Automatic keyboard keycap assembling equipment and process

An automatic assembly and key cap technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of gaps between the film and the keyboard, time-consuming and laborious, and inconvenient key cap installation, so as to prevent the protective film from falling off, and the operation is simple and convenient. The effect of improving the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

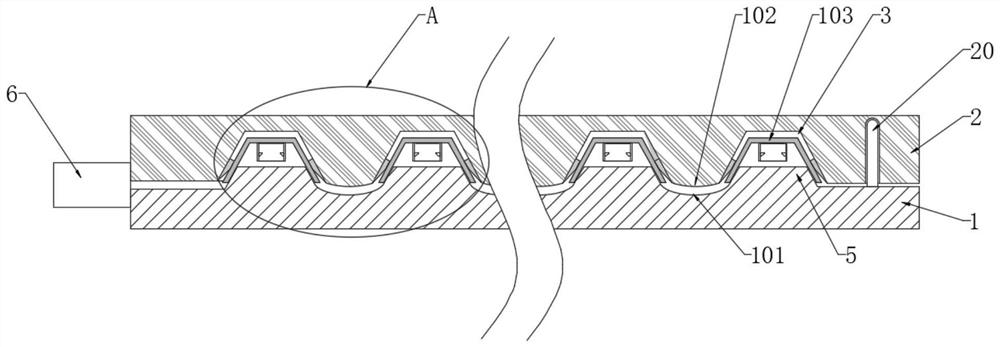

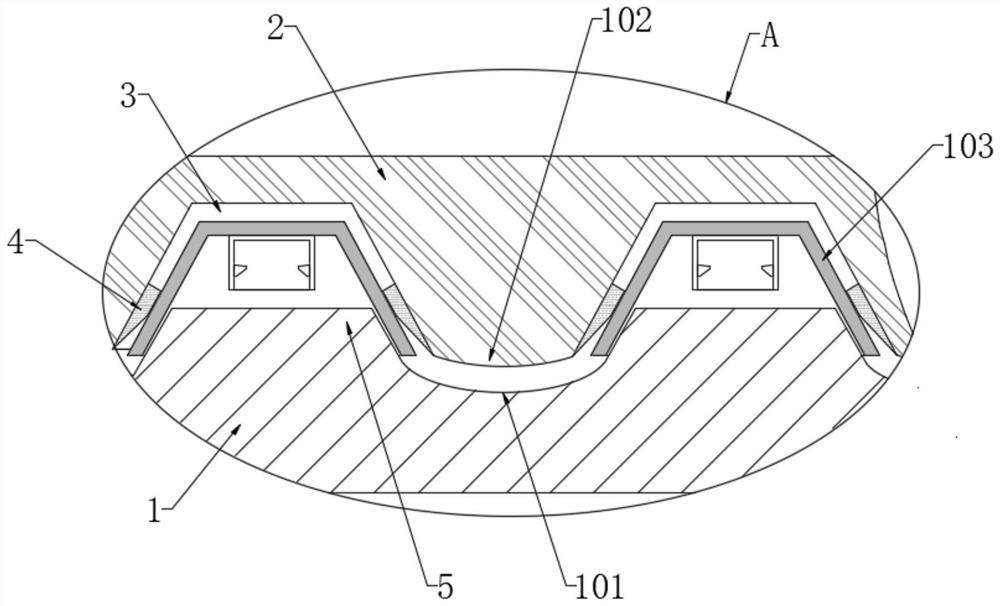

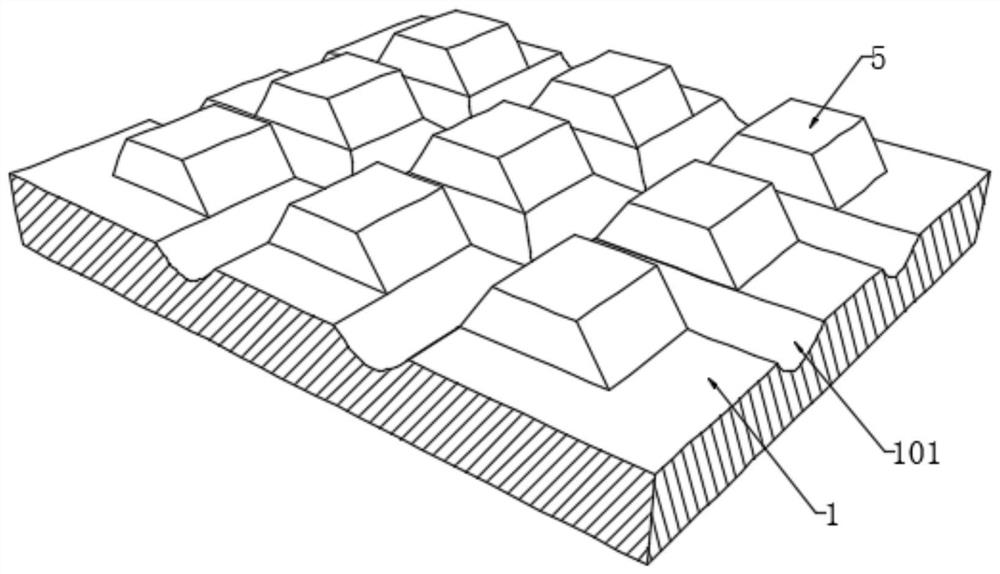

[0057] see Figure 1-6 , keyboard keycap automatic assembly equipment and technology, comprising a lower mold 1, a plurality of keycaps are placed on the lower mold (1), the upper end of the lower mold 1 is fixedly connected with a plurality of fixed blocks 5 matching the keycaps 103, the lower mold 1 Arc-shaped grooves 101 are excavated between the plurality of fixing blocks 5, the upper side of the lower die 1 is provided with an upper die 2, and the lower side wall of the upper die 2 is dug with fixing holes 3 matching the plurality of fixing blocks 5. The lower side wall of the mold 2 is located between a plurality of fixing holes 3 and is fixedly connected with an arc-shaped block 102 that matches the arc-shaped groove 101, and a plurality of keycaps 103 are located between the fixing holes 3 and the arc-shaped groove 101. The lower mold 1 The upper side wall is fixedly connected with 20 on the right side of a plurality of fixed blocks 5, and the lower side wall of the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com