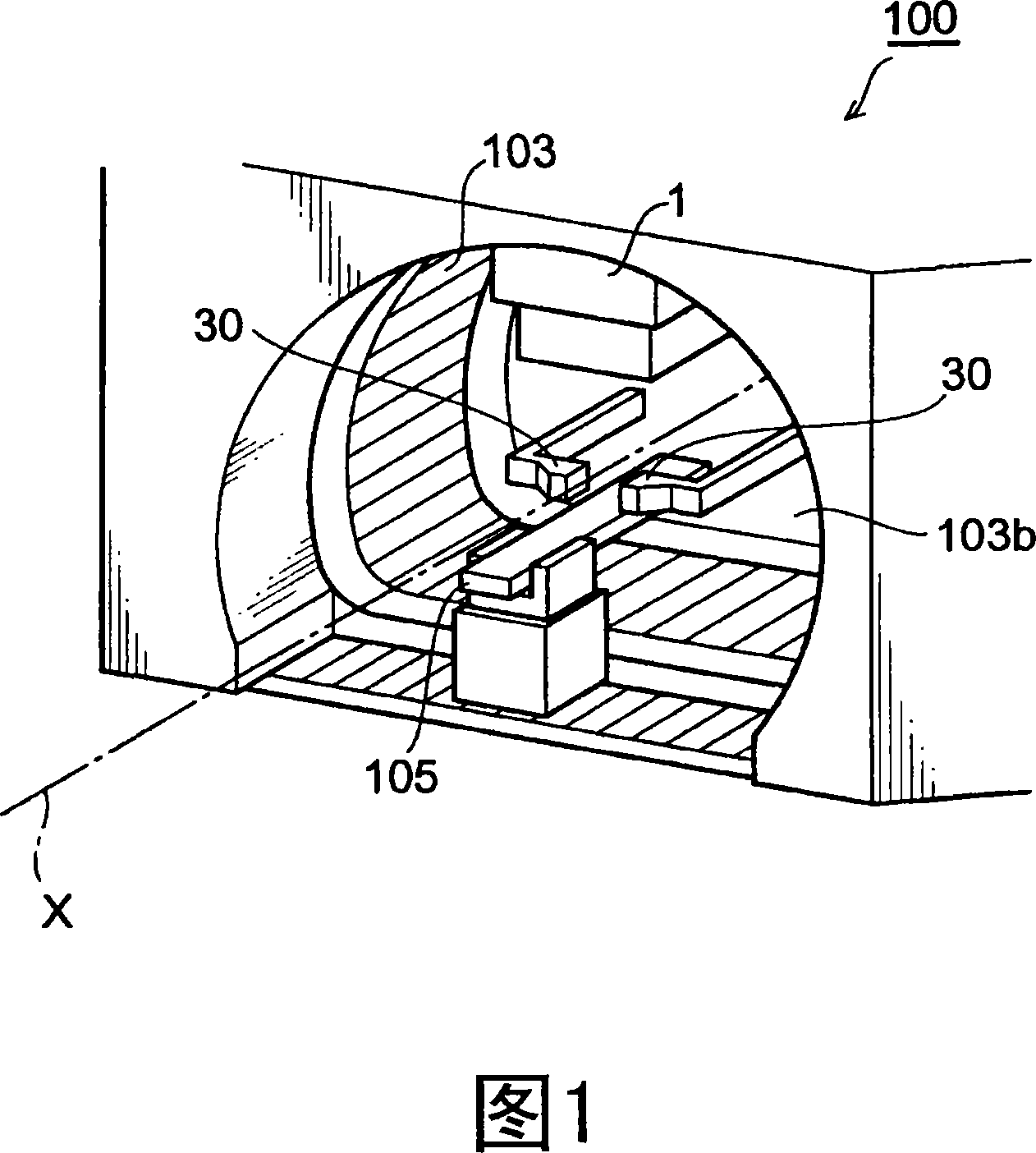

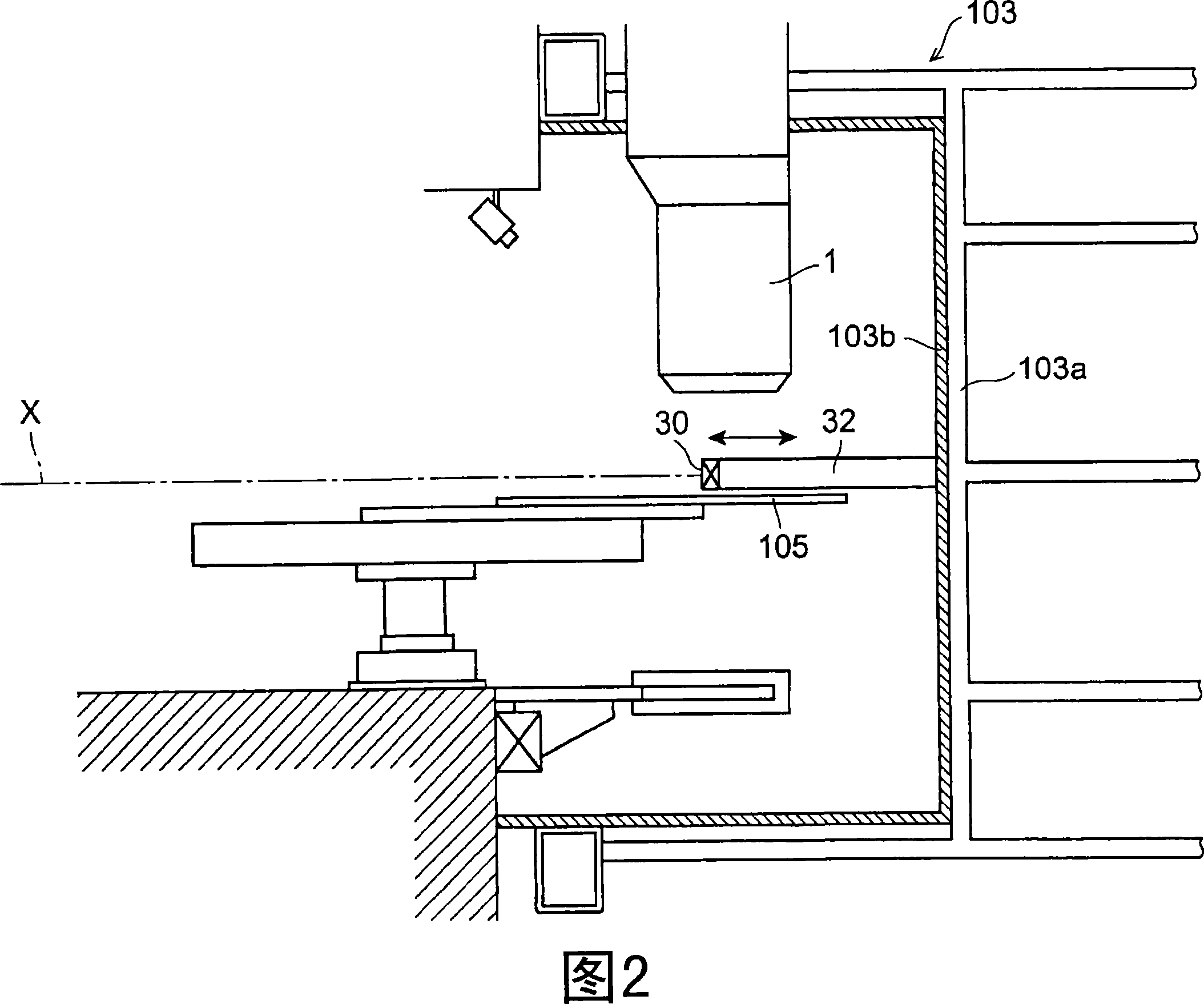

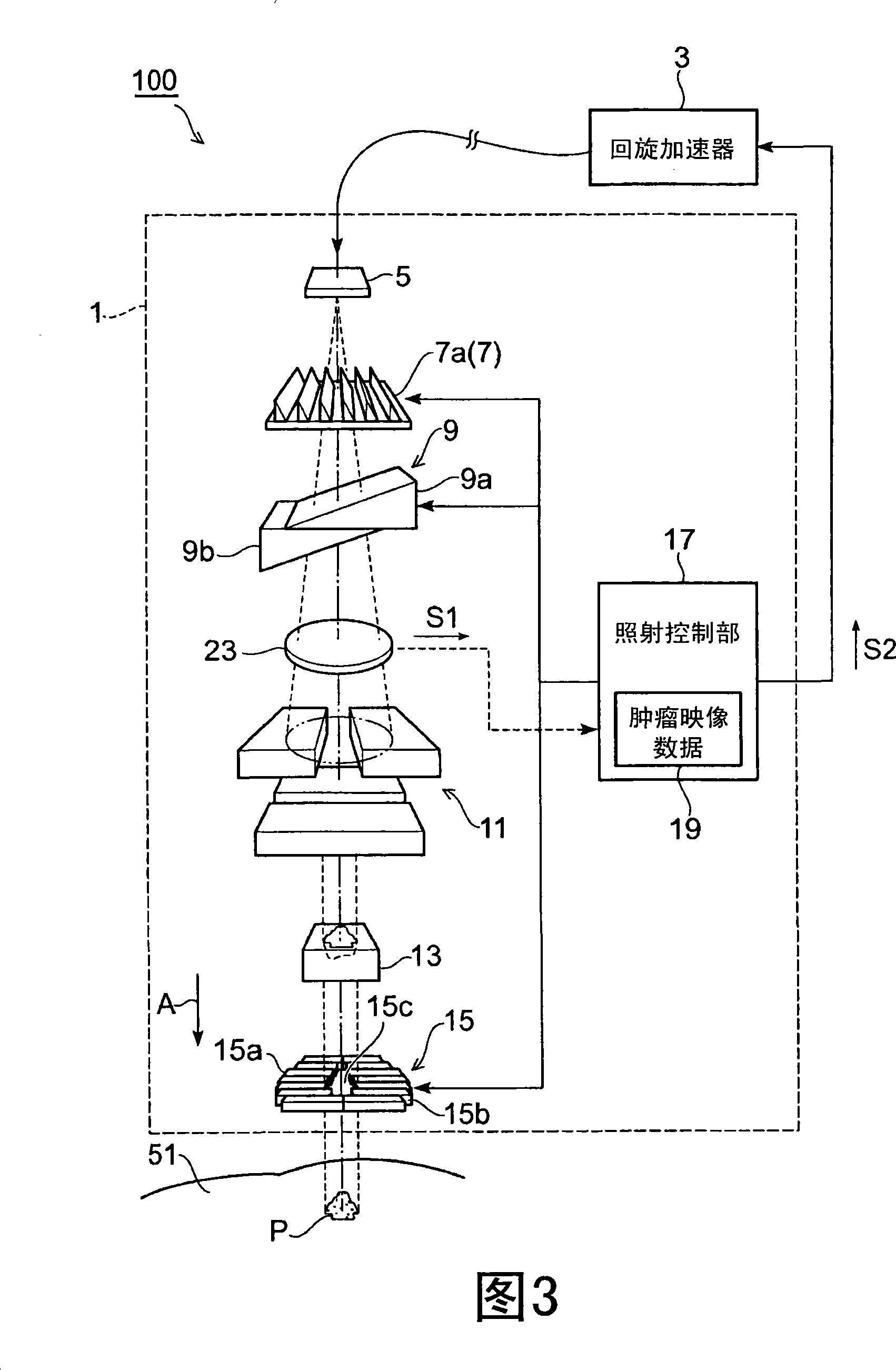

Charged particles ray irradiation device

The invention provides a charged particle ray irradiation unit for confirming the irradiation position of desired site. An irradiation room (103) comprises a charged particle ray irradiation part (1) rotating around the irradiated object (51), a detection part (30) for detecting the silent gamma ray generated by the irradiated object (51) which can move along the extending direction of the pivot point X of the charged particle ray irradiation part (1). Thus, the detection part moves along the direction of the X axle to prevent the detection part (30) interfering the rotation of the charged particle ray irradiation part (1). Moreover, when the irradiated object moves into and out the irradiation room (103), the detection part (30) is out of the way. And, the position confirmation of the desired site can be performed. The detection part (30) moves upwards along the direction of axle X and cooperates with the size of the irradiation object, thus the detection range of the detection part (30) can be enlarged.

