Full-automatic sheet screen printing machine

A fully automatic screen printing machine technology, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve problems such as low printing accuracy, increased equipment costs, and product position changes, so as to avoid defective products, save time, and The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

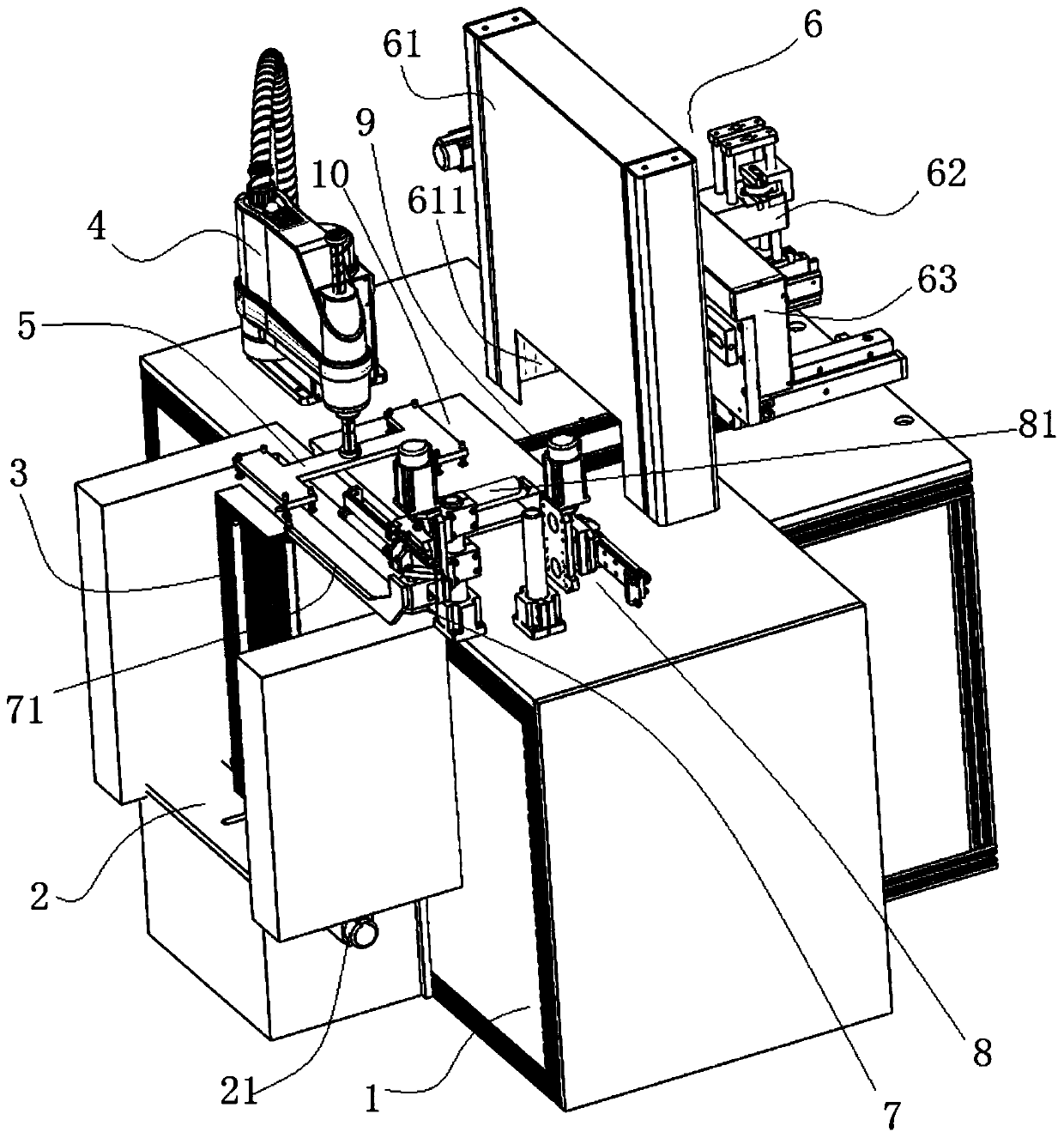

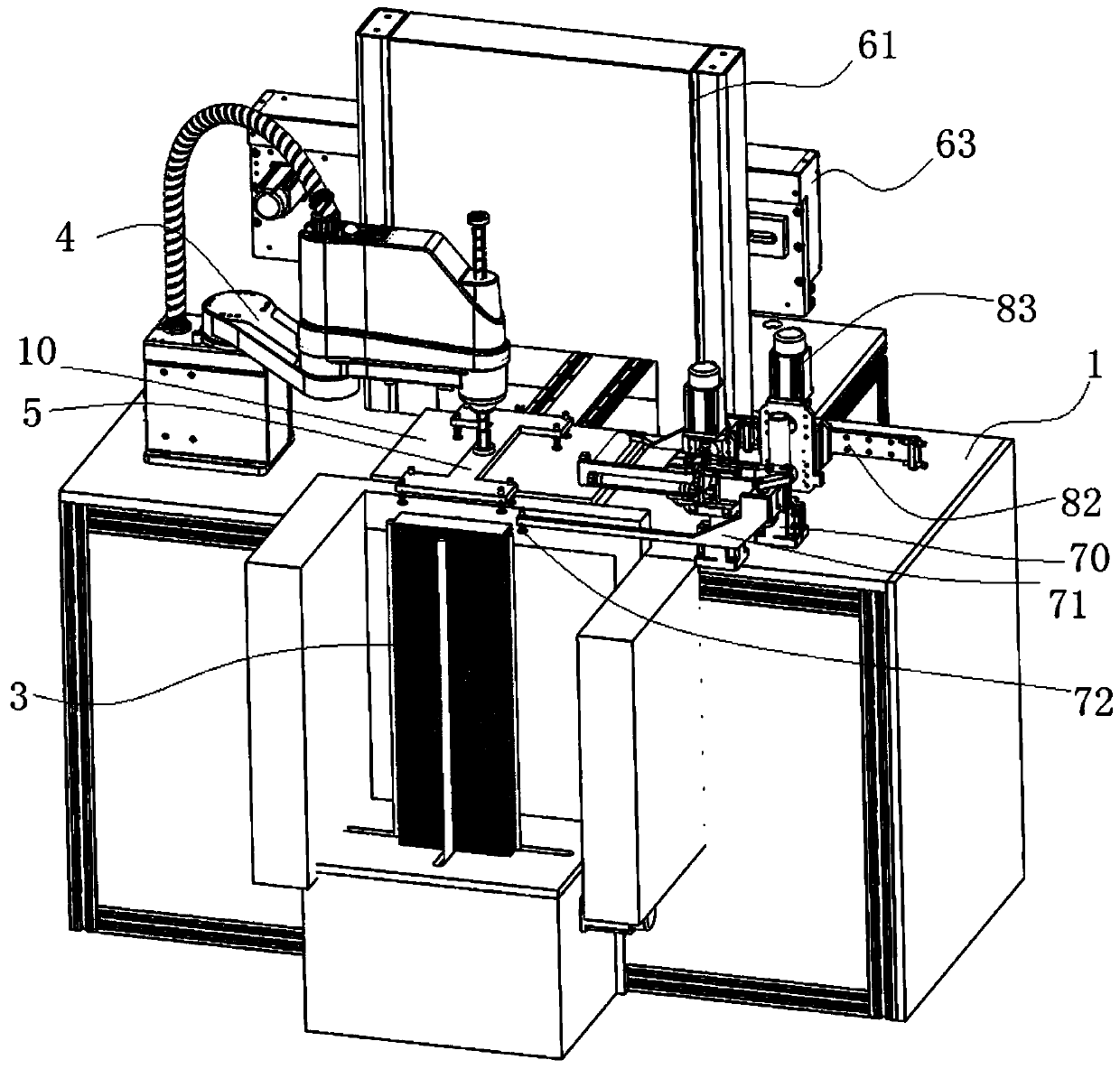

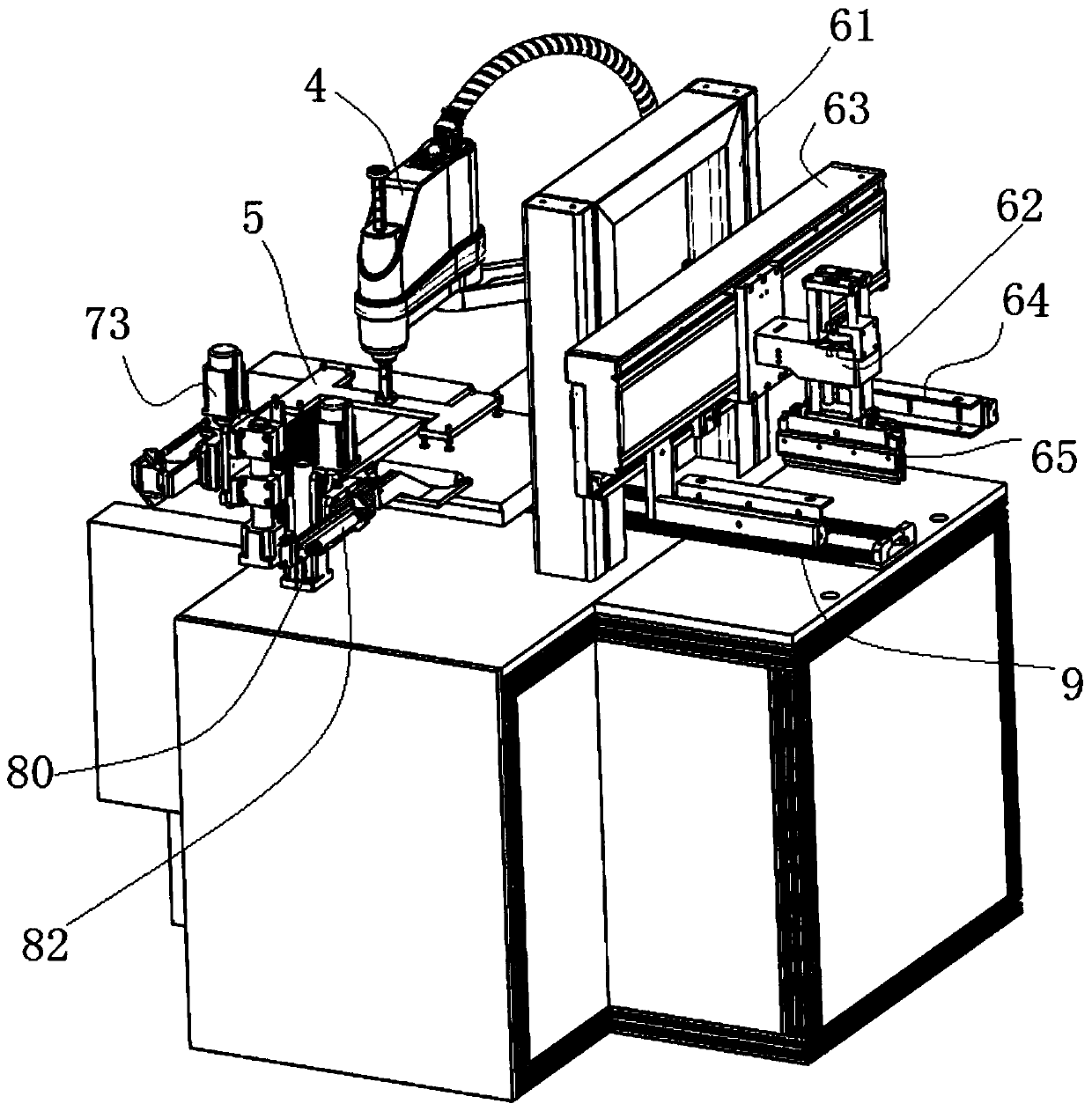

[0023] Embodiment 1 of the present invention: as Figure 1-Figure 6 as shown,

[0024] Fully automatic sheet screen printing machine, including frame 1, automatic feeding device 2 for stacking sheet products, frame 1 is equipped with loading and unloading robot 4, movable substrate platform 10, guide rail 9, and machine head The guide rail frame 61 is a printing head assembly arranged on the head rail frame 61 . The length direction of the guide rail 9 is defined as the left-right direction.

[0025] The automatic feeding device 2 can adopt the structure in the prior art, and its main component is a lifting seat driven by a servo feeding motor 21, which drives the balanced feeding of the whole stack of sheets.

[0026] The output end of the loading and unloading robot 4 is provided with a suction cup 5, the loading and unloading robot 4 is a horizontal multi-joint robot, and the suction cup 5 is vertically fixed on the lower end of the ball screw of the loading and unloading...

Embodiment 2

[0043] The only difference between this embodiment and embodiment 1 is that in this embodiment 2, the film remover is omitted, and it is suitable for printing on sheets without a protective film between two adjacent sheets in the whole stack of sheets. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com