Dynamic vibration-absorption turning tool based on extruding working mode of magnetorheological fluid

A technology of dynamic vibration absorption and magnetorheological fluid, which is applied in the direction of tools, liquid shock absorbers and shock absorbers for lathes to simplify turning operations, enhance the suppression range, and reduce magnetic flux leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

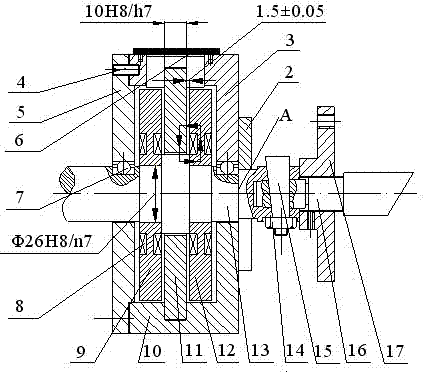

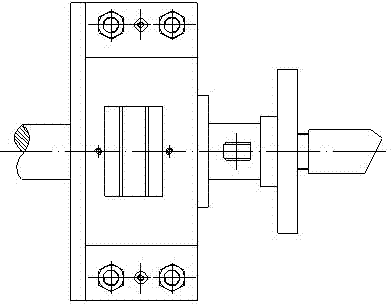

[0021] Such as Figure 1 to Figure 3 As shown, a power vibration-absorbing turning tool based on magneto-rheological fluid extrusion working mode is composed of two parts: the main vibration part fixedly connected with the ordinary turning tool 16 and the magneto-rheological power vibration-absorbing part suspended thereon.

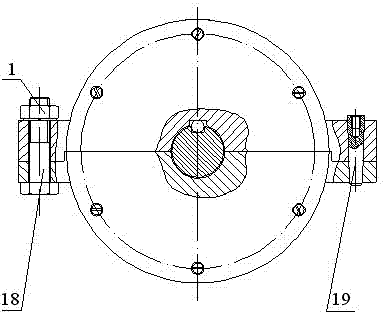

[0022] The magneto-rheological shock-absorbing component includes an upper box body 3 , a lower box body 10 , a disk-shaped magnetic pole 11 and an end cover 5 . The upper box body 3 and the lower box body 10 are positioned by the internal threaded conical pin 19 and fastened by the bolt 18 and the nut 1, and the disc-shaped magnetic pole 11 and the ring grooves in the upper and lower box bodies 3, 10 have an axial gap. Fitting connection, the end cover 5 is positioned with the upper and lower boxes by the boss at one end and fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com