Patents

Literature

124results about How to "High specific surface energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

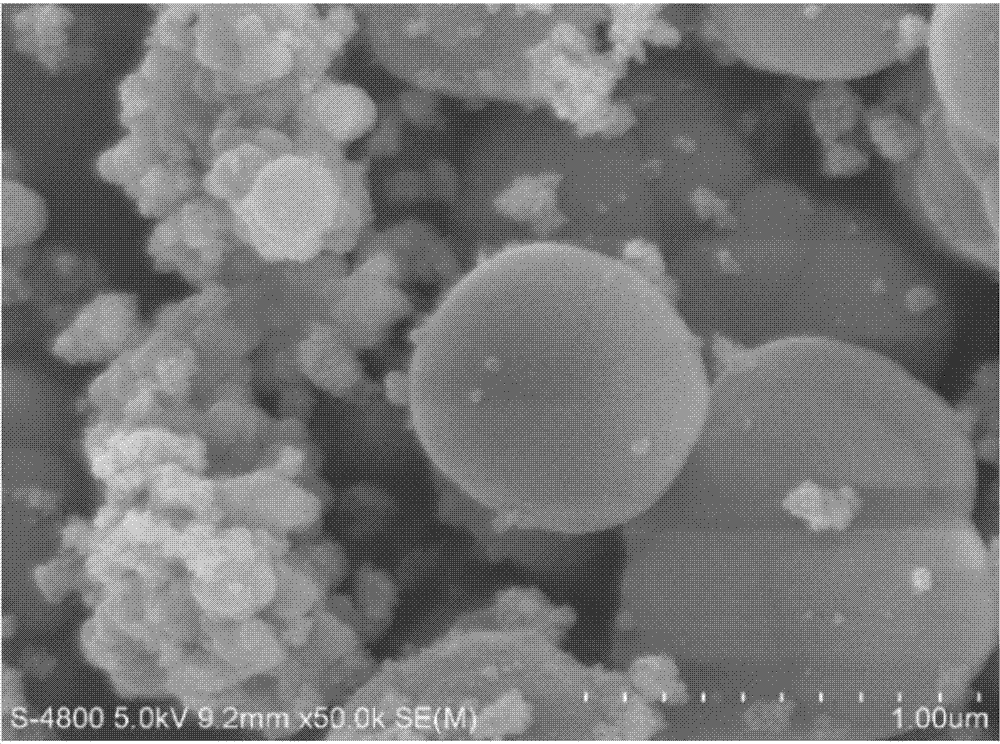

Amino-functionalization magnetic silicon dioxide-ferroferric oxide composite nanomaterial and preparation method thereof

InactiveCN104759260AEasy to prepareLow costOther chemical processesAlkali metal oxides/hydroxidesMicrosphereOxide composite

