Patents

Literature

83 results about "Basic dimension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a technical drawing, a basic dimension is a theoretically exact dimension, given from a datum to a feature of interest. In Geometric dimensioning and tolerancing, basic dimensions are defined as a numerical value used to describe the theoretically exact size, profile, orientation or location of a feature or datum target.

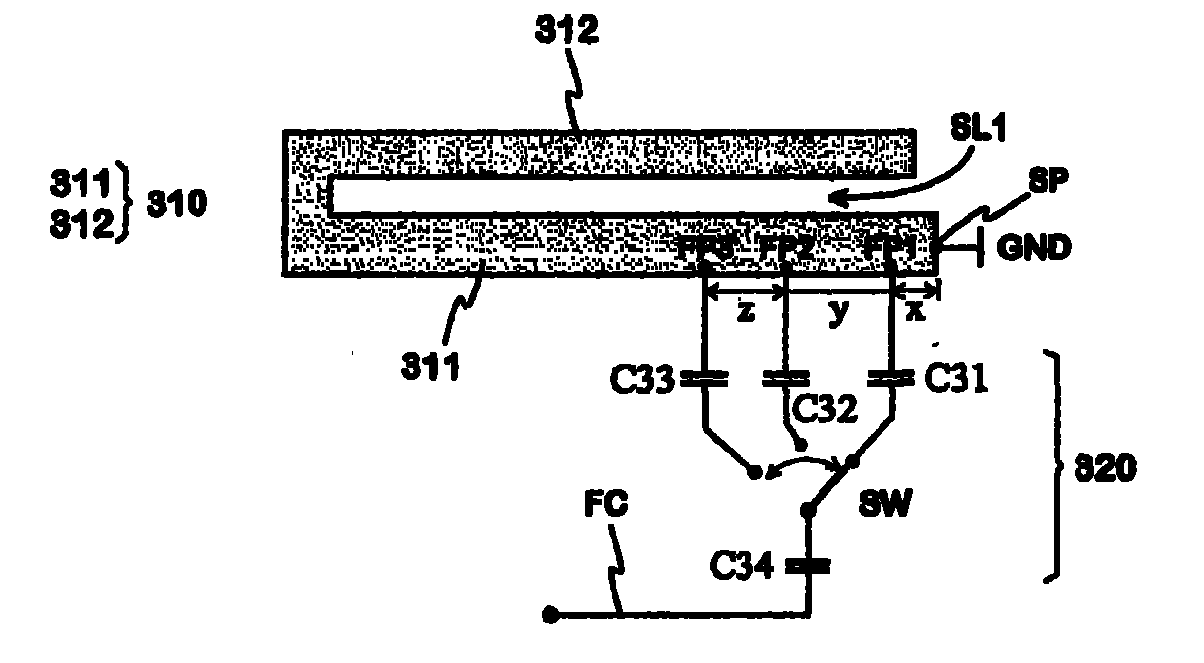

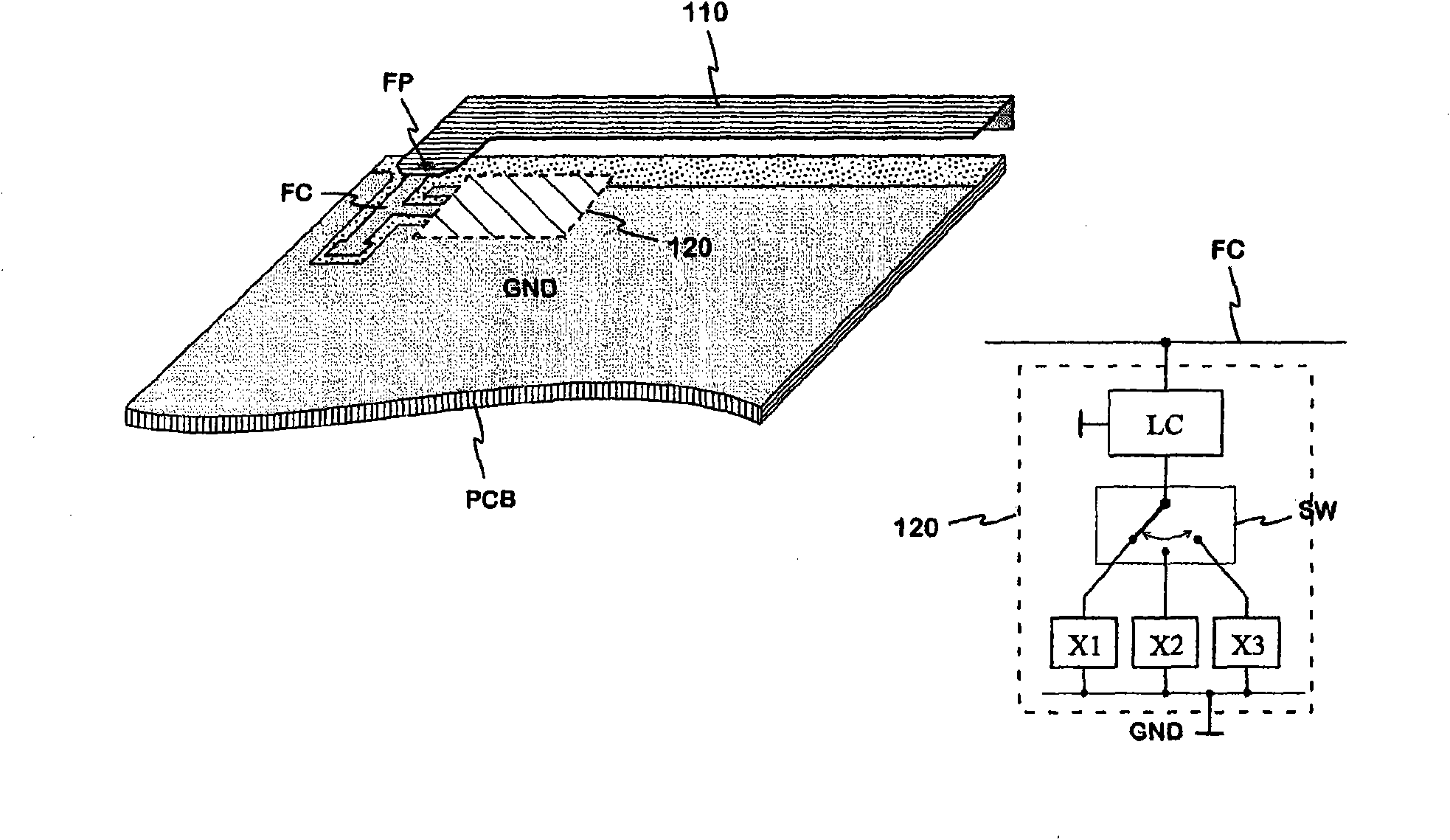

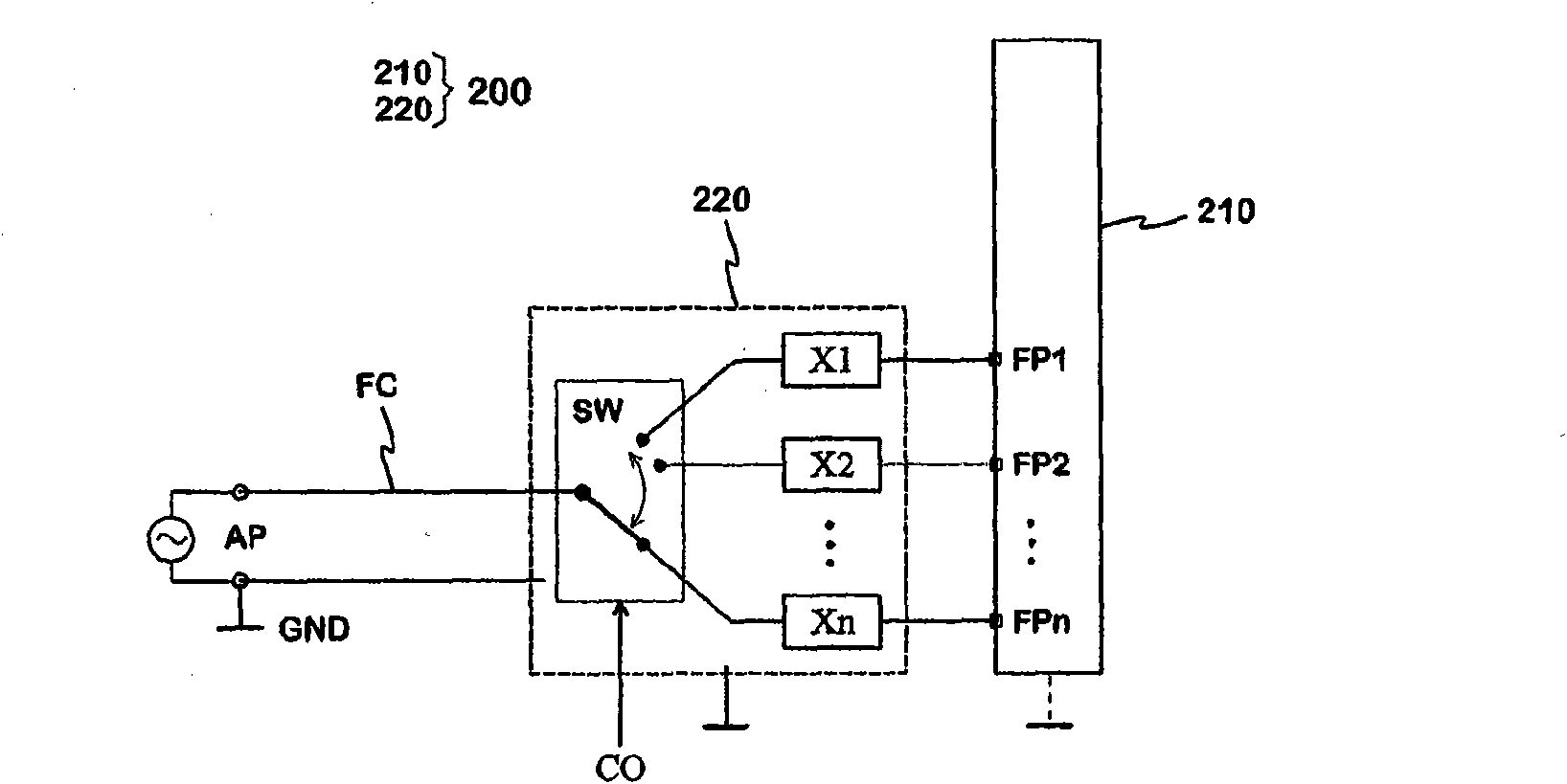

Adjustable multiband antenna

ActiveCN101809813AImprove efficiencySave spaceSimultaneous aerial operationsAntenna supports/mountingsBasic dimensionCapacitance

An adjustable multi-band planar antenna especially applicable in mobile terminals. The feed of the antenna can be connected by a multiple-way switch (SW) to at least two alternative points (FP1, FP2, FP3) in the radiator (310). When the feed point is changed, the resonance frequencies and thus the operating bands of the antenna change. Besides the basic dimensions of the antenna, the distance (x, y, z) of each feed point to other feed points and possible short-circuit point in the radiator, the value of the series capacitance (C31; C32; C33) belonging to a reactive circuit between the feed point and switch and the distance of the ground plane (GND) from the radiator are variables in the antenna design.

Owner:PULSE FINLAND

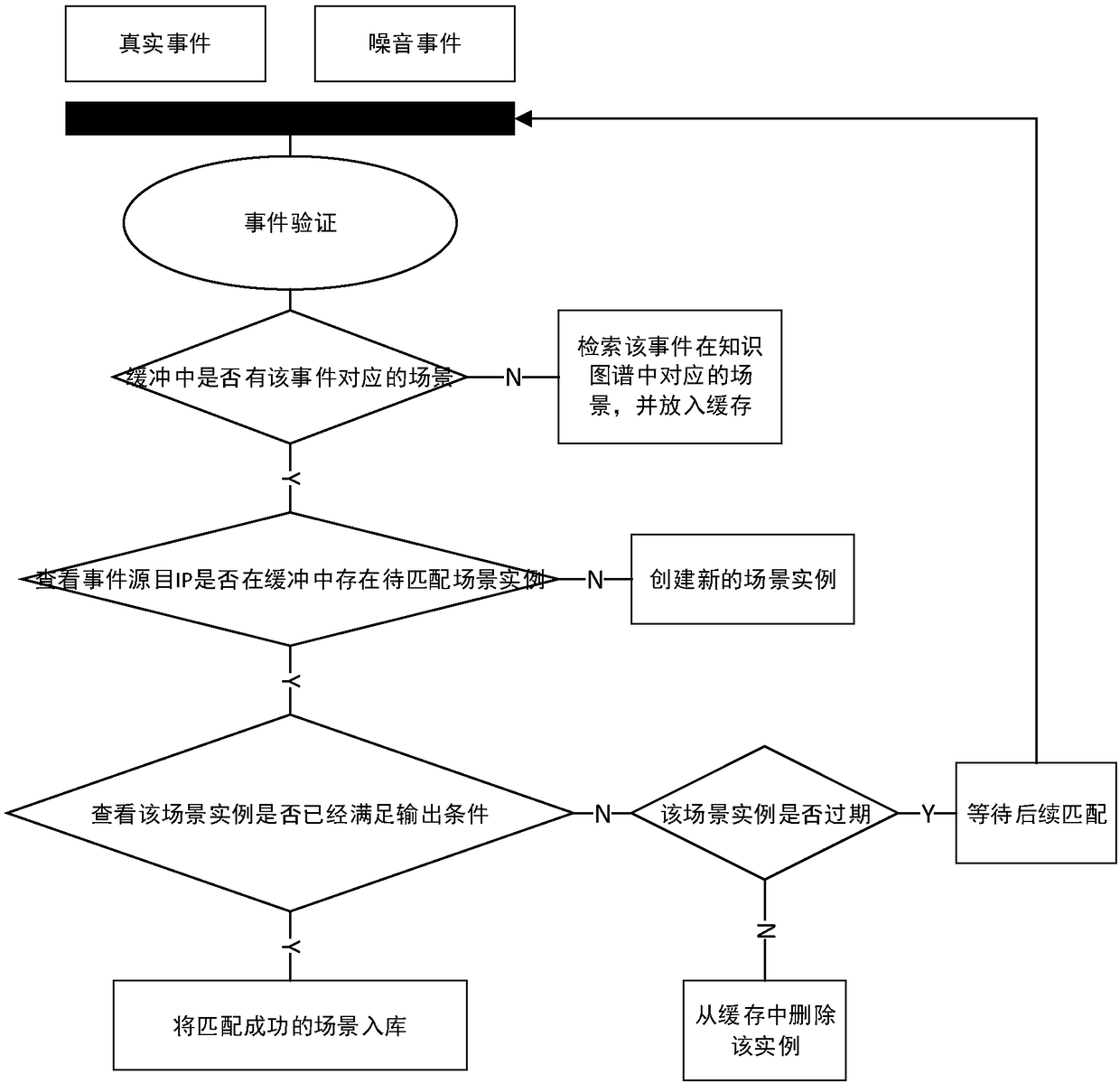

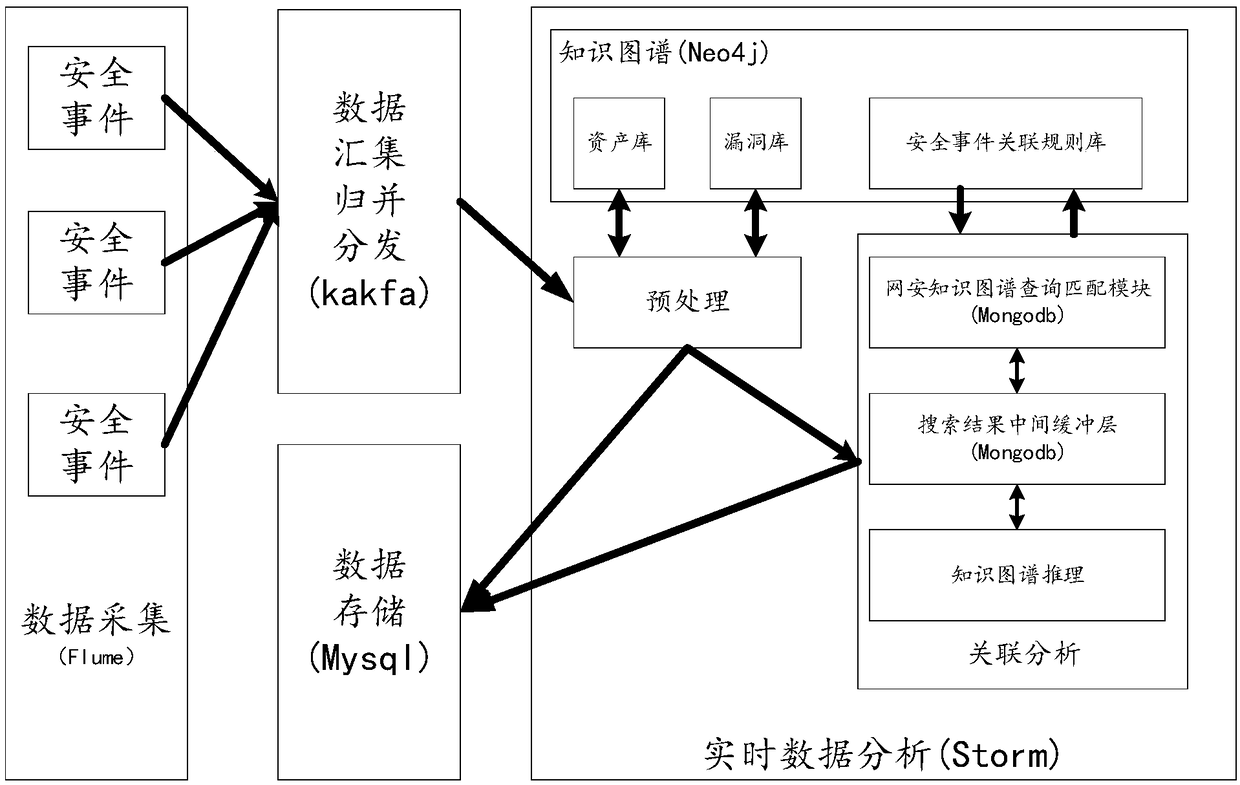

Distributed security event associated analysis method based on knowledge graph

ActiveCN108270785ASpeed up federated searchesRealize the designData switching networksBasic dimensionData platform

The invention discloses a distributed network security event associated analysis method based on a knowledge graph. The method specifically comprises the following steps of 1, building a network security knowledge graph comprising five dimensions such as the basic dimension, the loophole dimension, the threat dimension, the alarm event dimension and the attack rule dimension; 2, designing a security event implementation associated analysis algorithm based on the knowledge graph built in the step 1; and 3, building a real-time big data analysis platform, applying the associated analysis algorithm designed in the step 2 to the built big data platform, and thus achieving a distributed associated analysis system. According to the method provided by the invention, related technologies of current big data process are fully used for dealing with the large data volume, the associated analysis algorithm is parallelized, and the design of the distributed associated analysis algorithm based on the knowledge graph is achieved.

Owner:NAT UNIV OF DEFENSE TECH +1

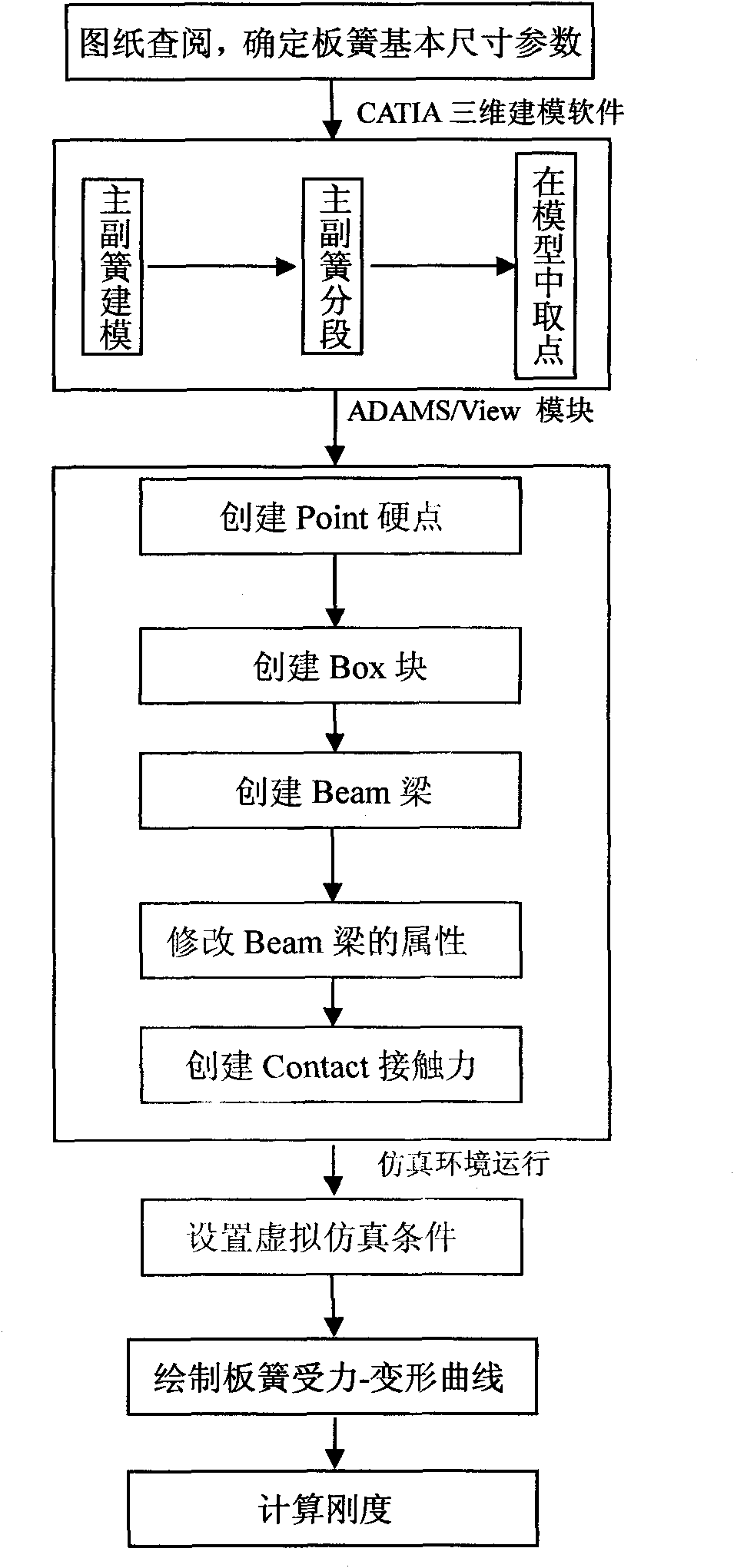

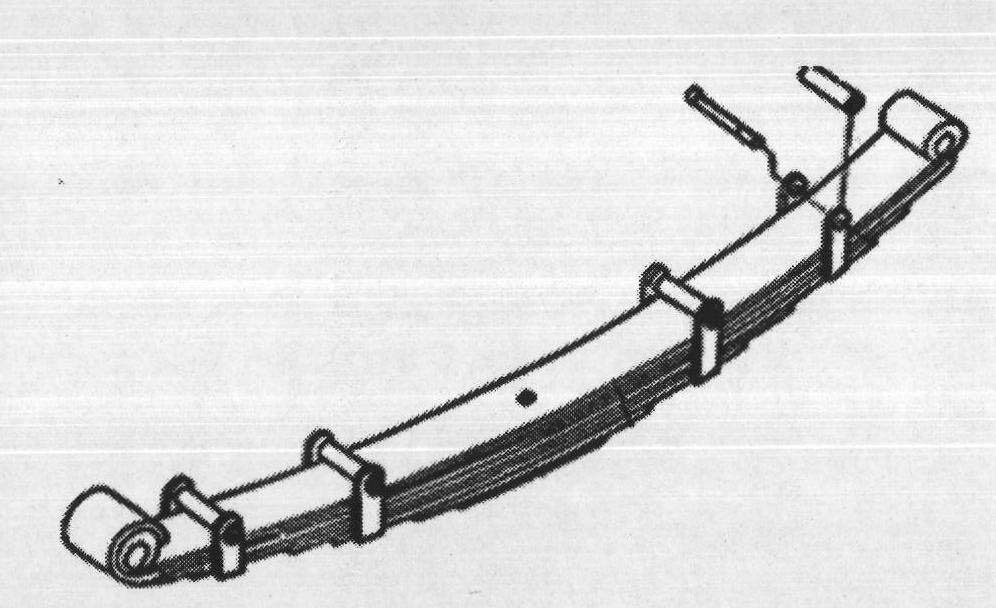

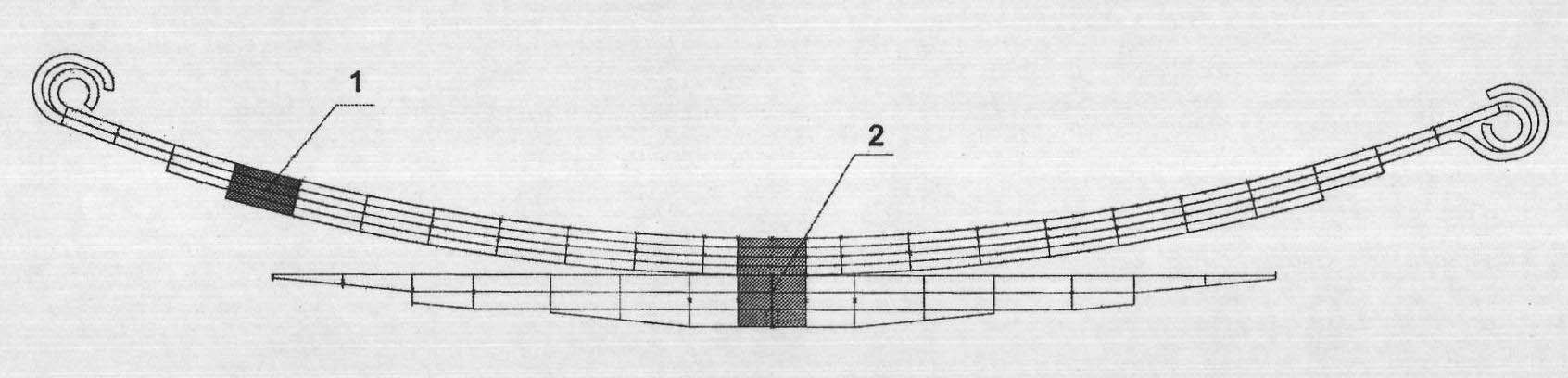

Method for solving rigidity of plate spring by using automatic dynamic analysis of mechanical system (ADAMS)

InactiveCN101866378AIncrease stiffnessCalculation speedSpecial data processing applicationsBasic dimensionSimulation

The invention discloses a method for solving rigidity of a plate spring by using an automatic dynamic analysis of mechanical system (ADAMS). The method comprises the following steps of: step one, determining basic dimension parameters of the plate spring according to a design paper of the plate spring; step two, establishing a three-dimensional model by employing CATIA software to perform reasonable segmentation, and selecting necessary coordinate points; step three, establishing a Point hard-point, a Box block and a Beam beam in an ADAMS / View, putting forward an equivalent middle surface method in attribute setting of the Beam beam, and establishing contact force Contact; and step four, setting a simulation analysis environment of a stress-deformation curve of the plate spring, and employing a method for loading loads through contact of a flat plate and a spheroid to obtain a simulation curve. The method solves the problems in establishing a plate spring flexible body model through the ADAMS software, and the problems in performing simulation setting on the stress-deformation curve of the plate spring flexible body model, and has important meanings for improving the modeling, analyzing and solving accuracies and the calculation speed of mechanical simulation software.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

