Design method for section closure accuracy of octagonal pile leg

An octagonal pile and design method technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as unmentioned precision design, save man-hours and materials, ensure work requirements, reduce impact loads and The effect of material wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

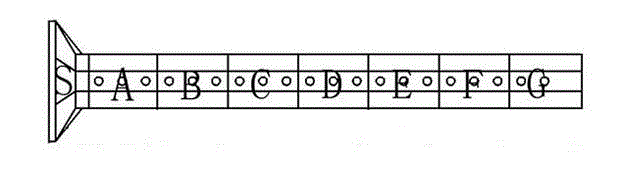

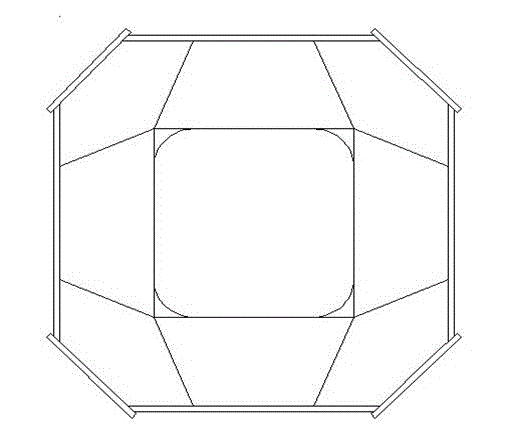

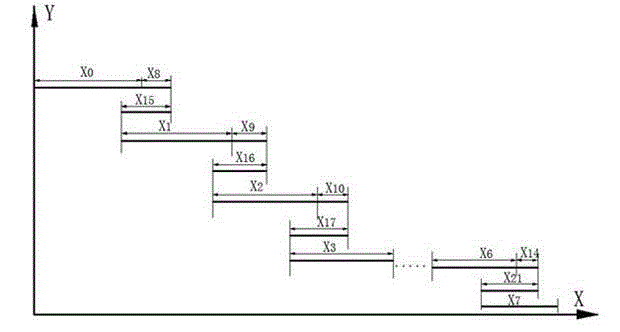

[0016] The present invention shows a method for designing the dimensional accuracy of octagonal pile legs segmented and closed. This embodiment takes the precision design of large-scale wind power installation ship pile legs as an example. The pile legs are octagonal orifice plate structures, and the main board is NV690 Ultra-high-strength steel with a thickness of 100mm, a pile leg height of 71.5m, and a single weight of 630T. The precision design steps of the pile leg are divided into sections, drawing a size chain diagram, precision distribution, compensation amount calculation, size and tolerance determination, etc. multiple steps.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com