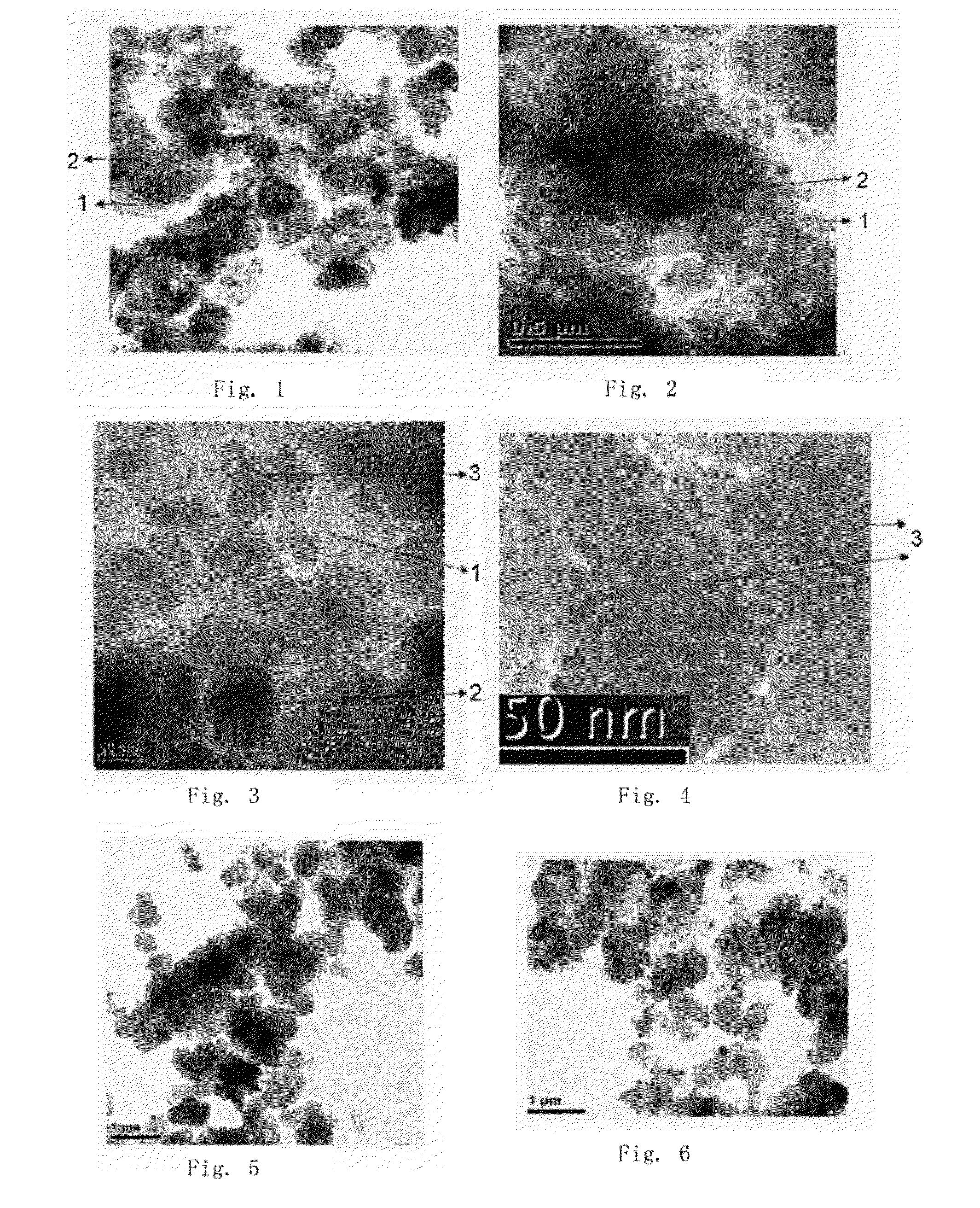

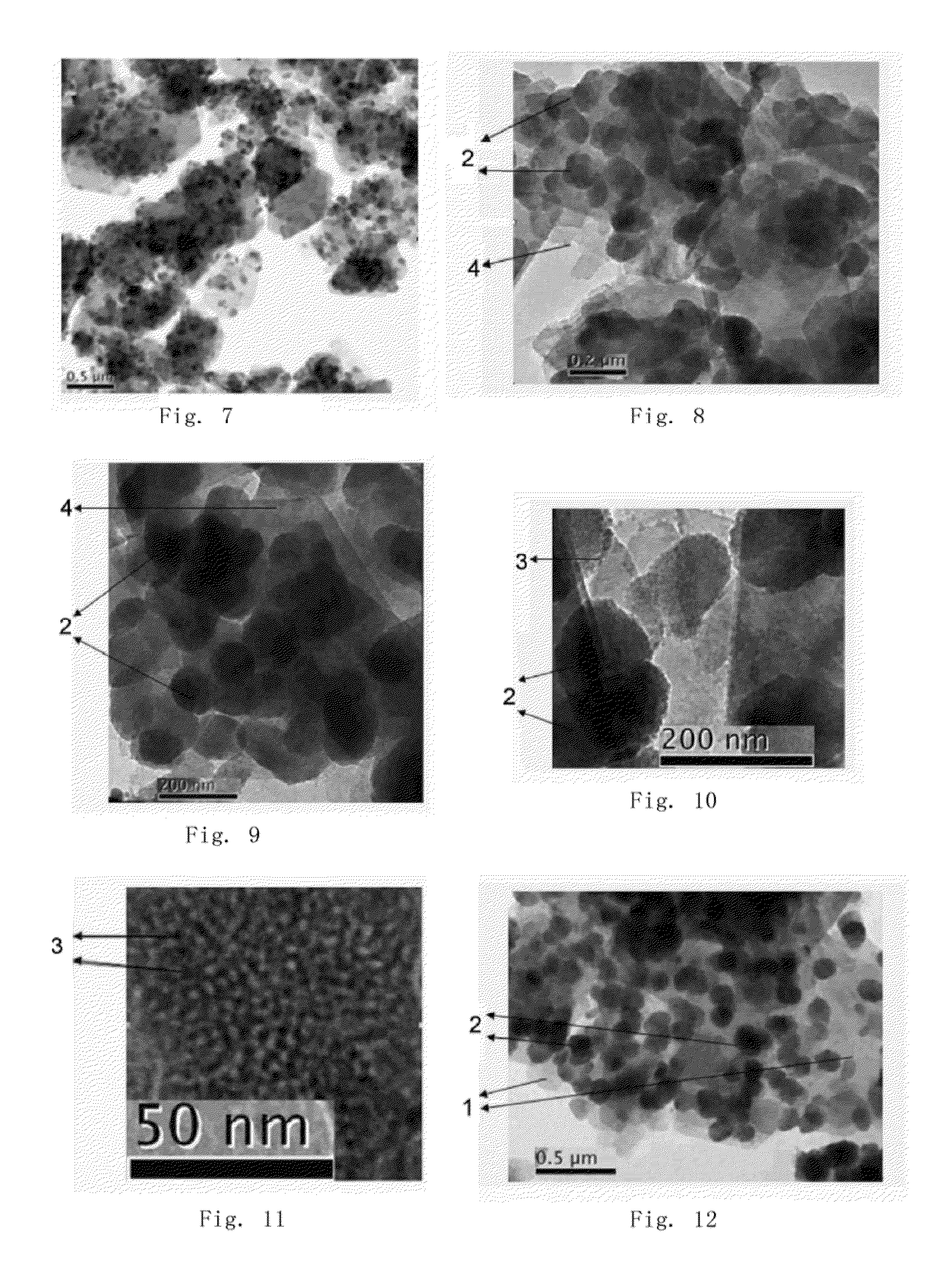

The invention provides an amino-functionalization magnetic silicon dioxide-ferroferric oxide composite nanomaterial. The material is characterized in that a microsphere structure is formed as magnetic ferroferric oxide is used as an inner core, silicon dioxide is used as an outer-layer coating material, amino groups with positive charges are used as functionalization modifying groups. The invention also provides a preparation method of the material, and an application of the material in water environment pollutant trace chemistry detection. The material is simple in preparation method, low in cost, high in extraction efficiency and high in adsorptive property, has selectivity on complex organic pollutants, is a reproducible environment-friendly novel material, and can be applied in trace chemistry analysis of a plurality of kinds of complex organic pollutants (particularly pollutants with negative charges) in a water environment.

Owner:HOHAI UNIV

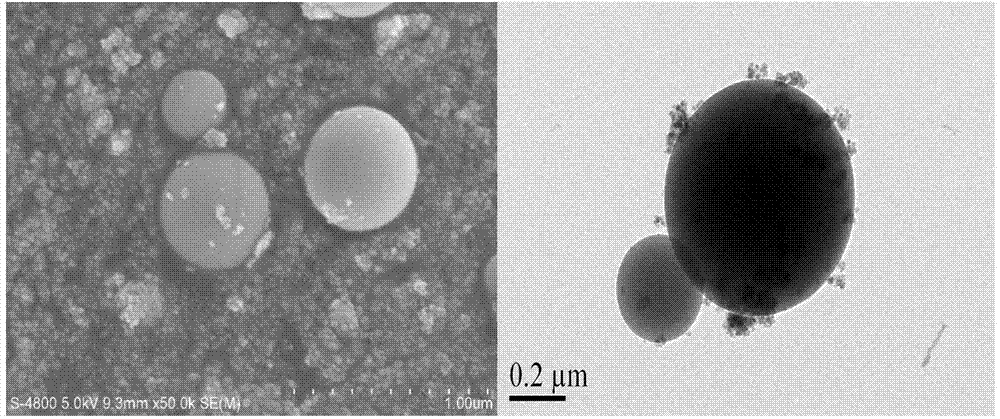

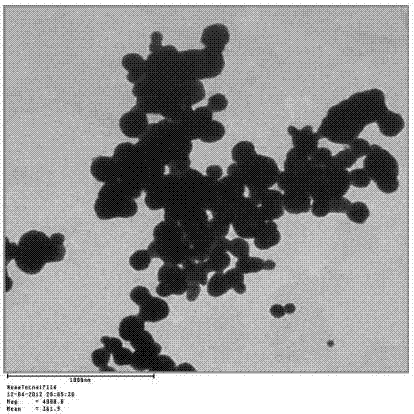

Graphite silicon-based composite anode material and preparation method thereof

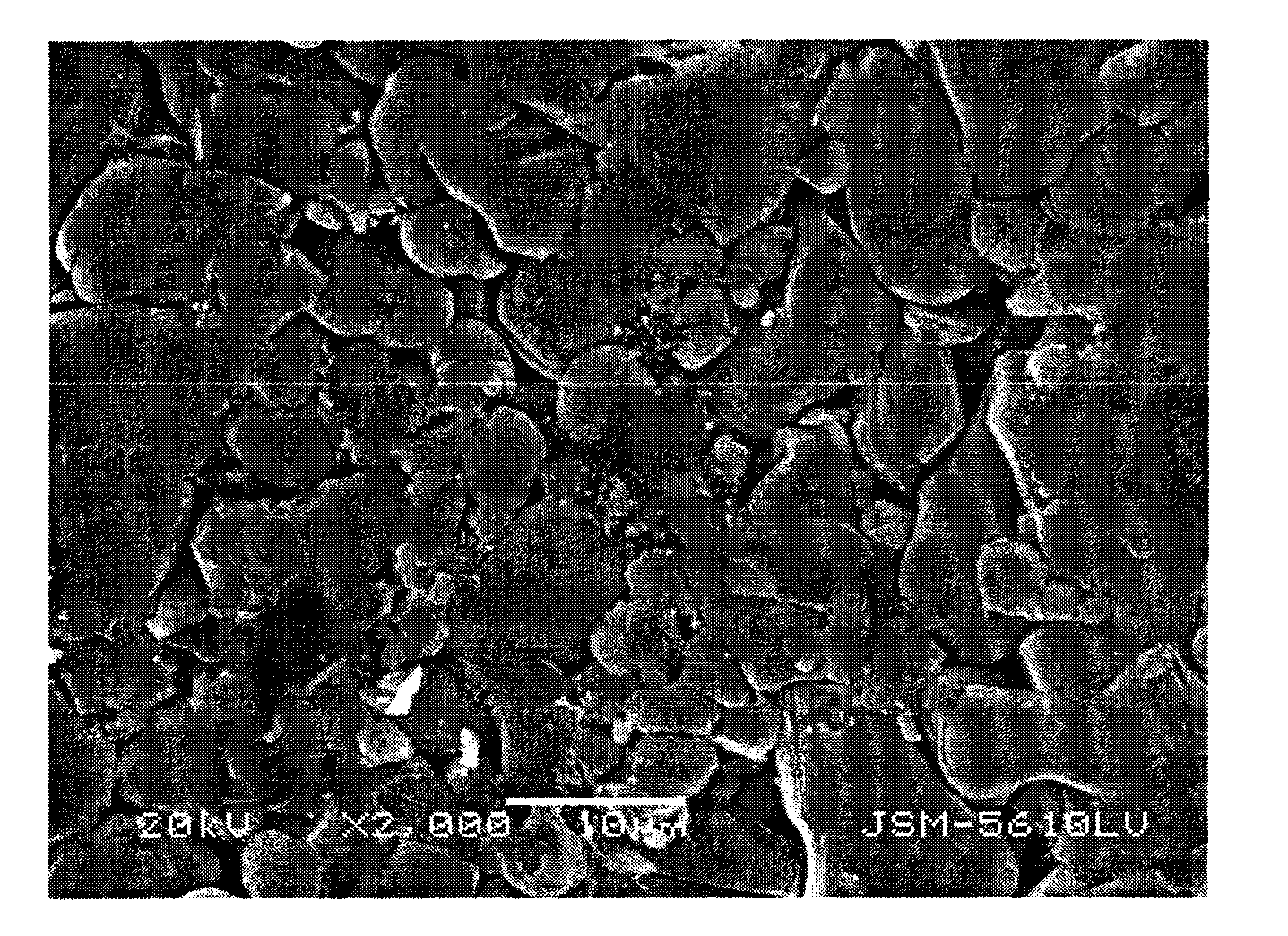

InactiveCN104362307ASmall granularityHigh specific surface energyCell electrodesSecondary cellsCarbon compositesHigh carbon

