Assembly position precision analysis method considering geometric tolerance and deformation influence

A technology of assembly position and accuracy analysis, applied in instruments, calculations, electrical and digital data processing, etc., can solve the problems of simulating the size distribution of closed loops, not conforming to parts processing conditions, unreliable analysis results, etc., to achieve accurate analysis results and simulation results. Intuitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

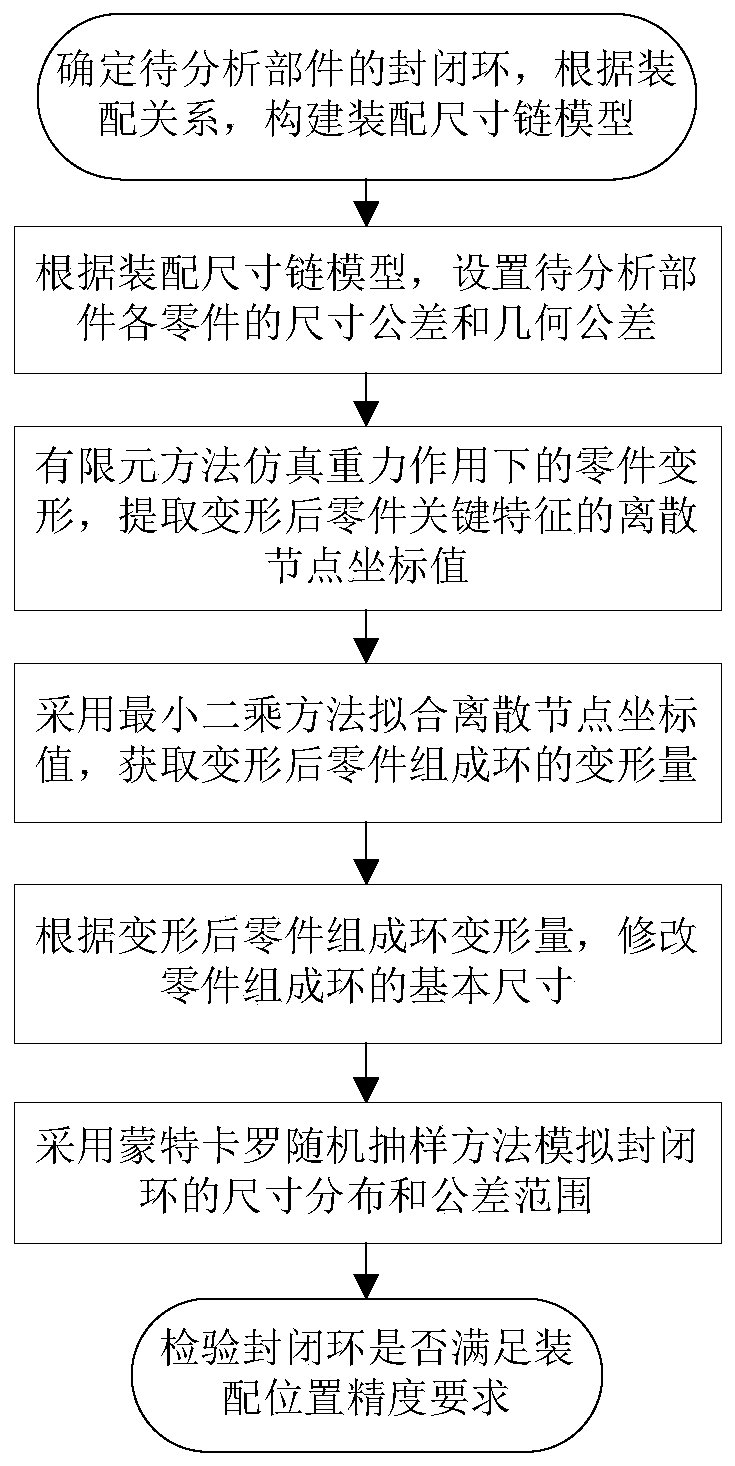

[0060] Taking the crankshaft transmission part of a high-speed warp knitting machine as an example, the implementation flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0061] Step 1. Determine the closed loop of the parts to be analyzed, and construct the assembly dimension chain model according to the assembly relationship;