Owner:PRESIDENT OF NAT CANCER CENT +1

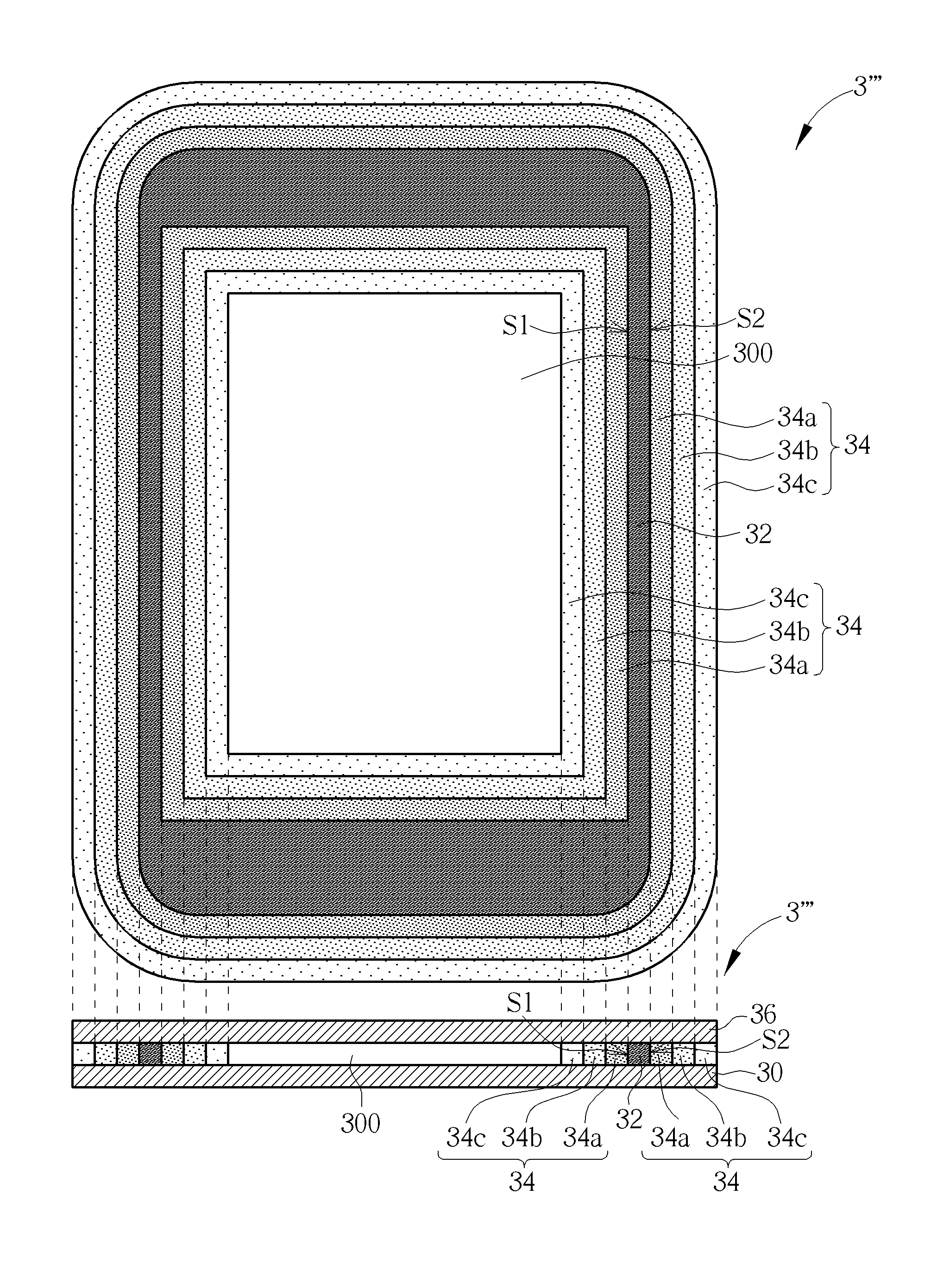

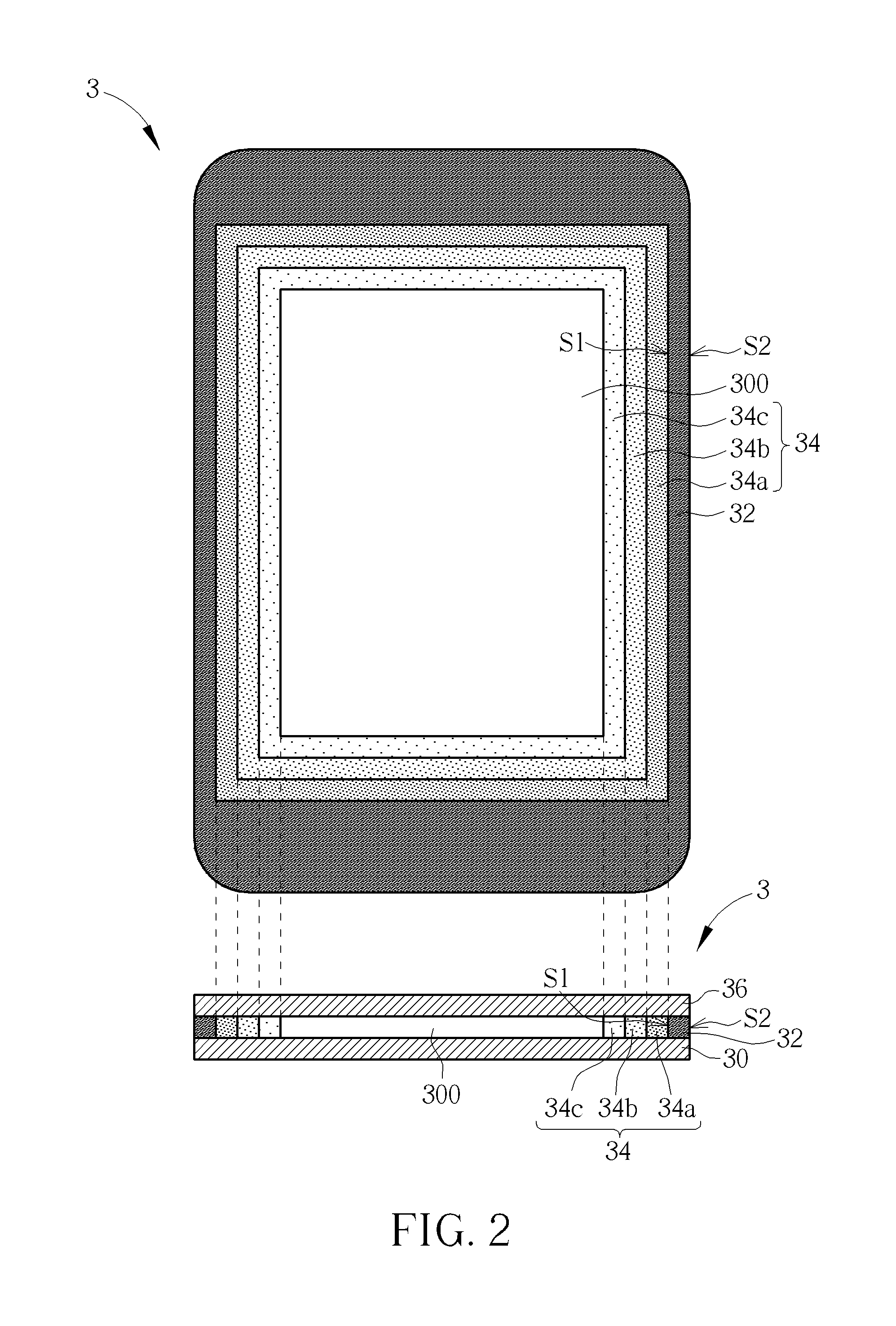

Display device

A display device includes a substrate, a light shielding layer, at least one fading pattern and a display module. The display module is disposed on the substrate and has a display area. The light shielding layer is disposed on a periphery of the substrate and has a first side and a second side, wherein the first side is opposite to the second side. The at least one fading pattern is disposed on the substrate, is adjacent to at least one side of the first side and the second side of the light shielding layer, and does not overlap the display area of the display module. Each fading pattern includes N light transmissible areas, the N light transmissible areas are adjacent to each other, and transmittances of the N light transmissible areas are different from each other, wherein N is a positive integer larger than one.

