A kind of surface ultrasonic processing method of tungsten/molybdenum product

A processing method, ultrasonic technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as surface damage and difficulty in obtaining surface effects, and achieve the effects of prolonging the service life, shortening the processing and manufacturing cycle, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below by embodiment the content of the present invention is specified:

[0026] According to the surface ultrasonic processing method of the present invention, the process step of carrying out surface processing to molybdenum rod is as follows:

[0027] (1) Install the molybdenum rod on the lathe, so that the workpiece is in the center of the lathe, and the runout is ≤0.05mm;

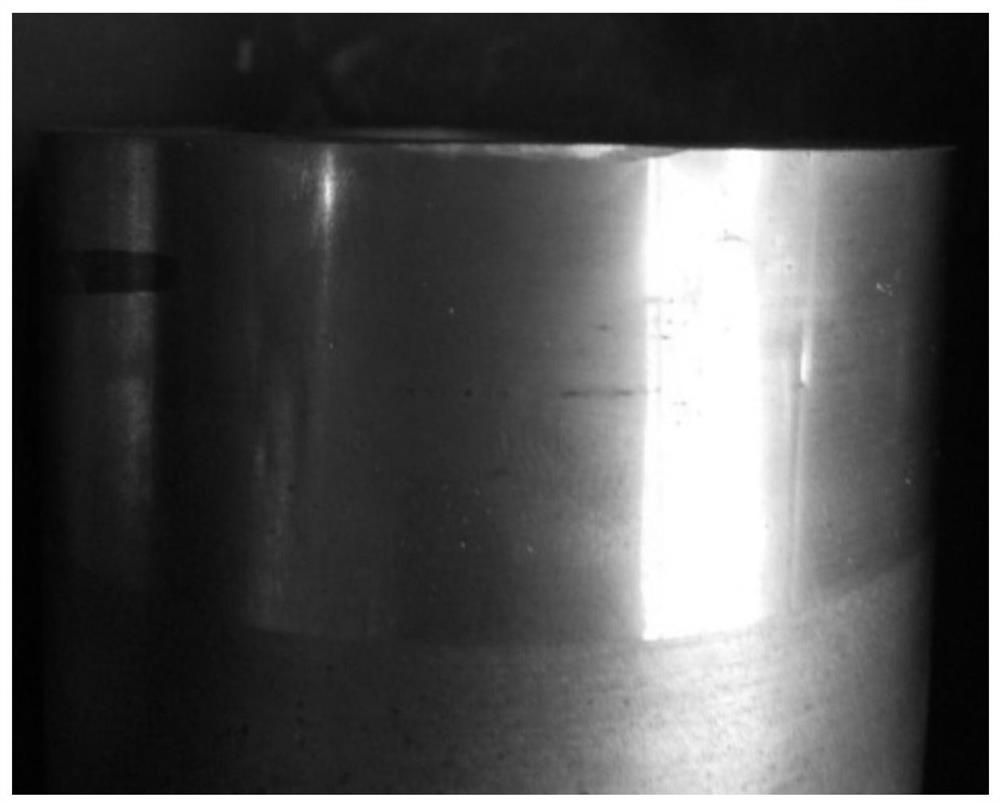

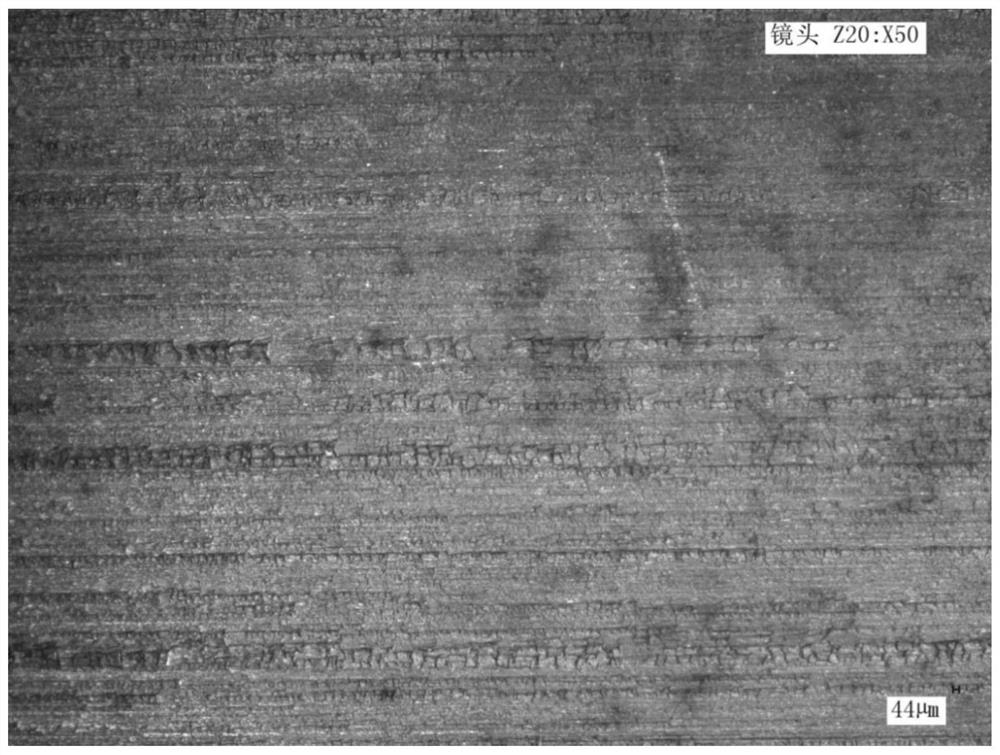

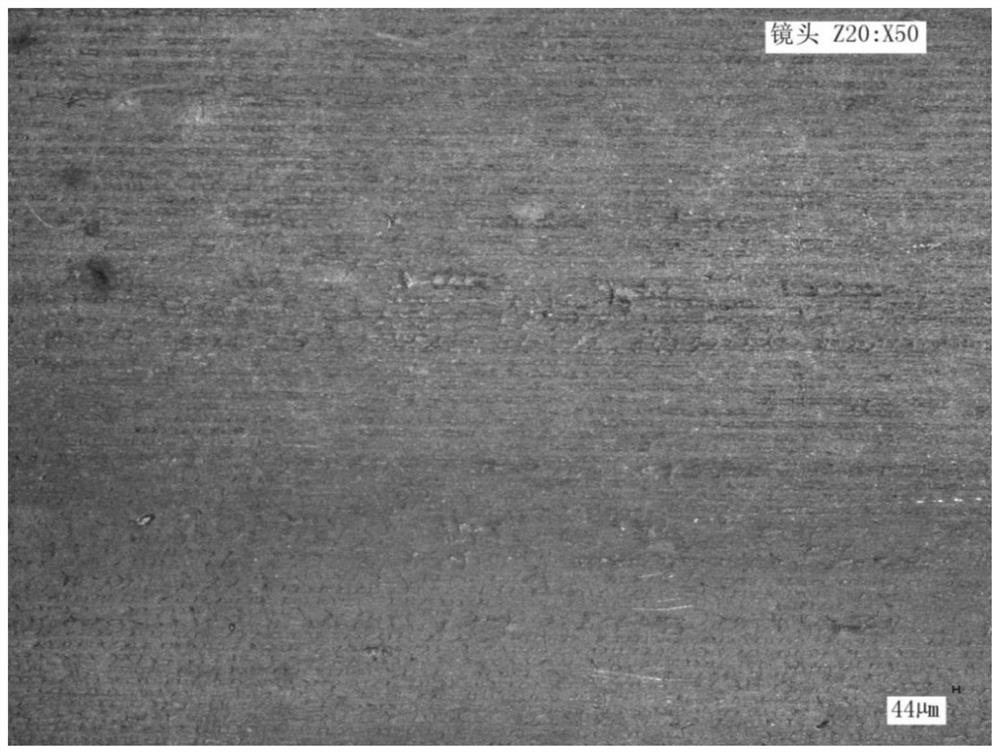

[0028] (2) Adopt suitable tool to produce molybdenum rods with basic dimensions and geometric tolerances and surface roughness up to 3.0-5.0 μm that meet the requirements of the drawings; in this embodiment, it is φ240mm molybdenum rods after turning, with a purity > 99%, the surface roughness is 3.12μm;

[0029] (3) Connect the cable between the ultrasonic cutter and the external ultrasonic generator;

[0030] (4) Adjust cutting parameters: the linear speed of ultrasonic tool processing is adjusted to 71m / min, and the cutting speed (ie feed per revolution) is adjusted to 0.15mm / r;

[0031] (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com