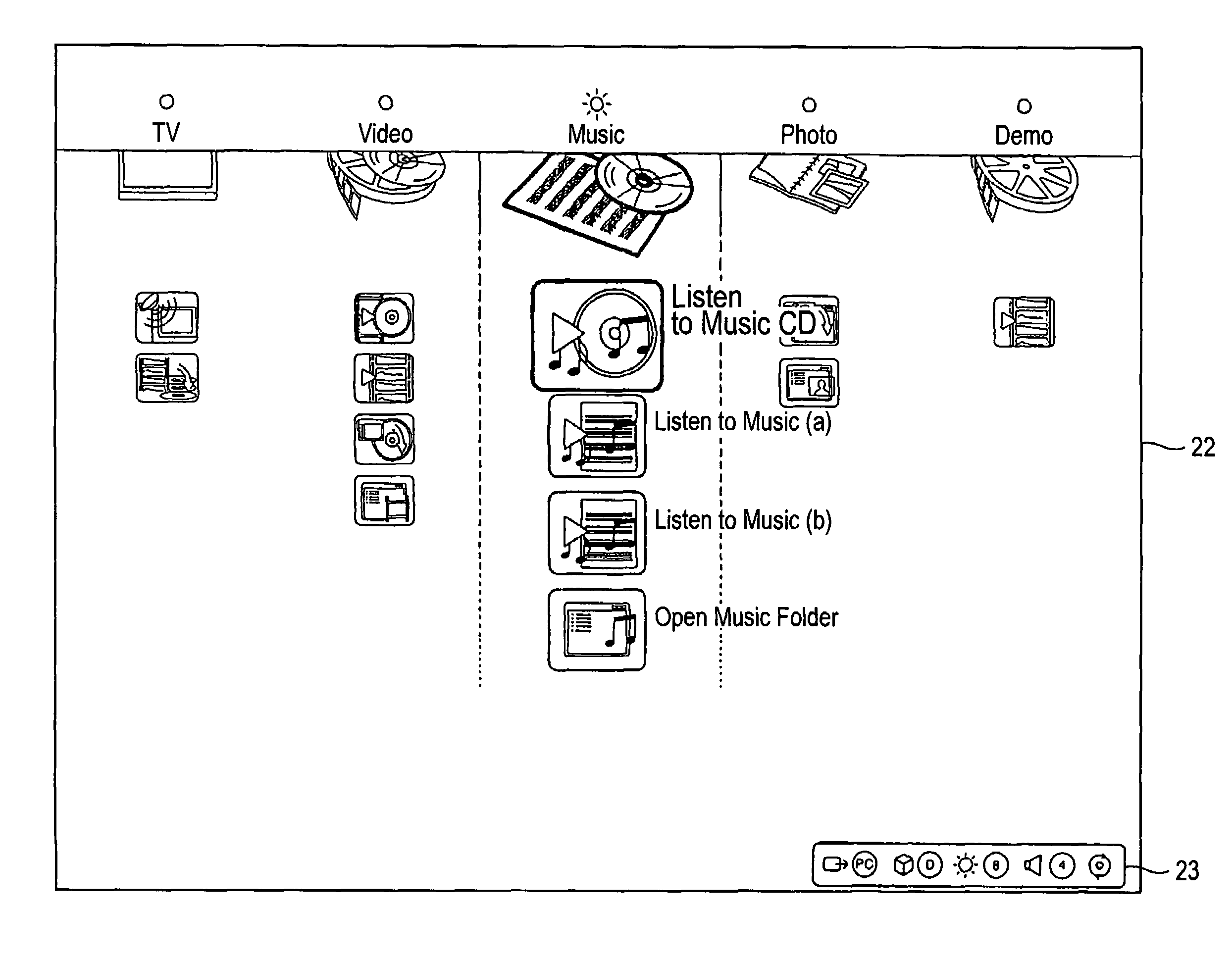

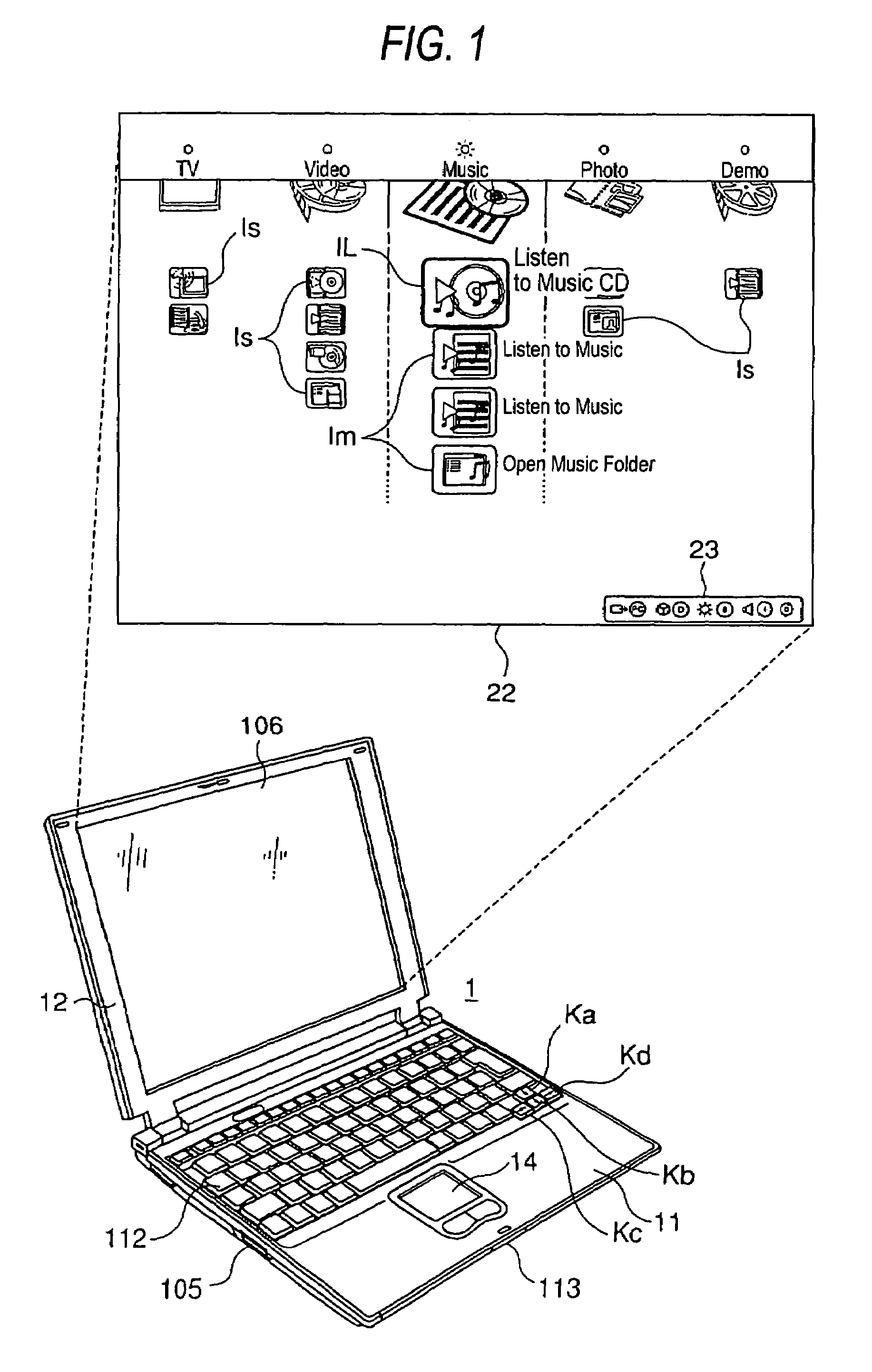

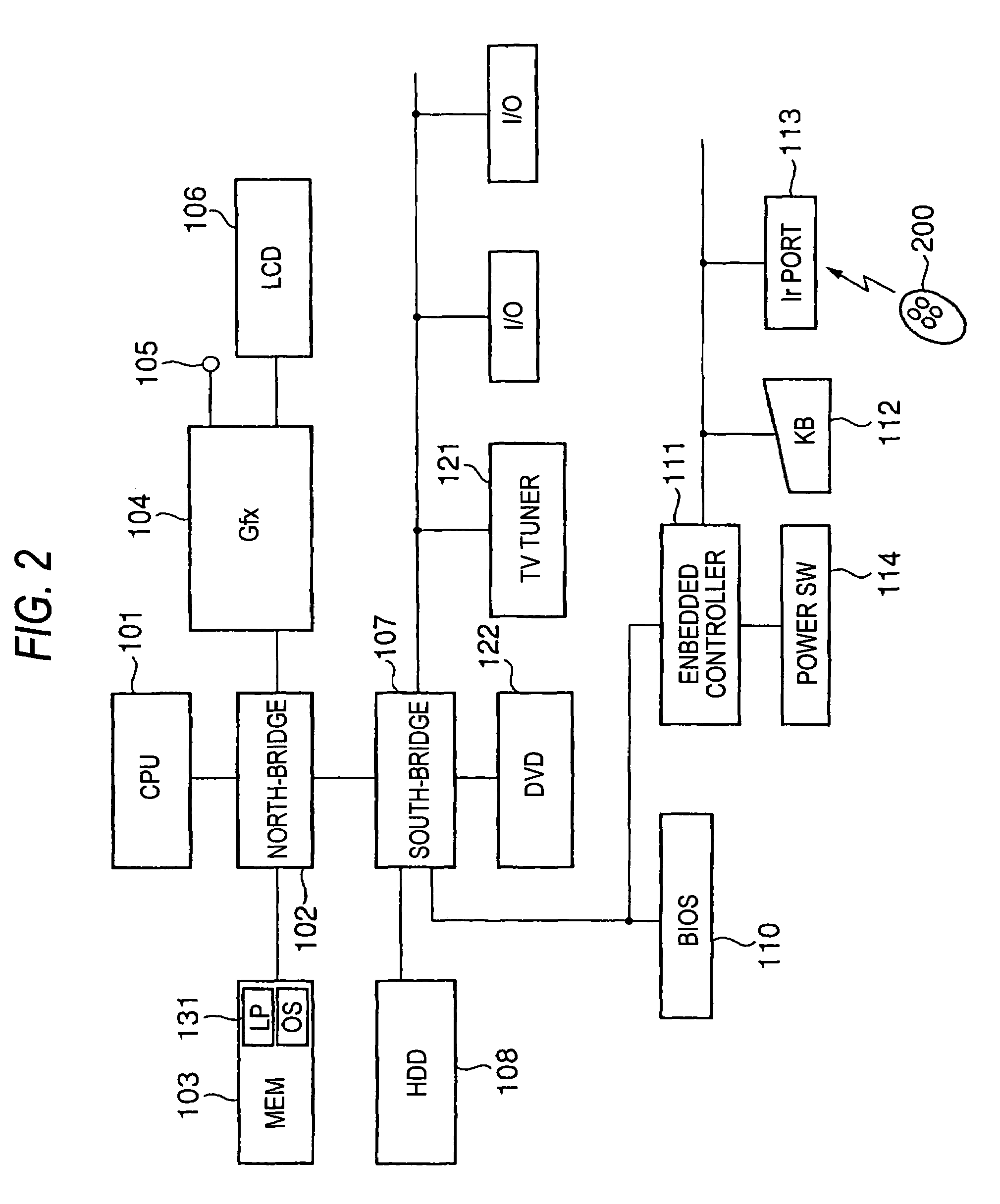

Information processing apparatus

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

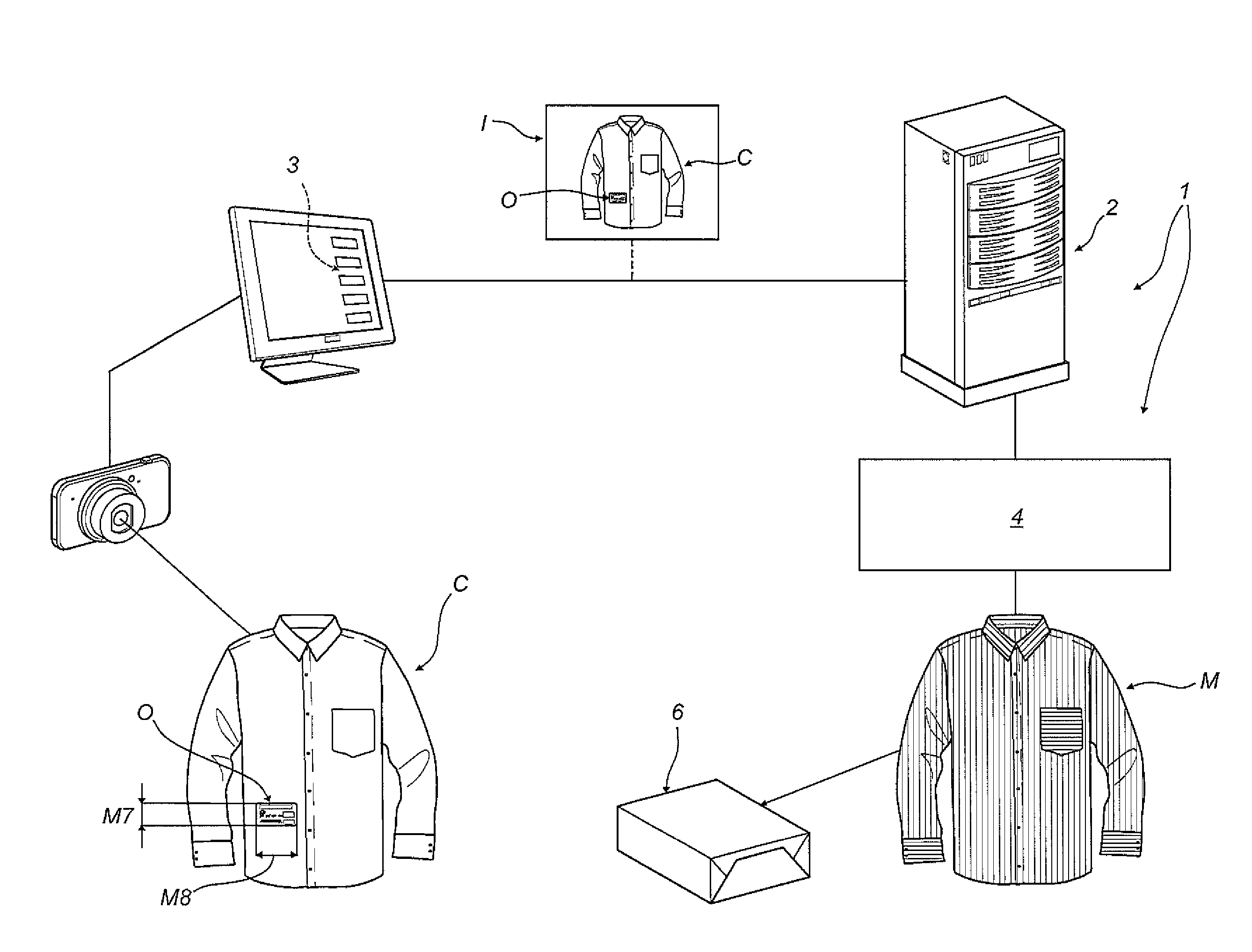

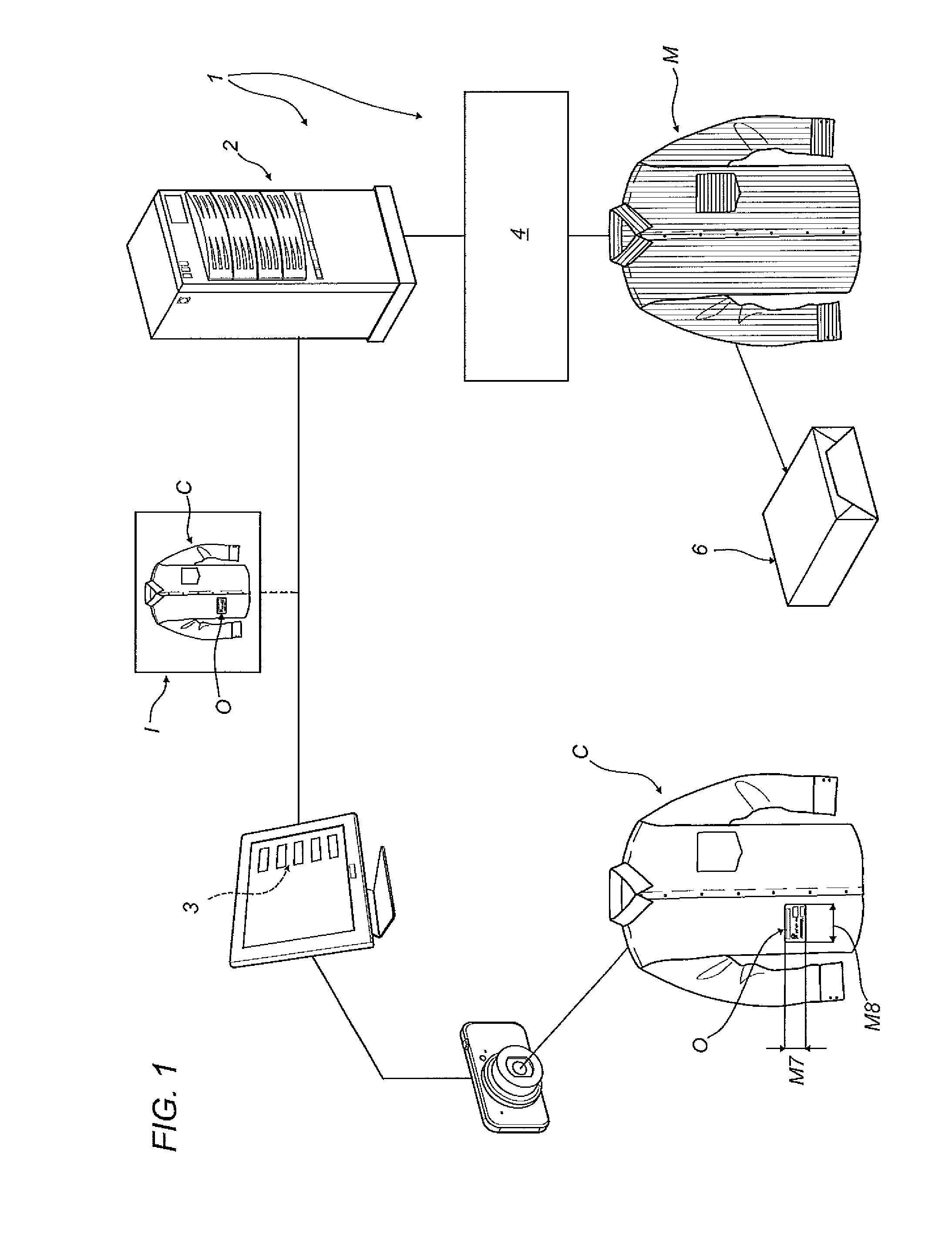

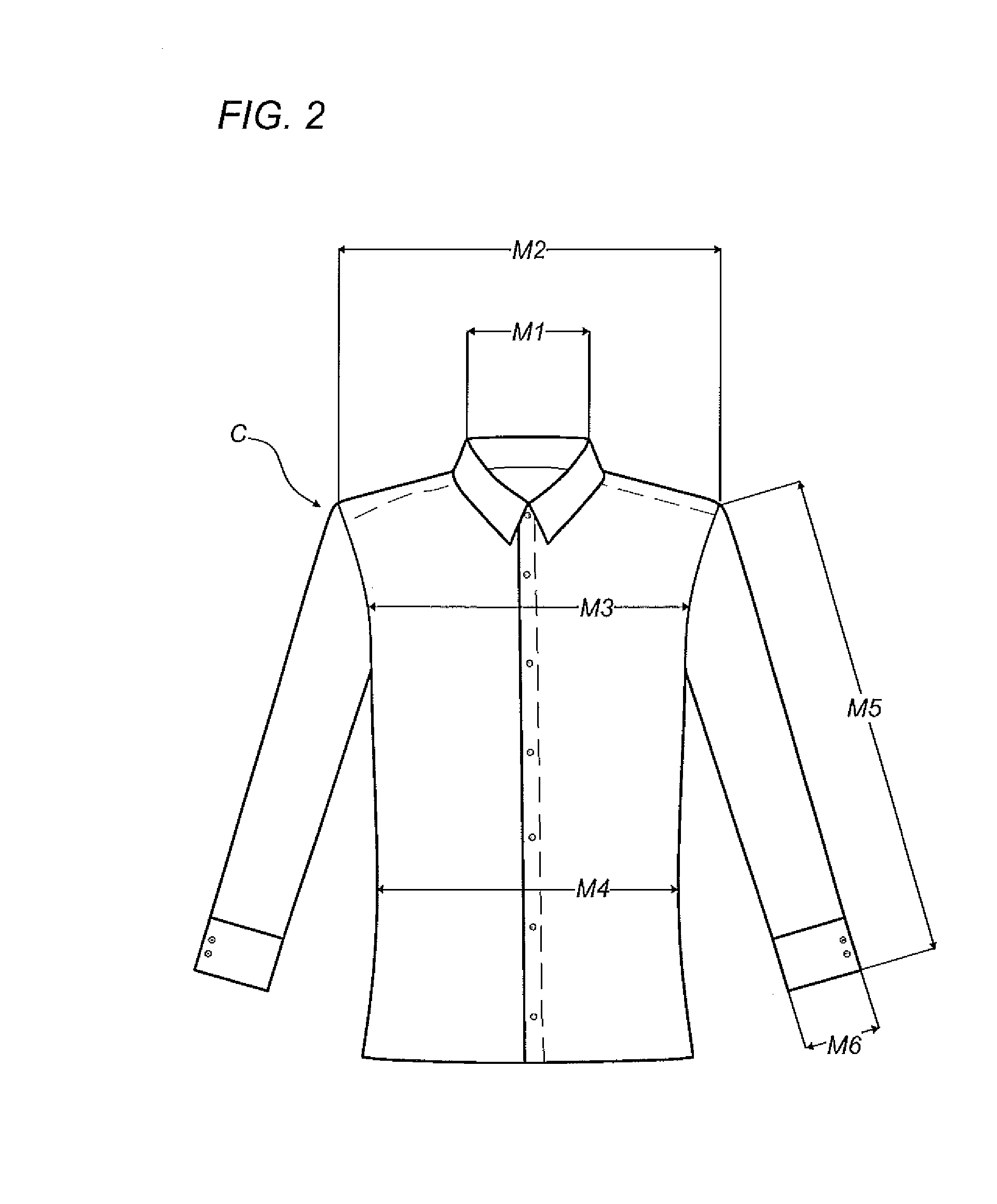

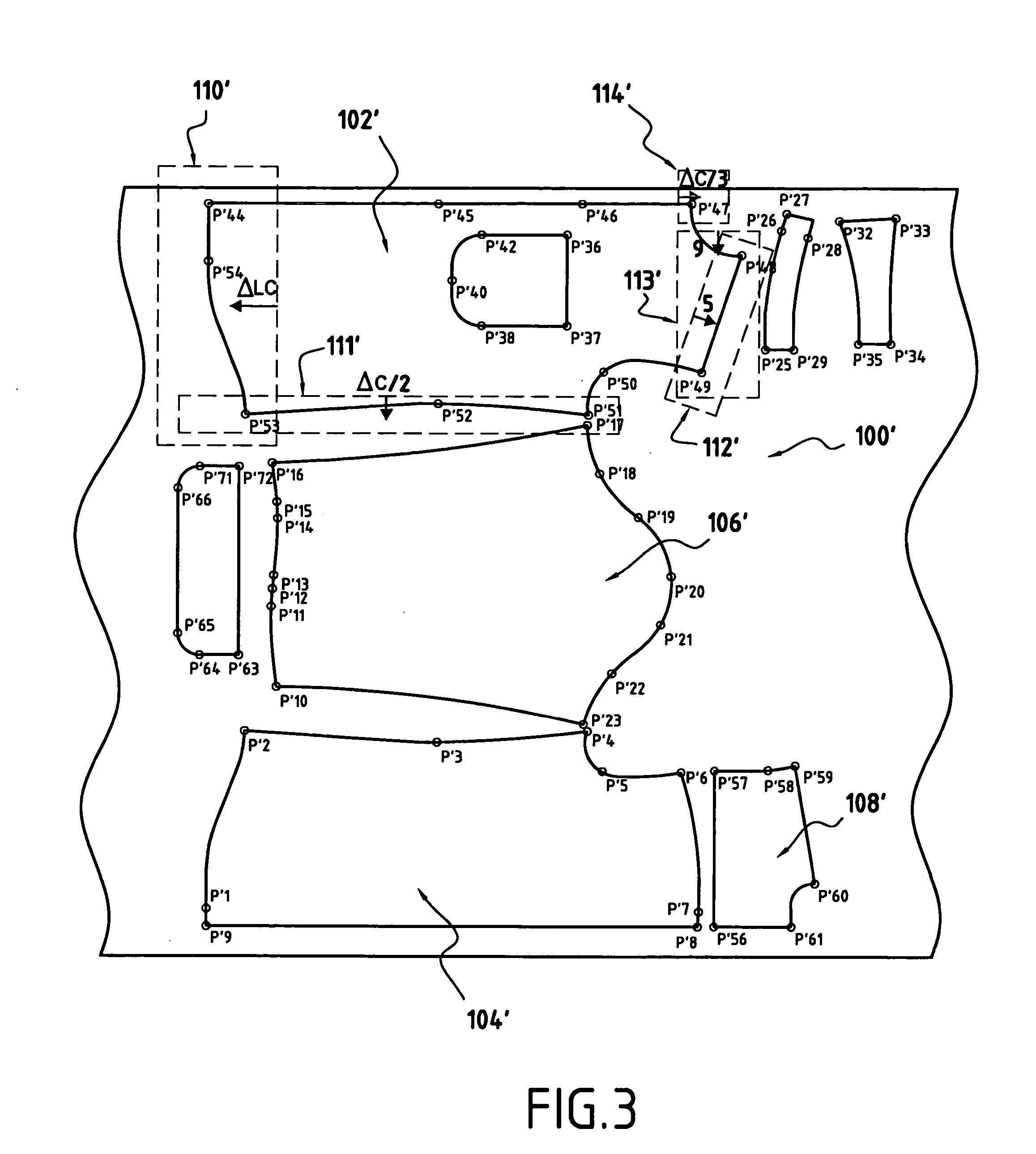

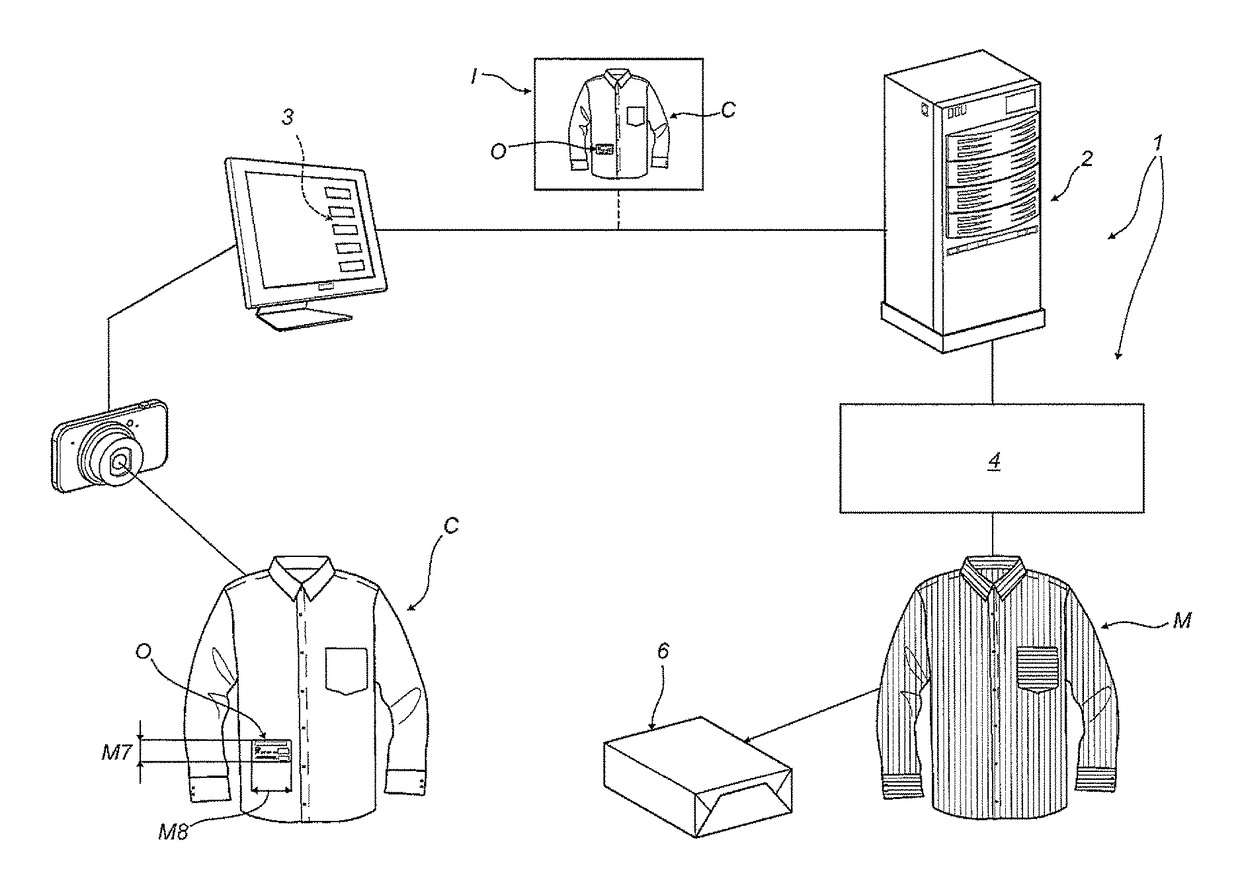

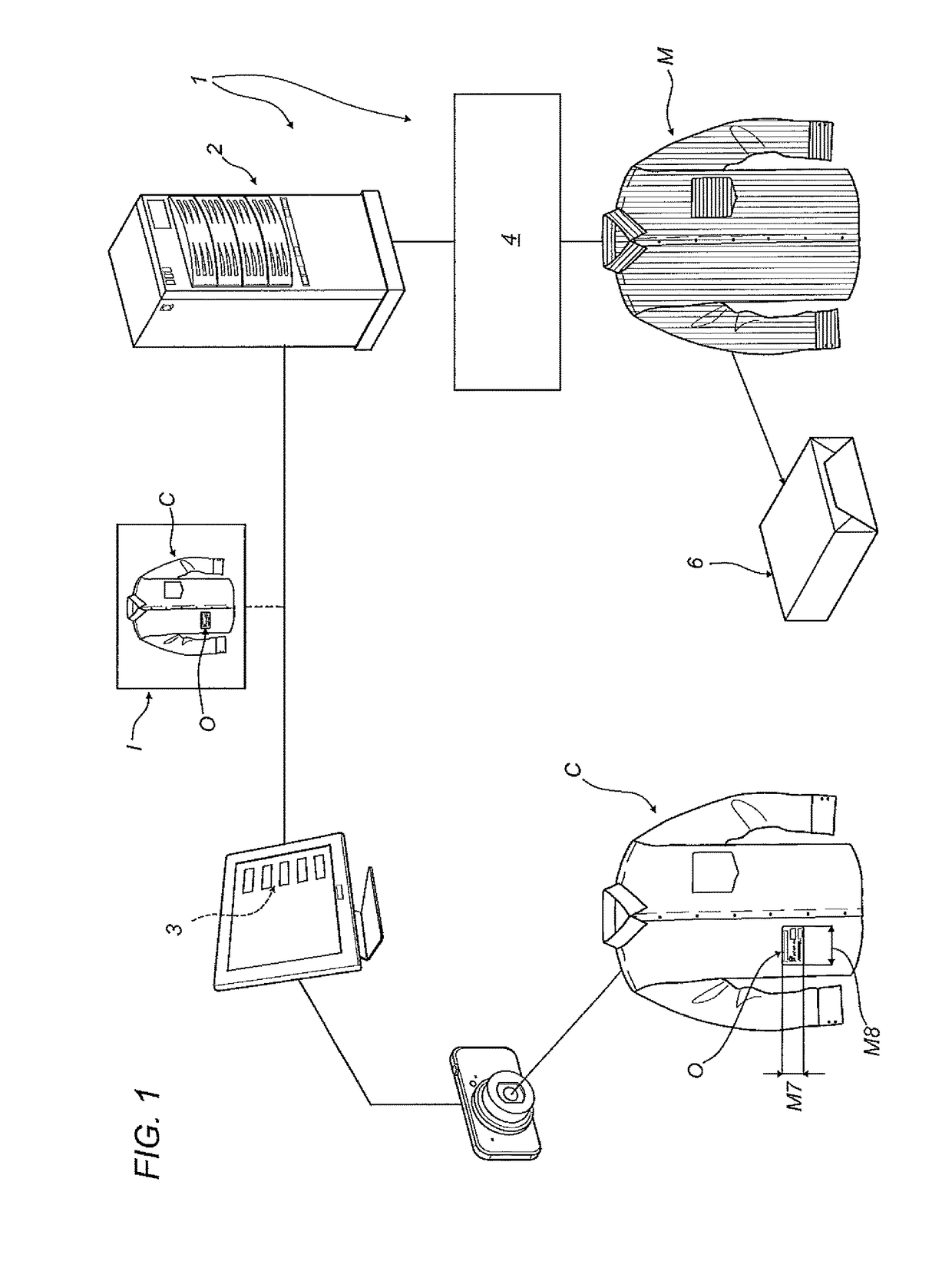

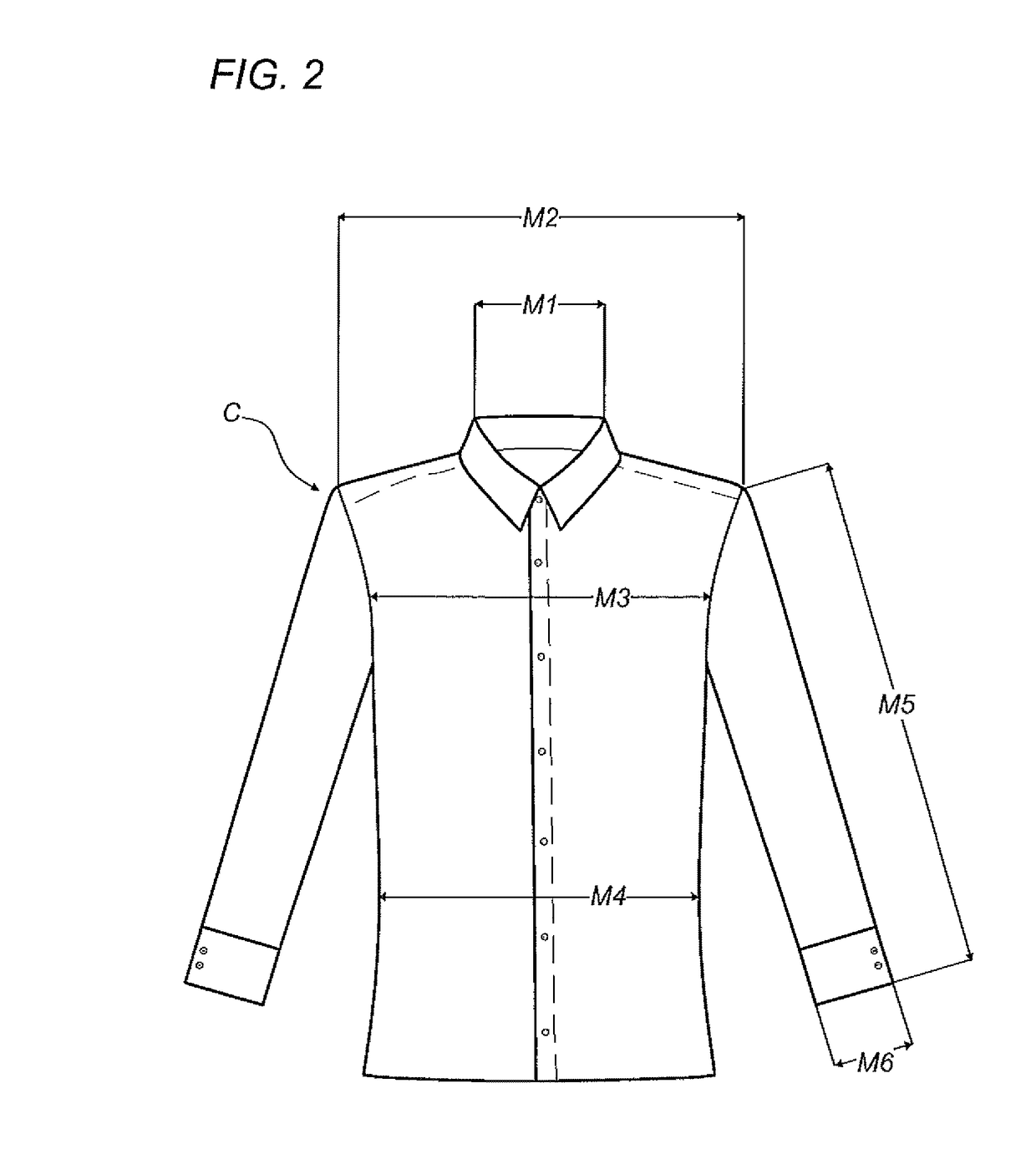

Method and system for making tailored garments

ActiveUS20160249699A1Quick and easy mannerSize quickly and easilyProgramme-controlled sewing machinesClothes making applicancesBasic dimensionEngineering

A method for allowing a user to make a tailored garment (M) comprises the following steps: preparing at least one image (I) comprising a sample garment (C) of the same type as the tailored garment (M) to be made and also comprising a reference object (O) with actual standardized dimensions (M / ,M8); measuring on the at least one image (I) the dimensions of the reference object (O) and a set of basic dimensions (M1,M2,M3,M4,M5,M6) of the sample garment (C); calculating the actual dimensional values of the set of basic dimensions of the sample garment (C) as a function of: the dimensional values of the set of basic dimensions (M1,M2,M3,M4,M5,M6) of the sample garment (C) measured on the image (I), the dimensional values of the reference object (O) and the actual dimensions (M7,M8) of the reference object (O); selecting the aesthetic features of the tailored garment (M) to be made; transmitting to a tailoring apparatus (4) the calculated actual dimensional values of the set of basic dimensions of the sample garment (C) and the selected aesthetic features; performing on the tailoring apparatus (4) a sequence of operations of cutting and sewing the tailored garment (M), to make the tailored garment (M) so its basic dimensions are substantially equal to the previously calculated actual dimensional values of the set of basic dimensions of the sample garment (C).