Owner:AU OPTRONICS CORP

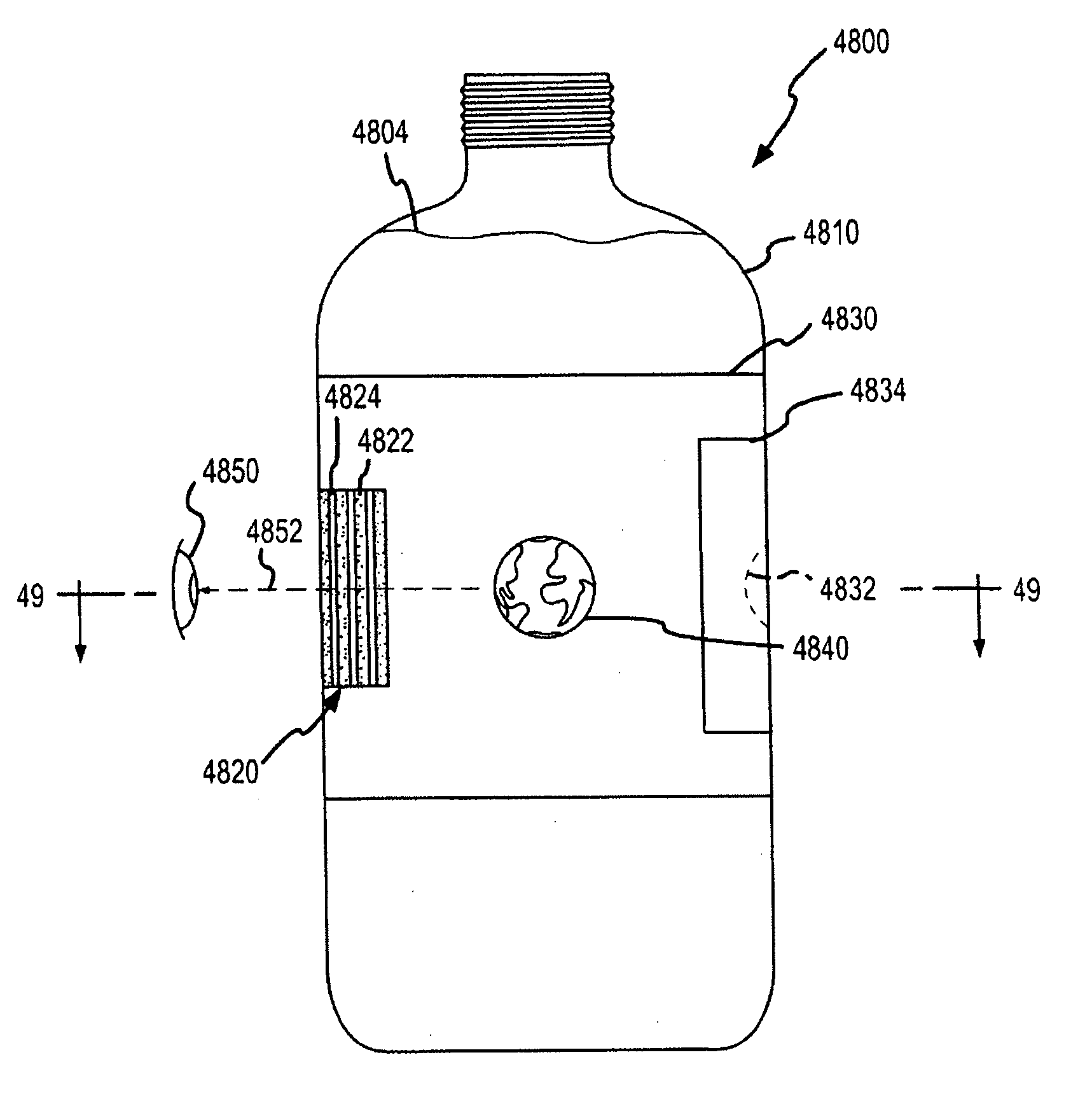

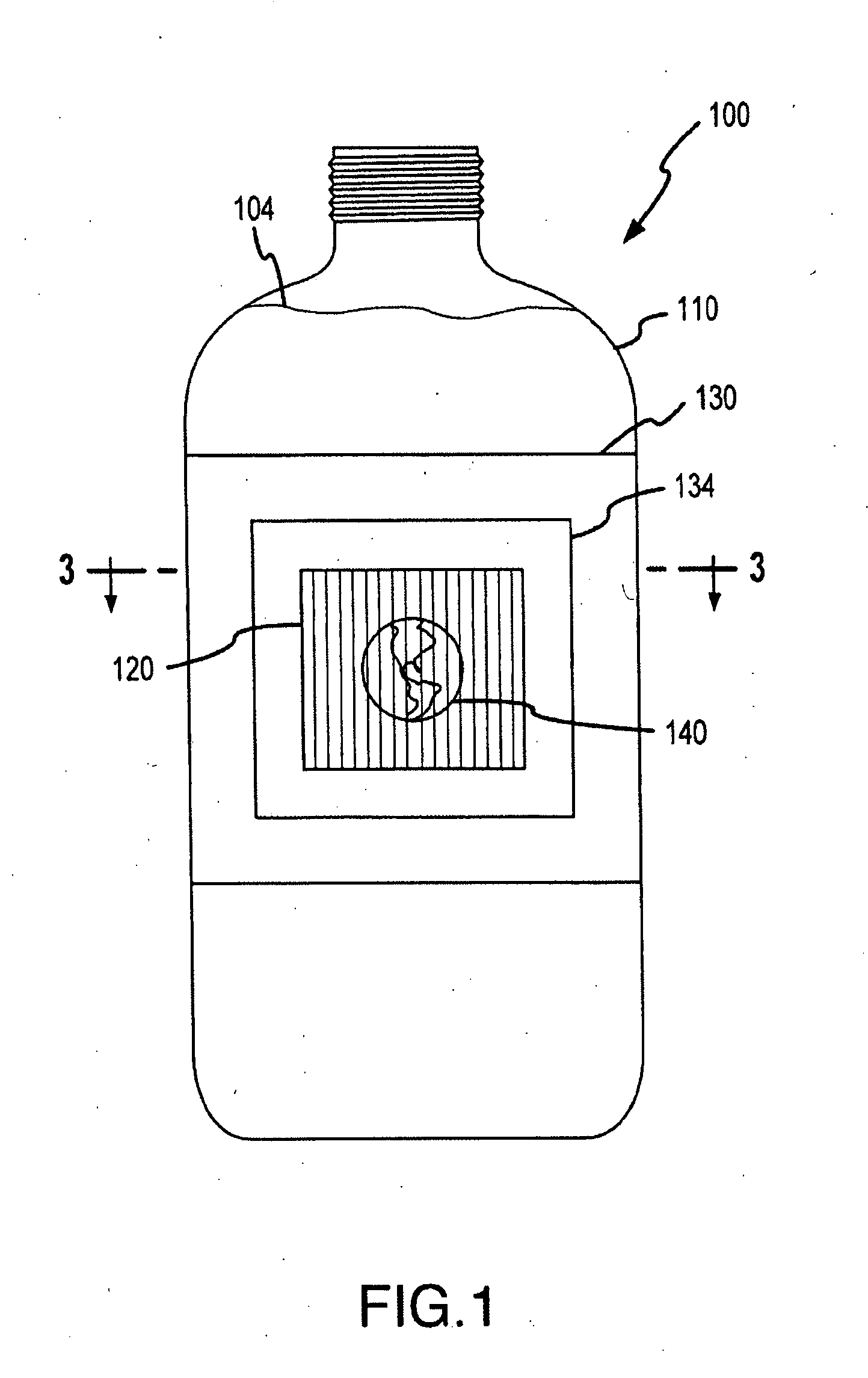

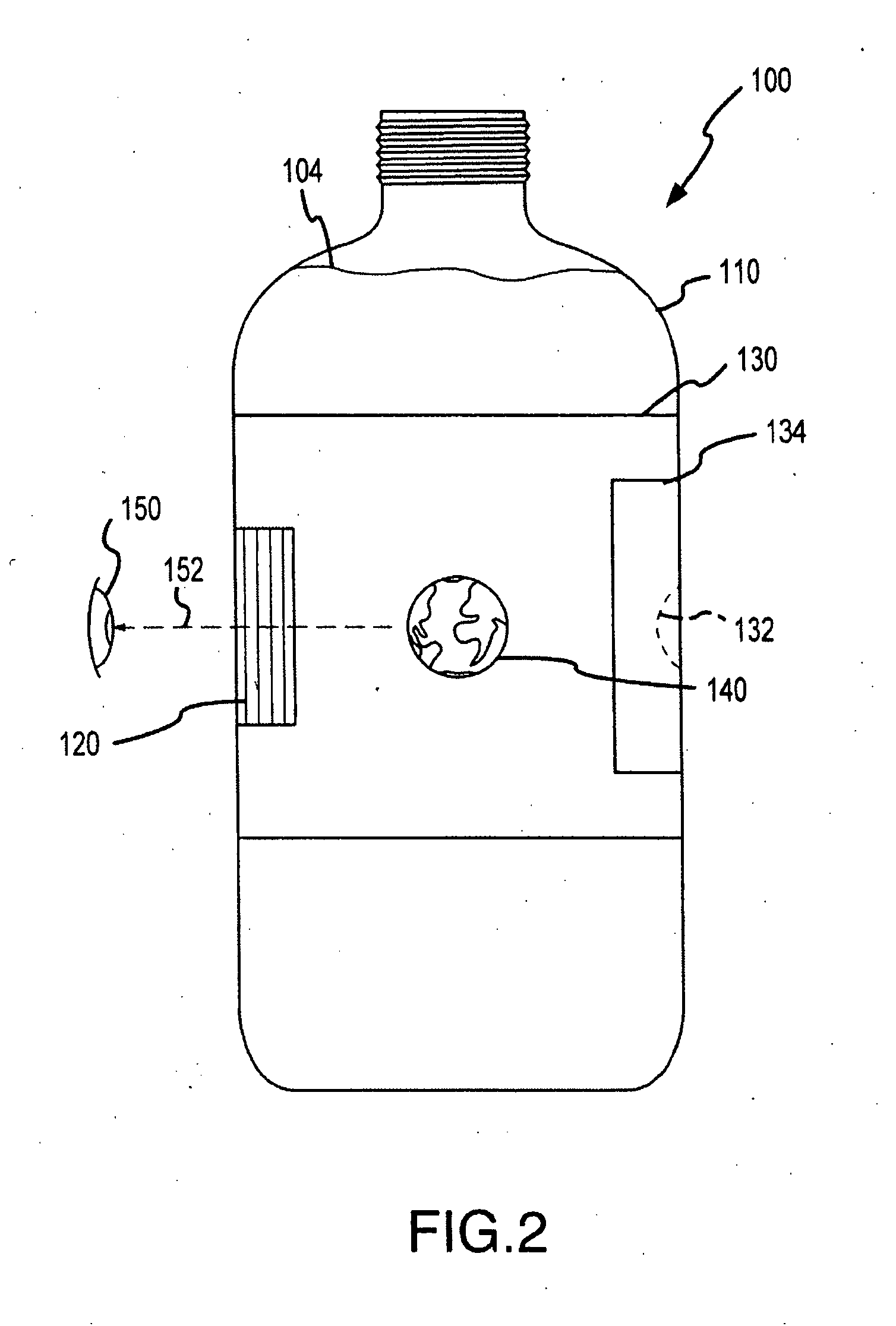

Visual effect apparatus for displaying interlaced images using block out grids

InactiveUS20080019029A1View effectivelyIncrease shelf appealStampsWrappers shrinkageGraphicsEngineering

A container for producing a graphical image. The container includes a container wall with front and rear portions. A label is included that extends about the circumference of the container with an inner surface contacting an exterior surface of the rear portion of the container wall and contacting an exterior surface of the front portion of the container wall. The label includes a block out grid made up of alternating block out lines and transparent viewing gaps on the outer or inner surface of the label. The view gaps provide a line of sight to subset of the segments of an interlaced image provided on or proximate to the rear portion of the container wall when the block out grid is positioned near the front portion of the container wall. The label may be used to create an air gap between the block out grid and the interlaced image.