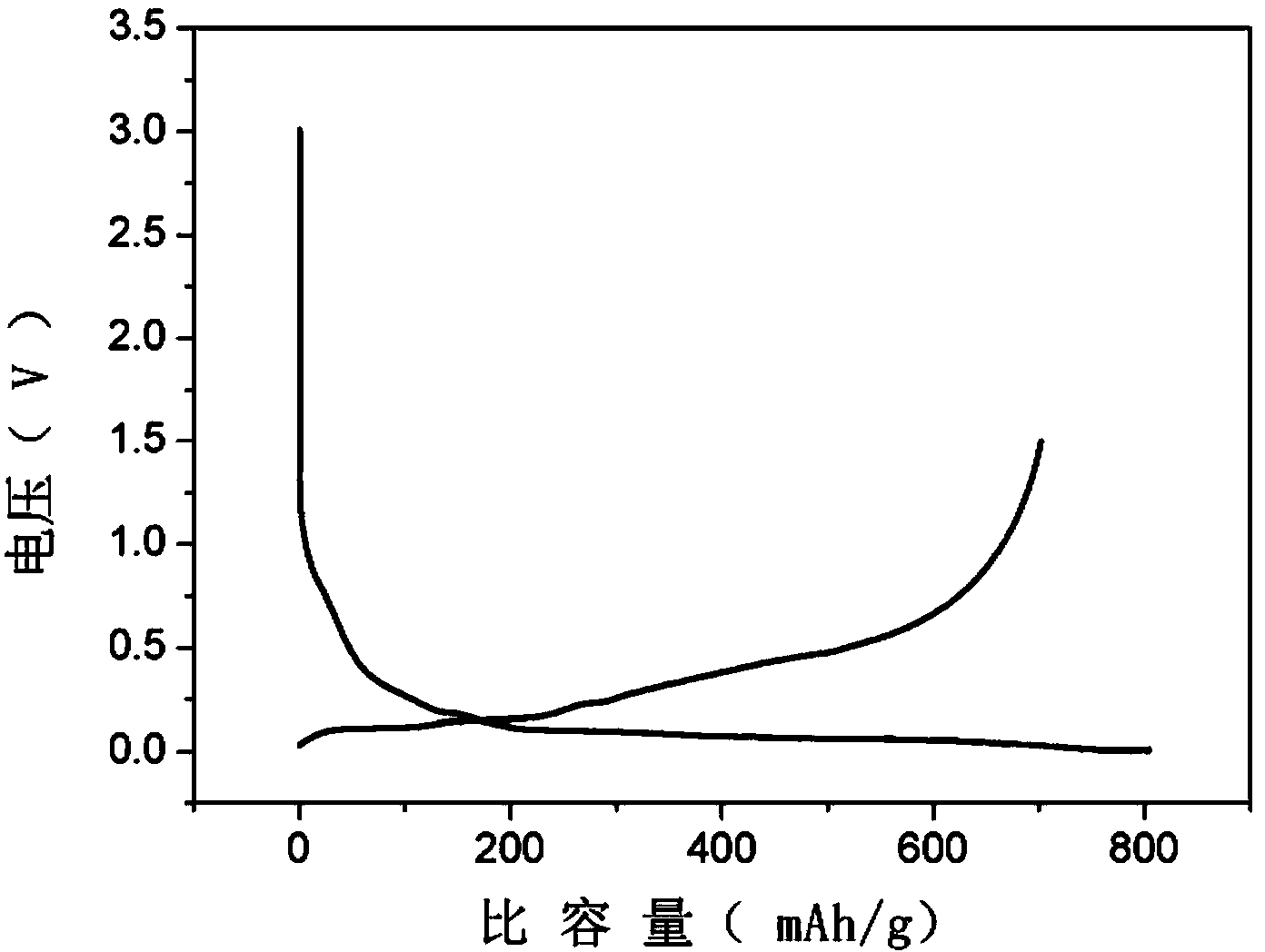

The invention relates to a graphite silicon-based composite anode material for a lithium ion battery and a preparation method thereof. The graphite silicon-based composite anode material comprises a nano-silicon cracked carbon composite material, graphite and a carbon material coating layer. The preparation method comprises the following steps: firstly, nano-silicon is obtained by a high-energy wet mechanical milling method; secondly, nano-silicon and a polymer with high carbon residue are compounded by dispersion polymerization so as to form a polymer / nano-silicon composite microsphere emulsion with nano-silicon inlaid in polymeric microspheres; thirdly, the microsphere emulsion and graphite are compounded; and finally, solid-phase coating is carried out by the use of an organic carbon source, and heat treatment is conducted to obtain the graphite silicon-based composite anode material for a lithium ion battery. By the above method, the problem that nano-silicon is liable to agglomeration, especially agglomeration of nano-silicon from a liquid disperse state to a dry state, due to low granularity and high specific surface energy is solved. The anode material has characteristics of high specific capacity (greater than 550mAh / g), high initial charge discharge efficiency (greater than 80%) and high conductivity.

