Device and method for measuring inclined hole position dimensions

A measuring device and oblique hole technology, applied in the field of measurement, can solve problems such as high measurement cost, large measurement error, and low measurement efficiency, and achieve the effects of simple operation, stable measurement data, and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the required protection scope is not limited to the description;

[0041] Implementation steps of the present invention are as follows:

[0042] 1. Analysis of parts diagram

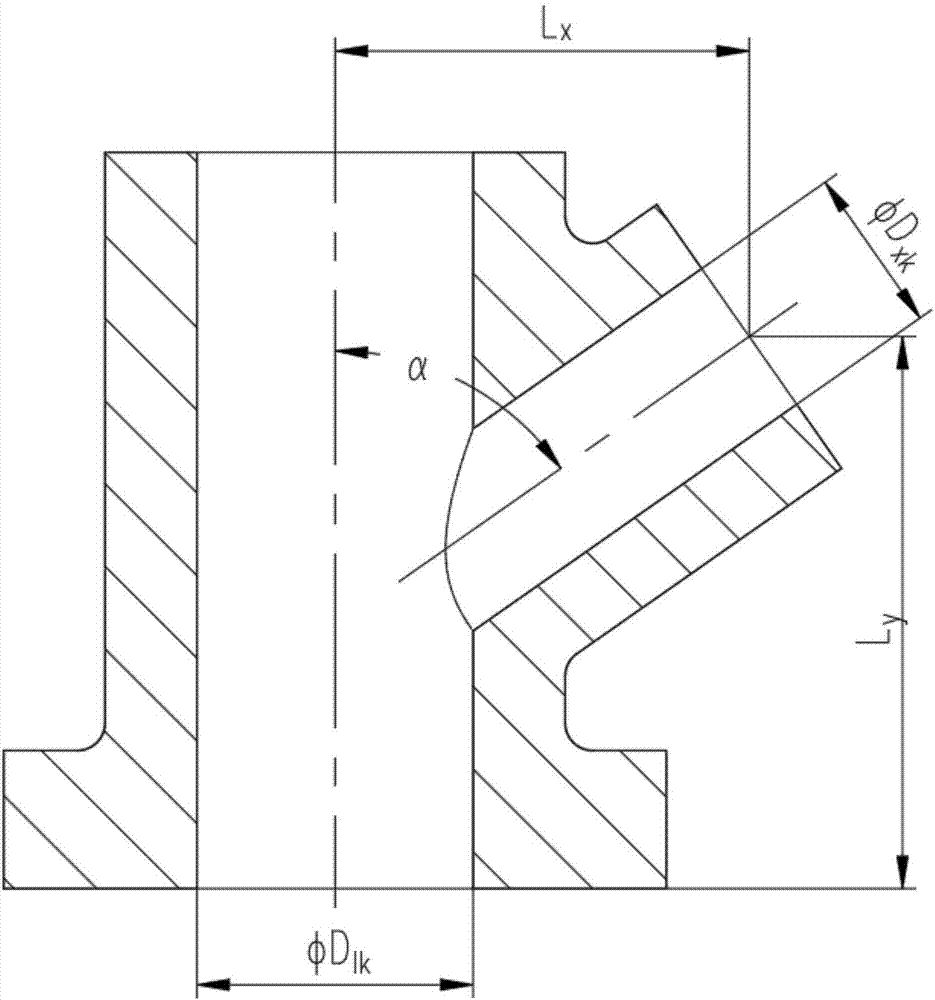

[0043] Such as figure 1Shown is the dimension L of the oblique hole position of the part to be measured X , L Y , the tolerance level is IT7 level, before designing the measuring device, first analyze the part drawing:

[0044] a. Analyze the outline structure, dimensions and weight of the part drawing, whether the individual can easily carry it, and the placement of the parts during measurement, so as to preliminarily determine the structure and size of the measuring device;

[0045] b Analyzing the dimensional accuracy of the inclined hole position and the selection of the measurement benchmark. During the process, the measurement benchmark should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com