Resistance stabilizing cable

A cable and resistance value technology, applied in the field of wire and cable, can solve problems such as increased cable attenuation, affecting system stability, and decreasing supply current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

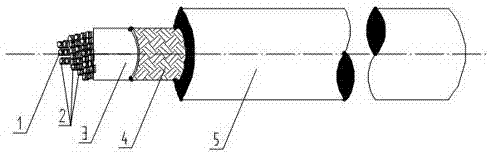

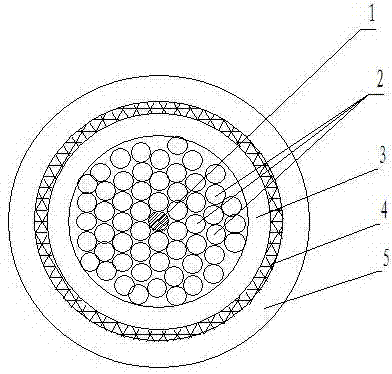

[0020] Embodiment 1: see attached figure 1 and 2 .

[0021] A stable resistance cable, comprising a composite conductive wire core, an insulating layer 3 wrapped outside the composite conductive wire core, a braided shielding layer 4 wrapped outside the insulating layer 3, and an outer sheath wrapped outside the braided shielding layer 4 Set of 5 compositions.

[0022] The production process of the stable resistance cable in this embodiment is: twist the multi-metal composite wire to obtain a composite conductive core, extrude a plastic insulating layer 3 on the composite conductive core, and then use metal wires to braid the shielding layer 4 and then extrude the outer sheath. Set 5 protective layers, that is, to make a stable resistance cable product.

Embodiment 2

[0024] A stable resistance cable, characterized in that it consists of a composite conductive core, an insulating layer 3 wrapped outside the composite conductive core, a braided shielding layer 4 wrapped outside the insulating layer 3, and a braided shielding layer 4 wrapped The outer outer sheath 5 is composed of;

[0025] The composite conductive wire core is composed of a metal wire whose resistance value (or resistivity) increases with temperature rise and a metal wire whose resistance value (or resistivity) decreases with temperature rise. The resistance value of the core remains constant or substantially constant during the working process of the stabilizing cable;

[0026] The composite conductive wire core consists of a cross-sectional area (that is, the radial cross-sectional area of the metal wire, the same below) as 0.30mm 2 The copper wires 1 and 56 have a cross-sectional area of 0.30mm 2 The chromium-aluminum alloy wire is composed of 2 composite strands. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com