Owner:南京毕汉特威高分子材料有限公司

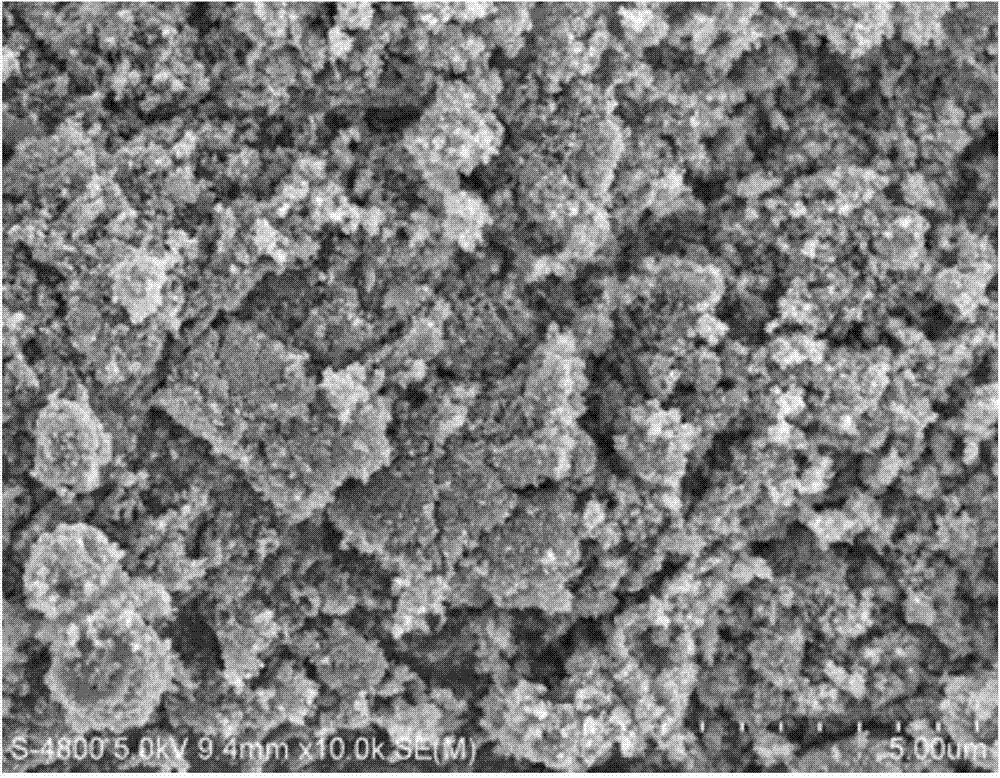

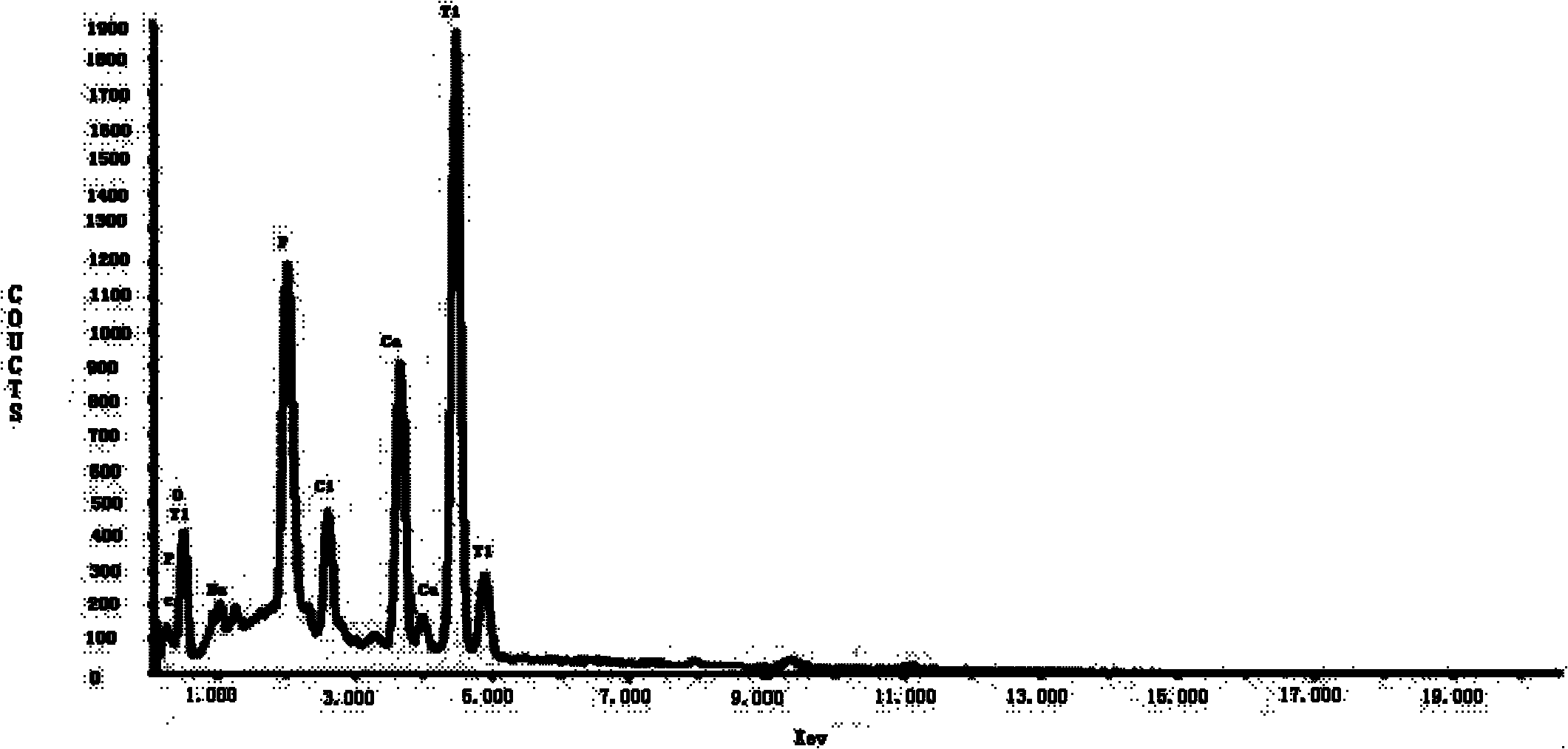

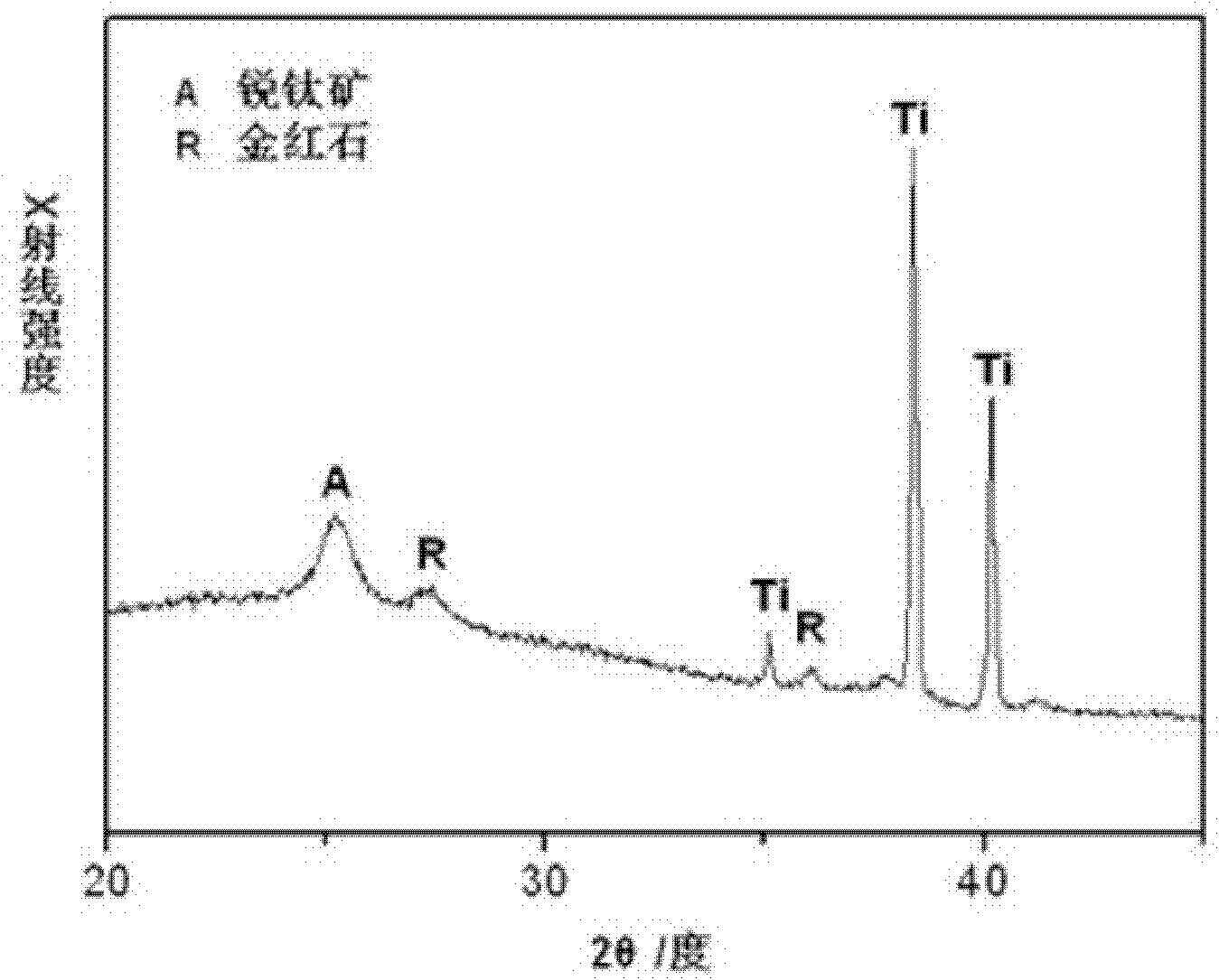

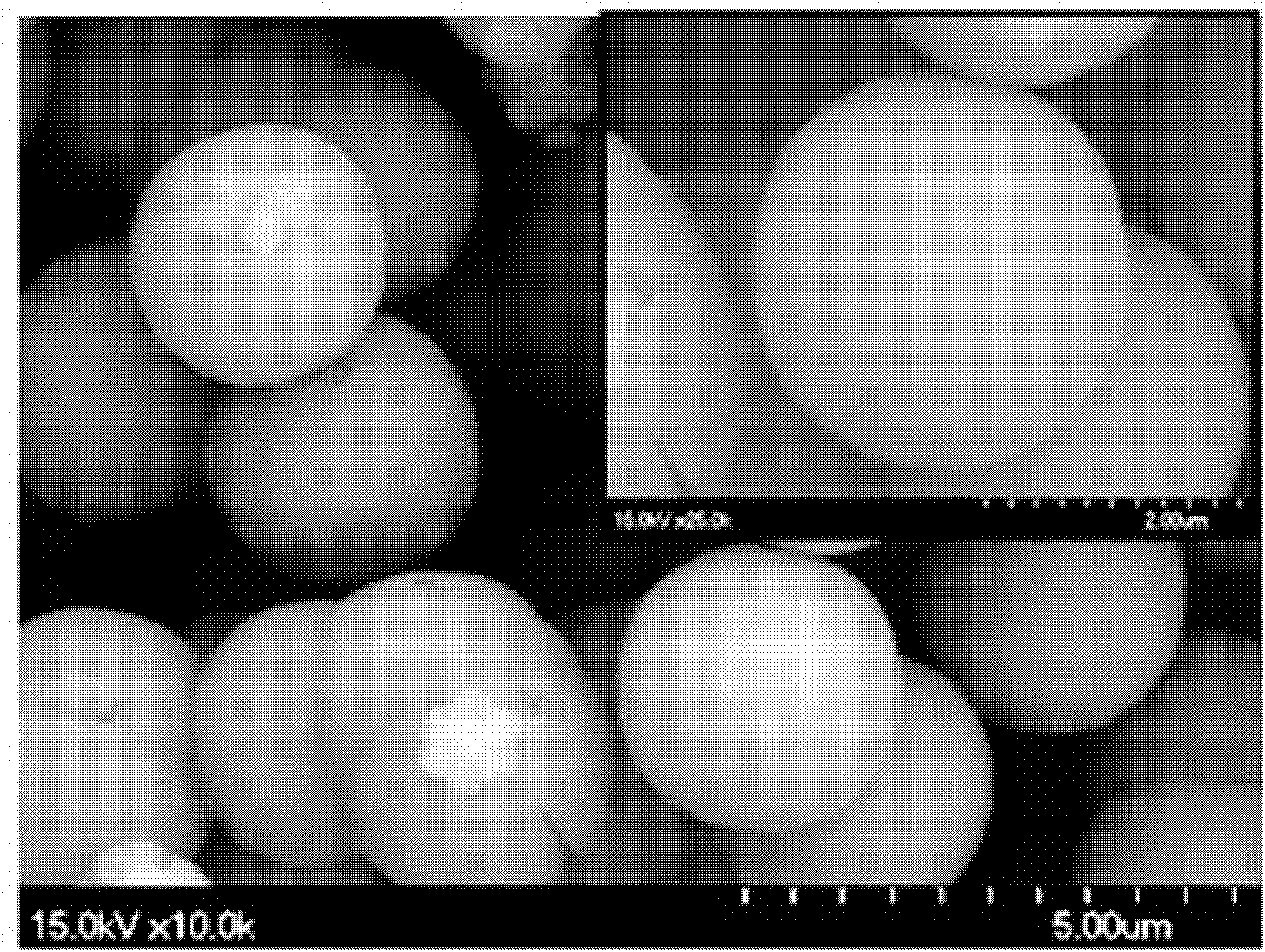

Composite material of inorganic nonmetallic mineral loaded with titania layer, preparation process and use thereof

InactiveUS20130052243A1Simple processLow costMaterial nanotechnologyBiocideNanoparticleRefractive index

The invention discloses composite materials, comprising an inorganic nonmetallic mineral as a support and a nanotitania layer loaded on the support, wherein the layer is comprised of a plurality of titania nanospheres, and the titania nanosphere is comprised of a plurality of nanotitania single particles. The invention also discloses composite materials further comprising one or more functional layers loaded on the nanotitania layer. The above composite materials may not only take advantage of the high refractive index and the high covering power of the nanotitania layer, but also make use of the good photocatalytic activity of the small single nanoparticles. Furthermore, the composite materials can be more readily coated by other functional layer(s) to prepare functionally strengthened or multi-functional composite materials. The invention also discloses methods for preparing the composite materials. The composite materials may be used as an additive with good compatibility in various industrial fields.

