Machining method of sliding block cavity formed through precision cold drawing and guiding rail pair

A forming method and a technology of guide rail pairs, which are applied in the direction of manufacturing tools, heat treatment equipment, quenching agents, etc., can solve the problems of oil fume, mineral oil easily heated, etc., to reduce production costs, improve market competitiveness, and reduce grinding time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

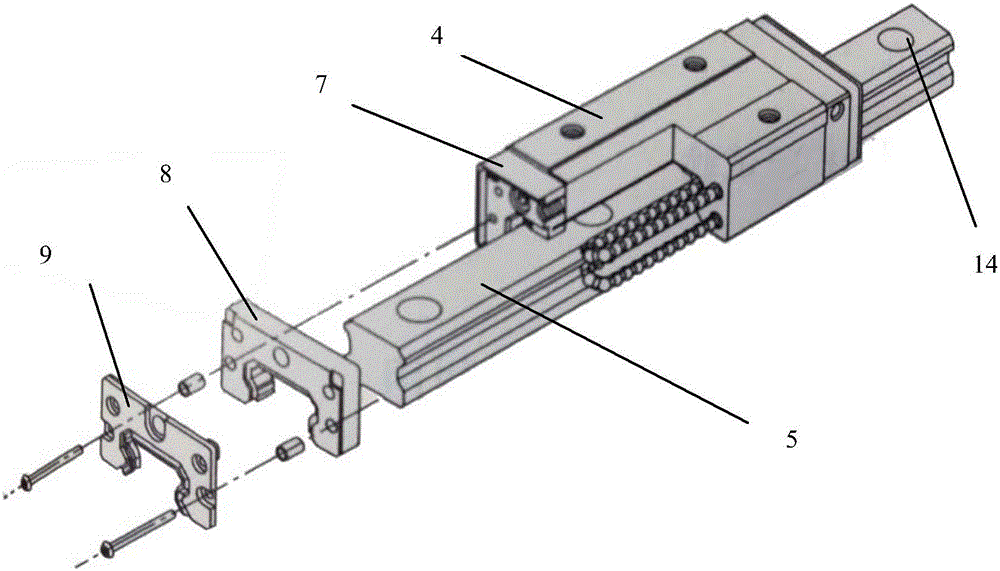

[0086] Such as Figure 3-7 As shown, a slider produced by the above method, the slider 4 and the guide rail 5 form a guide pair, the raceway of the slider is provided with rolling balls, and both ends of the slider are sequentially provided with a ball returner 7, a self-lubricator 8. The end sealing baffle 9. The self-lubricator includes a shell 81 and a high-density fiber net 82, an oil control board 83 and a high-oil fiber net 84 sequentially arranged in the shell, the high-oil fiber net is arranged at the end Seal one side of the baffle. The arrow in the figure shows the direction of lubricant flow 85. A rolling ball 6 is provided on the raceway 10, a ball holder 12 is provided between the rolling balls, a grease bag 13 is provided in the space between the rolling ball and the ball holder, and one end of the telescopic shield 11 is connected to the slider The end is sealed and fixed with the baffle, and the other end is fixed with the end of the guide rail. Grease bags c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com