Owner:IN PRO DI INGHIRAMI PRODUZIONE DISTRIBUZIONE

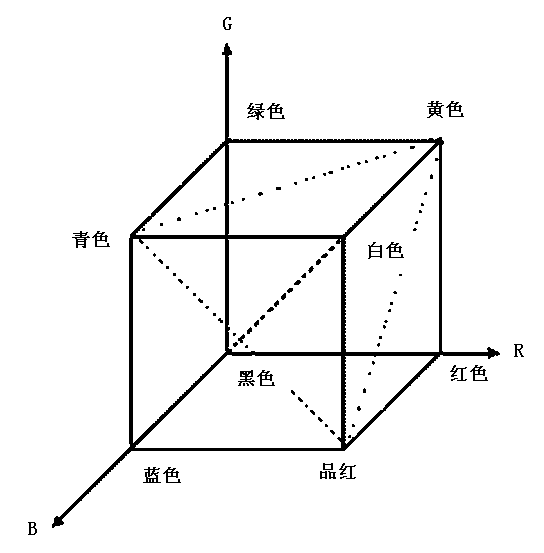

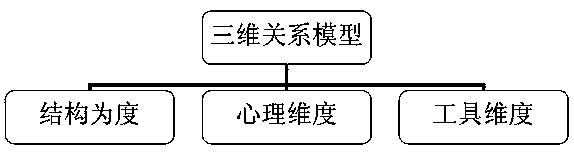

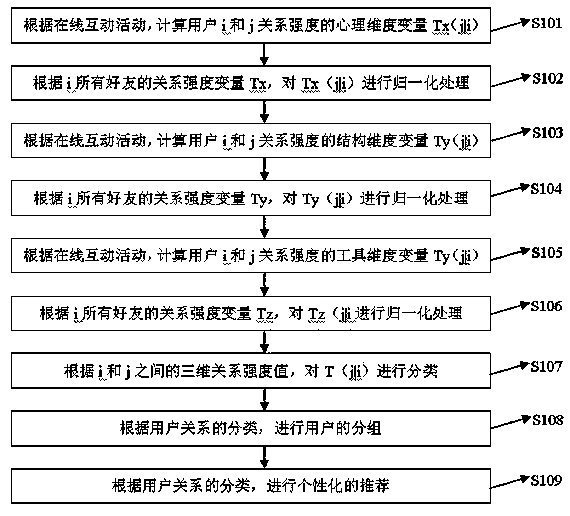

Online user relation measurement and classification method based on three-dimensional relation strength model

InactiveCN103995909APractical methodMake up for the lack of binary one-way relationship strengthData processing applicationsRelational databasesRelation classificationBasic dimension

An online user relation measurement and classification method based on a three-dimensional relation strength model includes the step of setting up the three-dimensional relation strength model, the step of setting up a visualized model of relation strength, the step of measuring the social network user relation and the step of social user classification and recommendation. Social relations of users in a social network are abstracted into three basic dimensions, namely, the structure dimension, the psychological dimension and the tool dimension, and the dimensions are continuous variables from zero to one. Vectors of the three dimensions are mapped to three basic colors, then the problem of the relation strength can be converted into the color problem, and therefore visualized analysis on the relation strength can be conducted. According to the different relation classifications, the relations between the users are more accurately classified, and therefore basis is provided for subsequent processing, and the user classification and recommendation method which is more practical, more convenient to implement and more accurate can be provided for social network service platforms such as the SNS.

Owner:SOUTHEAST UNIV CHENGXIAN COLLEGE +1

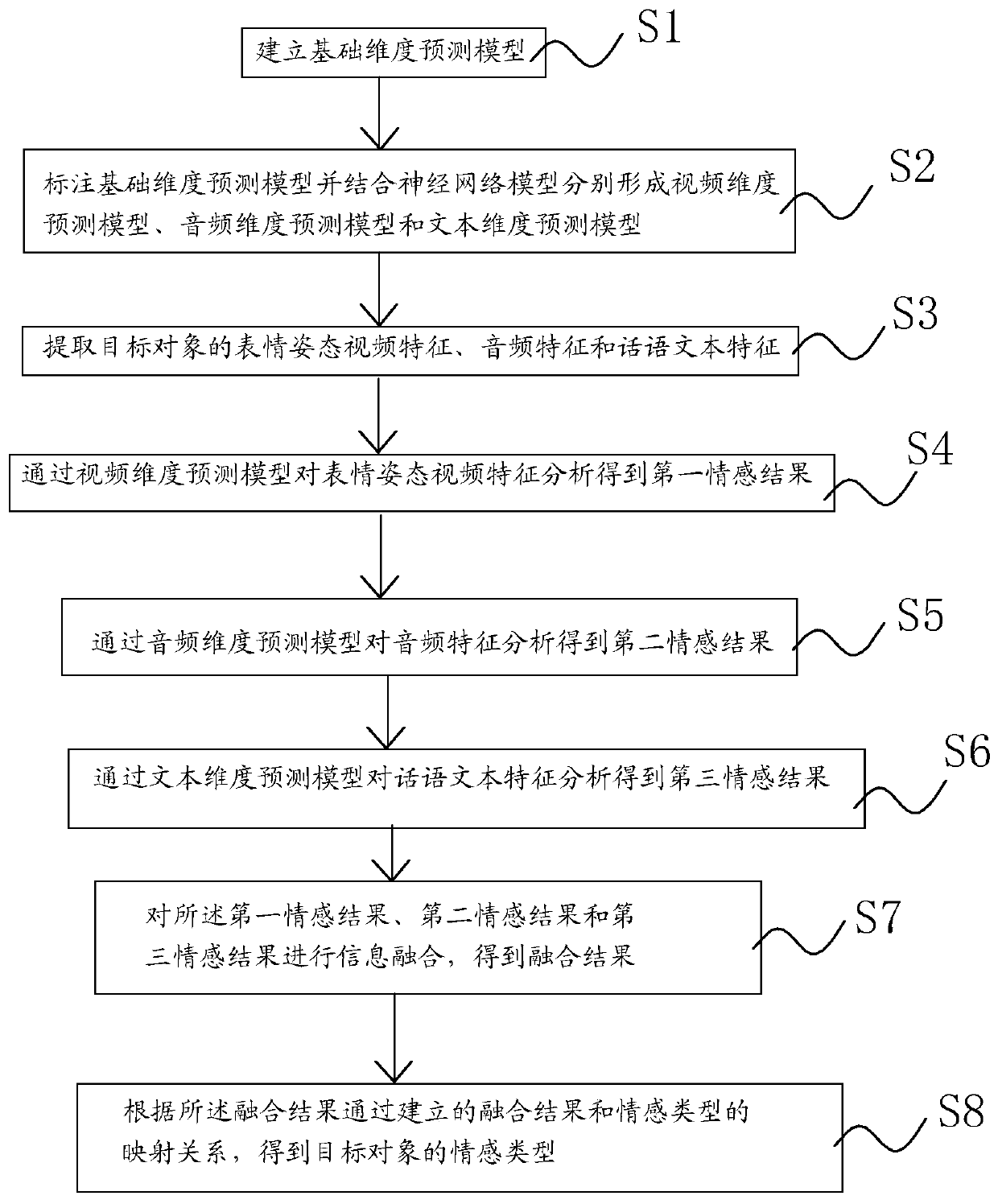

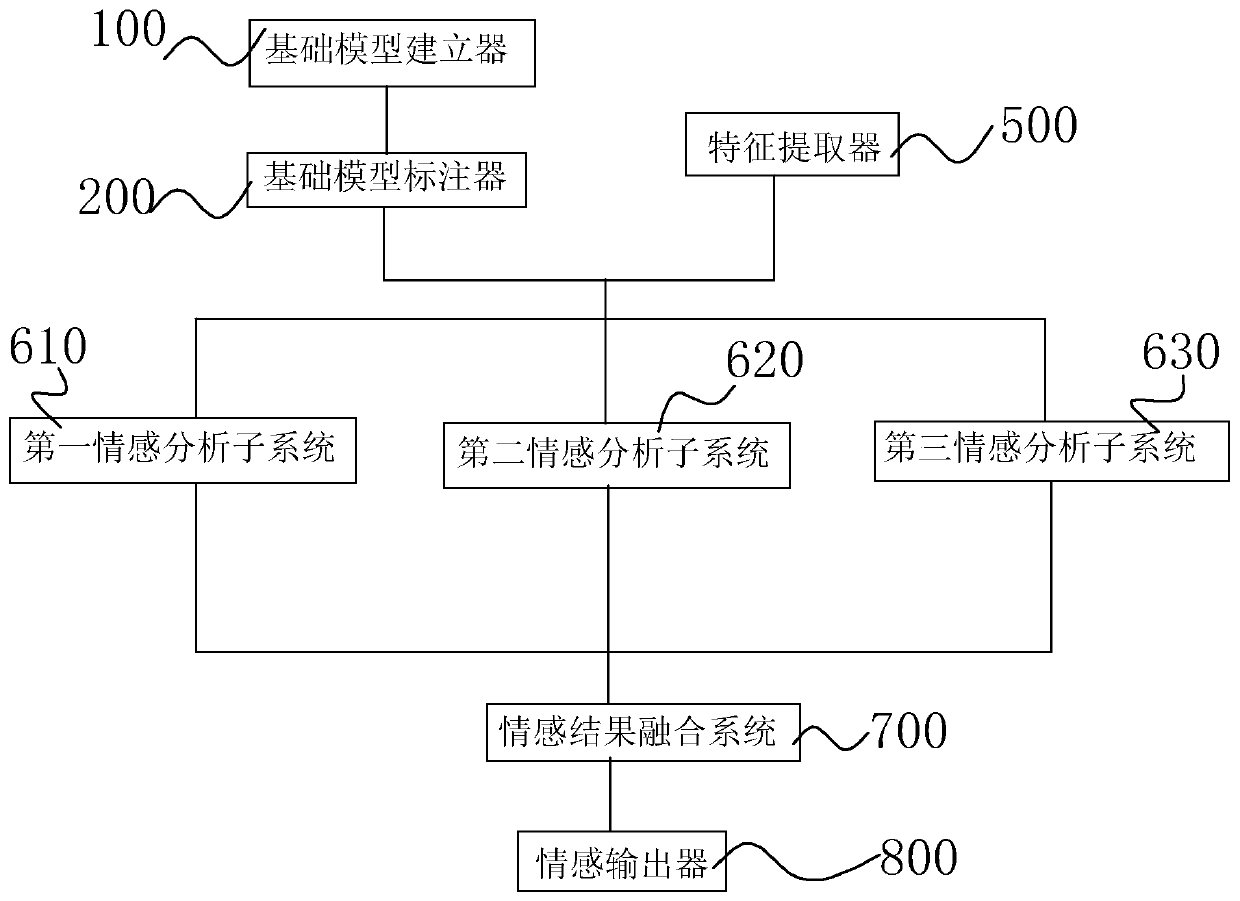

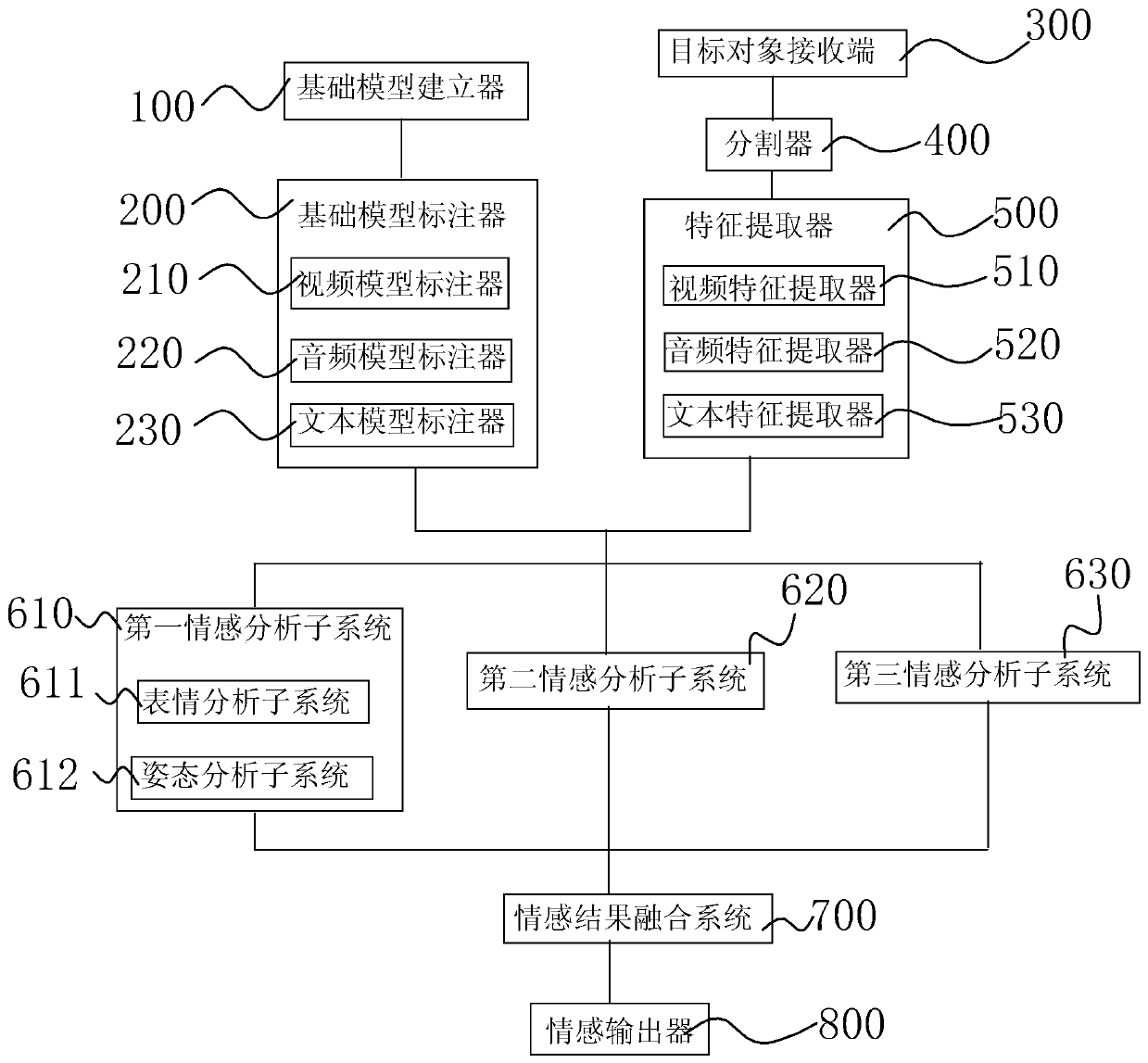

Emotion recognition method and device based on multi-modal emotion model

PendingCN110033029AInformativeImprove anti-interference abilityCharacter and pattern recognitionNeural architecturesPattern recognitionBasic dimension

The invention discloses an emotion recognition method and device based on a multi-modal emotion model. The method comprises the steps of establishing a basic dimension prediction model, obtaining a video dimension prediction model, an audio dimension prediction model and a text dimension prediction model through the basic dimension prediction model, and analyzing the expression posture video features, audio features and utterance text features respectively to obtain a first emotion result, a second emotion result and a third emotion result; fusing the three results and obtaining an emotion category of the target object by combining a mapping relation based on a basic dimension prediction model. The method and the device carry out the emotion recognition from multiple modes and multiple angles, so that the method and the device have the advantages of being comprehensive in information, strong in anti-interference performance and high in accuracy.

Owner:WUYI UNIV

Power station great mirror board and mirror face hkusm machining technique

InactiveCN101224532AImprove machining accuracyReduce investmentAutomatic control devicesFeeding apparatusBasic dimensionProcess equipment

The invention discloses a hauk energy processing technology used for the large mirror plate surface of a power plant, comprising the steps of: (1) a suitable cutter is adopted to fabricate a mirror plate which complies with the basic dimension and the geometrical tolerance required by the drawing and the surface roughness of which reaches 2.3-2.8 micro meters; (2) the cutting parameter is adjusted, the processing linear speed of the hauk energy cutter is adjusted to 39m / min and the feeding speed is adjusted to 0.3mm / r; (3) the surface of the mirror plate which is processed and formed in the step (1) is processed by the hauk energy cutter. The invention has the advantages of greatly improving the processing precision of the metal surface, the surface roughness of the workpiece reaching 0.07-0.10 micro meters, reducing the investment of process equipments, reducing the manufacturing cost, shortening the processing and manufacturing period, improving the working efficiency, reducing the environmental pollution, being suitable for processing the surface of the external round and the mainshaft mirror surface, etc. of the parts such as the large mirror plate surface of the power plant, a mainshaft, etc.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

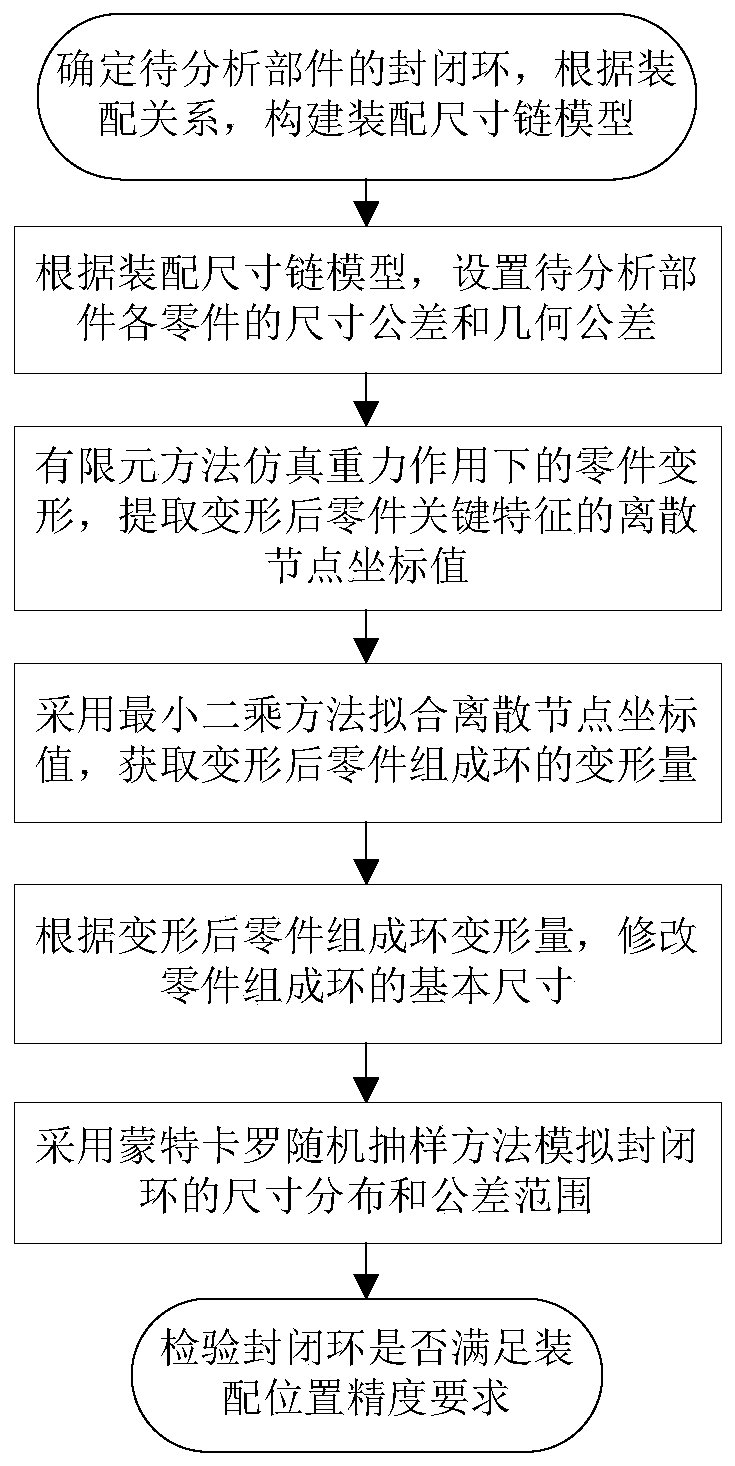

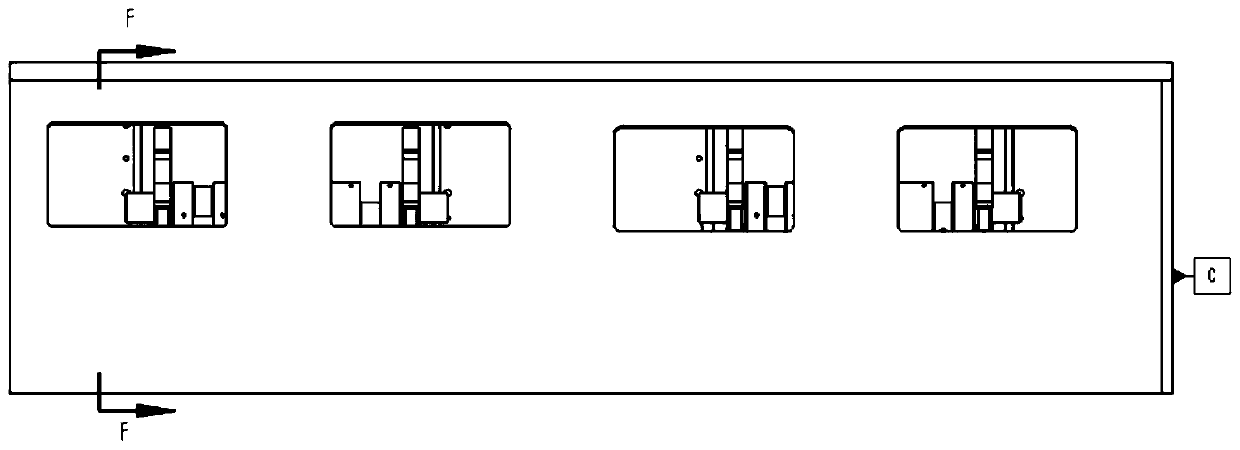

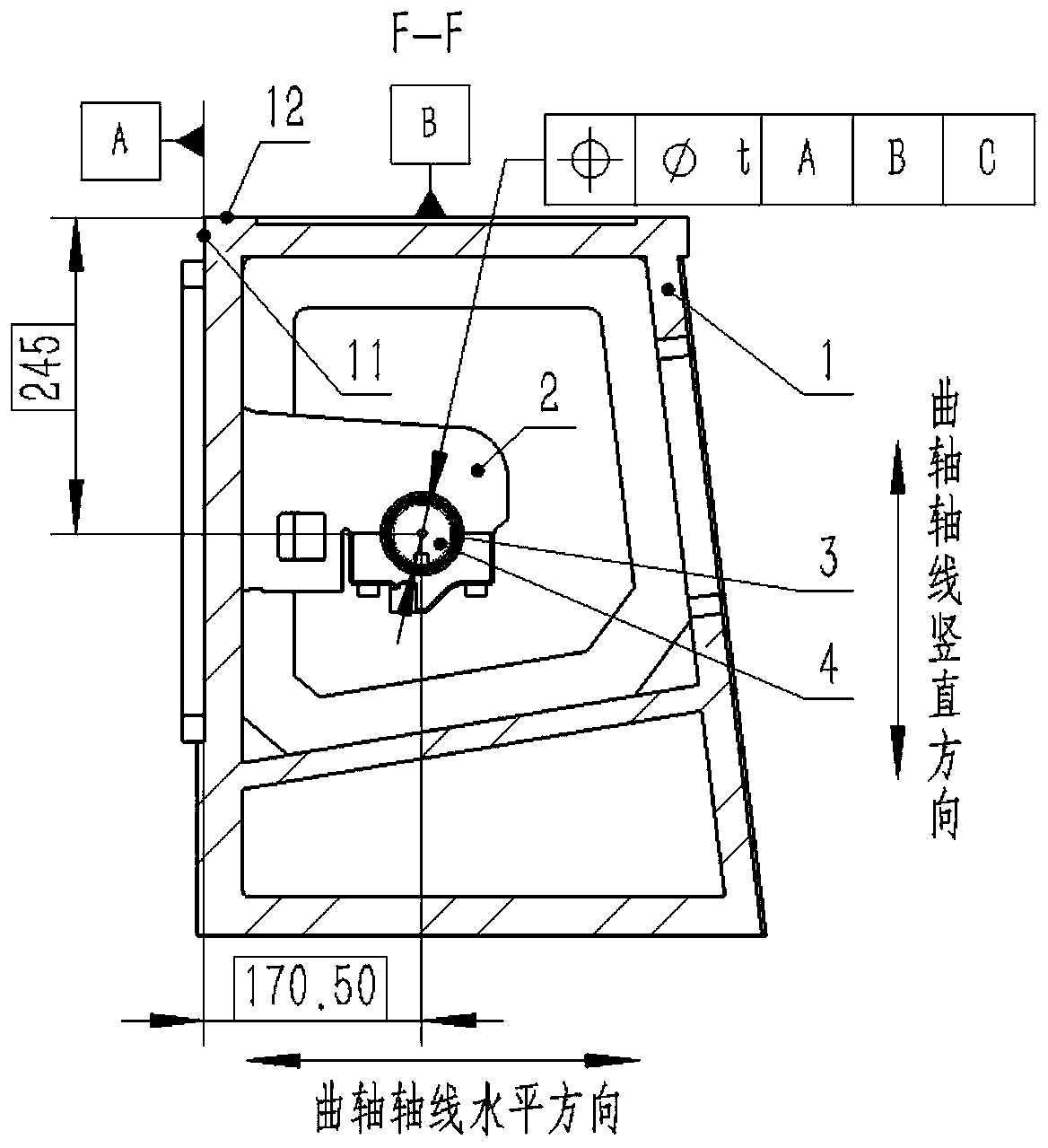

Assembly position precision analysis method considering geometric tolerance and deformation influence

PendingCN110276108ASolving the Problem of Accuracy AnalysisThe analysis result is accurateGeometric CADDesign optimisation/simulationBasic dimensionExtended finite element method

The invention discloses an assembly position precision analysis method considering geometric tolerance and deformation influence. The method comprises the following steps: determining a closed ring of a to-be-analyzed part, and constructing an assembly dimension chain model according to an assembly relationship; according to the assembly dimension chain model, setting the dimension tolerance and the geometric tolerance of each part forming ring of the to-be-analyzed part; simulating part deformation under the action of gravity by a finite element method, and extracting discrete node coordinate values of key characteristics of the deformed part; fitting discrete node coordinate values by adopting a least square method, and obtaining the deformation amount of a ring formed by the deformed part; according to the deformation of the deformed part forming ring, modifying the basic size value of the part forming ring; simulating the size distribution and tolerance range of the closed ring by adopting a Monte Carlo random sampling method; and detecting whether the closed ring meets the crankshaft assembly position precision requirement or not. According to the method, whether the tolerance of each currently arranged part forming ring can meet the assembly position precision can be analyzed.

