Clamping device for intermittently feeding films

A clamping device and feeding technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problem of difficulty in achieving pressure uniformity between upper and lower platens, difficulty in ensuring the stability of clamping force, and difficulty in cylinder movement accuracy. Guarantee and other issues, to achieve the effect of high quality film products, convenient debugging and smooth work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

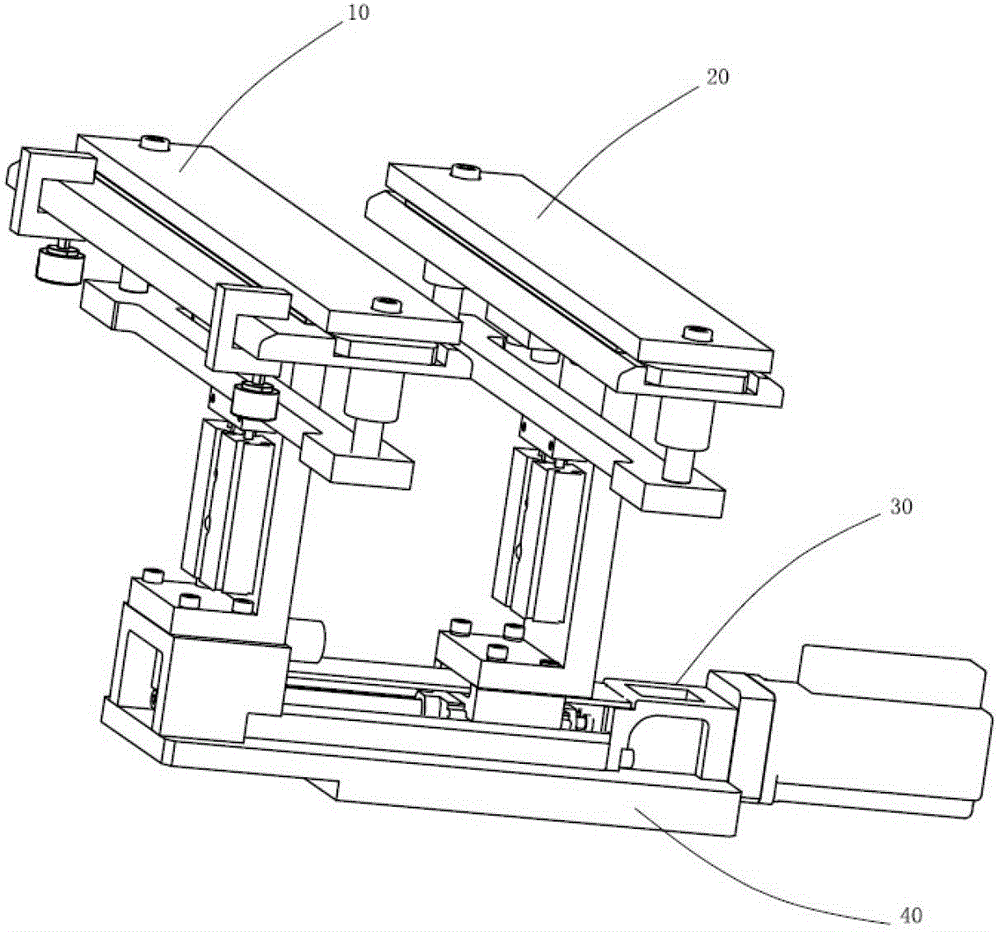

[0036] figure 1 It is a three-dimensional structure diagram of a clamping device for intermittent feeding of flexible films according to the present invention. Such as figure 1 As shown in , the clamping device according to the preferred embodiment of the present invention mainly includes a fixed clamping part 10 , a moving clamping part 20 , a driving assembly 30 and a supporting base 40 . The support base 40 is roughly in the shape of a flat plate, and its function is to serve as the general installation basis for other elements of the clamping device, so that the drive assembly 30 and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com