Owner:GENIE LENS TECH

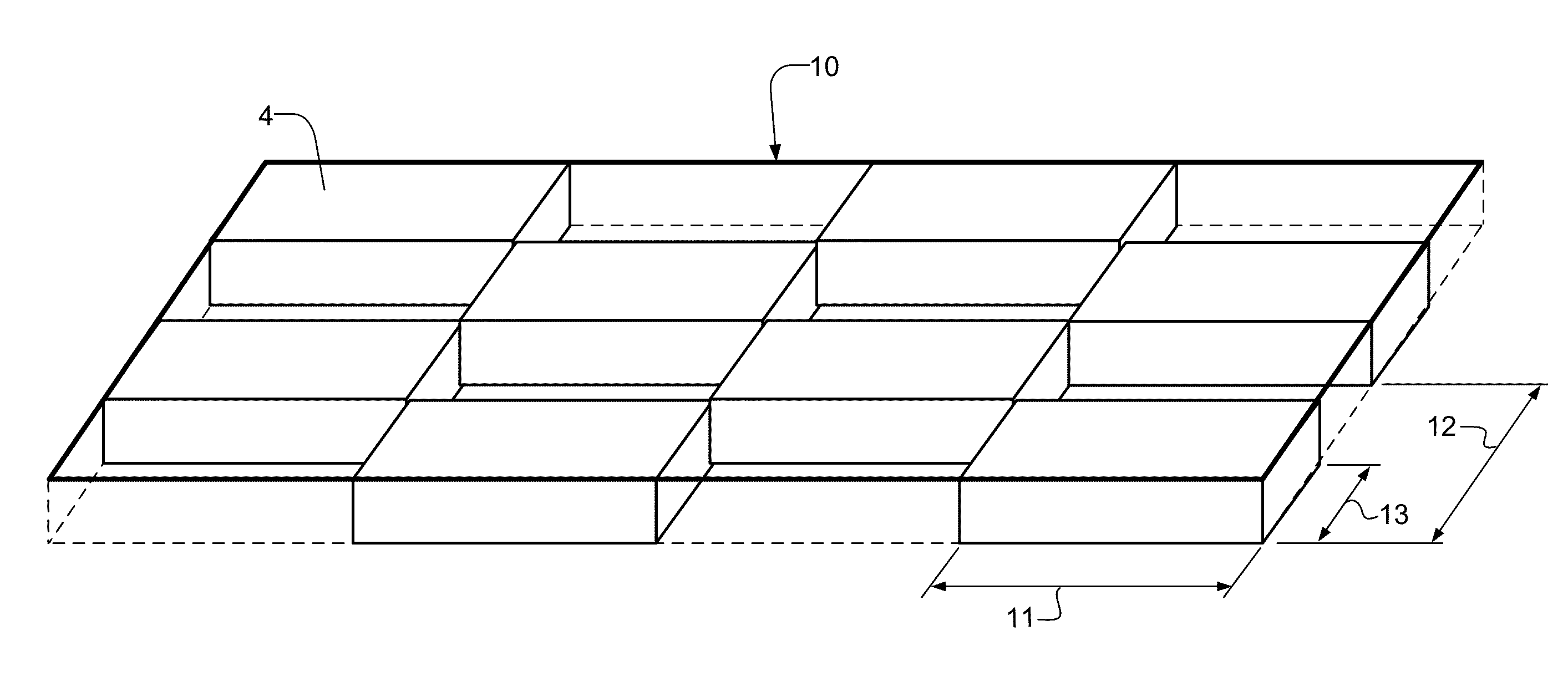

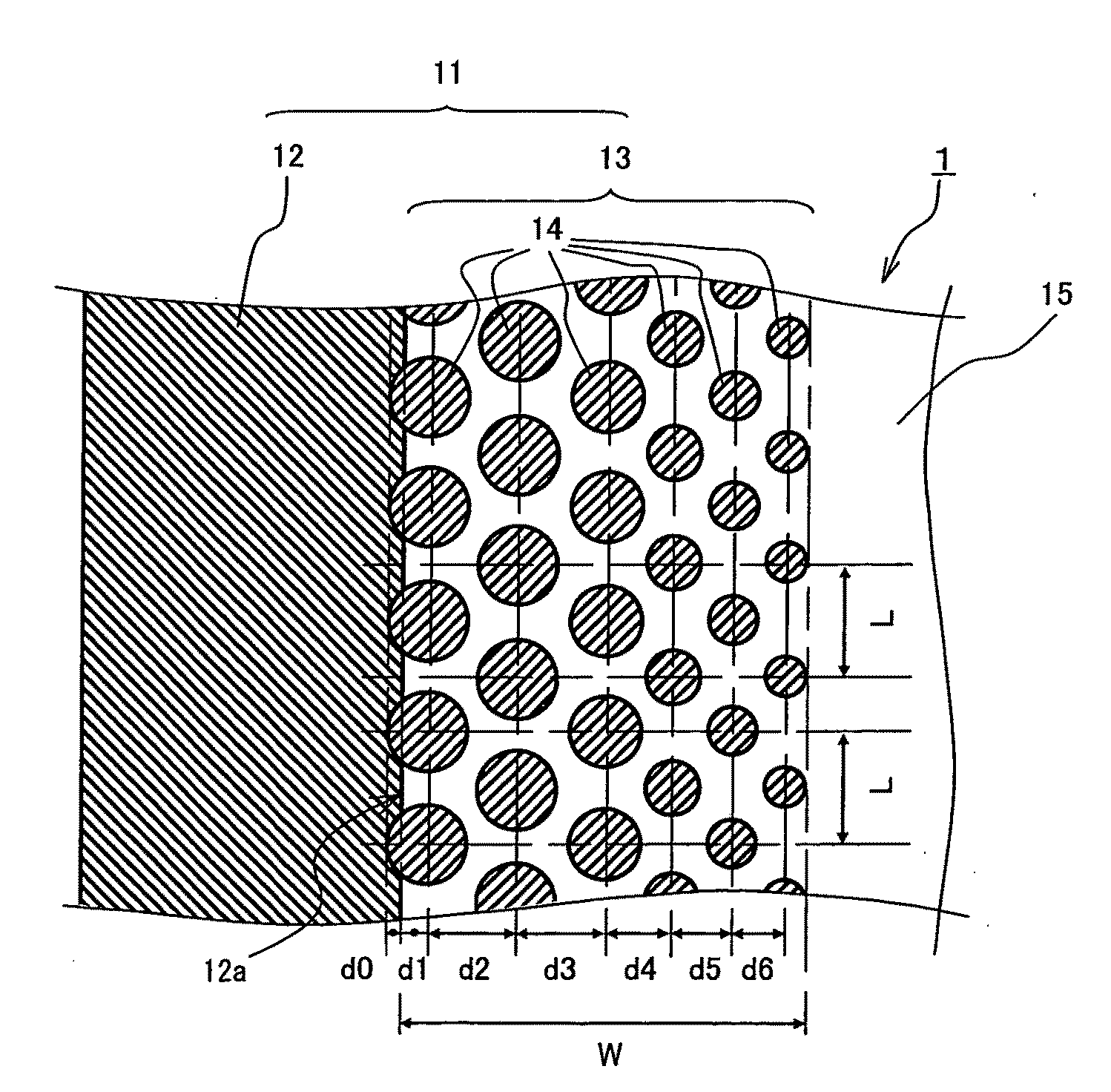

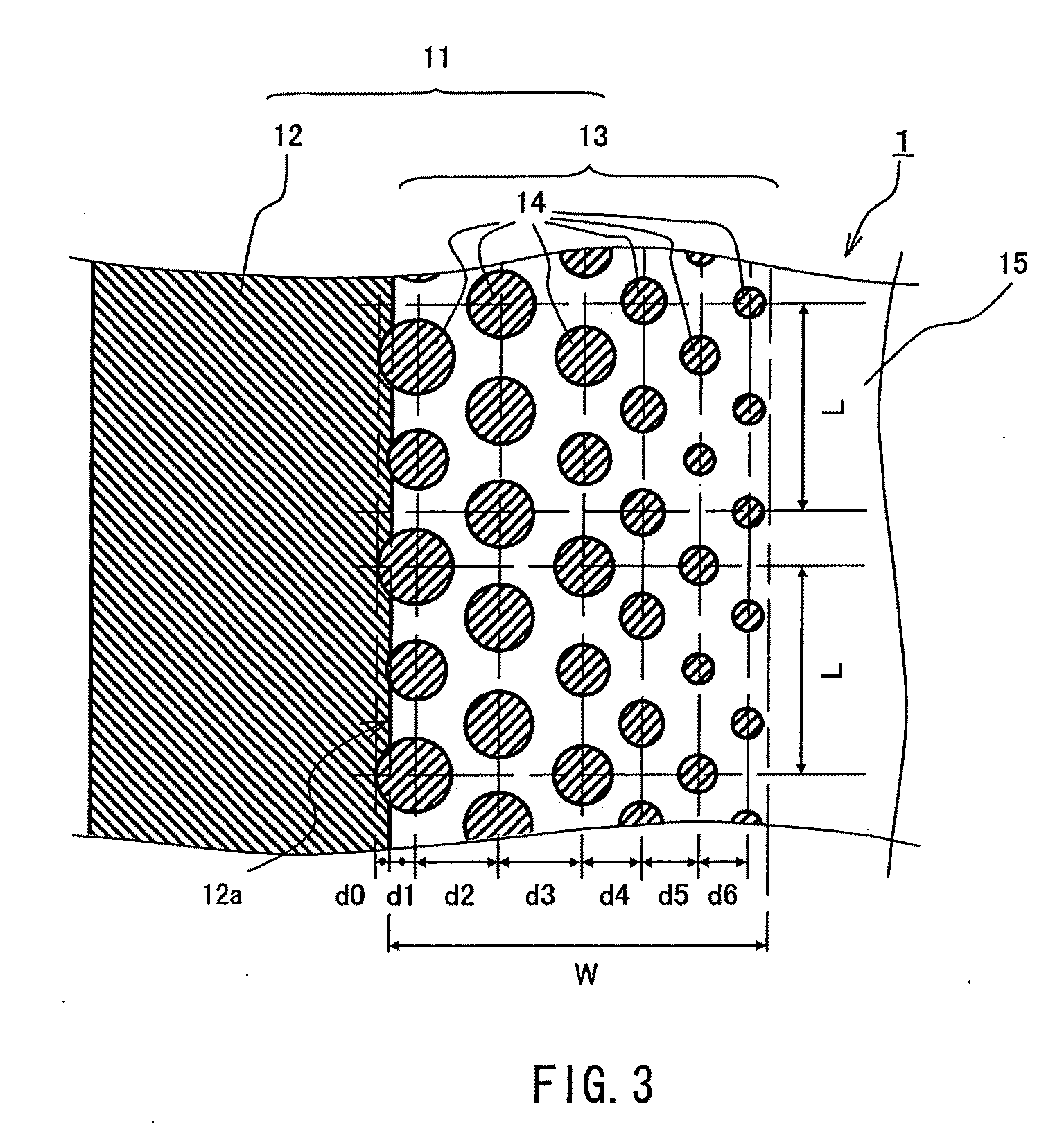

Bent Glass Sheet With Light-Shielding Film for Vehicles

InactiveUS20090257141A1Improve visibilityEase distortionWindowsAntiglare equipmentBand shapeGlass sheet

A bent glass sheet (1) with a light-shielding film for vehicles includes a glass sheet, and a light-shielding film formed in at least a part, i.e. a film-formed portion (11), of a peripheral portion of one surface of the glass sheet. The light-shielding film is composed of a band-shaped film (12) and a dot-patterned film (13). The band-shaped film is arranged in an outer part of the peripheral portion. The dot-patterned film composed of a plurality of dots (14) is arranged in an inner part with reference to the band-shaped film. The plurality of dots are positioned so that a distribution of the dot shielding ratios decreases from the edge of the band-shaped film toward a side of a glass surface (a non-film-formed portion (15)) on which the band-shaped film is not formed, where the dot shielding ratios are values of peaks of mountains formed of a distribution of the dot-width shielding ratios, or dot-diameter shielding ratios. A region in which the dot shielding ratio is at least 50% extends up to at least 4 mm from the edge of the band-shaped film.

Owner:NIPPON SHEET GLASS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com