Owner:NANJING UNIV OF SCI & TECH

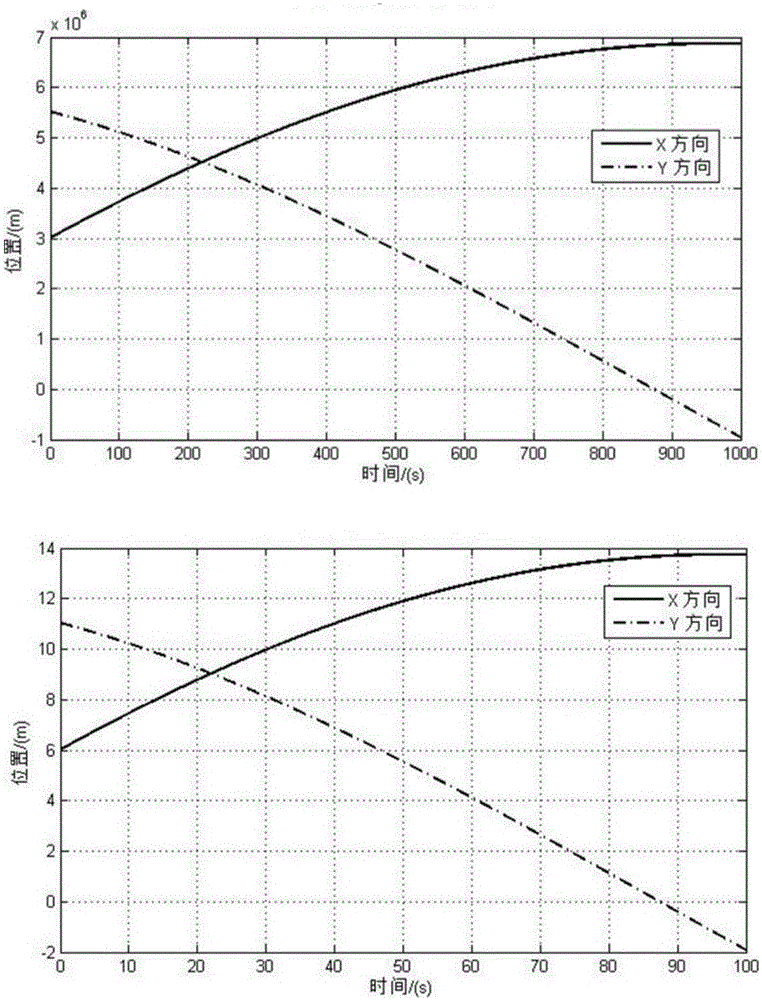

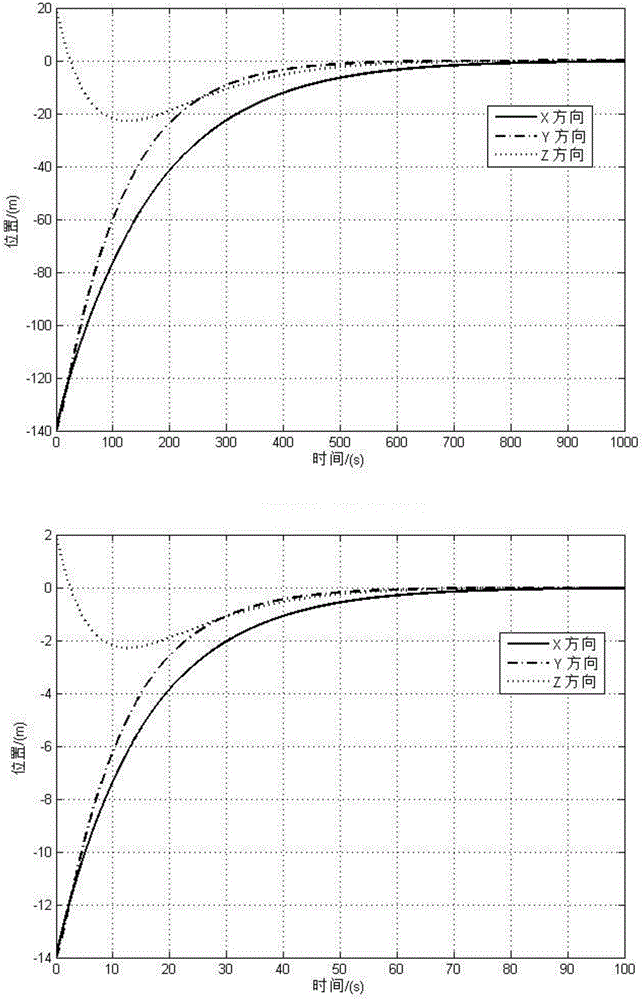

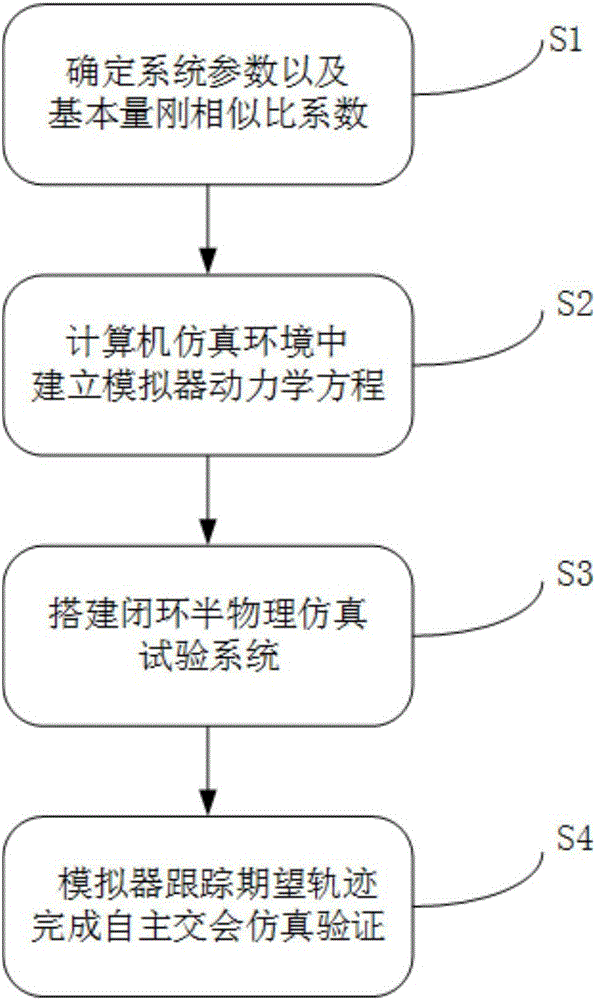

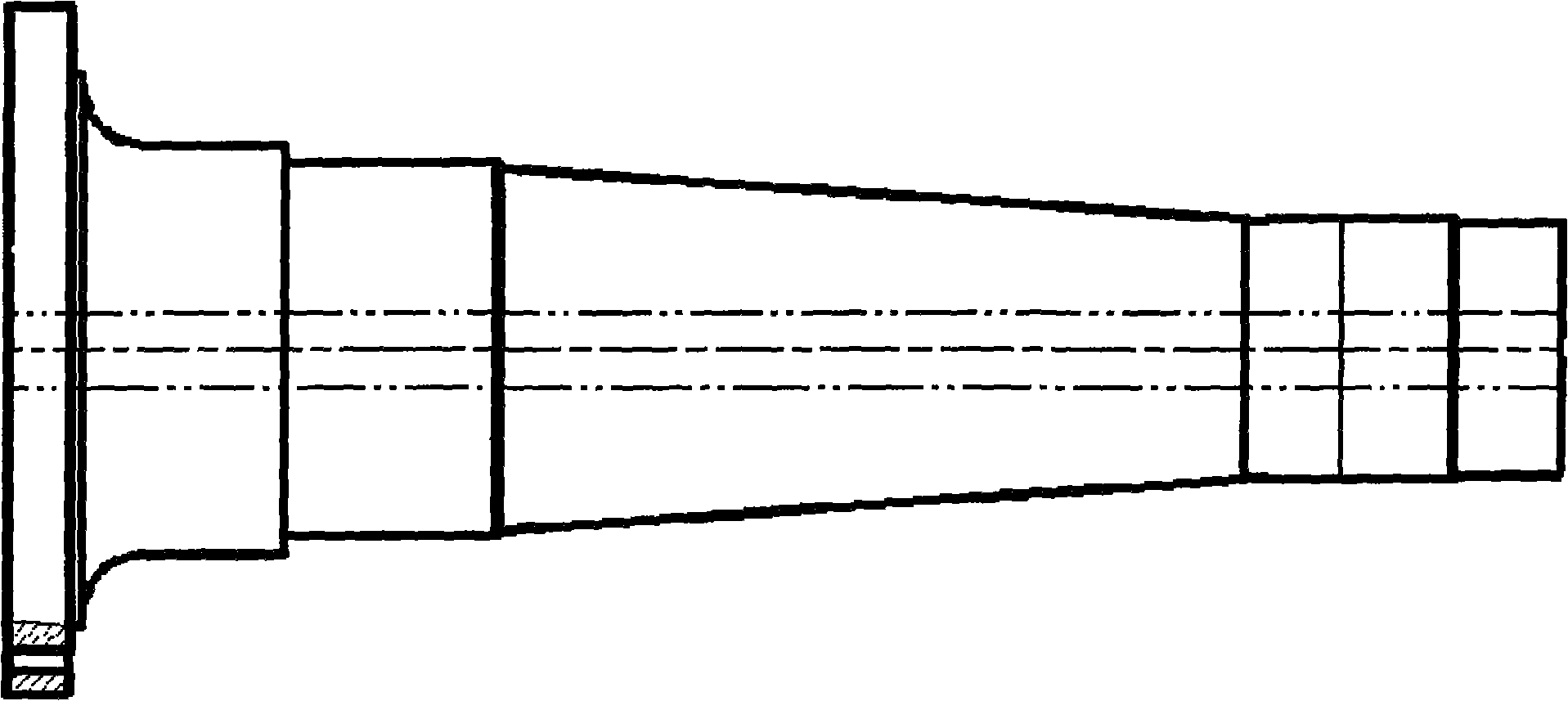

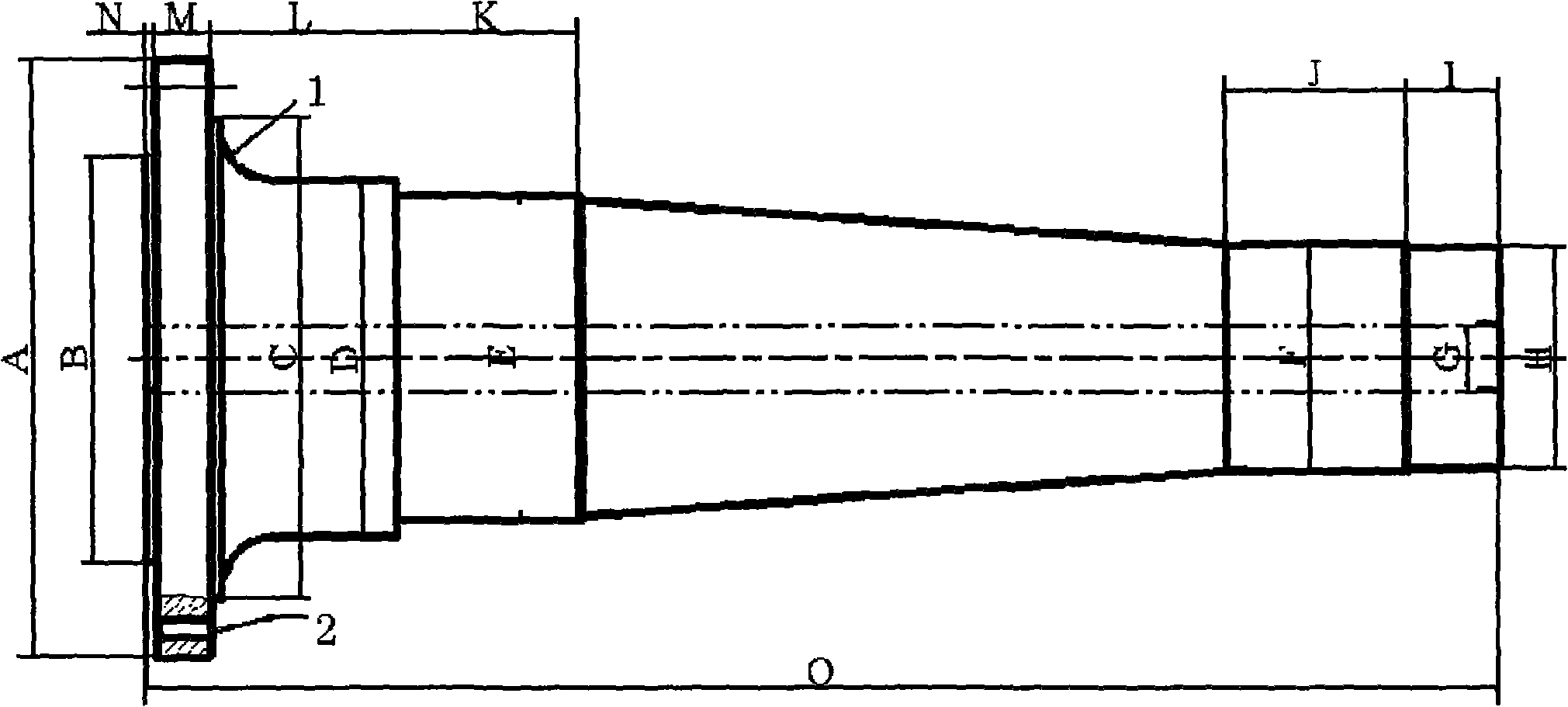

Spacecraft autonomous rendezvous control system ground simulation test method

Provided is a spacecraft autonomous rendezvous control system ground simulation test method, belonging to the spaceflight control ground simulation field. The method comprises the steps of: 1) determining a basic dimension corresponding physical quantity similarity ratio coefficient according to the relation between verification object task parameters and ground test system parameters; 2) according to the similarity ratio coefficient, respectively establishing kinetic equations of a target simulator and tracking simulator motion in computer simulation; 3) connecting the simulator kinetic equation, the simulator (including control), a motion measuring sensor and an autonomous rendezvous controller to form a ground test closed loop system; and 4) controlling the simulator to track the motion track solved by a kinetic equation in the computer, and reproducing a spacecraft autonomous rendezvous motion process in a ground test room. The spacecraft autonomous rendezvous control system ground simulation test method lays a theoretical foundation for an autonomous rendezvous control semi-physical simulation test, and can simultaneously reflect simulator and tracking spacecraft absolute and relative motion characteristics on the ground, and verify an omnidirectional autonomous rendezvous control task.

Owner:BEIHANG UNIV

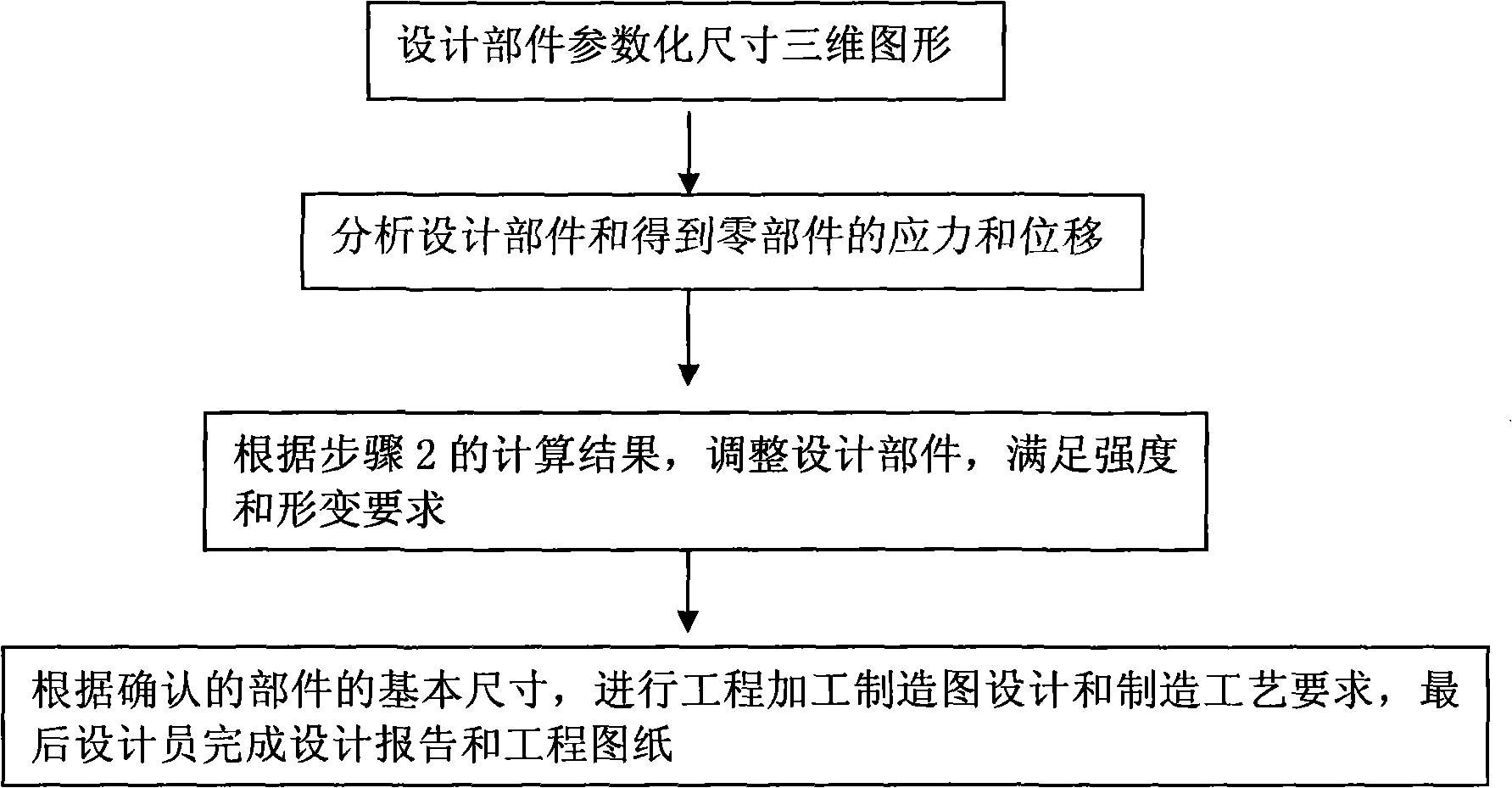

Design method of parameterized part of wind generating set

InactiveCN101539959ASimple and fast analysis and calculationSpecial data processing applicationsElectricityBasic dimension

The invention relates to a design method of a parameterized part of a wind generating set, belonging to the technical field of wind power generation. The design method comprises the following steps: 1. designing a three-dimensional graph of a parameterized dimension of the part; 2. acquiring the stress and the displacement of the part; 3. determining fundamental dimensions of the part according to a calculating result of the step 2; 4. carrying out the design of an engineering processing and manufacturing drawing and a manufacturing process requirement according to the determined fundamental dimensions of the part, and finally completing a design report and an engineering drawing by designers. The design method can simplify the mesh modeling of the part to enable the analysis calculation of a finite element to be simple and fast; software designed by the design method can simultaneously complete the integrated design and the structural design of the wind generating set and simultaneously complete calculation, analysis, check work and drawing design.

Owner:SHENYANG POLYTECHNIC UNIV

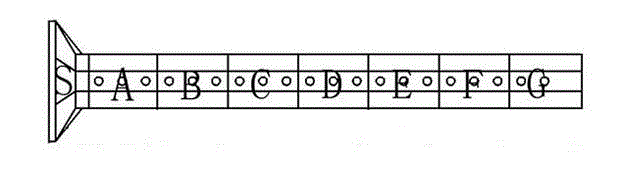

Design method for section closure accuracy of octagonal pile leg

InactiveCN102717248AGuaranteed normal work requirementsGuaranteed dimensional accuracyWelding apparatusBasic dimensionEngineering

The invention relates to a design method for the section closure accuracy of an octagonal pile leg. The method comprises the following steps of: dividing the pile legs into sections; performing accuracy distribution on each section by using the dimension chain principle; calculating the compensation amount of welding deformation to replace allowance by a method for calculating the compensation amount of ship sections, so that the sections are constructed without the allowance; and forming a dimension chain by using the added compensation amount, the basic dimensions of the sections and a gap between weld joints, and calculating the reasonable tolerance range of the closed sections. The method has the advantages that the dimension accuracy of pin holes after closure welding is ensured, an impact load and material wear which are caused when the pin holes are matched with pin shafts are reduced, working time and materials are saved, the working requirement of the pile leg is met, and the like.

Owner:COSCO SHIPPING SHIPYARD (NANGTONG) CO LTD +2

Manufacturing method of high-temperature tensile sample

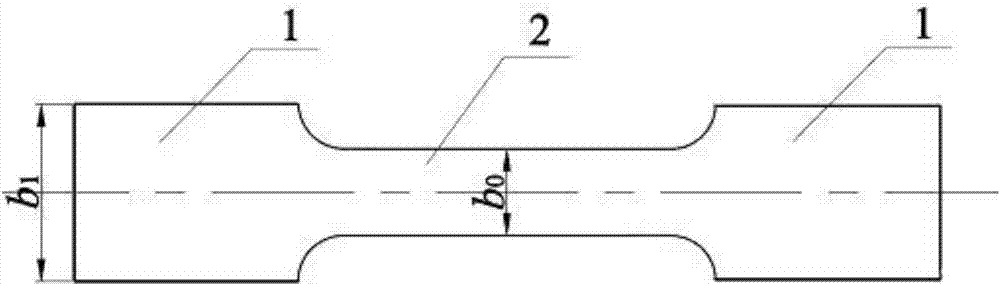

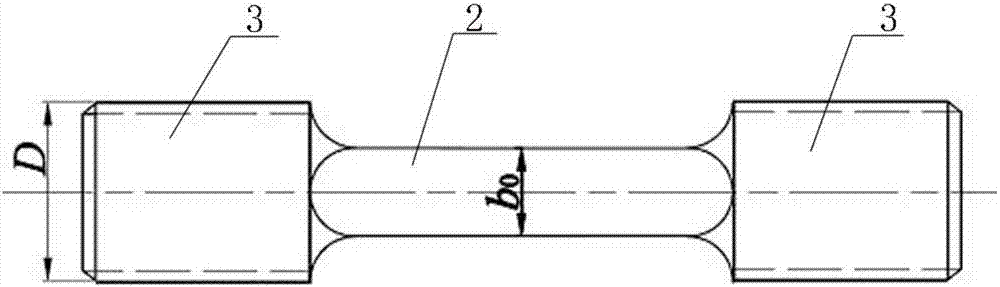

InactiveCN107132086ASolve fixed clamping problemsEasy alignmentPreparing sample for investigationGeneral purposeBasic dimension

The invention relates to a manufacturing method of a high-temperature tensile sample. The manufacturing method includes the steps of firstly, rounding is performed on the nominal diameter D of a threaded connecting section to allow the nominal diameter D to be close to an original sample width a0 and conform to the dimension value regulated in GB / T 196 General Purpose Metric Screw Threads Basic Dimensions; secondly, the original width b0 of a test section is determined, the cross section area of a high-temperature tensile sample clamp section is set as S1, and the cross section area of the test section is set as S0; b0m is not larger than 0.7854D1<2> / 1.1a0 under the requirement that S1 is not smaller than 1.1S0; the value, closest to the b0m, of b0 is taken and rounded off to 0.5mm; thirdly, the threaded connecting sections at two ends of the high-temperature tensile sample are machined into cylinders, and the original rectangular cross section of the middle test section is kept unchanged; fourthly, the threads of the threaded connecting sections at two ends of the high-temperature tensile sample are machined, and the major diameter dimension of the threads is D. The manufacturing method has the advantages that the coaxiality of the manufactured sample and a tensile testing machine and sample centering performance in the thickness direction can be increased, test result accuracy is guaranteed therefore, tensile test operation convenience is achieved, and test safety is increased.

Owner:ANGANG STEEL CO LTD

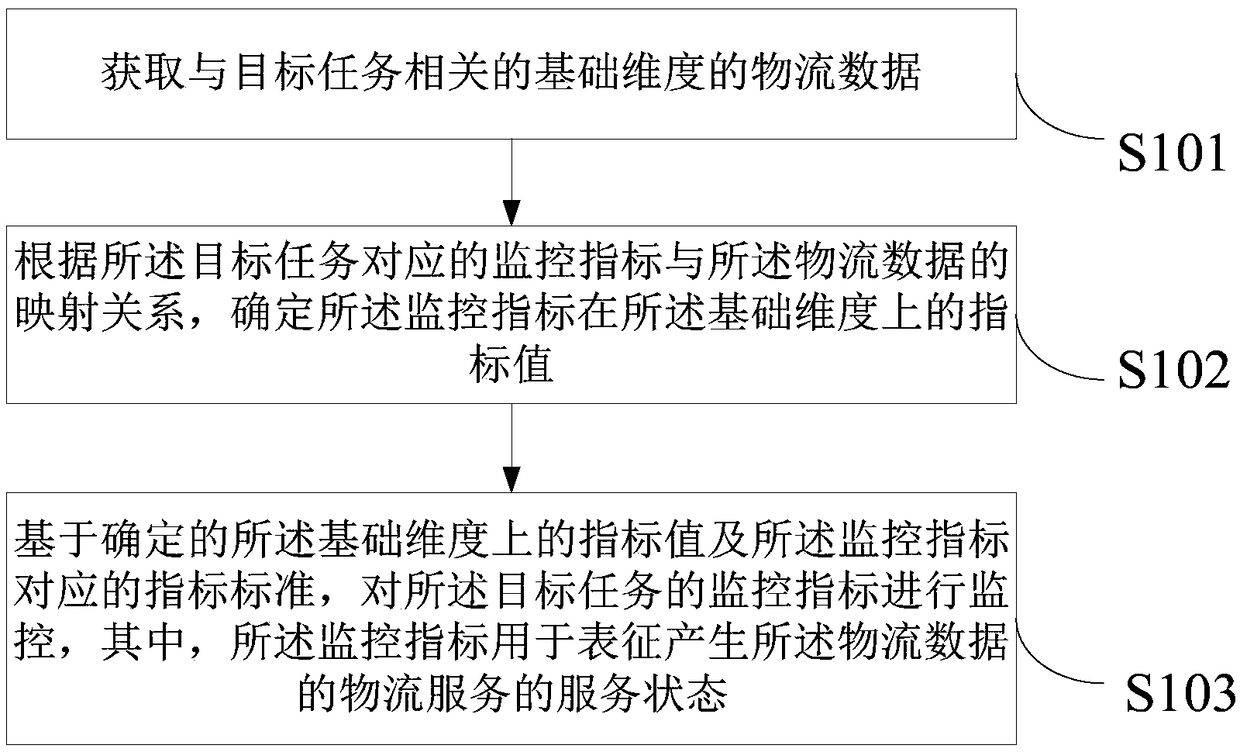

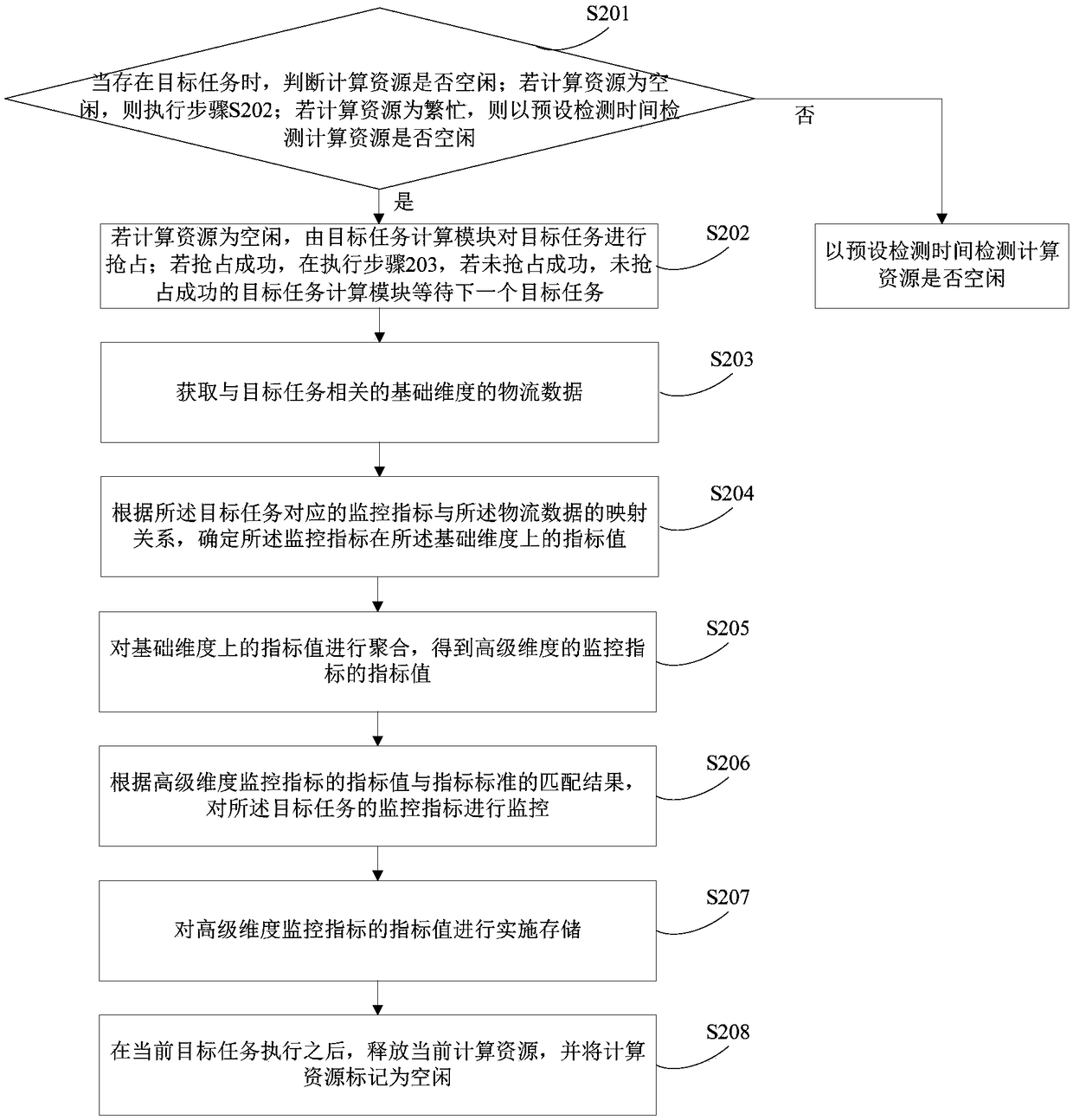

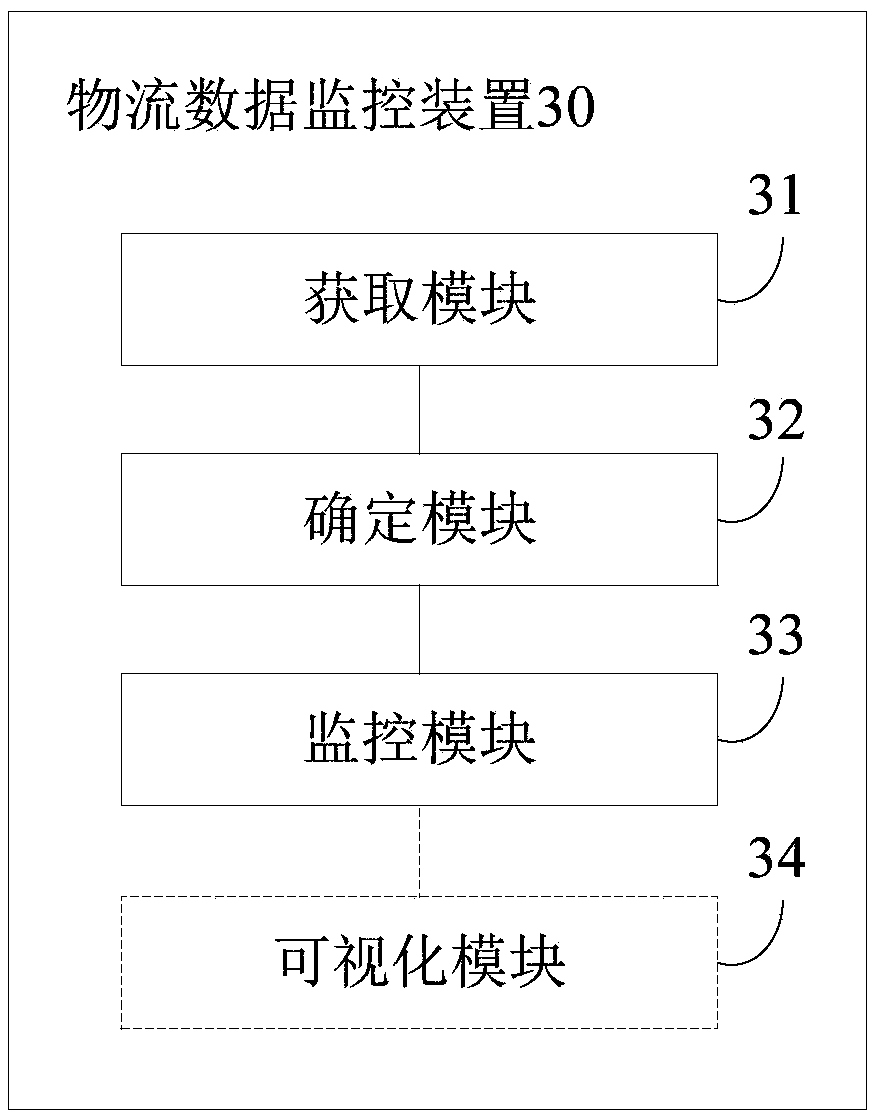

Logistics data monitoring method, device, electronic device and computer storage medium

InactiveCN109146381ATimely processingReal-time grasp of service statusDatabase distribution/replicationLogisticsBasic dimensionLogistics management

The present application provides a logistics data monitoring method, a device, an electronic device and a computer storage medium, wherein, the method includes: acquiring logistics data of a basic dimension related to a target task; determining an index value of the monitoring index on the basic dimension according to a mapping relationship between the monitoring index corresponding to the targettask and the logistics data; monitoring a monitoring index of the target task based on the determined index value on the basic dimension and an index standard corresponding to the monitoring index, wherein the monitoring index is used to characterize a service state of a logistics service that generates the logistics data. Embodiments of the present application can perform real-time monitoring ona large number of data related to logistics services in the same city by performing real-time processing on logistics data of a basic dimension and converting the logistics data into monitoring indicators, so as to improve the timeliness of logistics services in the same city.