Owner:SHANGHAI WORLD PROSPECT CHEMTECH

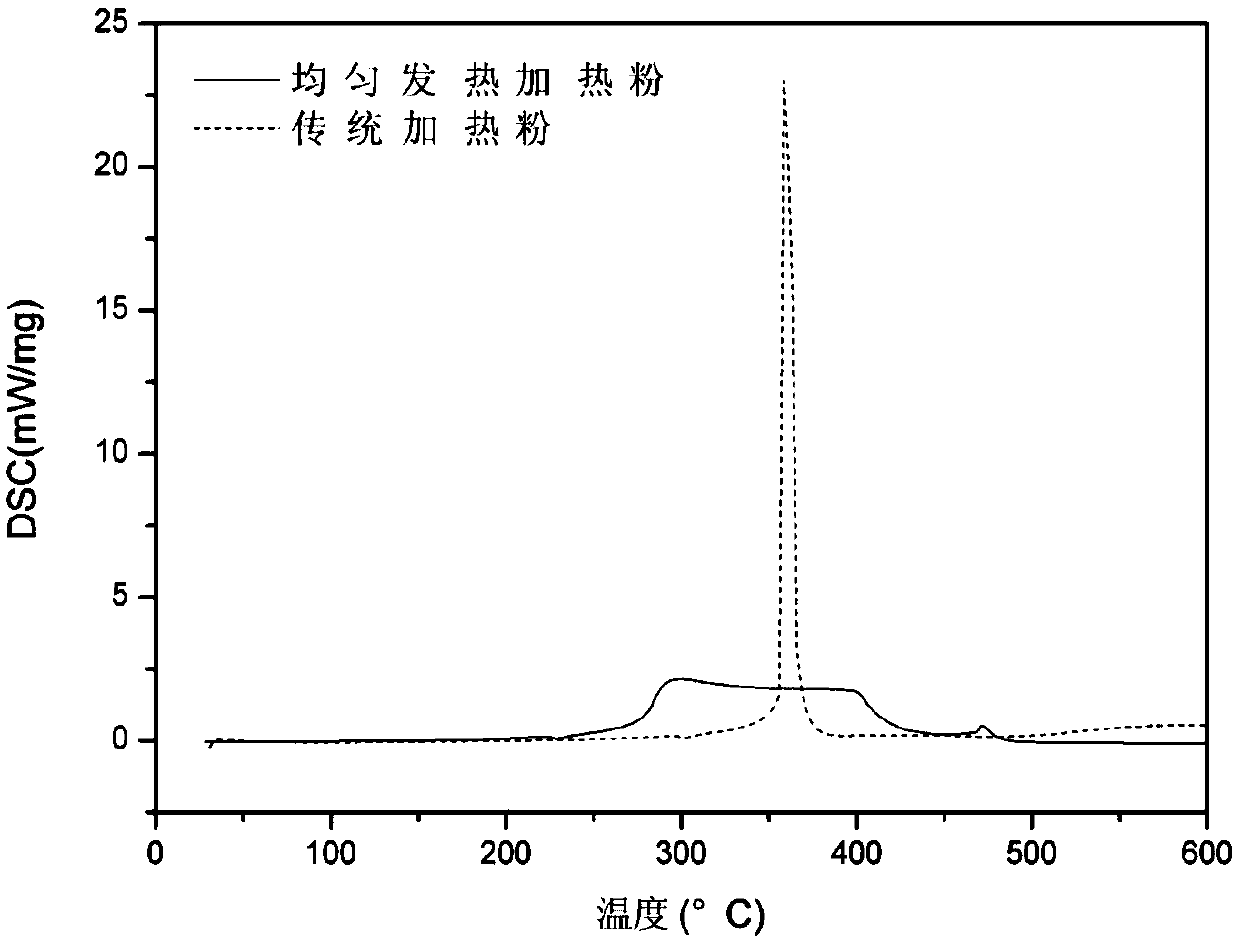

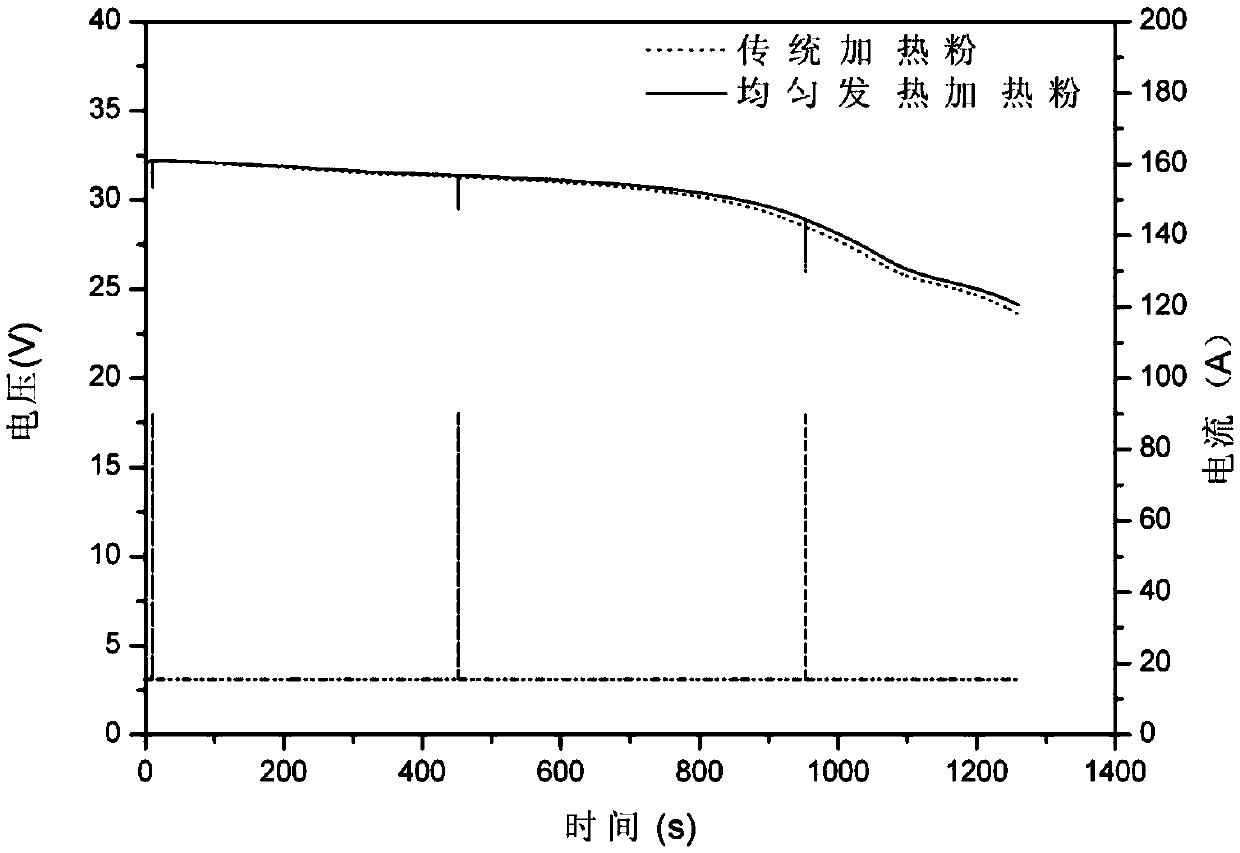

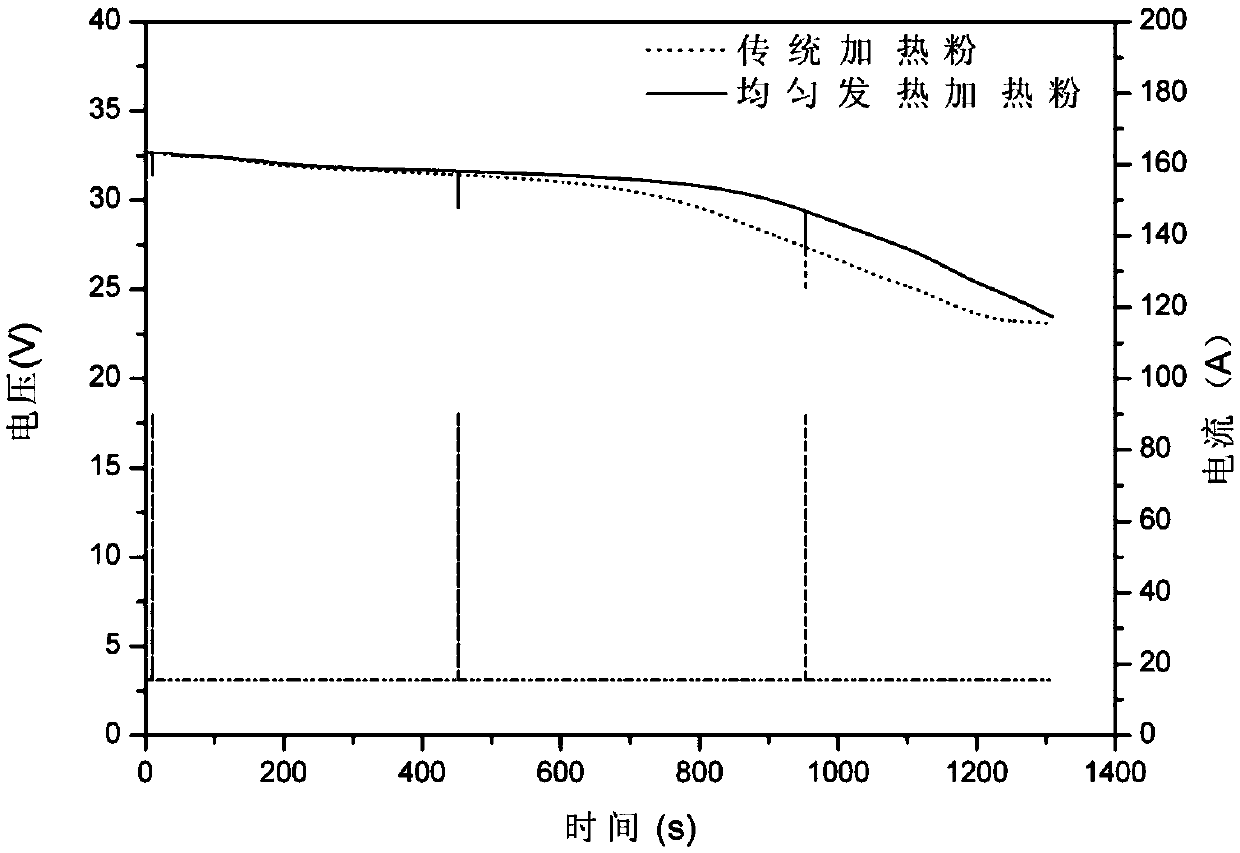

Manufacturing method for heating material uniformly heating used for thermal battery and application thereof

ActiveCN109546173AGood dispersionThe initial redox temperature value advancesDeferred-action cellsPrimary cell maintainance/servicingHigh energyFreeze-drying

The invention relates to a manufacturing method for a heating material uniformly heating used for a thermal battery and application thereof. The method comprises: pouring analytical pure grade potassium perchlorate into a high-energy ball-milling cup, adding appropriate water to prepare a slurry, placing a zirconia ball, performing high-energy ball milling, and then putting ball-milled powders into a freeze dryer to dehydrate, and then crushing using a pulverizer to obtain ultrafine potassium perchlorate, pouring active iron powders into an inert atmosphere glove box, adding an inorganic potassium salt, and then mixing the active iron powders and the inorganic potassium salt using a physical or chemical method, to form potassium-containing iron powders; finally, mixing the ultrafine potassium perchlorate and the potassium-containing iron powders according to a certain ratio. The method is beneficial to widening a heating region of a heating material, to release heat more uniformly, thereby weakening thermal shock amount on a positive electrode material of a thermal battery in an initial working phase of the material, and improving utilization rate of the positive electrode materialof the battery.

Owner:航天江南集团有限公司 +1

Silver/graphene low-temperature curing conductive rubber, conductive film, conductor and preparation method thereof

ActiveCN107502257AControl curing timeHigh specific surface energyNon-macromolecular adhesive additivesElectrically conductive adhesive connectionsFilling materialsLow temperature curing

The invention discloses a preparation method of low-temperature curing high-conductivity slurry and a conductive film. The low-temperature curing high-conductivity slurry is prepared by blending organic carriers with purpose-made nanometer stage silver powder mixed with a small amount of graphene as conductive filling materials. The conductive filling materials use nanometer stage silver powder compounding graphene, has the characteristic of high compactness, and enables the conducive rubber to form a better conductive path when being applied to the conductive rubber. The conductive slurry comprises double ingredients, and has the advantage of long storage period. Compared with the prior art, the preparation method has the advantages of low-temperature curing, high conductivity, high anti-shearing intensity, long storage period and the like and can be widely applied to printing circuit and LED (light emitting diode) chip bonding in electronic devices.

