Spraying material and electromagnetic flowmeter without inner liner

A technology of electromagnetic flowmeter and spraying materials, which is applied in the direction of application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effects, volume measurement, etc., which can solve problems such as unusability, wrong selection, wear and tear, etc., and achieve extension The effect of service life and data stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

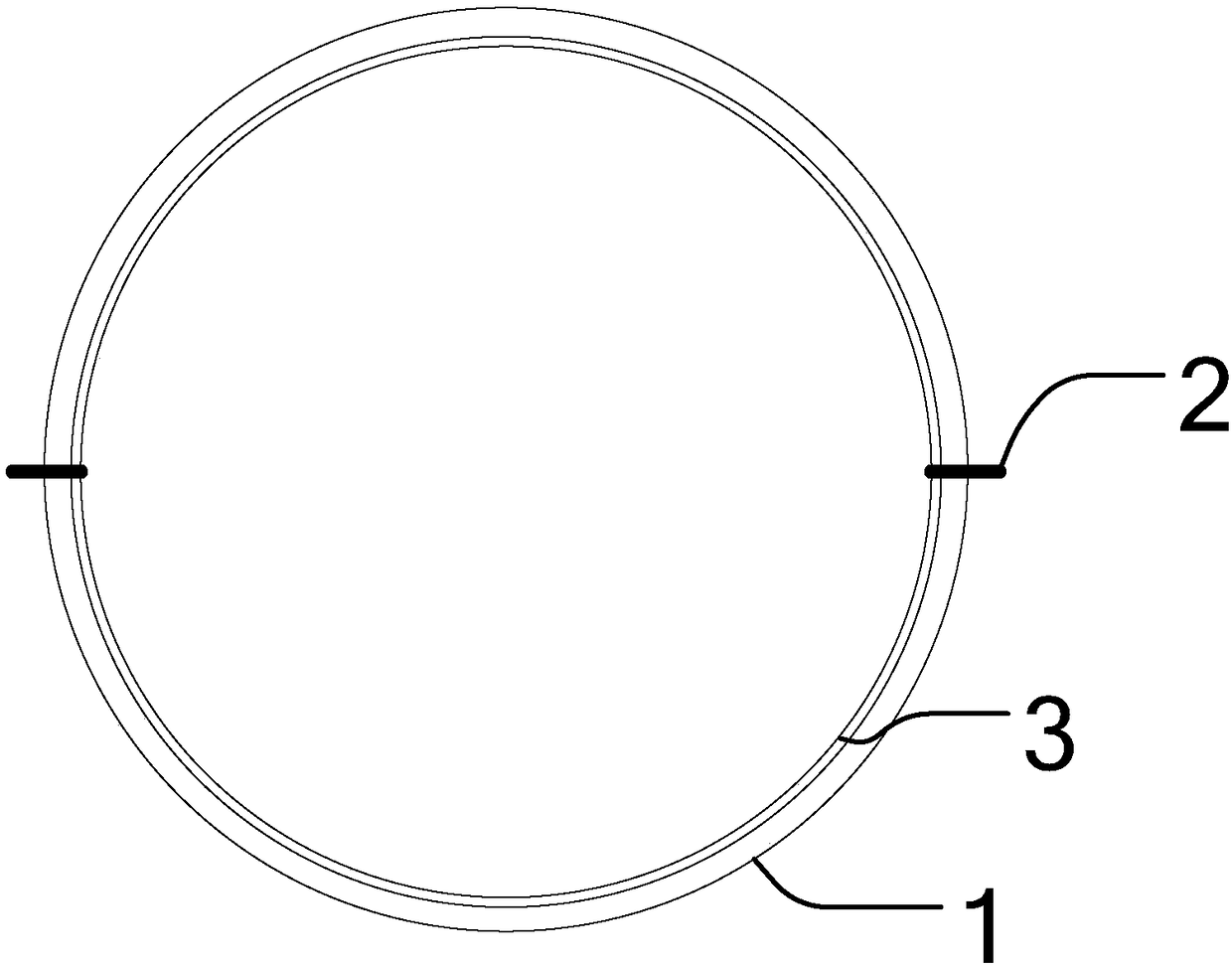

[0016] Example 1, such as figure 1 As shown, a liner-free electromagnetic flowmeter includes a measuring tube body 1, an electrode 2, a magnetic circuit system, a housing, and a converter. The specific connection structure is the same as that of the prior art, and the difference is that the electromagnetic The flowmeter has no inner lining, but an insulating layer 3 is sprayed on the inner wall of the measuring pipe body, and the inner lining is replaced by the insulating layer. The electrodes penetrate from the outer wall of the measuring tube to the inner wall of the measuring tube. The thickness of the insulating layer 3 is 10 microns-1000 microns. In this embodiment, it is preferably 500 microns. When spraying the insulating layer, the spraying conditions are normal temperature: 15°C-25°C; normal pressure: 1.01×10 5 Pa.

[0017] In this embodiment, the components of the spraying material used for the insulating layer 3 include modified isocyanate: 55%; modified silicat...

Embodiment 2

[0018] Embodiment 2, a liner-free electromagnetic flowmeter, including the measuring pipe body 1, the electrode 2, the magnetic circuit system, the casing and the converter, etc., its specific connection structure is the same as that of the prior art, the difference is that the present invention The electromagnetic flowmeter has no inner lining, but an insulating layer 3 is sprayed on the inner wall of the measuring pipe body, and the inner lining is replaced by the insulating layer 3 . The electrode 2 penetrates from the outer wall of the measuring tube body to the inner wall of the measuring tube body 1 . The thickness of the insulating layer 3 is 10 microns-1000 microns. In this embodiment, it is preferably 500 microns. When spraying the insulating layer, the spraying conditions are normal temperature: 15°C-25°C; normal pressure: 1.01×10 5 Pa.

[0019] In this embodiment, the components of the spraying material used for the insulating layer 3 include modified isocyanate:...

Embodiment 3

[0020] Embodiment 3. In this embodiment, the components of the spraying material used for the insulating layer 3 include modified isocyanate: 65%; modified silicate solution: 35% by mass percentage. The modified silicate concentration in the modified silicate solution is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com