Owner:BEIJING SHUNFENG TONGCHENG TECH CO LTD

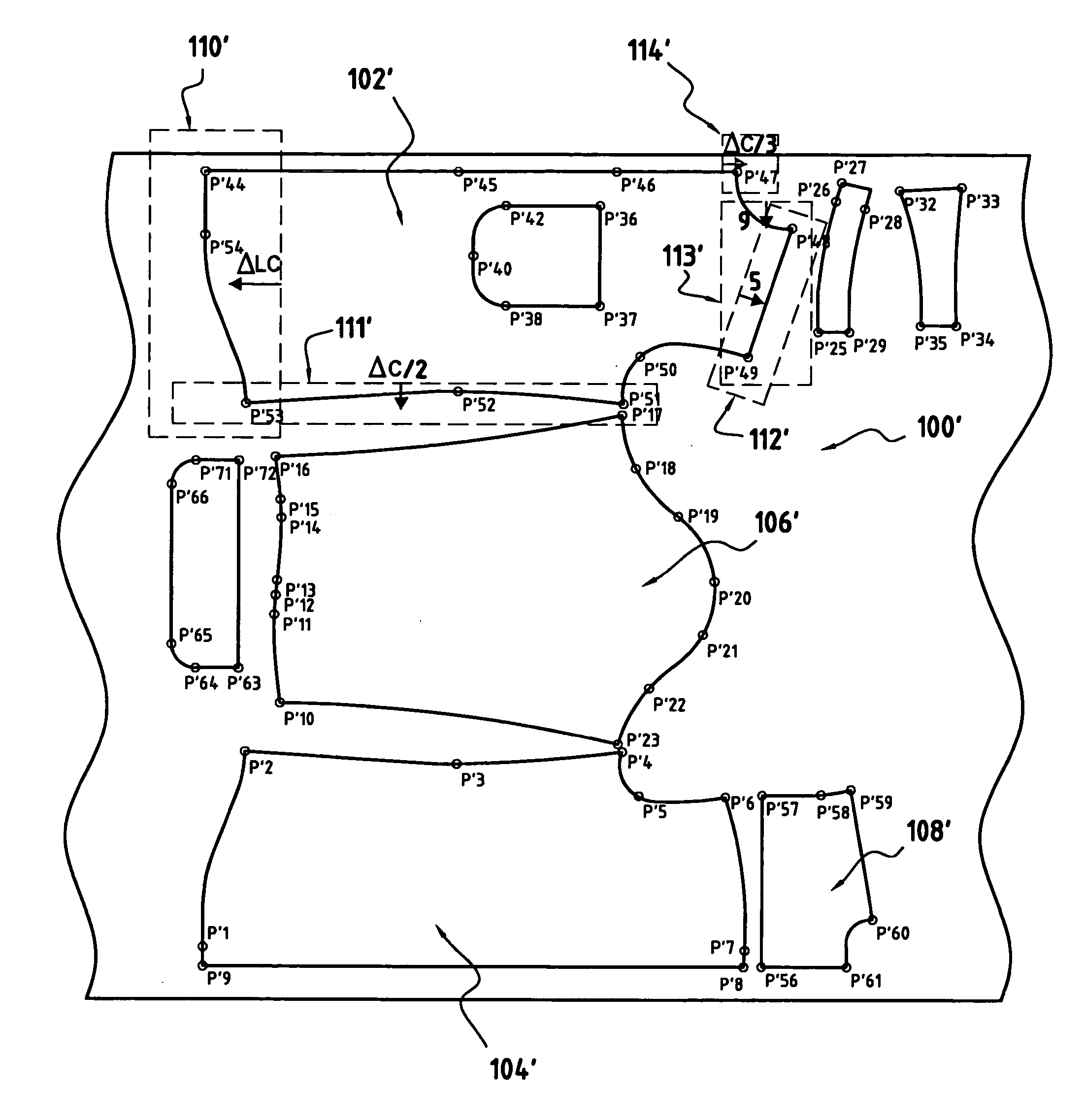

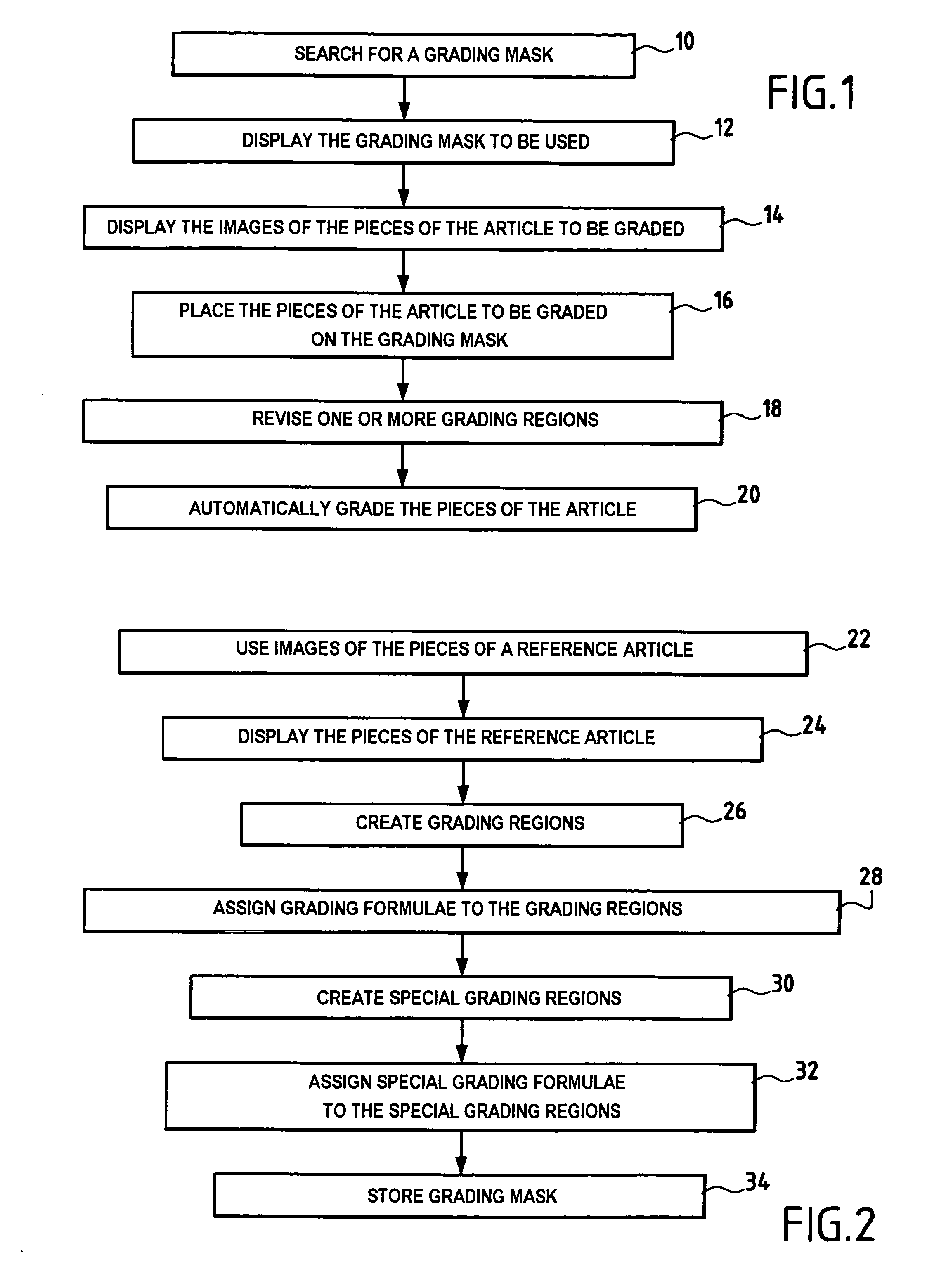

Method of automatically grading articles, in particular, garments

ActiveUS20070169358A1Easy to useSpecial data processing applicationsClothes making applicancesBasic dimensionComputer science

For an article of a given type, in particular a garment, a grading mask is used that has images of the pieces of a reference article, geometrical grading regions, each of which contains one or more characteristic points of a piece of the reference article, and grading formulae associated with respective ones of the various regions, each grading formula making it possible, in the associated grading region, and as a function of the variation in one or more magnitudes of a scale of measurements, or of a predetermined increment value, to determine a displacement to be applied to each characteristic point contained in said region for going from the base size to another size. Images of the pieces of the article to be graded for an article size corresponding to the base size of the grading mask are called up, said images are placed on the grading mask in positions corresponding to the positions of the pieces of the mask, and the pieces are graded automatically on the basis of the grading formulae of the mask and of a chosen scale of measurements.

Owner:LECTRA SA (FR)

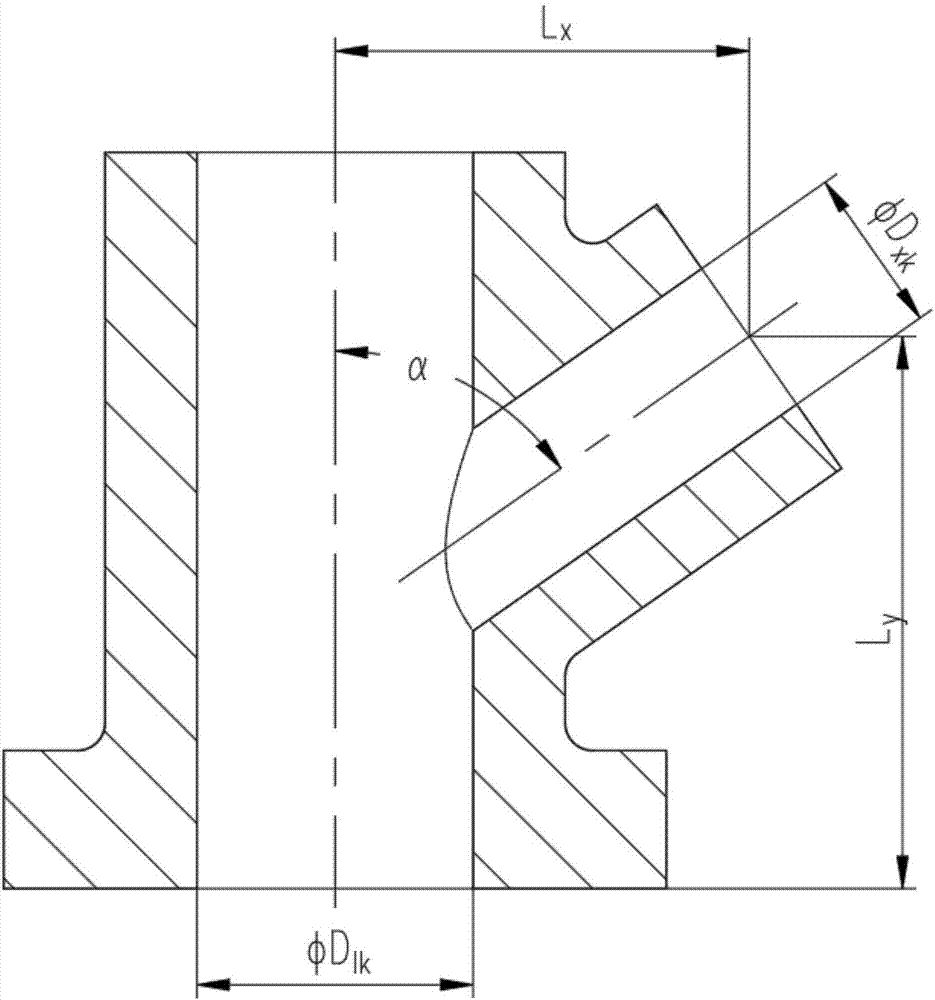

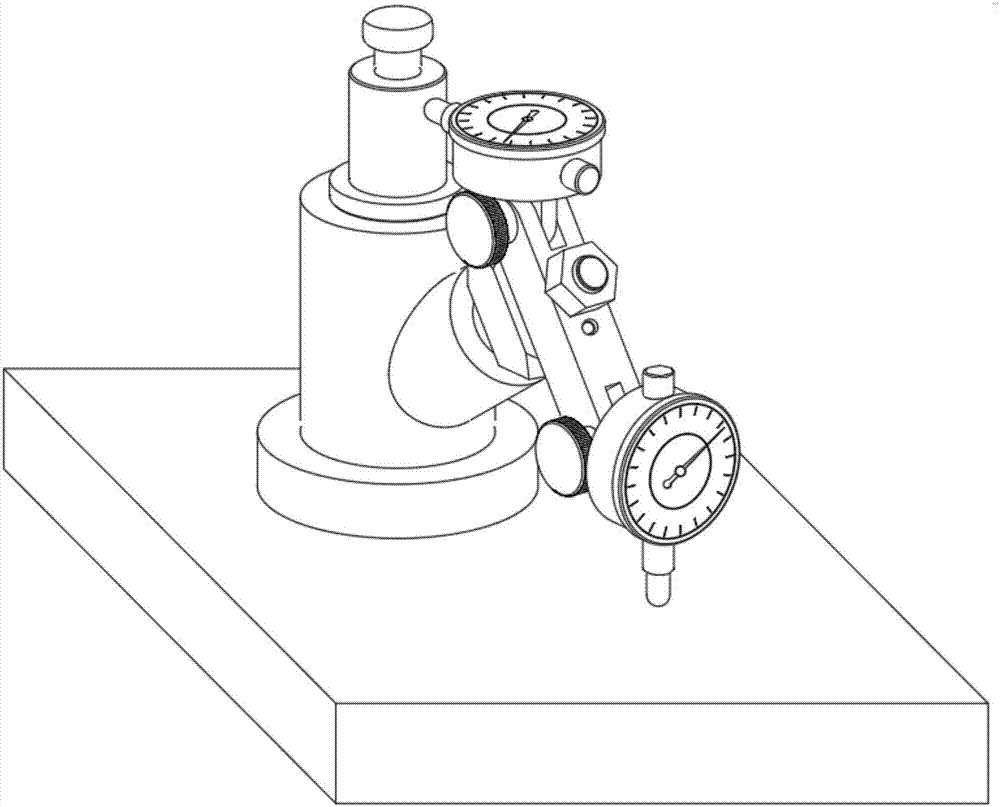

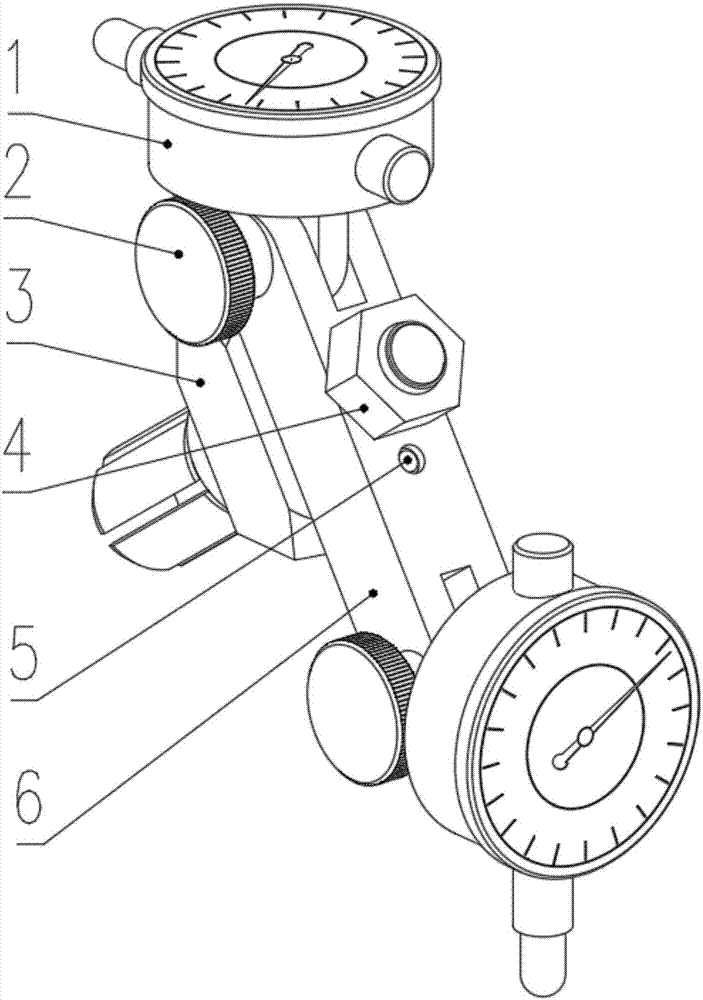

Device and method for measuring inclined hole position dimensions

ActiveCN107101550AMeasurement data is stableEasy to operateMechanical measuring arrangementsBasic dimensionMeasurement device

Owner:贵州凯星液力传动机械有限公司

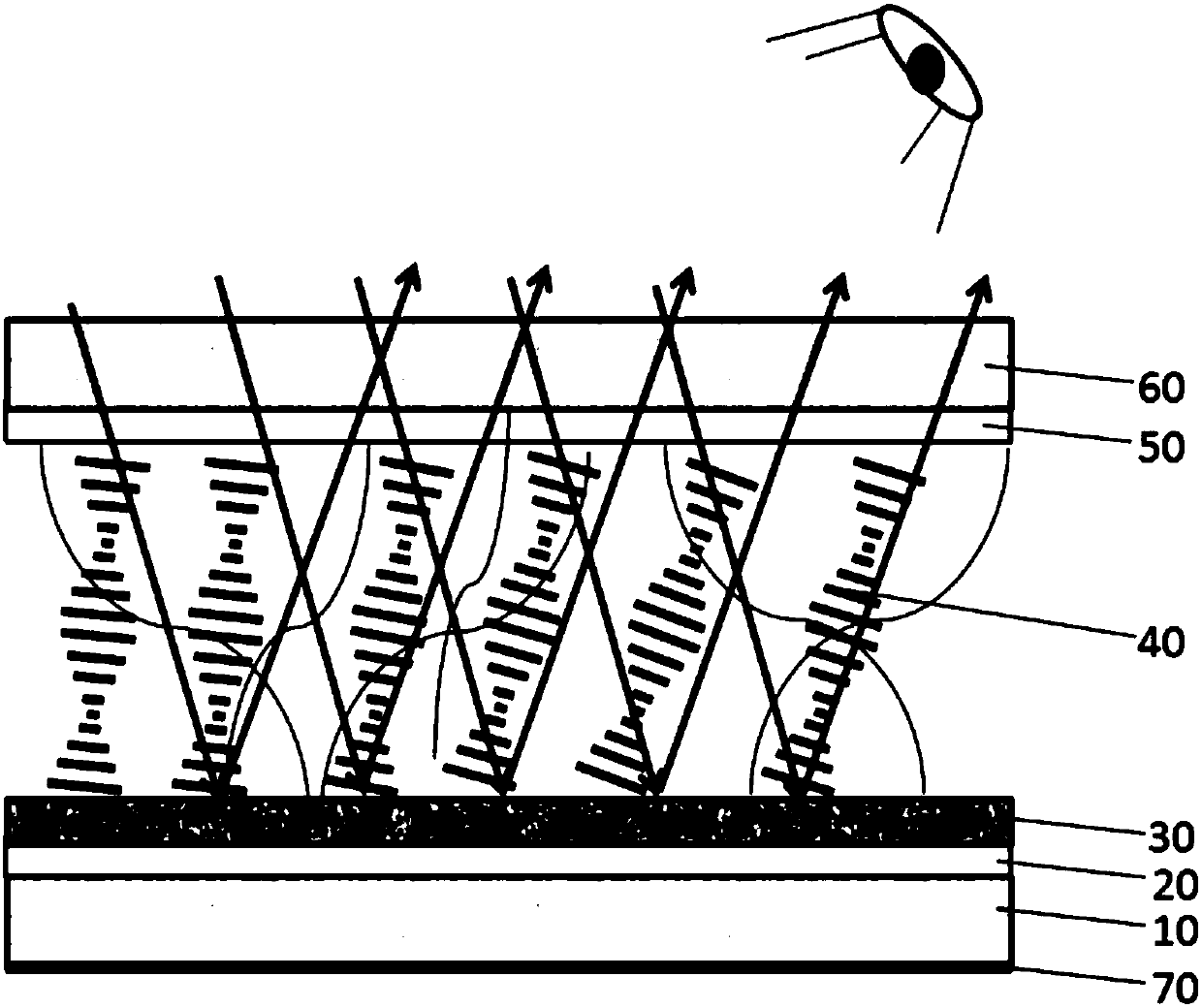

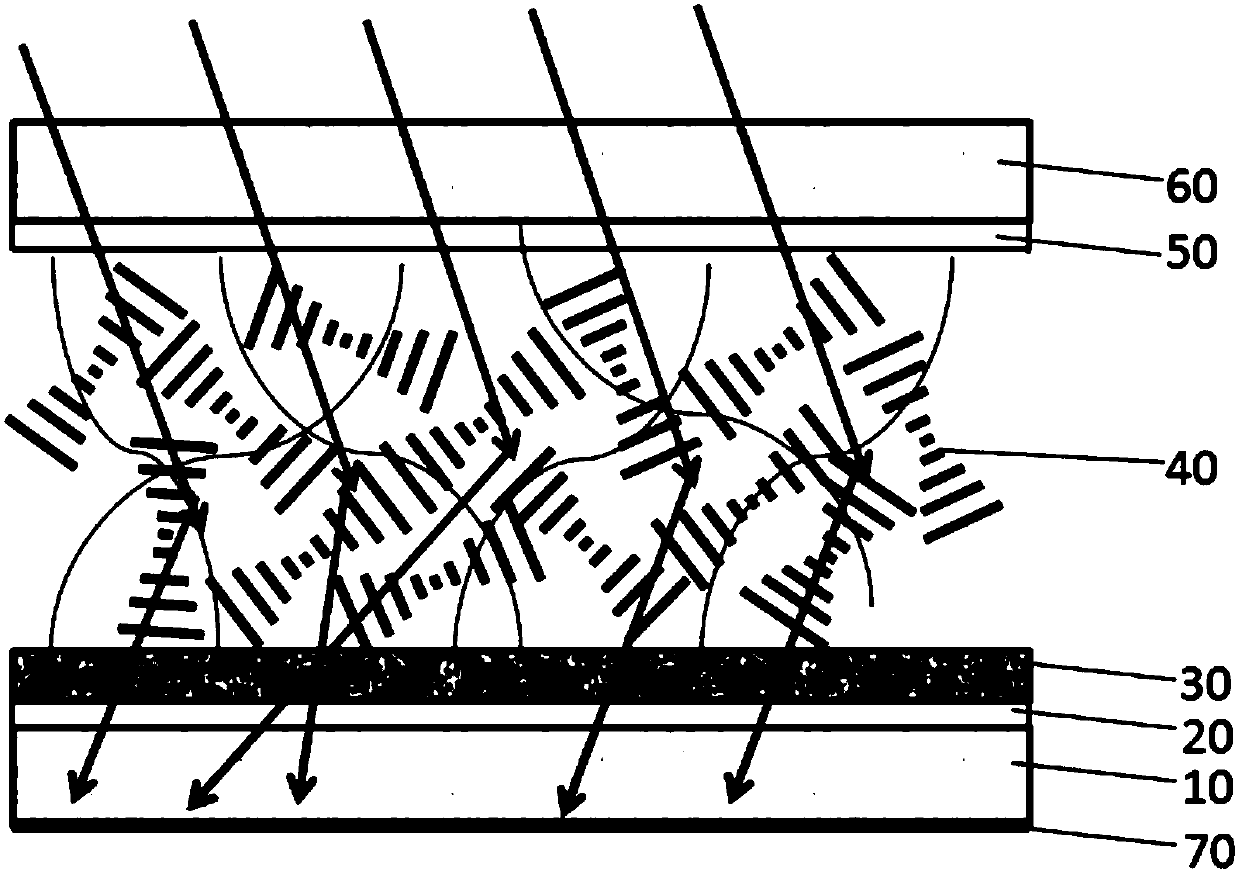

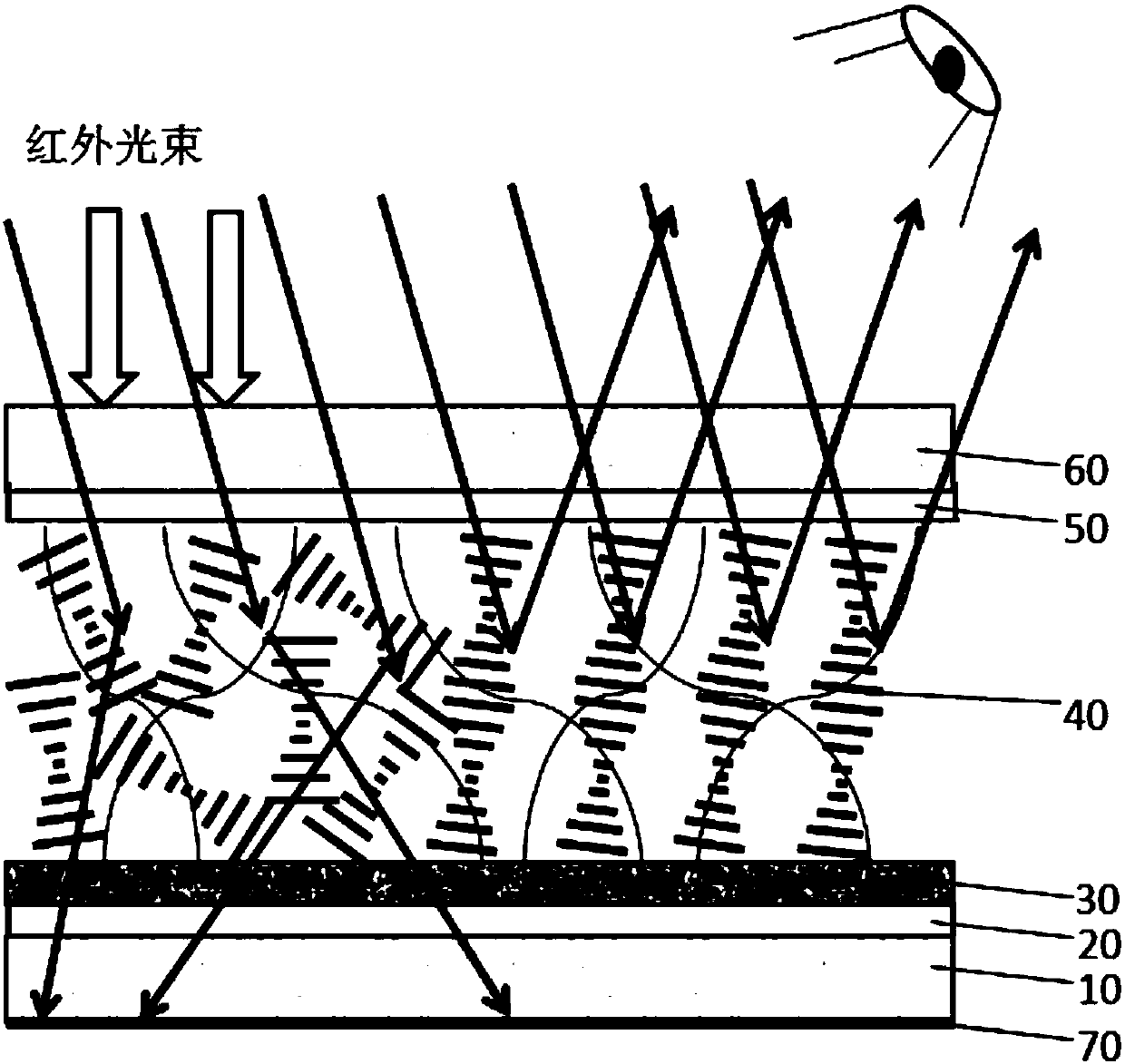

Partial erasing liquid-crystal handwriting board device and forming method thereof

ActiveCN109932834AFast implementation of partial erasurePartial Erase ImplementationNon-linear opticsInput/output processes for data processingInfraredBasic dimension

The invention discloses a partial erasing liquid-crystal handwriting board device and a forming method thereof. The partial erasing liquid-crystal handwriting board device comprises a liquid-crystal handwriting board and an erasing pen. The liquid-crystal handwriting board includes a substrate, a first conductive layer, an infrared absorbing material layer, a liquid crystal layer, a second conductive layer, and a flexible transparent substrate. The first conductive layer and the infrared absorbing material layer are arranged on the substrate in a basic dimension consistence manner. The first conductive layer and the second conductive layer are transparent conductive layers; the second conductive layer is formed on the flexible transparent substrate; and the substrate and the flexible transparent substrate jointly clamp the liquid crystal layer to form a liquid crystal box of the liquid-crystal handwriting board. The erasing pen includes an infrared emitting light source and a control switch. According to the partial erasing liquid-crystal handwriting board device, the partial erasing is realized by means of non-contact photothermal conversion; the erasing efficiency is high; the device is convenient to use; and energy-saving and low-cost effects are realized.