Owner:JINLING INST OF TECH

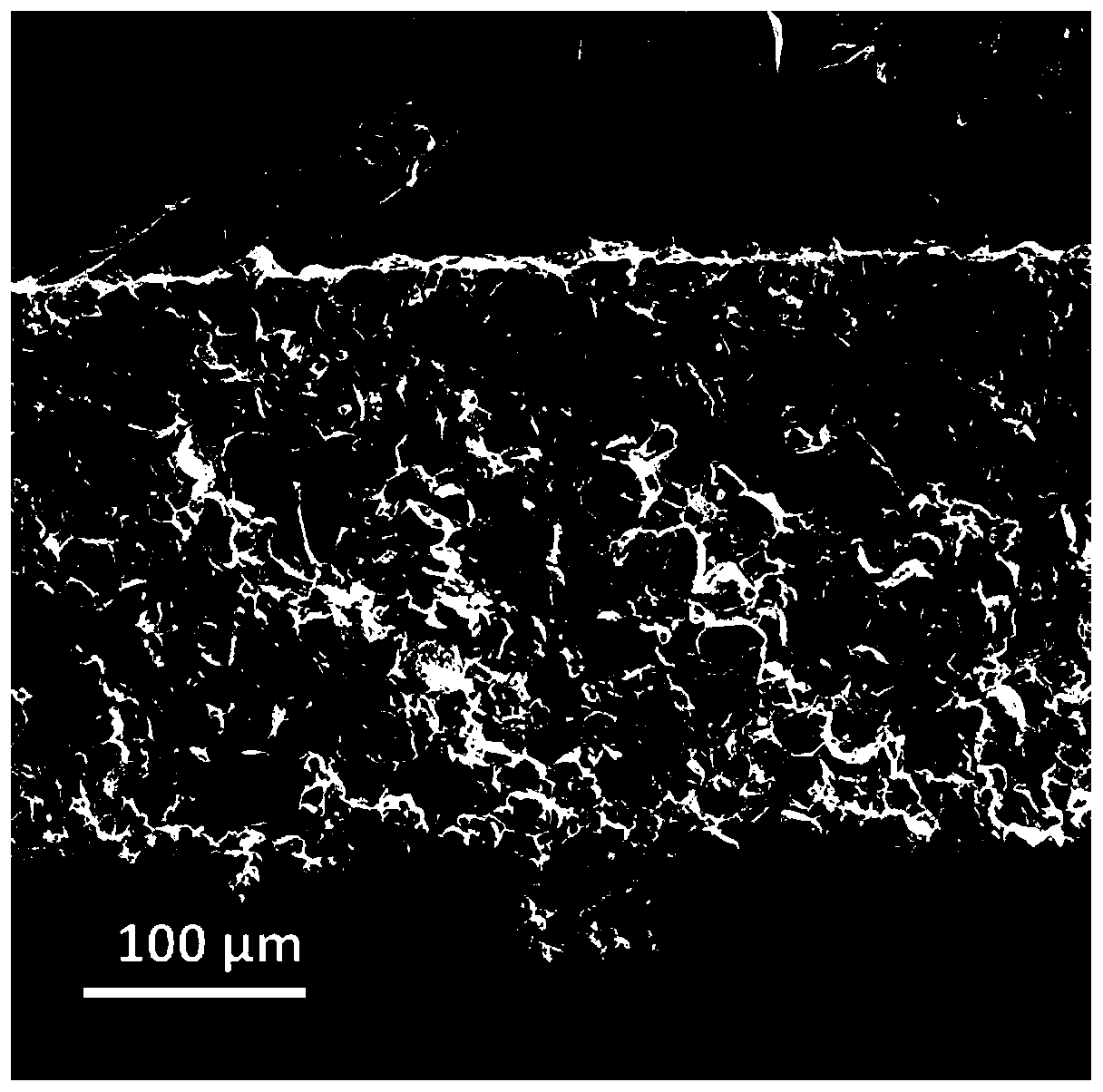

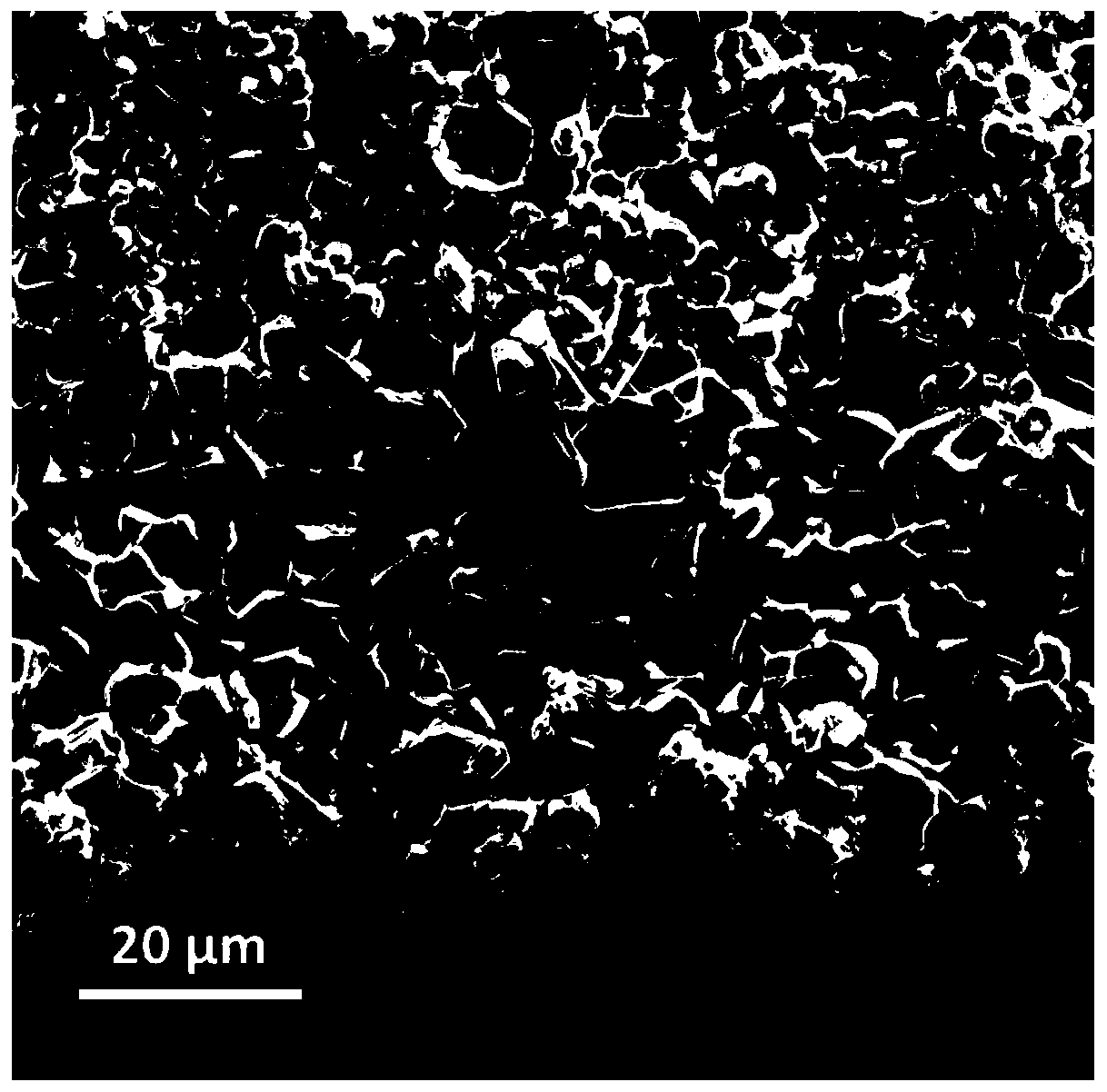

Preparation method of nano-fiber membrane with three-dimensional porous structure for lithium ion battery diaphragm

InactiveCN103618056ALarge specific surface areaHigh specific surface energyMaterial nanotechnologyFibre treatmentNonwoven fabricLithium-ion battery

The invention relates to a preparation method of a nano-fiber membrane with a three-dimensional porous structure for a lithium ion battery diaphragm. The preparation method comprises the steps of blending and extruding inorganic nanoparticles, ethylene-vinyl alcohol copolymer and cellulose acetate butyrate; extracting by using acetone to obtain inorganic nanoparticle / ethylene-vinyl alcohol copolymer nano-fibers; then, preparing the nano-fibers into a suspension; uniformly spraying the suspension on two surfaces of a non-woven fabric; drying to obtain an inorganic nanoparticle / ethylene-vinyl alcohol copolymer nano-fiber membrane; then, uniformly spraying the suspension prepared from the inorganic nanoparticles on a membranous layer of the nano-fiber membrane; drying to obtain the nano-fiber membrane with a three-dimensional porous structure for the lithium ion battery diaphragm. The nano-fiber membrane has the advantages of high porosity, high liquid absorption rate, good heat resistance and the like, can effectively absorb an electrolyte solution required by an electrochemical reaction, is favorable for transmission of lithium ions in the diaphragm, and improves the specific capacity, coulomb efficiency and safety performance of a lithium ion battery. The preparation method disclosed by the invention is simple in process, low in production cost, high in efficiency and capable of meeting requirements for industrial production.

