Angular selective light control sheeting and method of making the same

a technology of selective light control and angular structure, applied in the direction of photomechanical treatment, instruments, screening processes, etc., can solve the problems of difficult and/or expensive manufacturing at an industrial scale, certain disadvantages of conventional light control films, etc., and achieve the effect of enhancing the structural characteristics of the formed structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Referring more specifically to the drawings, for illustrative purposes, the present invention is embodied in the apparatus and method generally shown in the preceding figures. It will be appreciated that the apparatus and method may vary as to configuration and as to details of the parts and / or steps without departing from the basic concepts as disclosed herein. Furthermore, elements represented in one embodiment as taught herein are applicable without limitation to other embodiments taught herein, and in combination with those embodiments and what is known in the art.

[0026]The present invention particularly seeks to provide angularly selective sheet-form light control materials capable of providing variable transmissivity depending on the angle of incidence and particularly providing high levels of opacity at high incidence angles (generally above about 40 degrees or so).

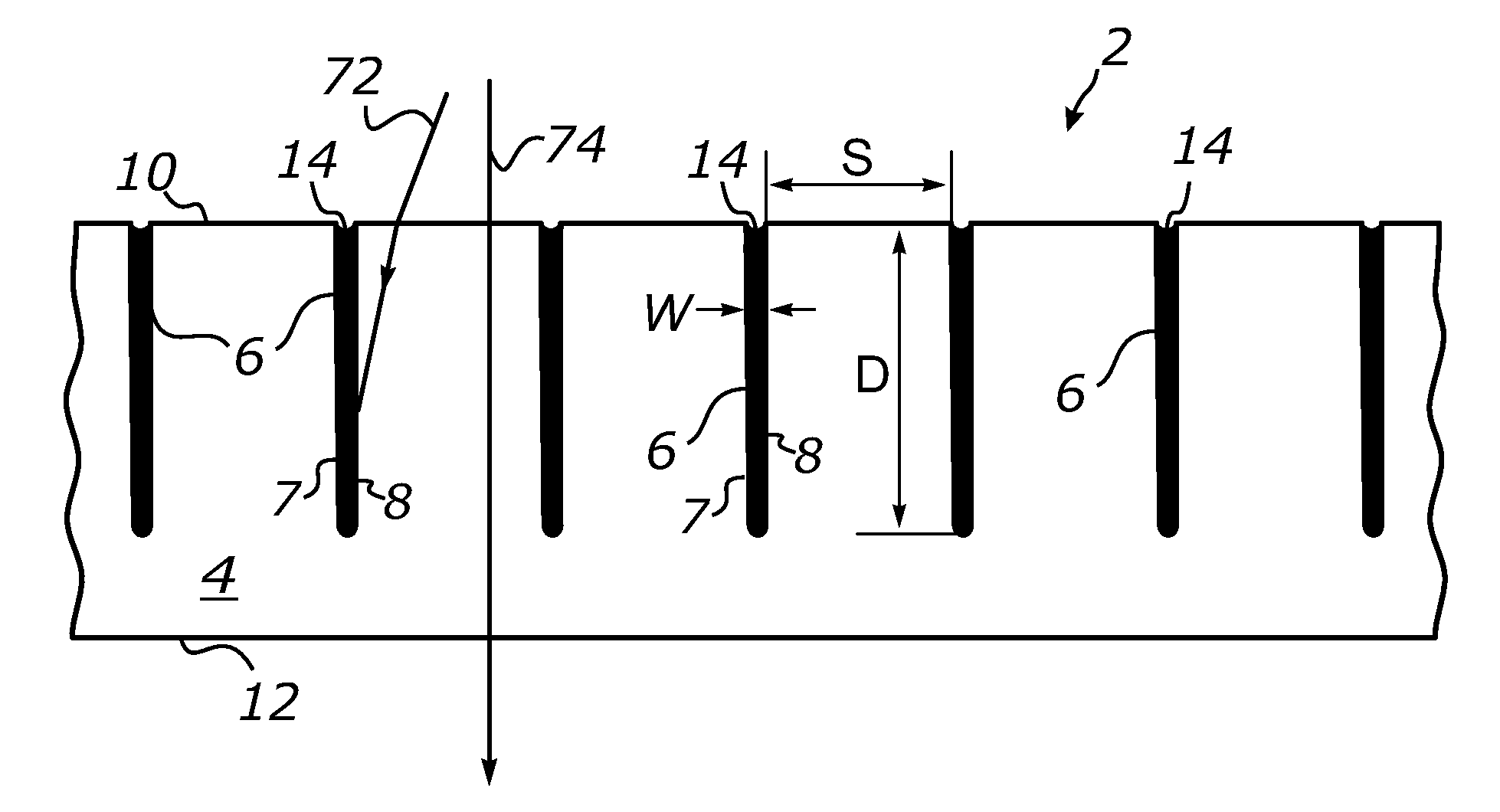

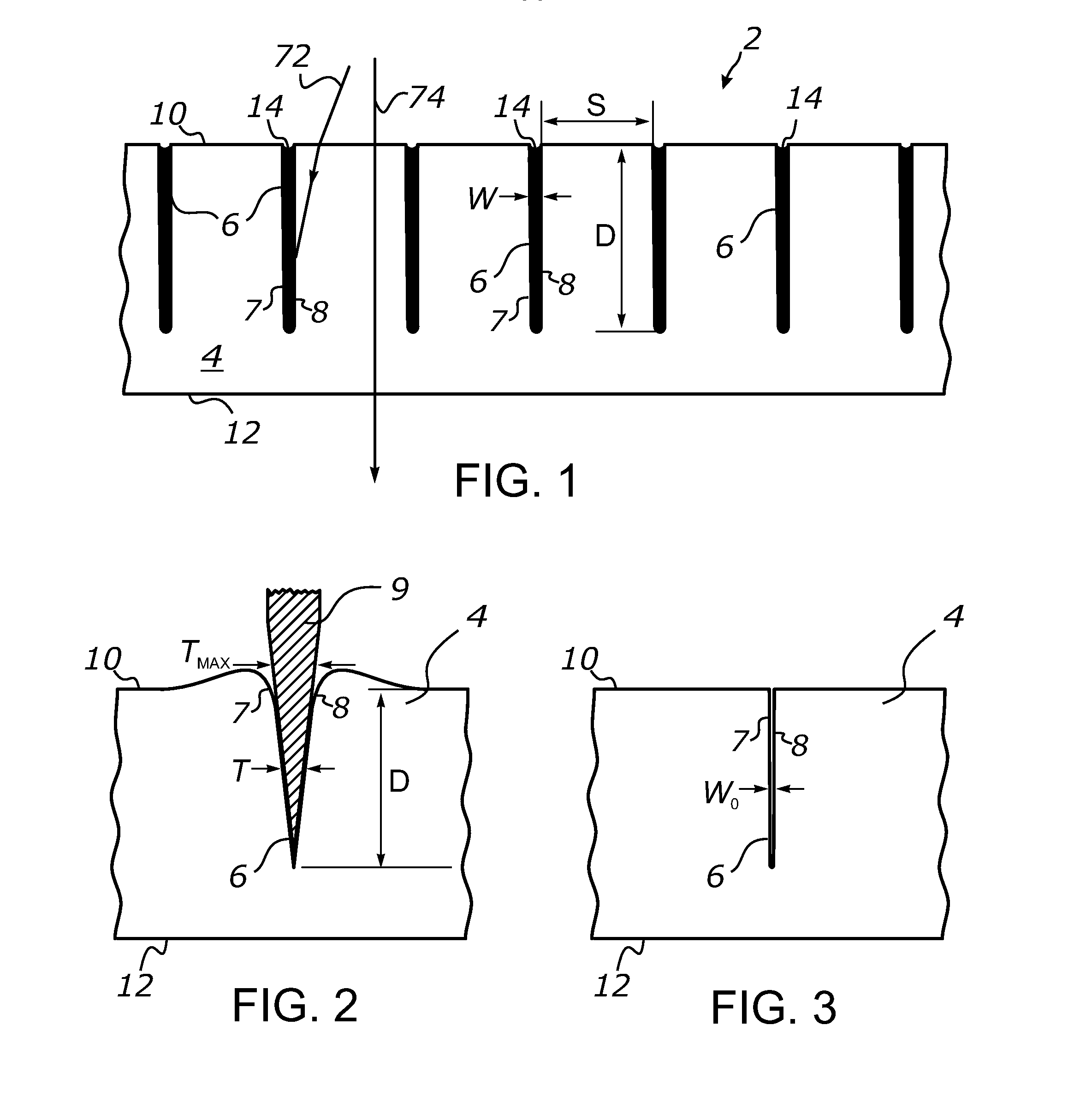

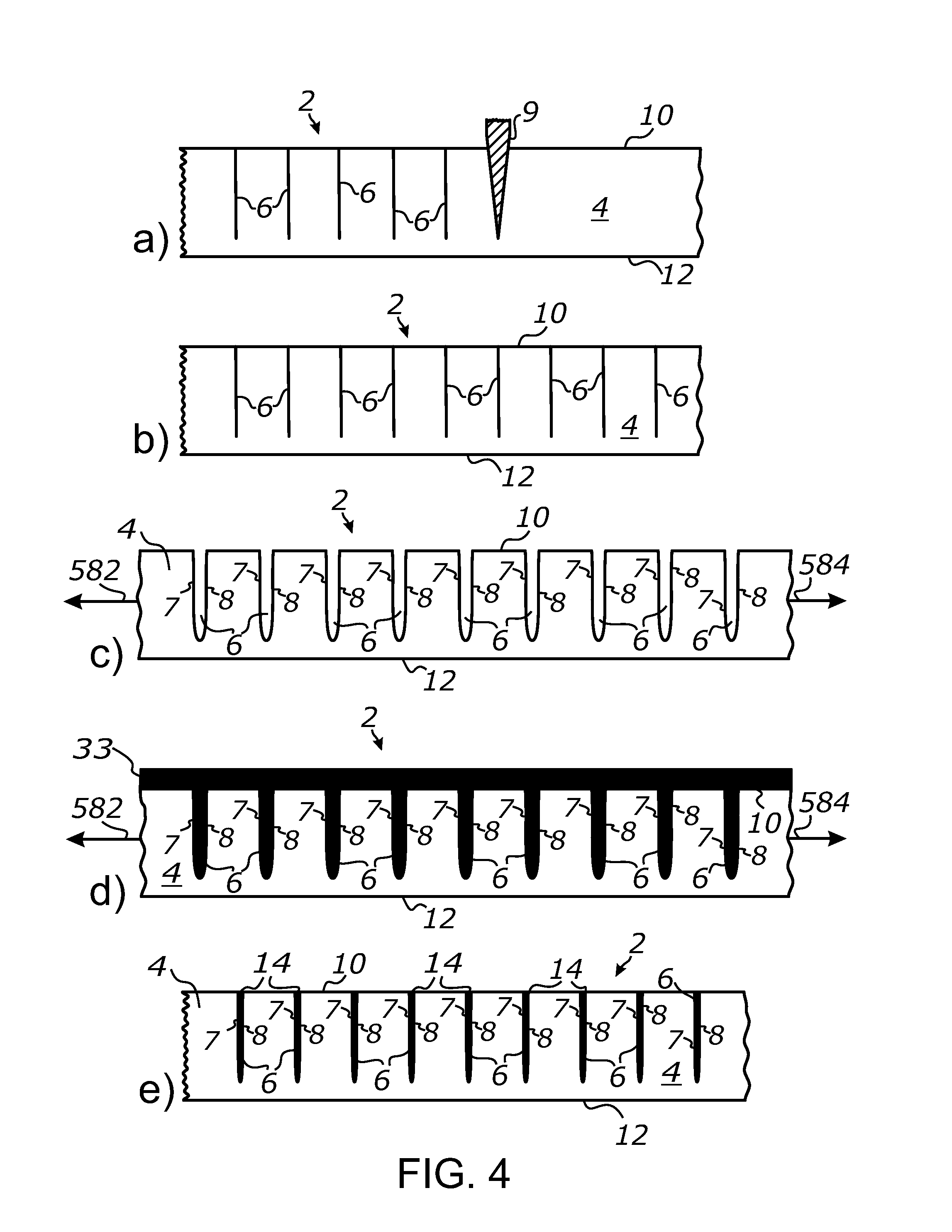

[0027]The following embodiments of the present invention are generally directed to a sheet-form optical ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at yield | aaaaa | aaaaa |

| elongation at yield | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com