Owner:JIANGSU JICUI INTELLIGENT LCD TECH CO LTD

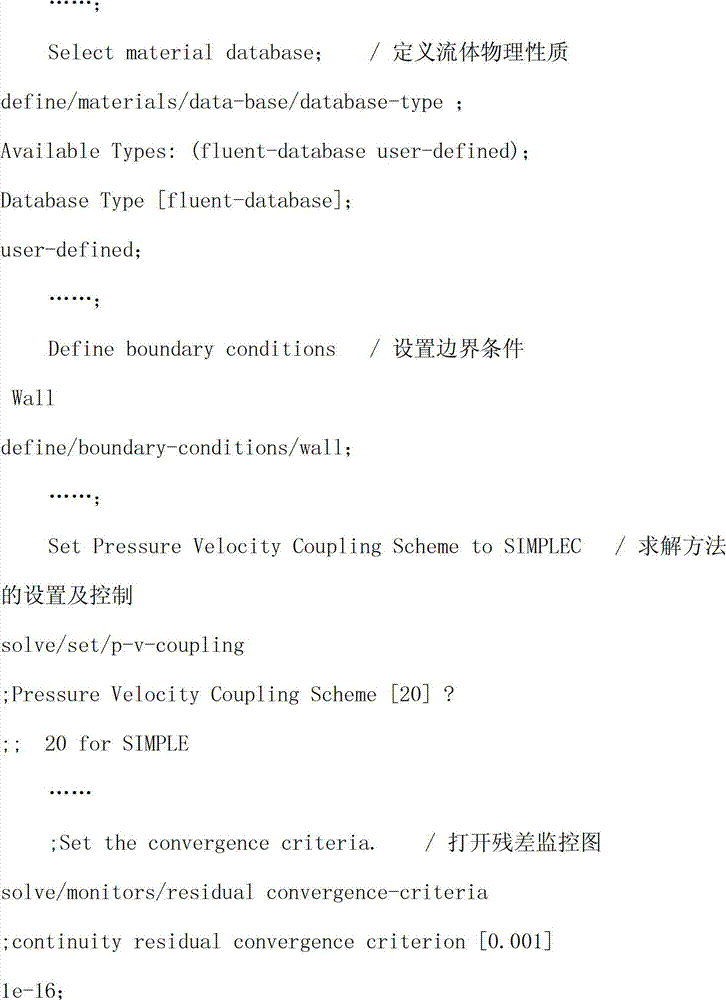

Method for optimally designing powder spray room based on fluent software

The invention provides a method for optimally designing a powder spray room based on fluent software, which comprises the following steps of: calculating the basic dimensions of the powder spray room according to field conditions, preliminarily determining the position of each input and outlet according to experience, and parameterizing the position; compiling the parametric input interface of the powder spray room by using VB (Visual Basic), inputting the parameters obtained in the calculation, and further generating APDL (ANSYS Parameter Design Language) codes; calling the batch program of ANSYS by using VB and generating APDL codes to perform mesh generation on a created powder spray room model, and generating a CBD format file; reading the CBD format file by the Fluent software, and simulating the model in an analogue way; and modifying the parameter model according to the analogue simulation result, and repeating the above steps until an optimal result is obtained. The method has the advantages that because the powder spray room is simulated in an analogue way by using the technical scheme, each parameter of the powder spray room is adjusted according to the simulation result, and the analogue simulation is repeated for many times until one optimal design of the powder spray room is obtained.

Owner:天津七所高科技有限公司

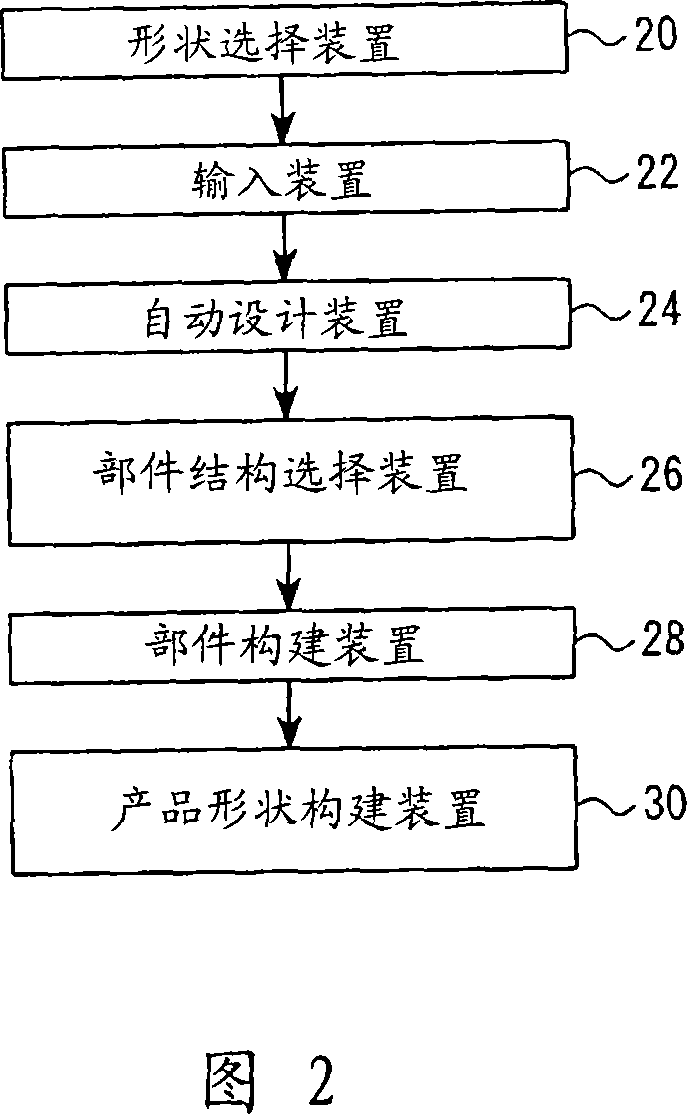

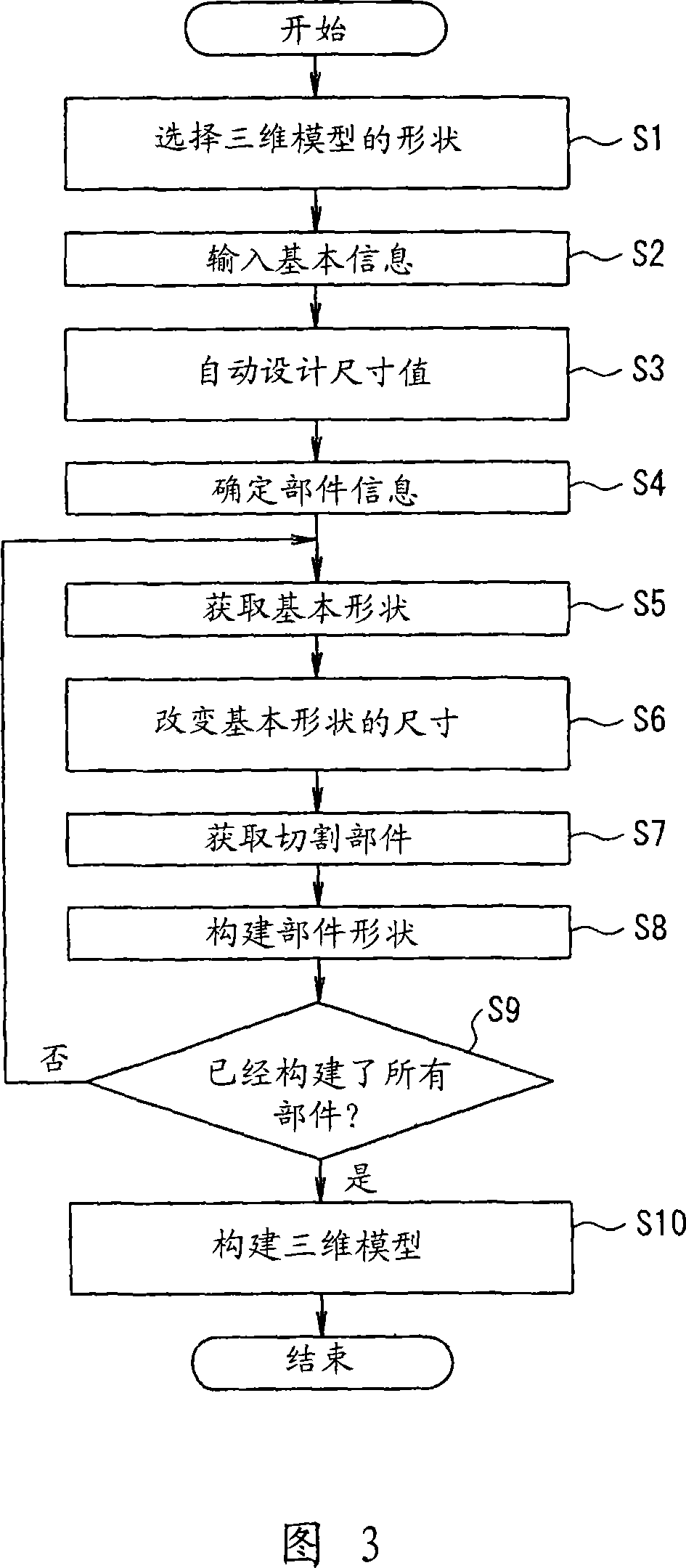

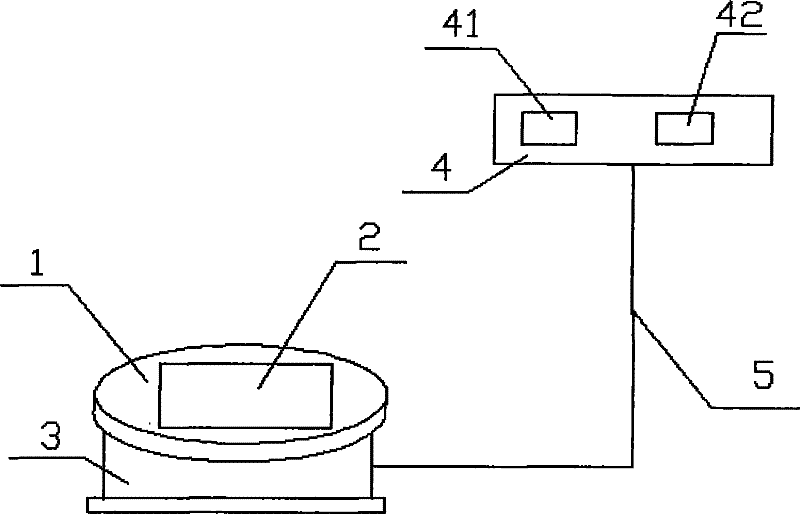

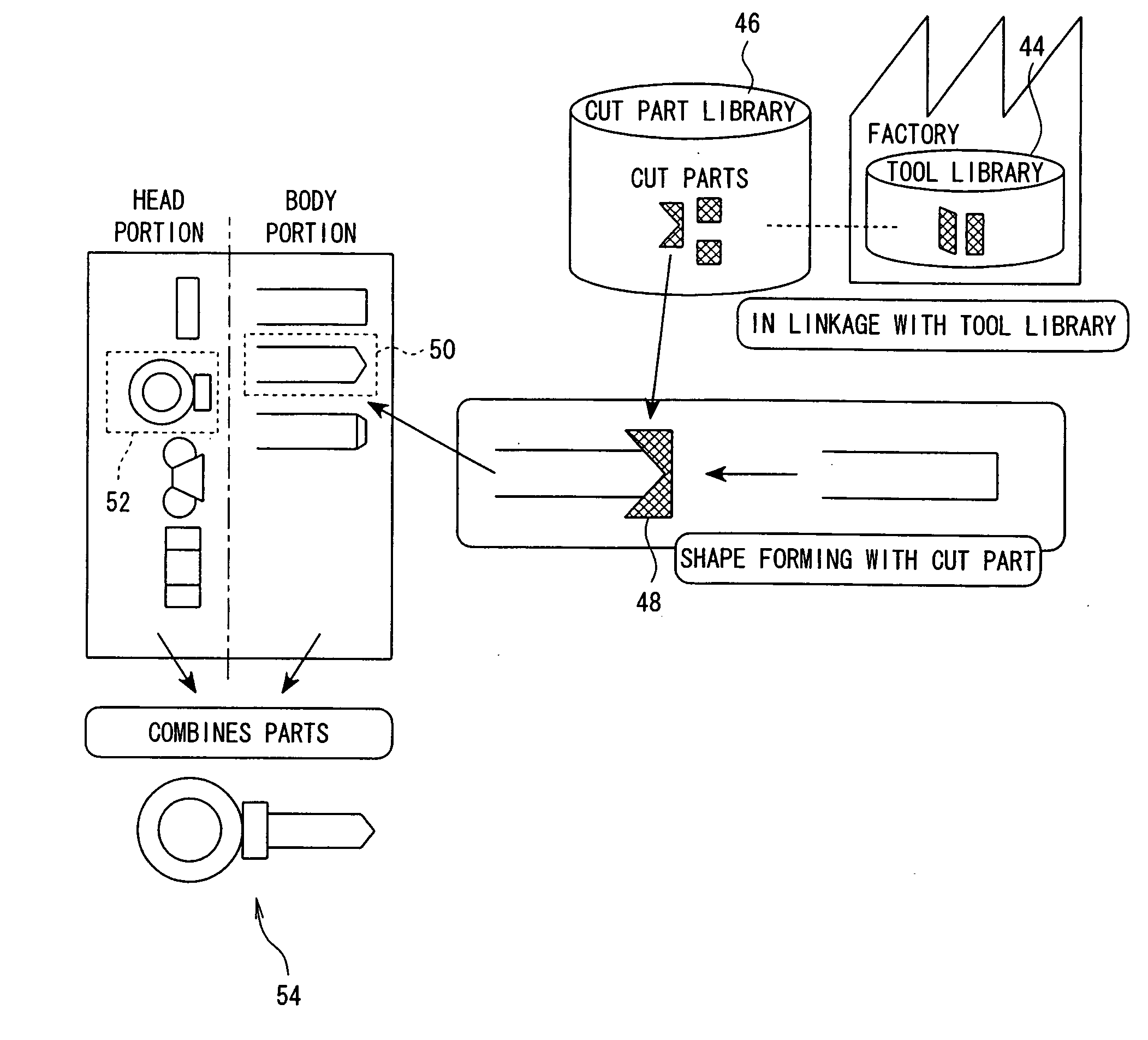

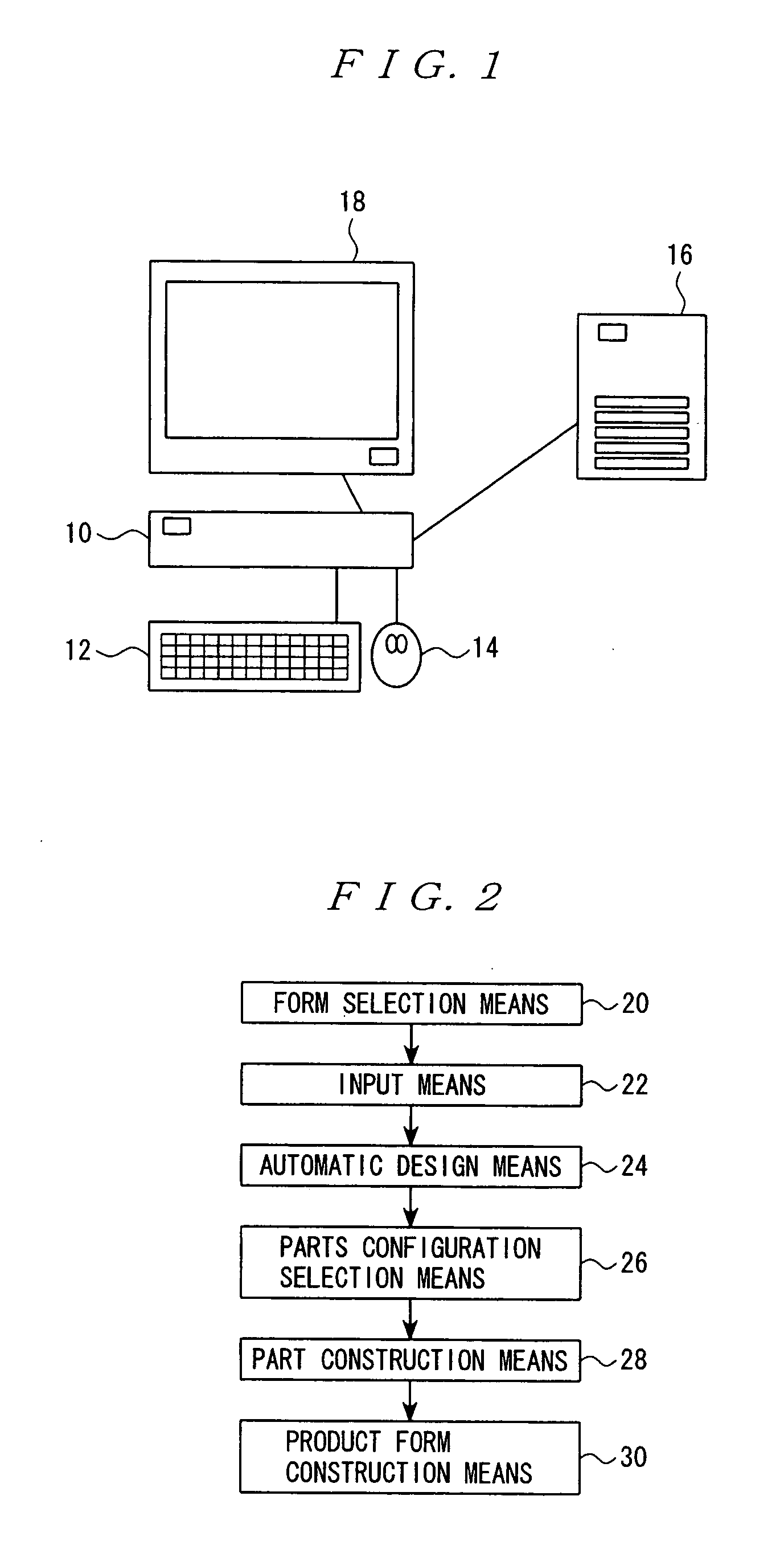

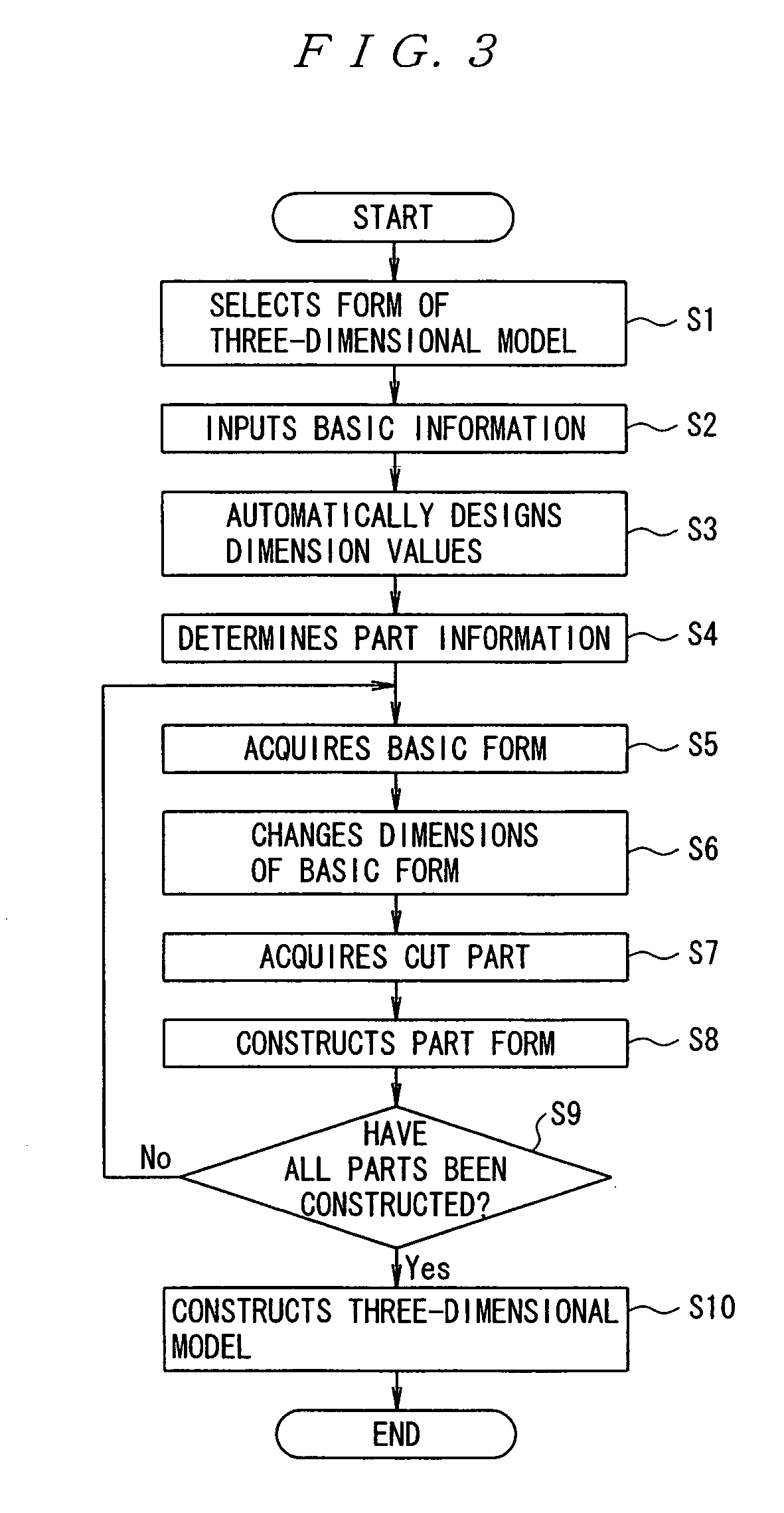

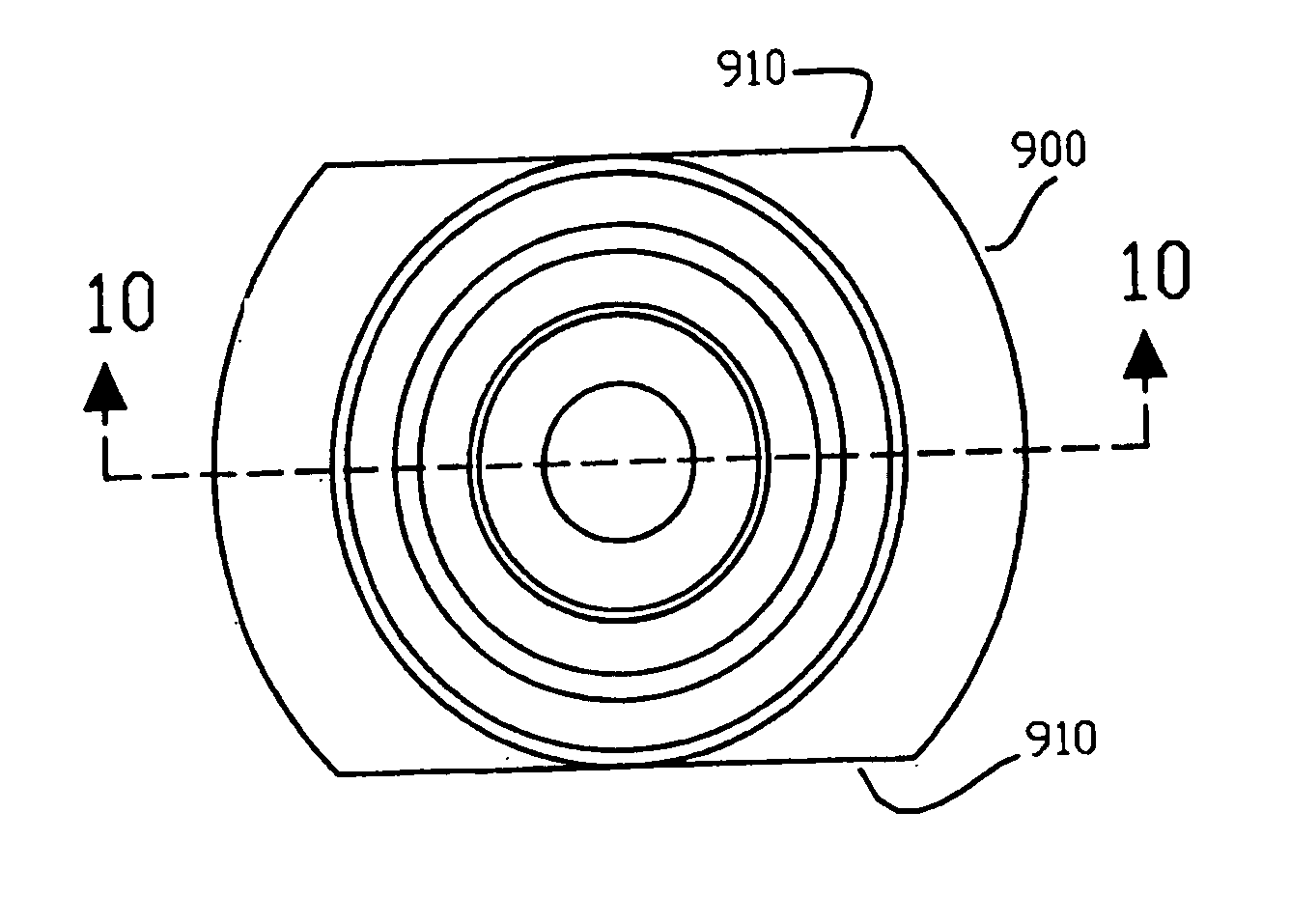

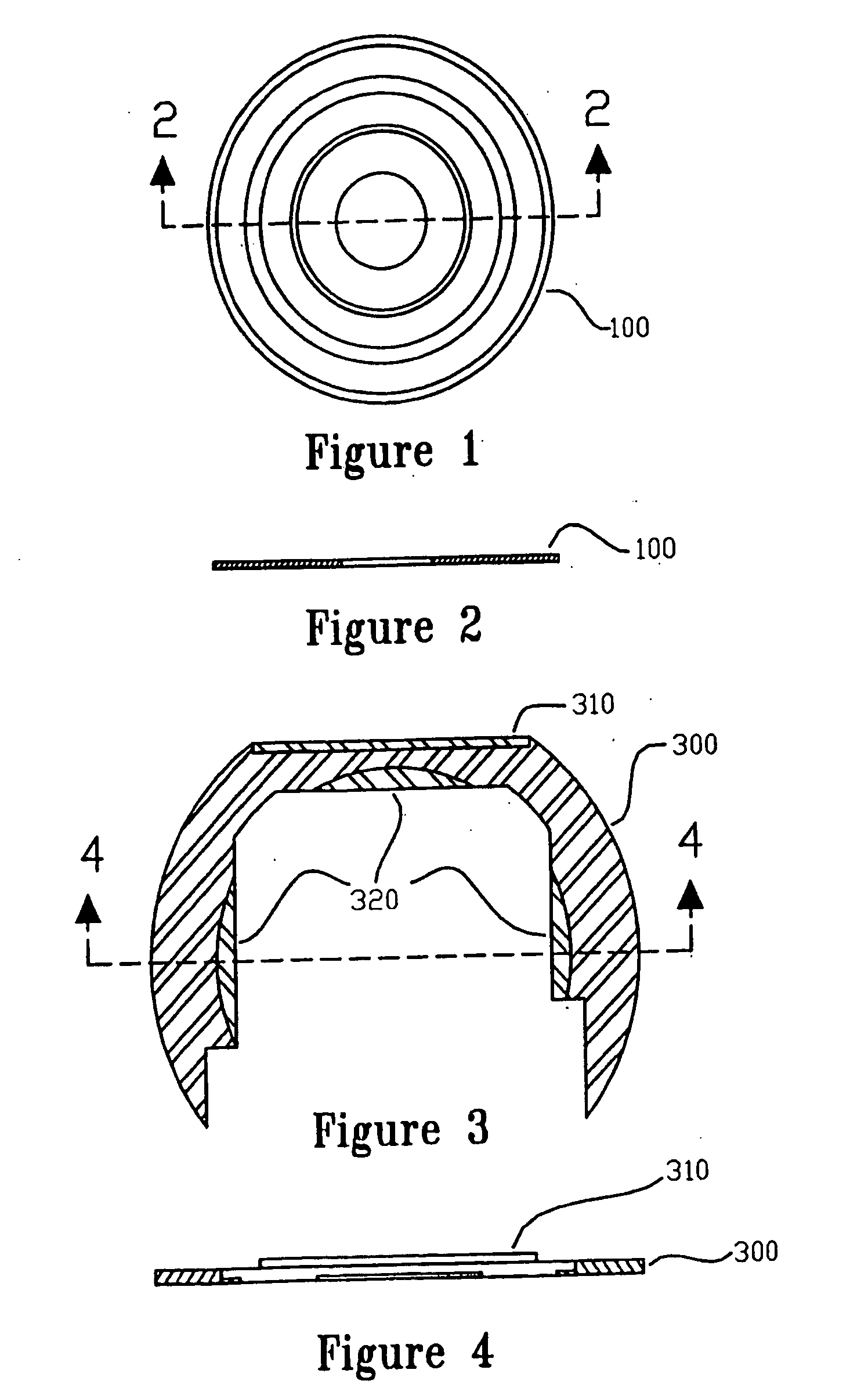

Automatic construction system for three dimensional model

To efficiently construct a three-dimensional model. A product is divided into two parts of a head portion and a neck portion. A head form 34 and a neck form 36 are selected as forms of a three-dimensional model. The basic dimensions of each part are inputted to calculate dimension values of each part, and a combination of a basic form and a cut part is selected in accordance with a table 38 . If it is necessary to change the basic form of the neck form 36 , the dimensions of a basic-form model 40 are changed to construct a model 42 . Furthermore, a cut part 48 is selected, and the model 42 is processed to construct a model 50 . Then, by combining a head-form model 52 and the neck-form model 50 , a three-dimensional model 54 of a bolt is constructed.

