Method for optimally designing powder spray room based on fluent software

A technology for optimizing design and powder spraying chamber, applied in computing, special data processing applications, instruments, etc., which can solve problems such as powder spillage, suboptimal design results, and unfavorable new product development and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

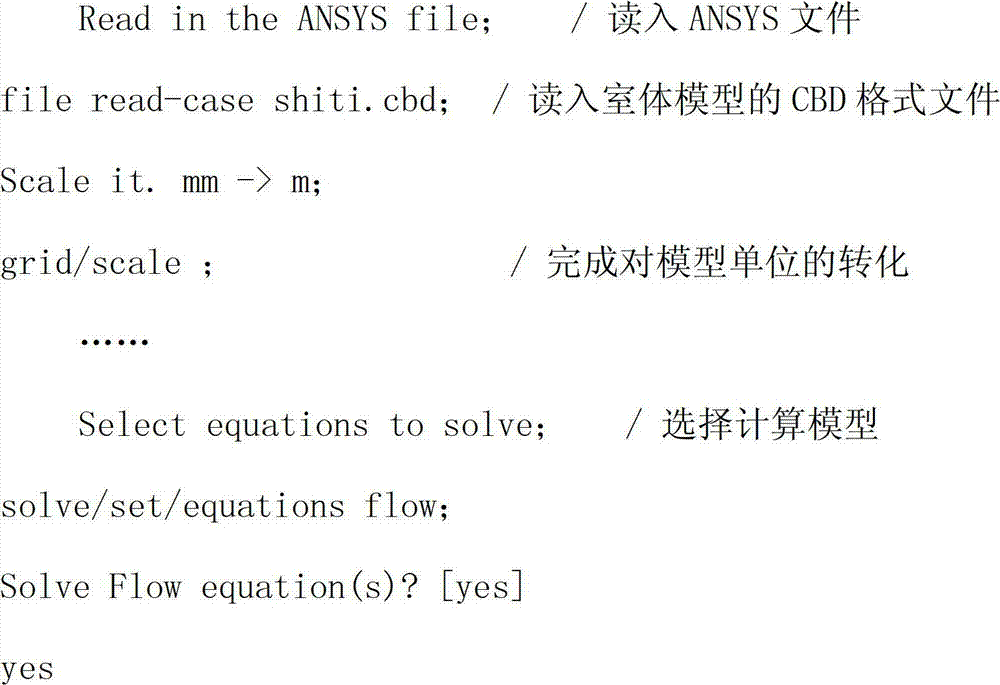

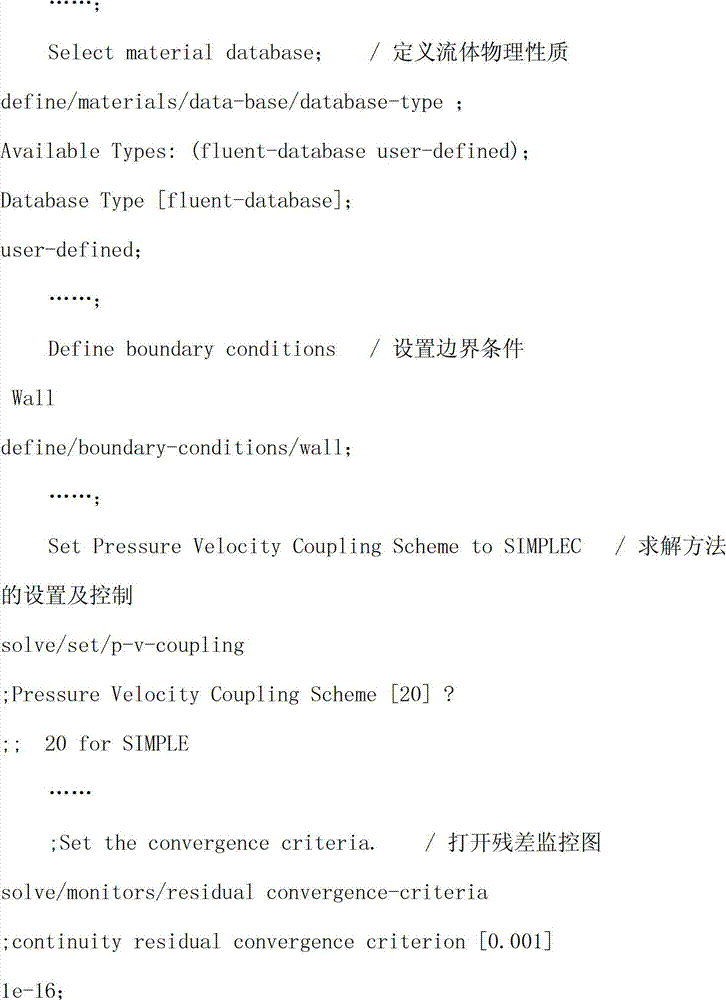

[0018] A kind of method of the present invention is based on fluent software to the method for optimal design of powder spraying chamber, comprises the following steps:

[0019] 1) According to the hanging size of the workpiece and the layout of the spray gun, determine the overall size and inlet and outlet dimensions of the powder spraying room, determine the recovery port and operating port size of the powder spraying room according to the recycling needs and operating requirements, and determine the size of the powder spraying room according to the electrostatic powder coating production line. Determine its specific location based on on-site conditions and experience, and parameterize the basic size of the spray booth and the location of each inlet and outlet;

[0020] 2) Using the good interactivity of VB, establish a parameterized input interface for the powder spraying room model, where the input parameters include: the basic dimensions of the powder spraying room, the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com