Device and method for measuring wall thickness dimension of hole bottom of deep hole part

A measuring device and part hole technology, which is applied in the direction of mechanical thickness measurement, etc., can solve the problems of large measurement errors, high precision parts that cannot meet the requirements, low measurement efficiency, etc., and achieve stable measurement data, simple operation, and fast measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

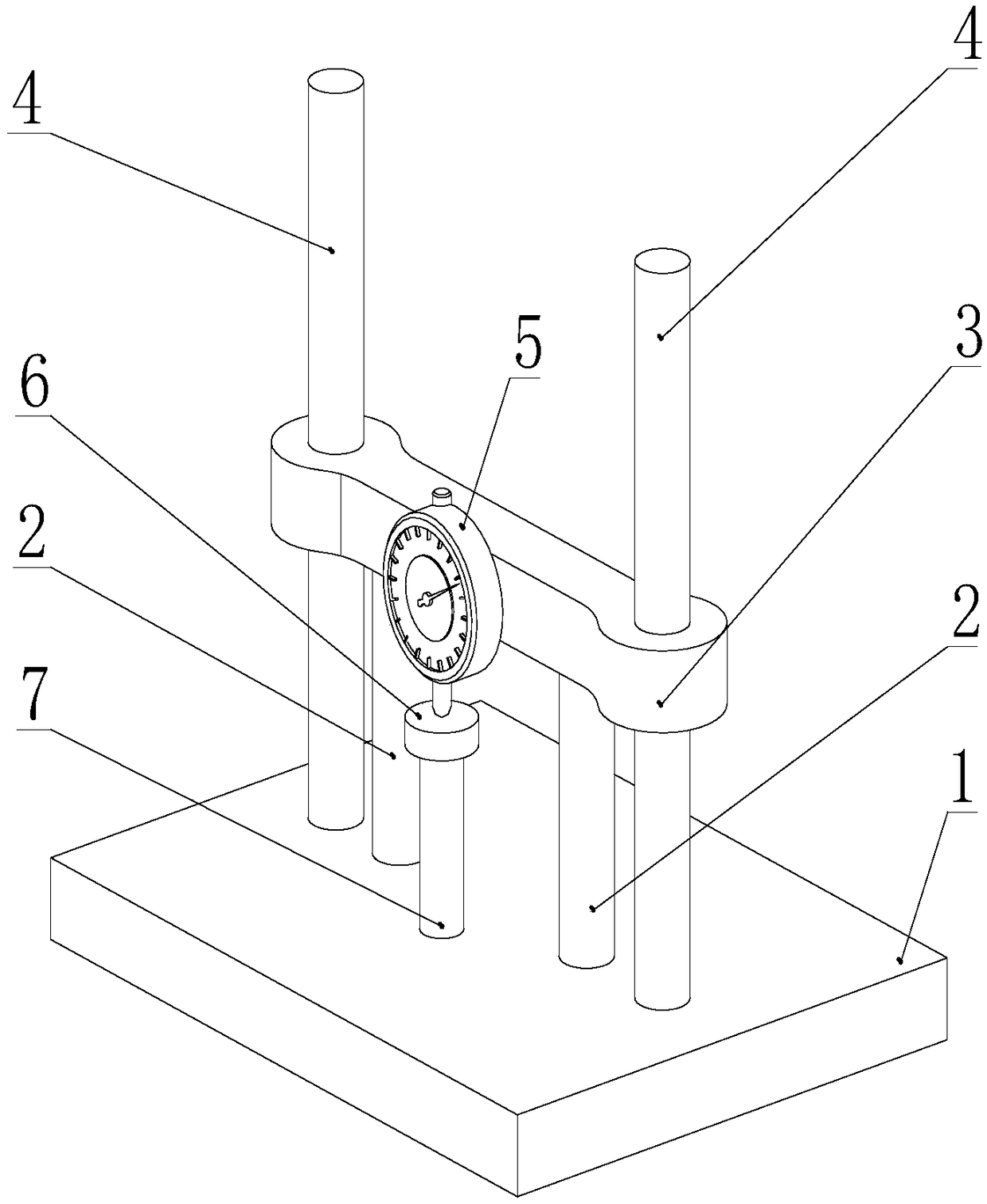

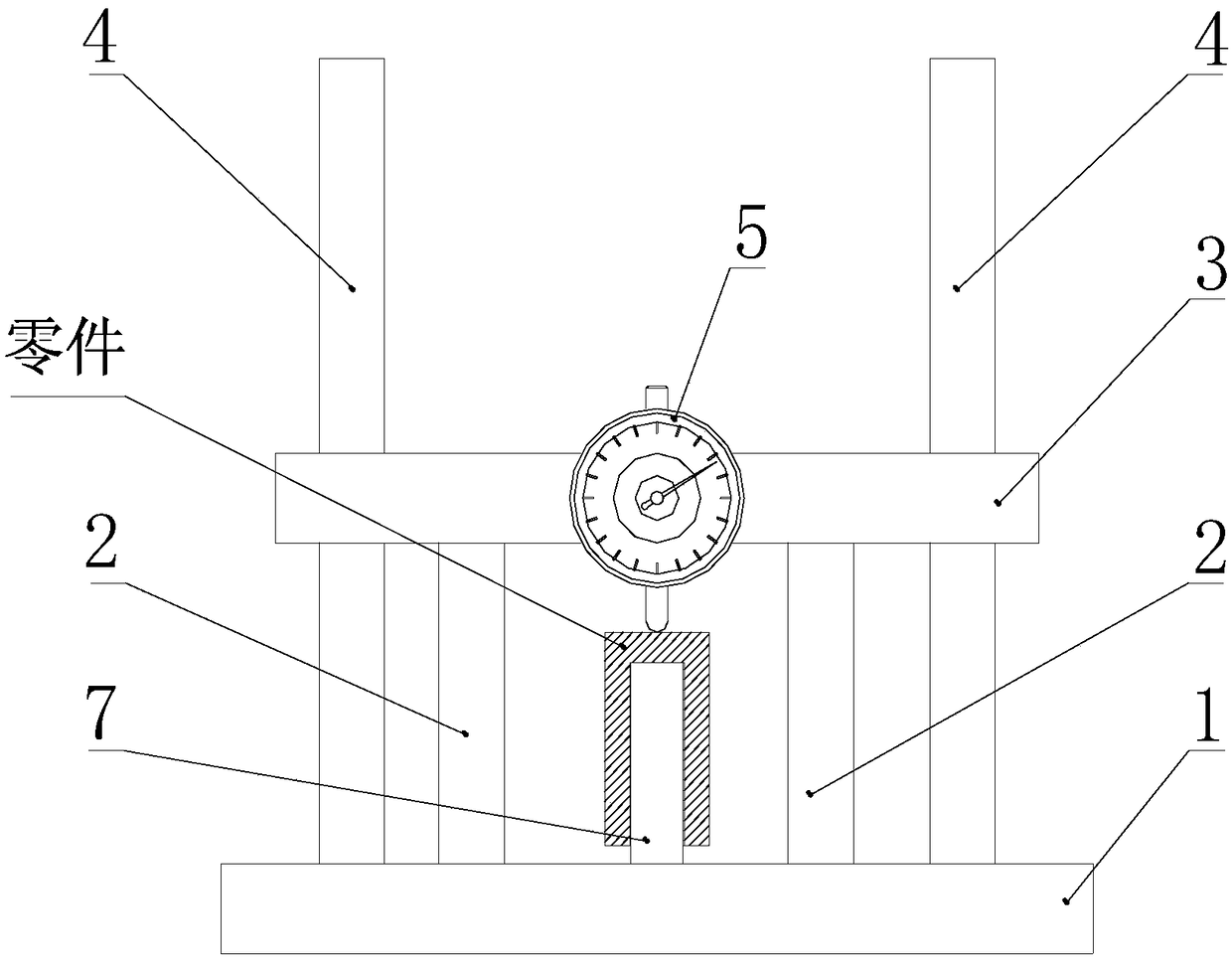

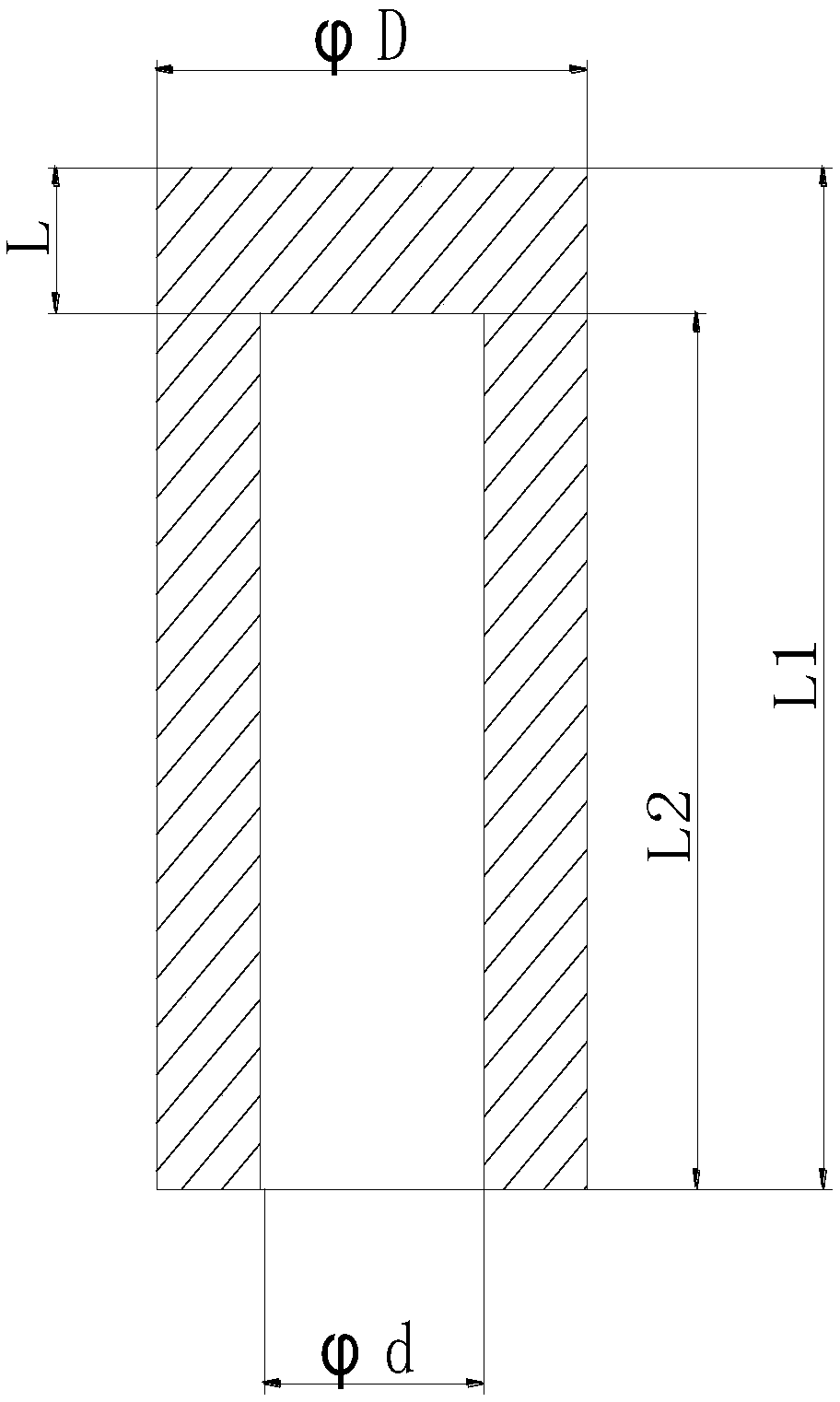

[0020] A measuring device and testing method for the wall thickness of the bottom of a deep hole part; it includes a base 1 on which a column 4 and two top columns 7 are vertically fixed, and the sliding beam 3 is arranged on the top column 7 On one side of the connection surface, a sliding crossbeam 3 of the base is movably installed on the two top posts 7 and the two top posts 7 are connected by the sliding crossbeam 3. The measuring head of Table 5 is on the same straight line as the center line of the top post 7 .

[0021] A limiting column 2 is also arranged between the two columns 4, and the limiting column 2 is fixedly connected to the base 1 and directly below the sliding beam 3.

[0022] A reference block 6 is also placed on the top column 7 .

[0023] The height of the limit post 2 is greater than that of the top post 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com