Owner:NSK LTD

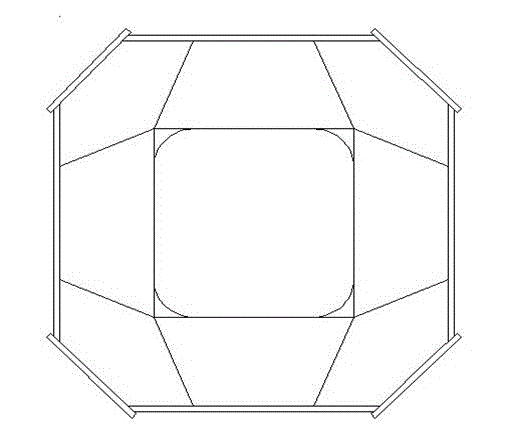

Hole system position determining method for cylinder body of engine

InactiveCN108280307AImprove efficiencyImprove accuracyGeometric CADDrawing from basic elementsBasic dimensionEngineering

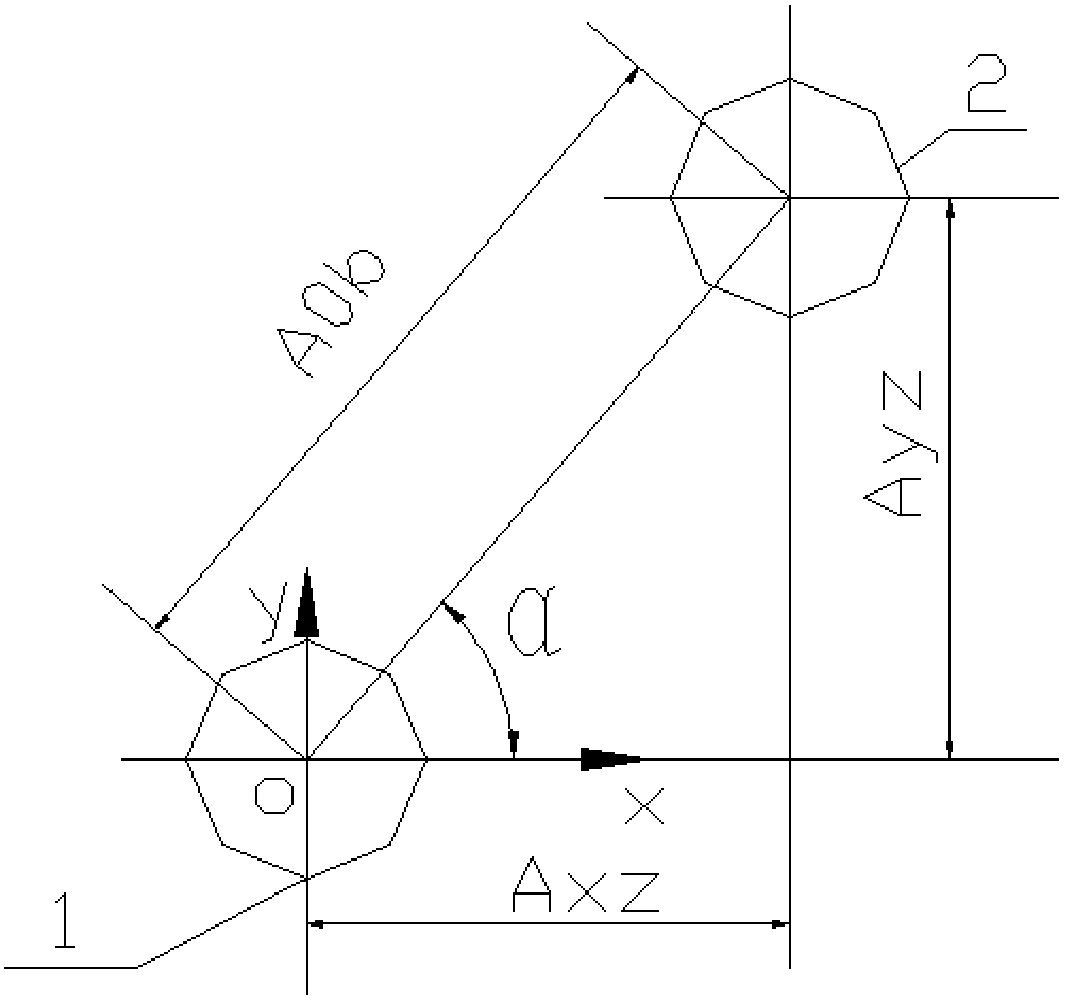

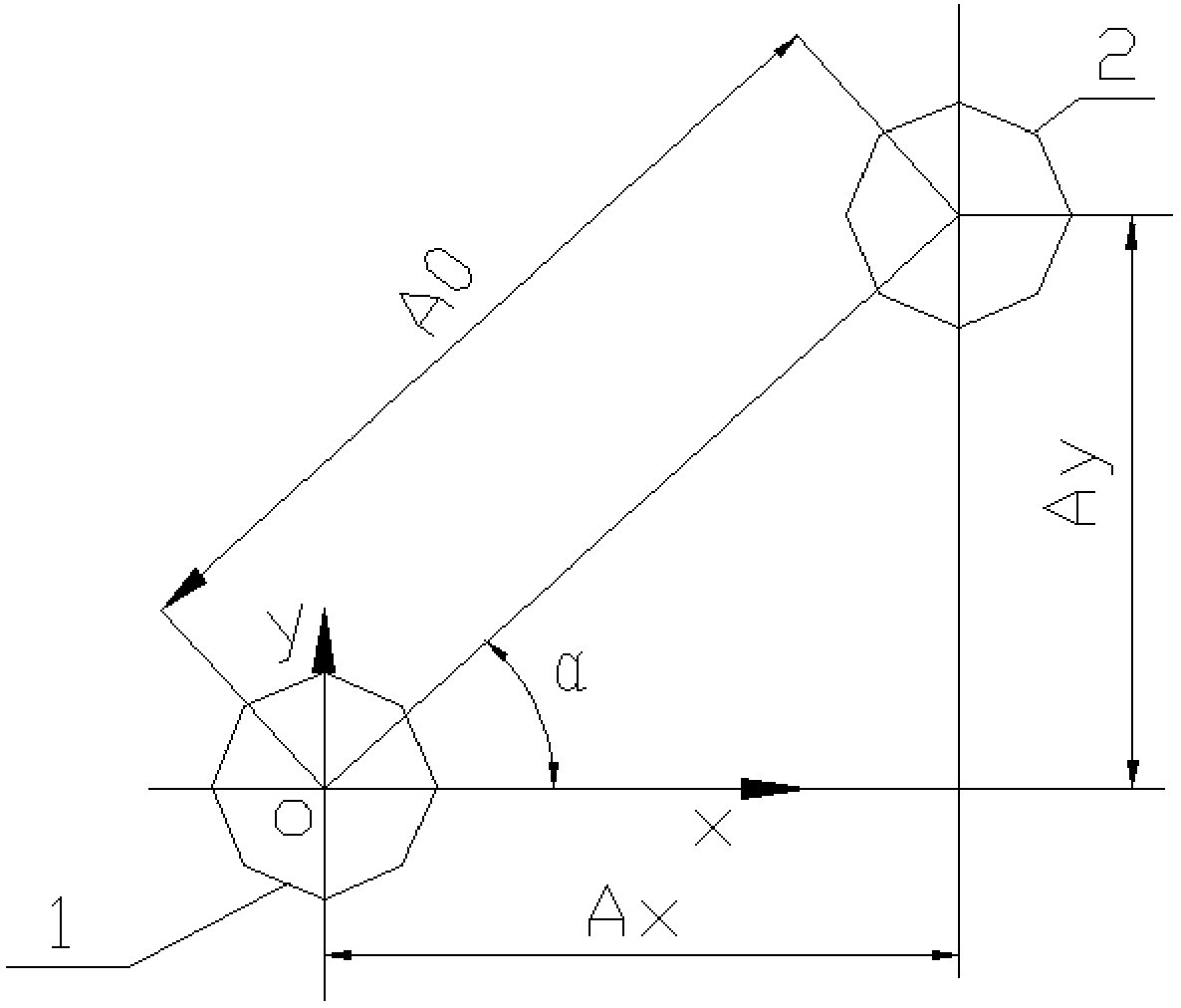

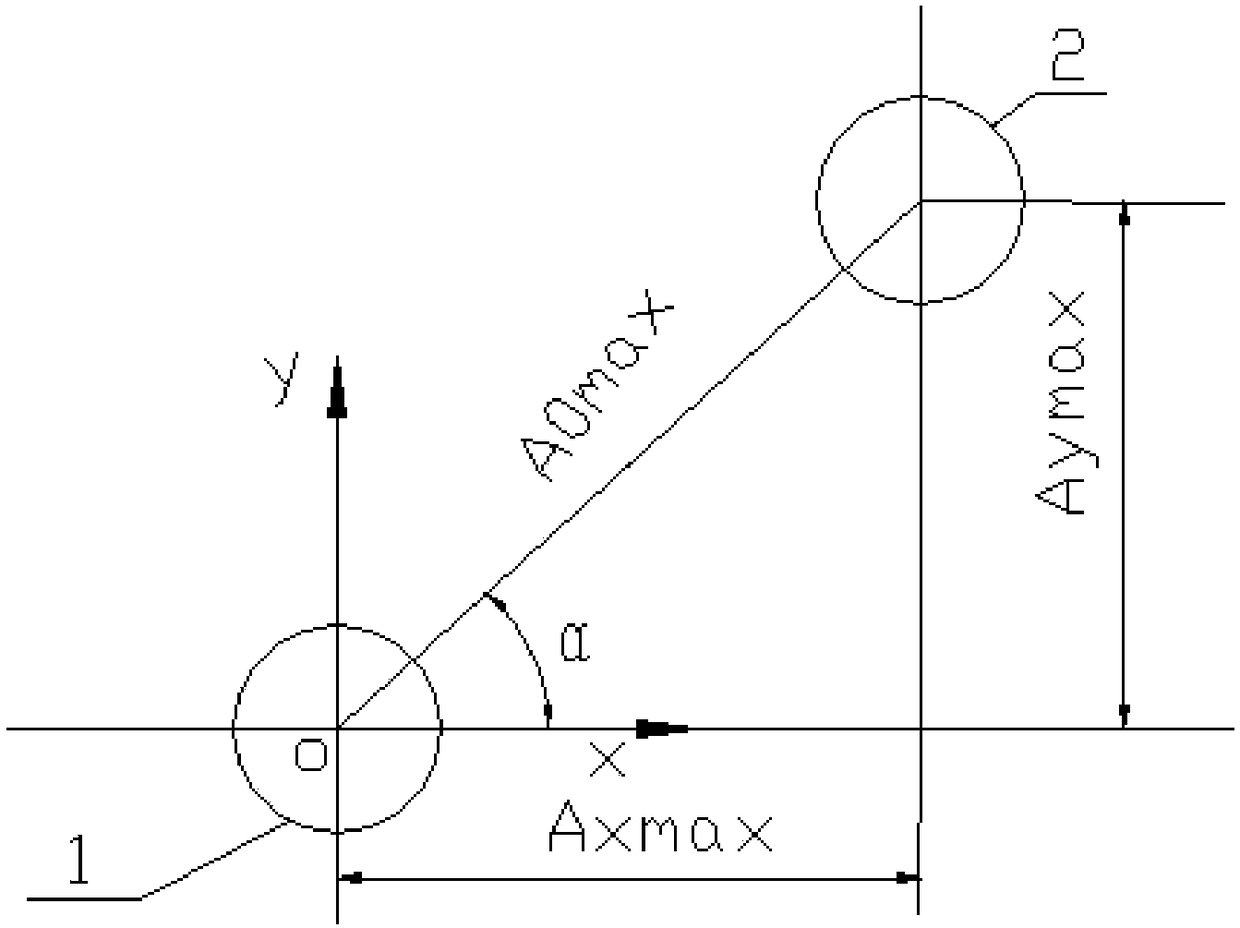

The embodiment of the invention provides a hole system position determining method for a cylinder body of an engine. The method comprises the steps of simulating hole system machining and a hole system position determining process, determining a relationship between hole system position coordinates and a hole center distance dimension, establishing a dimension-chain two-dimensional model of the relationship between the hole system position coordinates and the hole center distance dimension, and determining a closed ring; designing the dimension of the closed ring and the position of a reference hole, and establishing a two-dimensional model of the hole system machining position coordinates; obtaining the dimensions of the hole system machining position coordinates according to the two-dimensional model of the hole system machining position coordinates. According to the method, by establishing the two-dimensional model of the hole system machining position coordinates, the basic dimension, maximum limit dimension and minimum limit dimension of the machining position coordinates of a hole system can be visually and accurately presented. By establishing the dimension-chain two-dimensional model, determining the closed ring, based on the design of the closed ring and the reference hole, the two-dimensional model of the hole system machining position coordinates is established, andthe efficiency and accuracy of designing the dimensions of the hole system machining position coordinates can be improved.

Owner:XIAMEN UNIV OF TECH

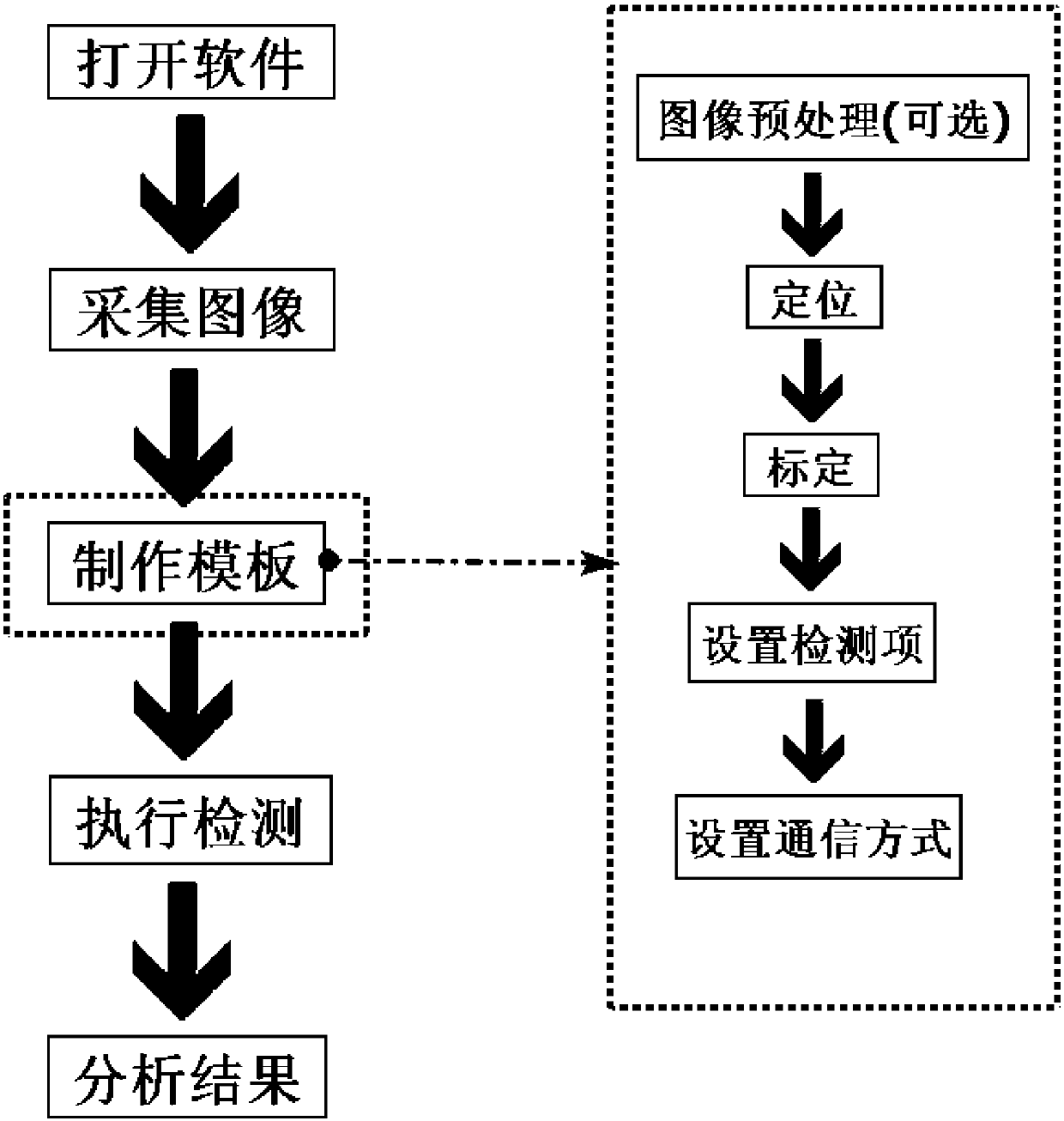

Visual inspection system of mixing defect of product

InactiveCN107622486AQuick buildEasy to operateImage analysisInput/output processes for data processingBasic dimensionVisual inspection

The invention discloses a visual inspection system of a mixing defect of a product. The system is composed of a presentation layer, a logic layer and a data layer in an organic manner. In addition, according to a visual inspection system of a mixing defect of a product, several kinds of detection operators are integrated; and characteristics of different products are determined by several kinds ofmethods, so that an objective of distinguishing mixing products is achieved. The software provides a user interface using an image as a center and a dragging type interaction way, so that a simple and high-efficiency working flow is provided for the user. Therefore, the system complexity is simplified and the technical requirement of the operator is reduced. The system is integrated with many measurement operators to realize functions of camera calibration, basic dimension measurement, character existence detection character, and soldering tin and the like.

Owner:陕西维视数字图像技术有限公司

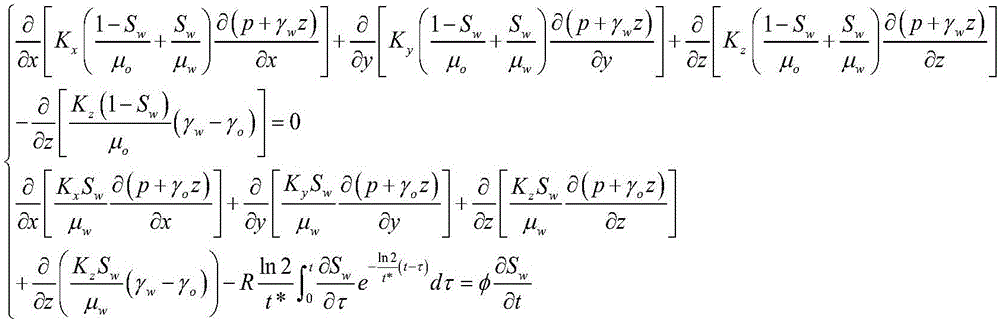

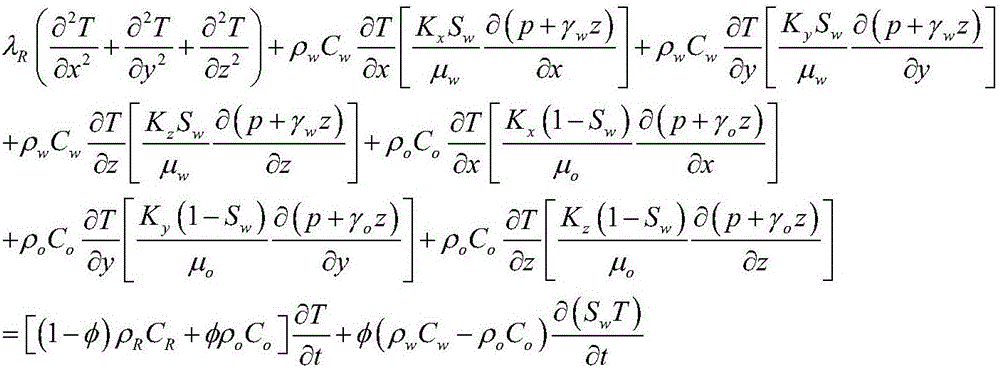

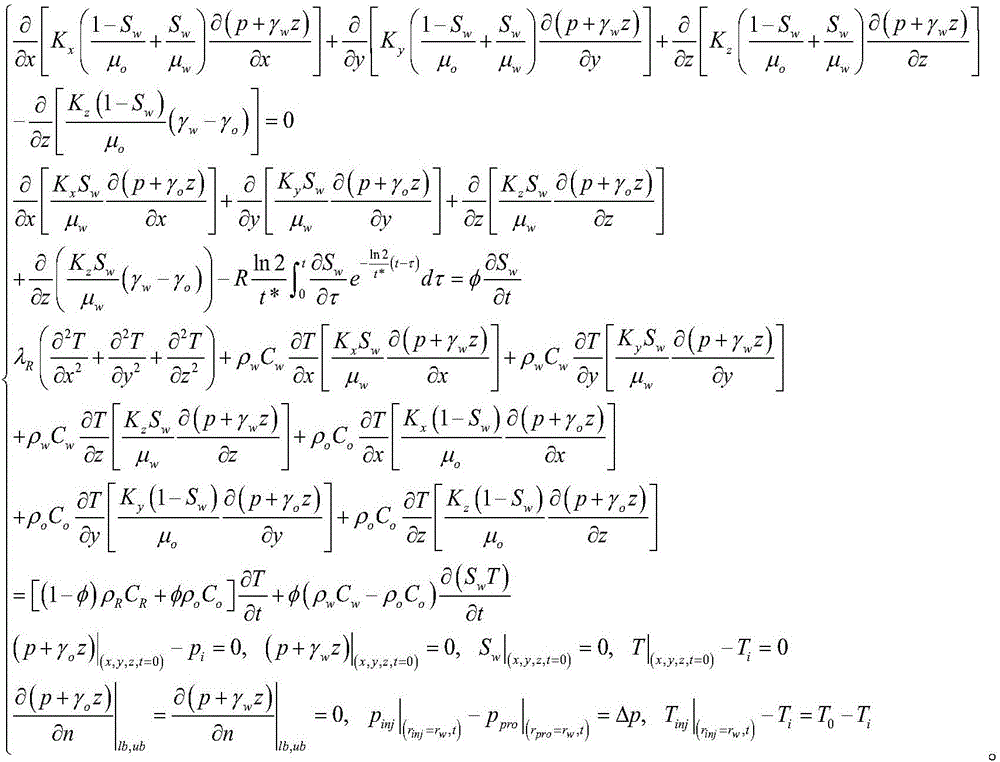

Determination method of hot-water drive physical simulation similarity criterion of fracture thickened oil deposit

The invention relates to a determination method of hot-water drive physical simulation similarity criterion of fracture thickened oil deposit. The determination method includes steps of 1) establishing basic assumption conditions according to hot-water drive seepage of fracture thickened oil deposit; 2) establishing a hot-water drive mathematical model of fracture thickened oil deposit according to the material balance equation and the energy balance equation in fracture and pressure, initial temperature and internal and external boundary conditions; 3) non-dimensionalizing relevant variables in the hot-water drive mathematical model of fracture thickened oil deposit, and simplifying the non-dimensionalized mathematical model of fracture thickened oil deposit; 4) listing physical variables in the hot-water drive mathematical model and the hot-water drive non-dimensionalized mathematical model of fracture thickened oil deposit; 5) listing basic dimensions included in all physical variables of step 4); 6) acquiring similarity criterion combined with analysis of Pi theory and similarity theory according to the hot-water drive non-dimensionalized mathematical model of fracture thickened oil deposit.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method and system for making tailored garments

ActiveUS9642408B2Quick and easy mannerSize quickly and easilyProgramme-controlled sewing machinesSpecial data processing applicationsBasic dimensionEngineering

A method for allowing a user to make a tailored garment (M) comprises the following steps: preparing at least one image (I) comprising a sample garment (C) of the same type as the tailored garment (M) to be made and also comprising a reference object (O) with actual standardized dimensions (M7,M8); measuring on the at least one image (I) the dimensions of the reference object (O) and a set of basic dimensions (M1,M2,M3,M4,M5,M6) of the sample garment (C); calculating the actual dimensional values of the set of basic dimensions of the sample garment (C) as a function of: the dimensional values of the set of basic dimensions (M1,M2,M3,M4,M5,M6) of the sample garment (C) measured on the image (I), the dimensional values of the reference object (O) and the actual dimensions (M7,M8) of the reference object (O); selecting the aesthetic features of the tailored garment (M) to be made; transmitting to a tailoring apparatus (4) the calculated actual dimensional values of the set of basic dimensions of the sample garment (C) and the selected aesthetic features; performing on the tailoring apparatus (4) a sequence of operations of cutting and sewing the tailored garment (M), to make the tailored garment (M) so its basic dimensions are substantially equal to the previously calculated actual dimensional values of the set of basic dimensions of the sample garment (C).

Owner:IN PRO DI INGHIRAMI PRODUZIONE DISTRIBUZIONE

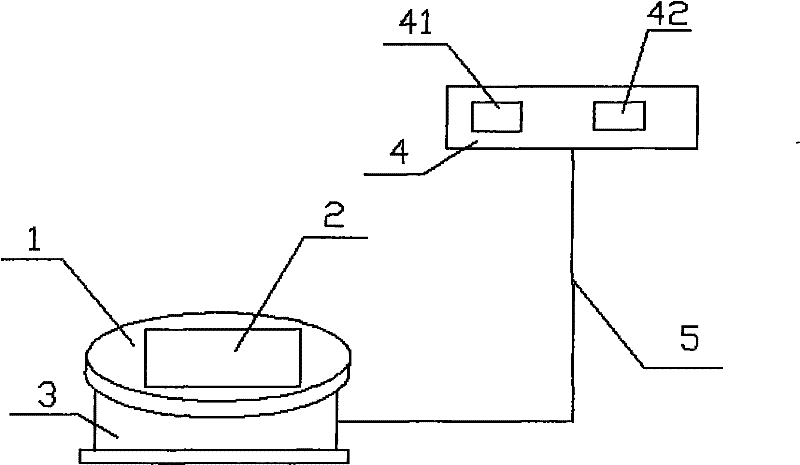

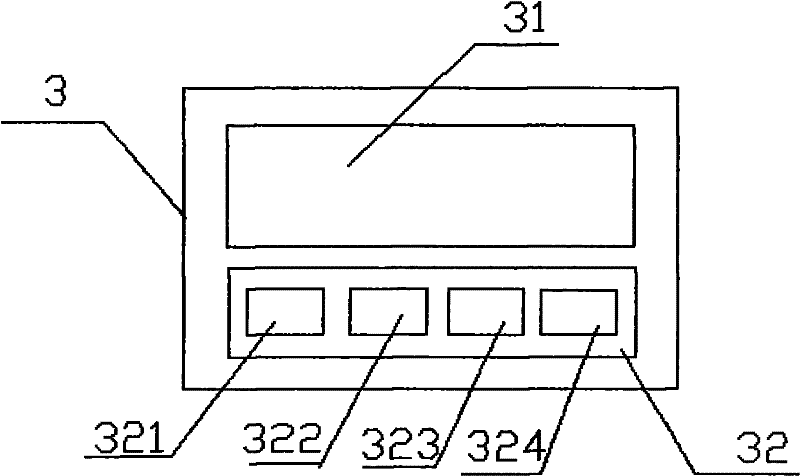

Intelligent foot sole measuring instrument for scanning measurement

InactiveCN102188075AEasy to useProfessionalFoot measurement devicesDiagnostic recording/measuringBasic dimensionData display

The invention discloses an intelligent foot sole measuring instrument for scanning measurement. The intelligent foot sole measuring instrument for scanning measurement comprises a measuring device and a data processing device, wherein the measuring device comprises a test desk and a scanner arranged under the test desk, and the scanner scans the shape of a foot sole in a noncontact mode through a scanning window formed on the test desk; the data processing device comprises a data acquisition module, a data processing module, a data display module and a data printing module; the parameters of the data acquisition comprise the length and width of a foot, the length of a foot arch, and the status of the foot sole; and the data processing device is connected with a terminal device of the measuring instrument. The measuring instrument analyzes scanned foot soles, and accurately and quickly measures basic dimension data of the foot soles so as to be matched with sold products; and the measuring instrument analyzes the health condition of feet, gives pertinent description prompts, and records and prints related content, so that the accurate market information is provided for enterprises, and the competitiveness of the products is improved. The measuring instrument is easy to operate, provides accurate data, and can greatly improve the efficiency.

Owner:金广华

Automatic Three-Dimensional Model Construction System

InactiveUS20080281452A1Efficient constructionExtension of timeComputer aided designSpecial data processing applicationsBasic dimensionEngineering

To efficiently construct a three-dimensional model. A product is divided into two parts of a head portion and a neck portion. A head form 34 and a neck form 36 are selected as forms of a three-dimensional model. The basic dimensions of each part are inputted to calculate dimension values of each part, and a combination of a basic form and a cut part is selected in accordance with a table 38. If it is necessary to change the basic form of the neck form 36, the dimensions of a basic-form model 40 are changed to construct a model 42. Furthermore, a cut part 48 is selected, and the model 42 is processed to construct a model 50. Then, by combining a head-form model 52 and the neck-form model 50, a three-dimensional model 54 of a bolt is constructed.