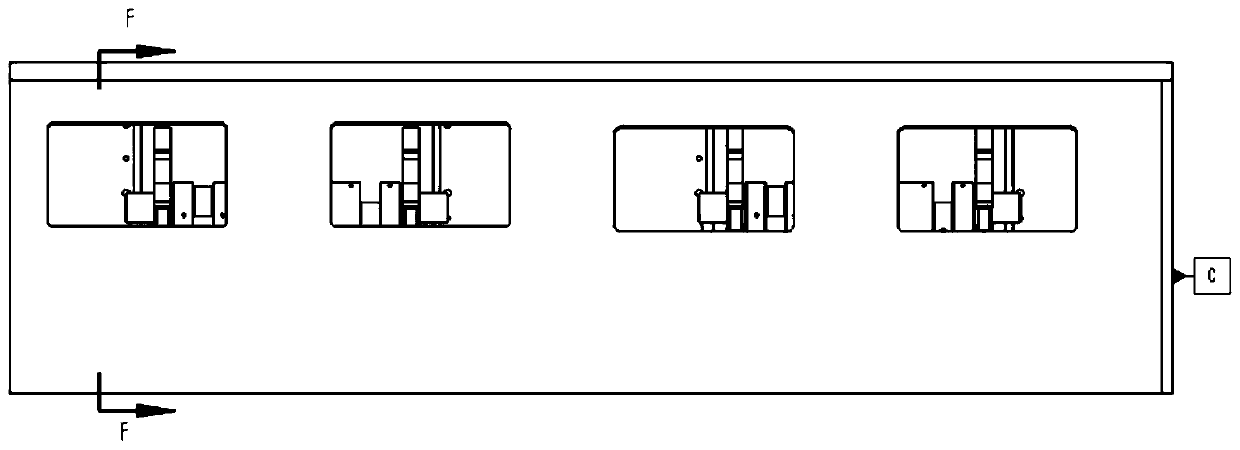

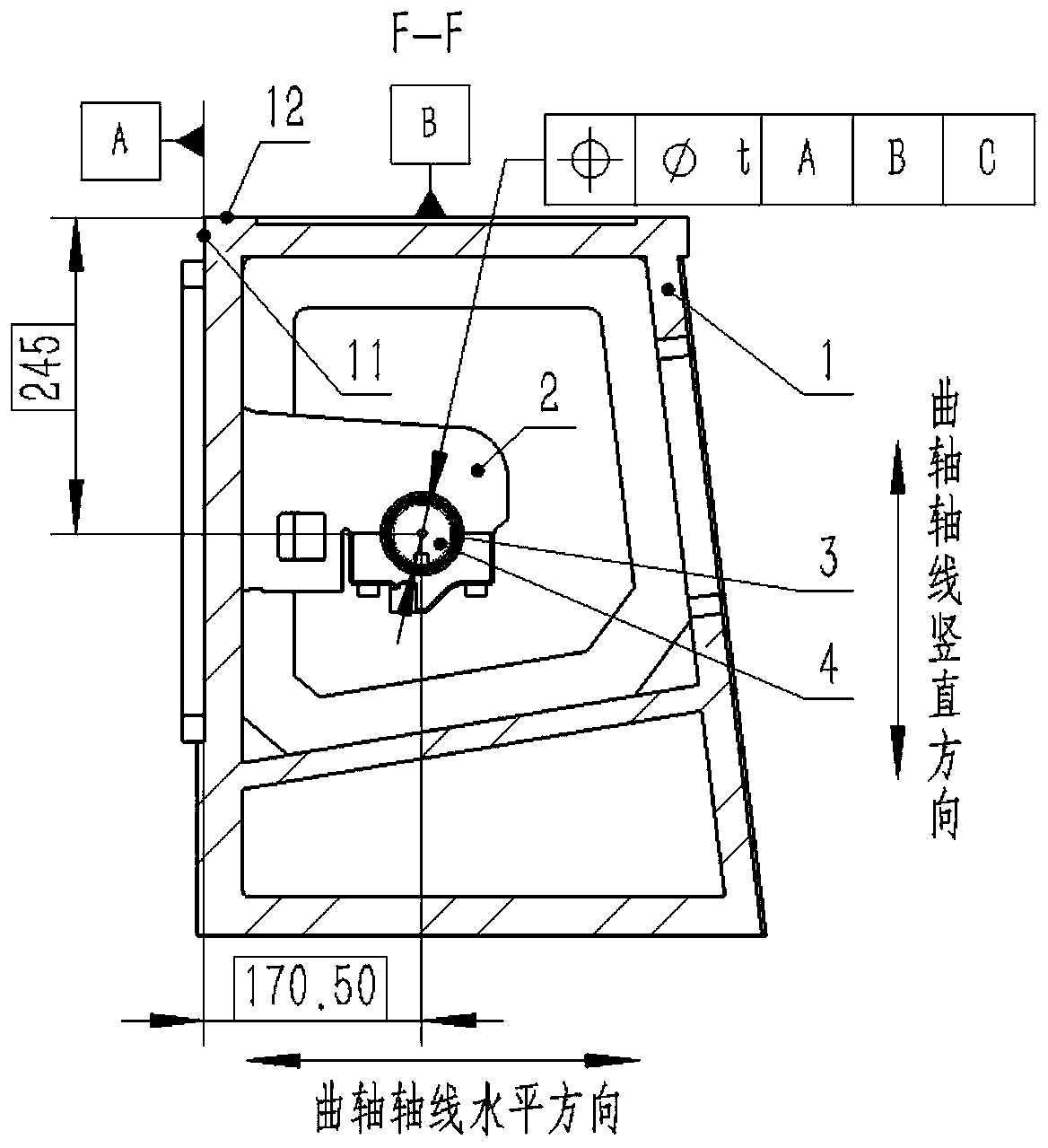

[0062] See attached figure 2 And attached image 3 , the crankshaft transmission part of the high-speed warp knitting machine is assembled from four parts: oil tank 1, connecting rod frame 2, bearing bush 3 and crankshaft 4; Above, the crankshaft 4 is installed on the connecting rod frame 2, and the bearing bush 3 is sleeved between the connecting rod frame 2 and the crankshaft 4. In the crankshaft transmission components, the assembly position of the crankshaft axis relative to the oil tank is the assembly function requirement. The assembly position of the crankshaft axis relative to the oil tank can be divided into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com