Owner:NSK LTD

Method and system for square object mode transformation of two-dimensional caption

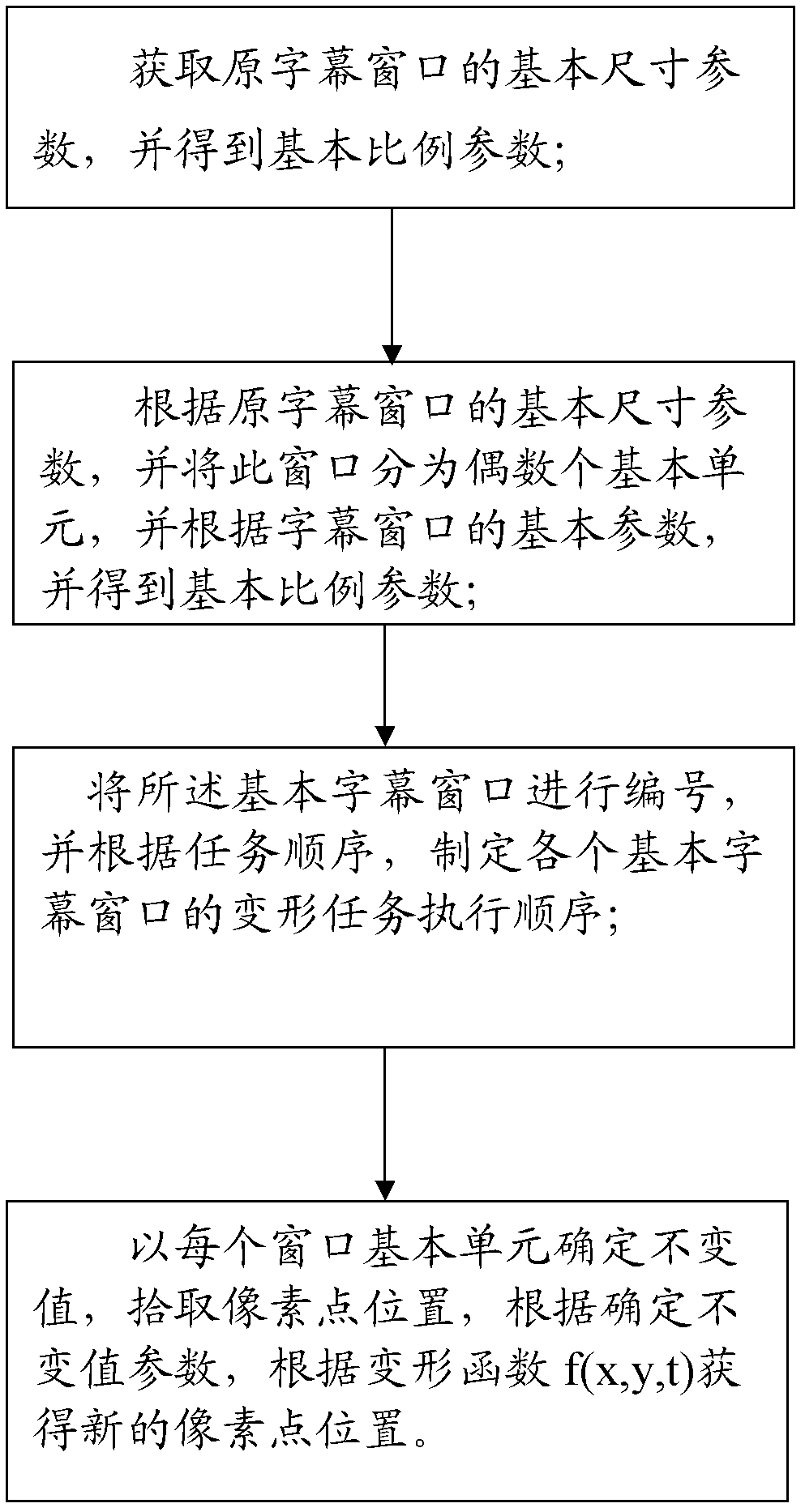

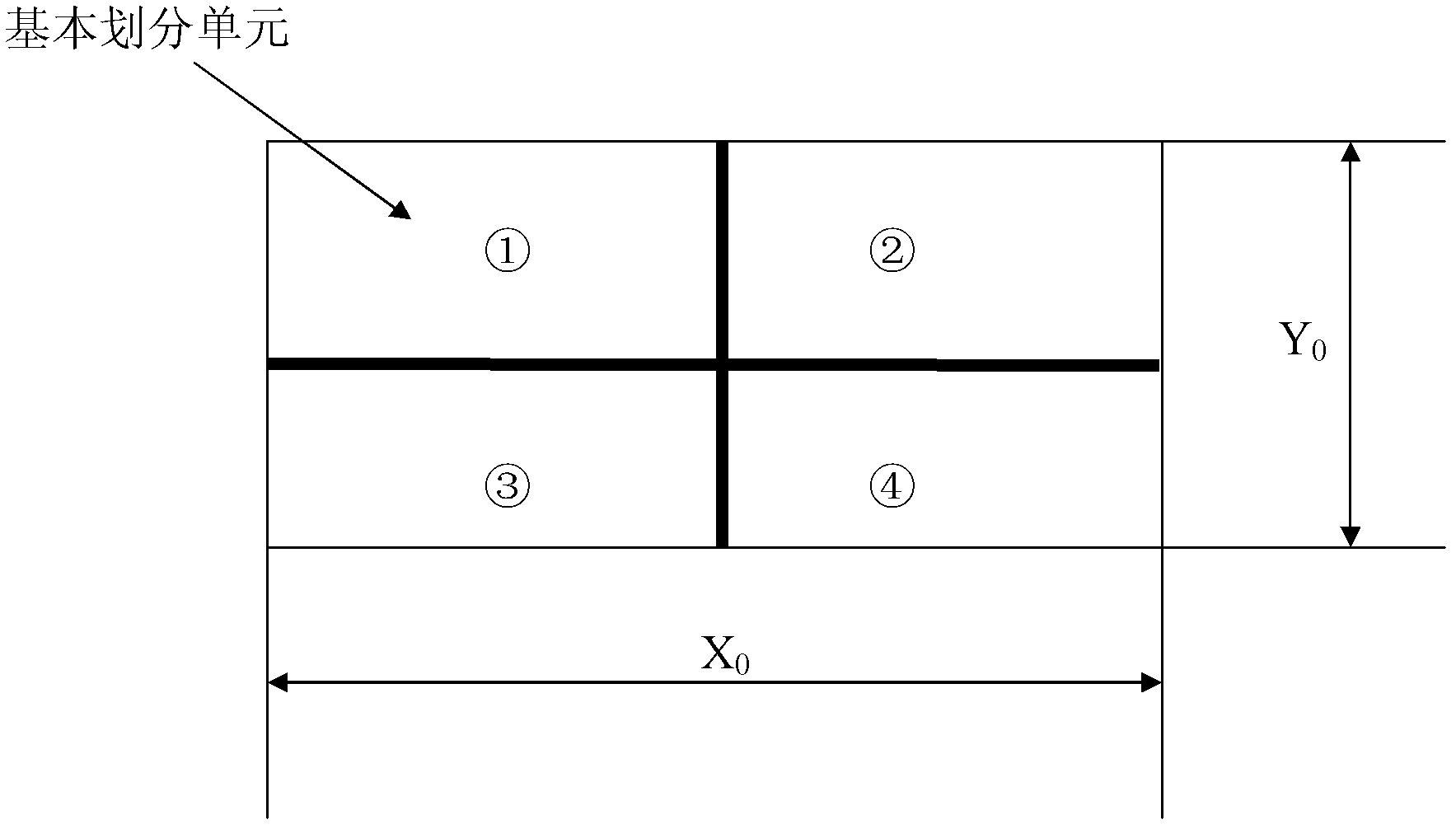

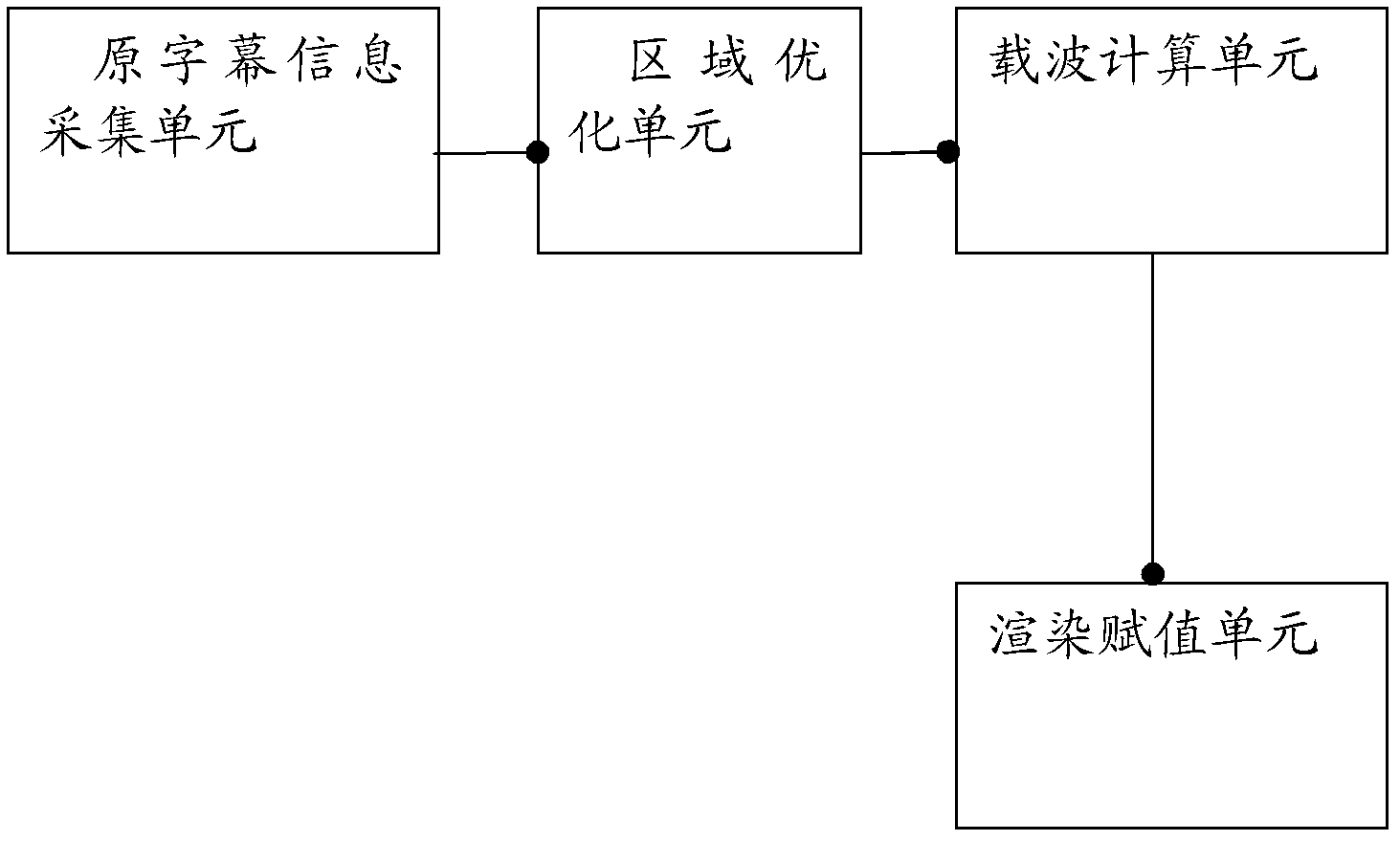

InactiveCN102724444ADynamic extraction of deformation parametersGet deformation effectTelevision system detailsGeometric image transformationBasic dimensionAlgorithm

The invention, which mainly relates to processing on a caption special effect in the broadcast television program manufacturing and broadcasting fields, discloses a method and system for square object mode transformation of a two-dimensional caption. The method comprises: (1), obtaining basic dimension parameters of an original caption window and basic scale parameters; (2), dividing the window into an even number of basic units according to the basic dimension parameters of the original caption window and obtaining basic scale parameters based on the basic parameters of the caption window; (3), numbering the basic caption windows and formulating a transformation task execution sequence of all the basic caption window based on a task order; and (4), collecting a pixel point position based on a determined fixed value of each window basic unit and obtaining a new pixel point position based on the determined fixed value parameters and a transformation function f (x, y, t). Moreover, the system consists of an original information collection unit, a window dividing unit, and a rendering assignment unit; according to basic scale parameters of an original caption window, the original information collection unit and the window dividing unit divide the window into an even number of basic units; according to the basic parameters of the caption window, basic scale parameters are obtained; and the rendering assignment unit carries out assignment. According to the invention, basic information collection of a caption window enables transformation parameters to be dynamically extracted; and division of the caption window enables coordinated displaying of different caption window units to be realized, thereby realizing a caption transformation effect.

Owner:CHINA DIGITAL VIDEO BEIJING

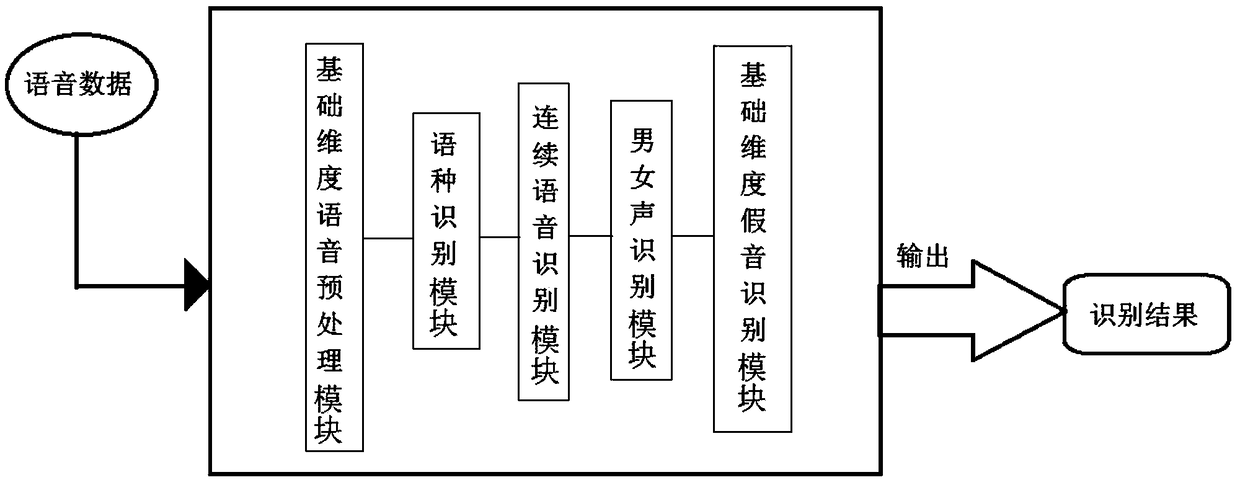

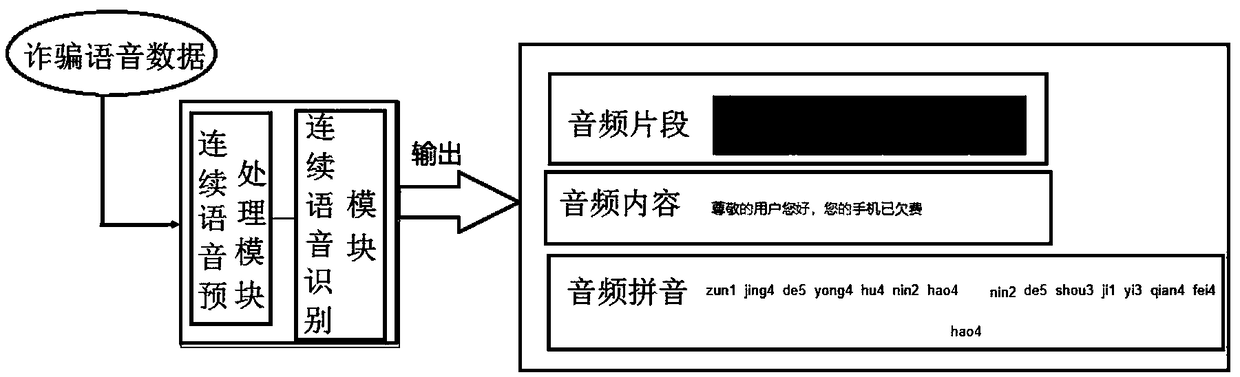

Automatic labelling system and method of swindle call voice

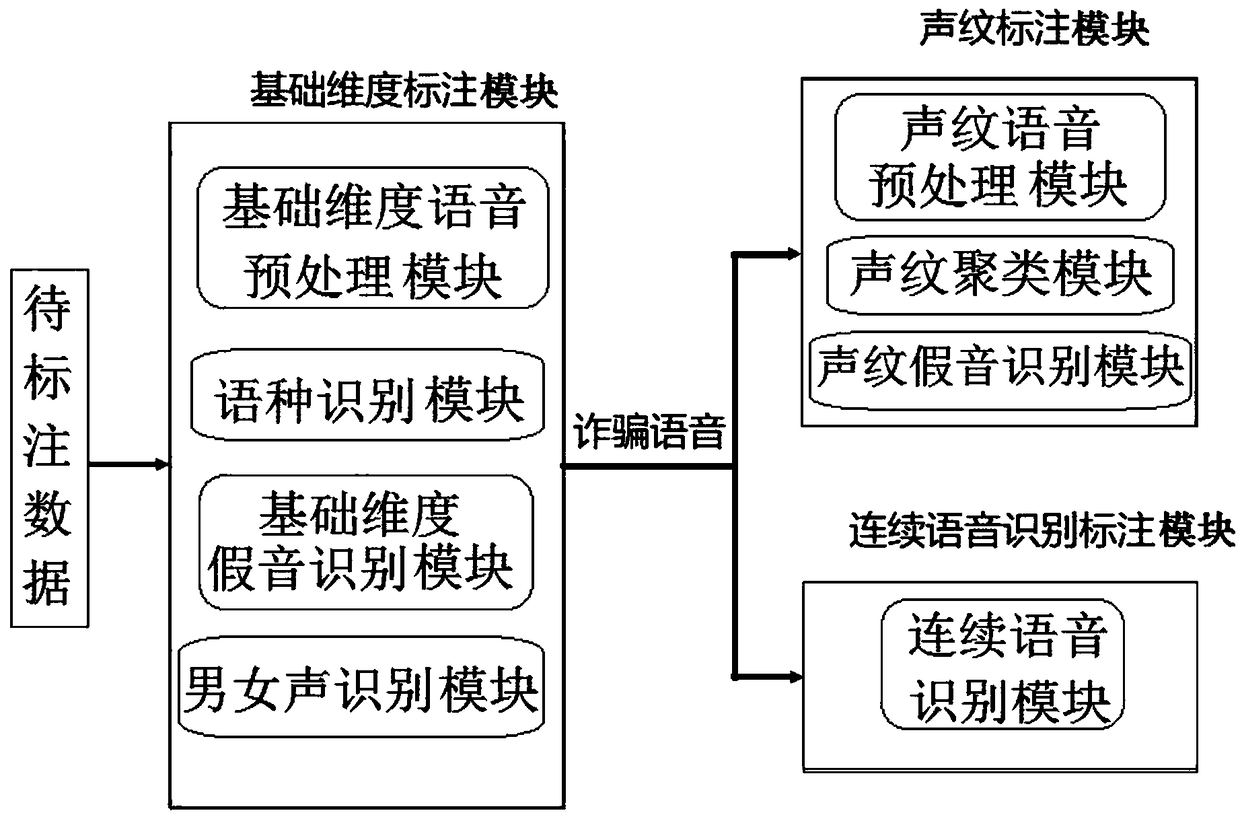

PendingCN109493882ARealize automatic analysis and identificationSupervisory/monitoring/testing arrangementsSpeech recognitionBasic dimensionLabelling

The invention discloses an automatic labelling system of swindle call voice. The system comprises a basic dimension labelling module, a vocal print labelling module and a continuous voice identification labelling module. The output end of the basic dimension labelling module is connected with the input end of the vocal print labelling module and the input end of the continuous voice identificationlabelling module separately. The invention further provides an automatic labelling method of swindle call voice. The method comprises the following specific steps of basic dimension labelling, continuous voice identification and vocal print labelling. According to an intelligent voice technology, input voice data is automatically processed, the voice data is automatically analyzed and identified,the pre-labelling work for labels is conducted, in combination with manual identification, effective labelling management for target data dimension labels is conducted, communication voice data is effectively used, the application and effect of the intelligent voice technology are optimized under the call swindle scene, and meanwhile decryption and encryption transmission of the data in the labelling process is guaranteed.

Owner:NAT COMP NETWORK & INFORMATION SECURITY MANAGEMENT CENT +1

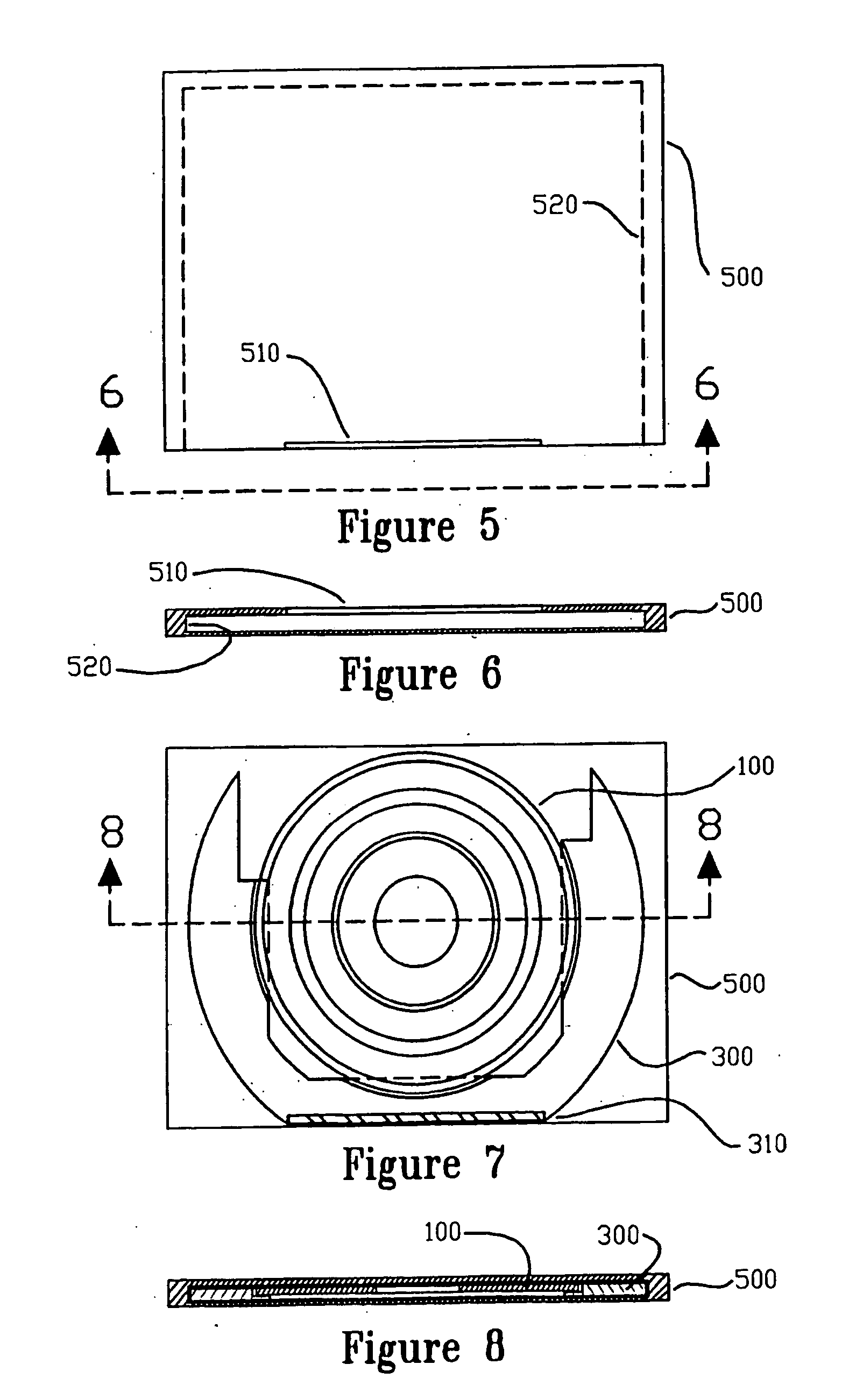

CD card

InactiveUS20070086277A1Increasing the thicknessPrecise positioningCombination recordingRecord information storageComputer hardwareCompact disc

A CD Card for packaging card like information and digital information in the basic dimensions (length and width) of a business, credit or collectors card. The CD Card is made up of one, two, or three major components. The first component is a small compact disc with dimensions small enough to be contained within the typical dimensions (length and width) of a business card, credit card, or collectors card. The second component is a container shaped like a business, credit, or collectors card in length and width, but with a depth large enough to hold the small compact disc and adaptor (if required) discussed subsequently. The third component is an adaptor designed to position the small compact disc of the first and third embodiments of the present invention correctly in standard CD drives. A second embodiment of the small compact disc may not require an adaptor or case. The adaptor also has dimensions small enough to be contained within the typical dimensions (length and width) of a business card, credit card, or collectors card.

Owner:SERIOUS IP

Method for power distribution device data interaction on basis of BIM technology

ActiveCN107301269AReduce workloadFull of informationDesign optimisation/simulationSpecial data processing applicationsBasic dimensionData information

The invention discloses a method for power distribution device data interaction on the basis of a BIM technology, and belongs to the field of transformer station design. The method mainly comprises the following steps of a, arranging a power distribution device model in a three-dimensional digitization design platform by the specialized field of electrics; b, summarizing model information of the power distribution device model and data information generated after the arrangement of the power distribution device into interaction information to be stored into a database; c, extracting interaction information from the database by the specialized field of civil engineering; and d, transmitting the interaction information into civil engineering calculation software to complete the calculation by the specialized field of civil engineering to obtain a proper power distribution device support frame and the basic dimension; and completing the building of the support frame and a basic model in a three-dimensional platform. The data interaction among different specialized fields is realized through the three-dimensional model; the constraint of the planar design is avoided; the workload of design personnel is reduced; and the information amount is more sufficient.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

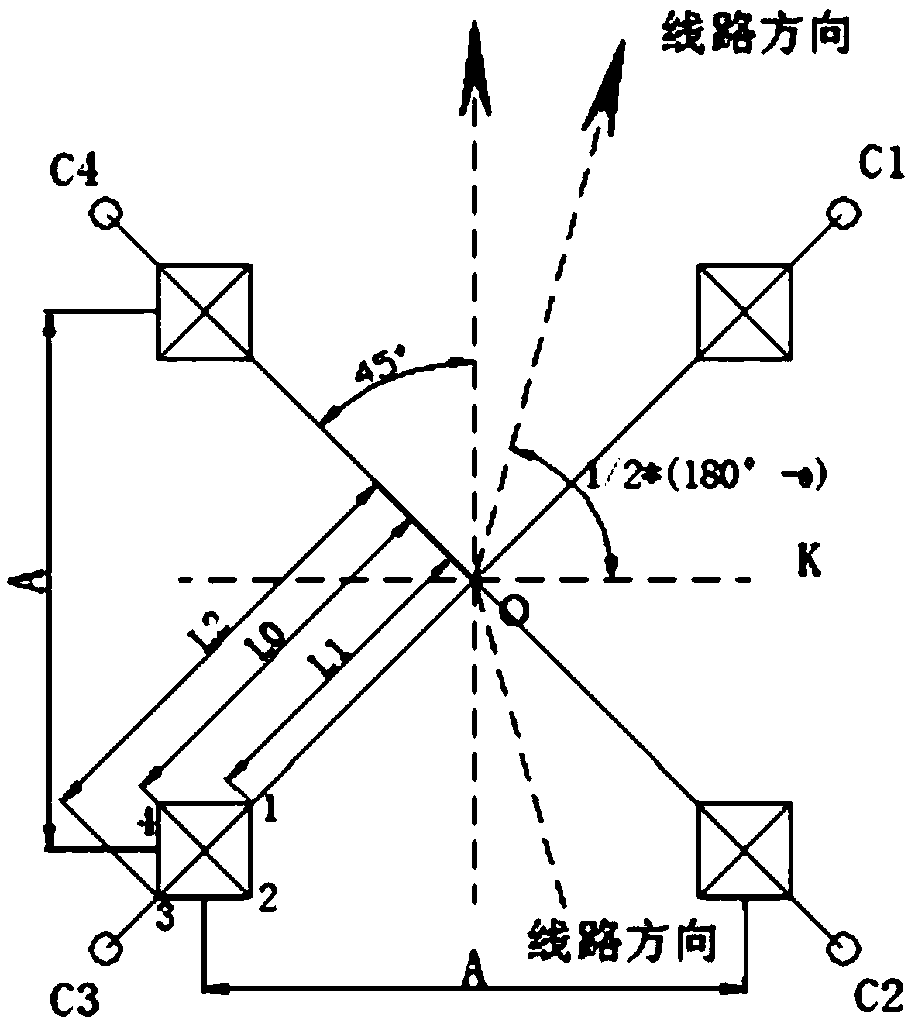

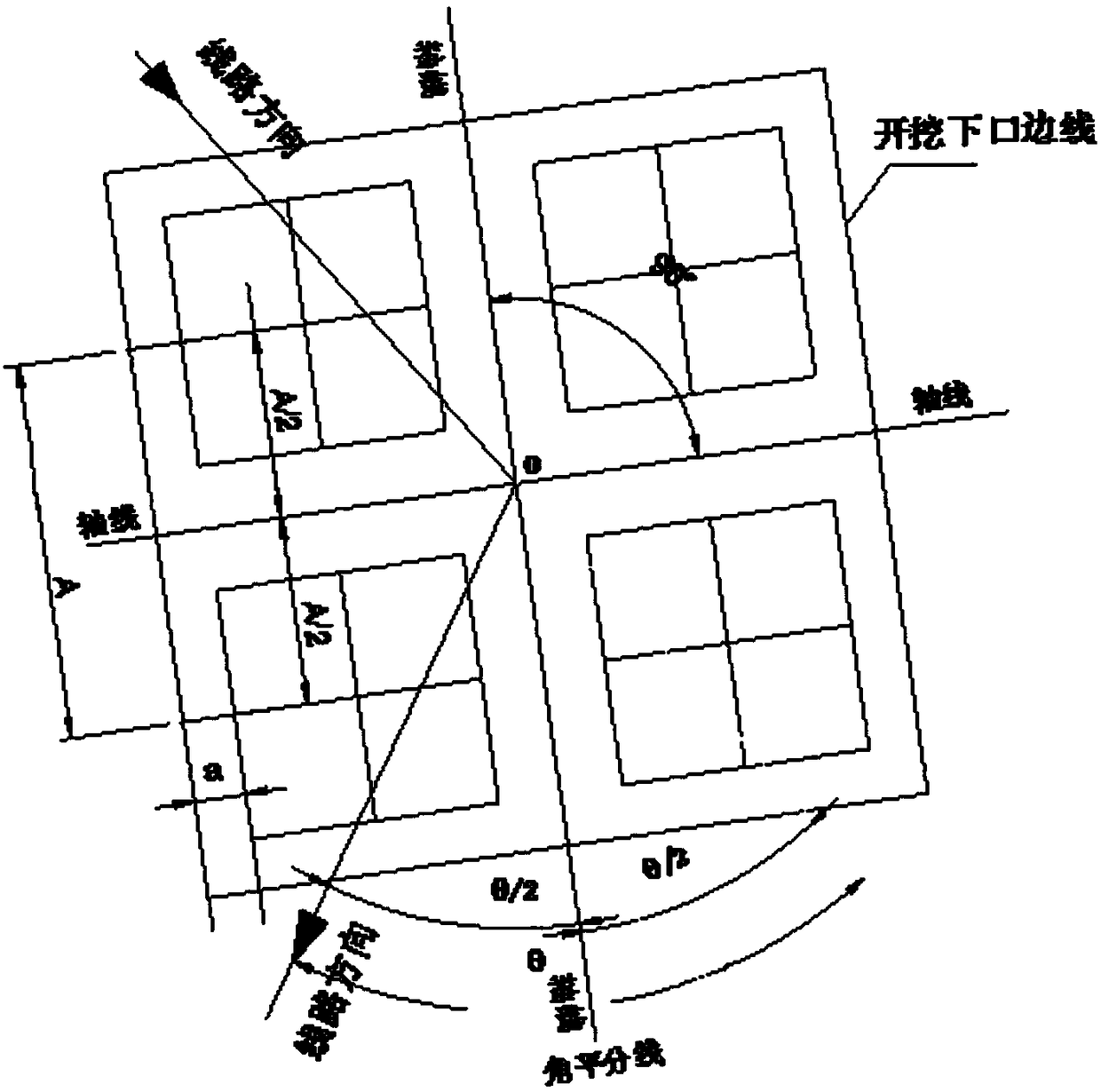

Method for quickly placing samples of ground of current collecting line

ActiveCN109358353ALower requirementEasy to useSatellite radio beaconingBasic dimensionGps measurement

The invention discloses a method for quickly placing samples of ground of a current collecting line. The method comprises the following steps of: A, inputting coordinates of a center pile of the ground of the collector line into a CAD software, wherein the center point of the ground is O; B, marking a rotation angle theta of the ground; C, making an angle bisector of the rotation angle theta, which is an axis of the ground, and making a vertical line of the axis through the center point O of the ground, wherein the other axis bases on the vertical line, to complete the axes of the ground; D, making two parallel lines of the axes of the ground according to basic dimension given by a draw and a lateral root opening value A, wherein the distance between the parallel lines and the axes is A / 2,and making 4 edges of a pile cap according to the size of the ground; and E, using the CAD software to mark the coordinates of the intersection of the axis and the edges of the excavation bottom, inputting to a GPS measuring instrument, and placing lines according to the coordinates on spot. According to the method for quickly placing samples of the ground of the current collecting line, the needfor multiple measurements and calculations is eliminated, the error rate and work intensity are reduced, and the requirements for operators are reduced.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com