Owner:WUHAN TEXTILE UNIV

High-toughness haydite concrete and preparation method thereof

ActiveCN105541201AEffectively exert the effect of synergistic tougheningPreparation conditions are easy to meetCrack resistanceSlag

The invention discloses a high-toughness haydite concrete and a preparation method thereof. The high-toughness haydite concrete is prepared from the following raw materials in parts by weight: 320-360 parts of cement, 40-80 parts of lithium slag powder, 20-40 parts of silica fume, 700-900 parts of regenerated coarse aggregate, 500-800 parts of haydite, 3-4 parts of water reducing agent, 100-120 parts of water, 10-20 parts of polyacrylate, 20-30 parts of toughening additive, 0.05-0.1 part of sodium gluconate and 10-15 parts of triethanolamine. A modified composite carbon nano material, activated wood meal and isotactic polypropylene are combined to prepare the unique toughening additive under the surface modification actions of a coupling agent and a compatilizer; and the toughening additive can be sufficiently dispersed in the concrete to effectively display the synergic toughening effect of the materials, so that the prepared concrete has the advantages of favorable toughness, favorable fatigue resistance, favorable isotropy, favorable impact resistance, favorable earthquake resistance and favorable crack resistance.

Owner:上犹万年青新型材料有限公司

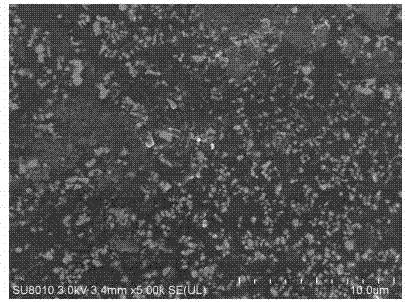

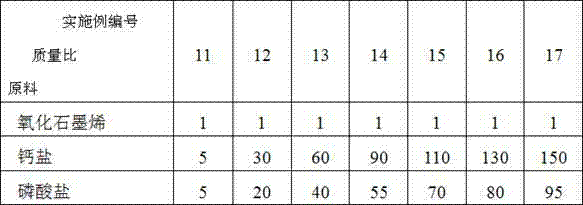

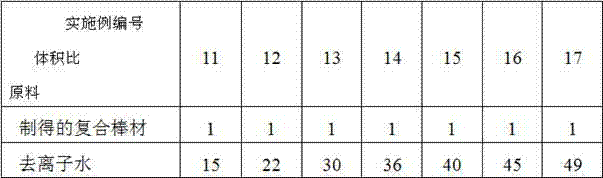

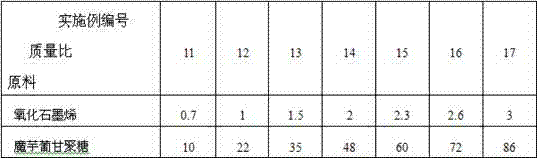

Production method of three-dimensional porous composite bar

The invention discloses a production method of a three-dimensional porous composite bar. The method is characterized by comprising the following steps of: preparing a graphene oxide solution; adding calcium salt and phosphate into the graphene oxide aqueous solution to be uniformly stirred, thus obtaining a graphene oxide / hydroxyapatite precursor solution; and adding konjac glucomannan into the graphene oxide / hydroxyapatite precursor solution under stirring, stirring the solution for 10-120 minutes at 35-60 DEG C, standing, filling the obtained mixed solution into a dialysis bag, soaking the sealed dialysis bag into alkaline solidification liquid, soaking the dialysis bag for 5-15 days at 40-60 DEG C, soaking materials in the dialysis bag in deionized water, cleaning and drying the materials, freezing the materials at a super low temperature and performing vacuum freeze drying on the materials to obtain the three-dimensional porous composite bar. The mechanical property and porosity of the produced composite bar can meet the clinical use requirements of bone repair scaffold materials, and the composite bar can effectively promote bone tissues to quickly and spontaneously repair defects and has a good effect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method for functional film capable of simultaneously realizing oil-water emulsion separation and dye removal

PendingCN108905651ANo secondary pollutionPost-processing is simpleSemi-permeable membranesMembranesMatrix solutionOrganic dye

The invention discloses a preparation method for a functional film capable of simultaneously realizing oil-water emulsion separation and dye removal. The method comprises the following steps: (1) preparing a polymer matrix solution; and (2) combining a hydroxyl-containing substrate with the polymer matrix solution, and enabling acceleration of gelation and introduction of charged functional groupsto be realized in one step to obtain the functional film capable of simultaneously realizing the oil-water emulsion separation and the dye removal. According to the method disclosed by the invention,the polymer matrix solution gives high specific surface energy to the hydroxyl-containing substrate, so that super-hydrophilic underwater super-oleophobic performance is obtained, and high-efficiencyseparation of oil and water can be realized; and the charged functional groups are introduced, organic dye is adsorbed through electrostatic interaction, so that the organic dye is removed, and finally dye pollutants are removed while an oil-water emulsion is separated only by gravity.

Owner:石狮市川大先进高分子材料研究中心

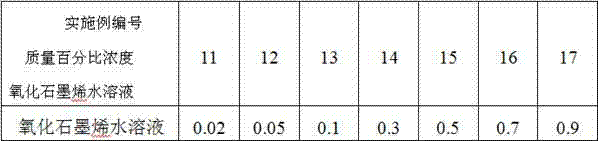

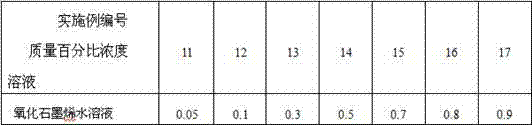

Preparation method of graphene oxide/konjac glucomannan degradable composite film material

The invention discloses a preparation method of a graphene oxide / konjac glucomannan degradable composite film material. The preparation method is characterized by comprising the steps of: preparing graphene oxide aqueous solution with mass percent concentration of 0.01-1%; adding konjac glucomannan in the graphene oxide aqueous solution under stirring according to a proportion that the mass ratio of graphene oxide to konjac glucomannan is 1: 1-200, stirring for 0.5-3 hours at 30-60DEG C, and standing to obtain a film solution; pouring the film solution in a die for manufacturing a film, drying in a drying oven, cooling, and uncovering the film to obtain the composite film; and placing the composite film in glutaraldehyde aqueous solution, reacting for 1-5 hours at 5-60DEG C, taking out, and drying to obtain the graphene oxide / konjac glucomannan degradable composite film material. The material prepared by the method has the advantages of good mechanical property, high heat stability, good degradability and biocompatibility and the like, and can be used as a tissue engineering support material or a package material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

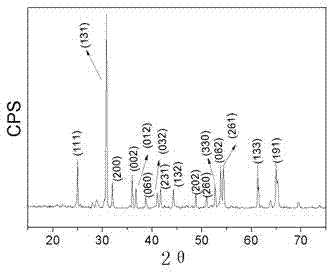

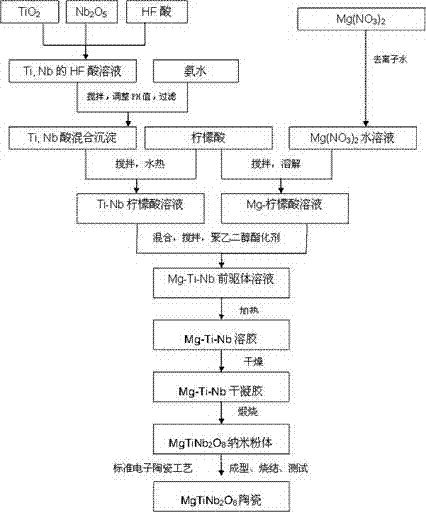

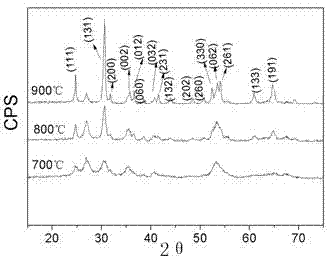

New method for finely preparing ixiolite structure MgTiNb2O8 microwave dielectric ceramic by using chemical process

Owner:UNIV OF JINAN

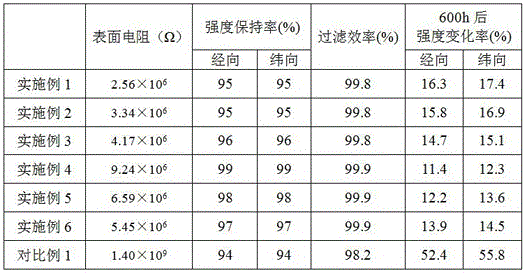

Preparation method of antistatic filter material

ActiveCN106377941AEfficient and durable antistaticImprove conductivityElectroconductive/antistatic filament manufactureDispersed particle filtrationPolymer scienceConductive polymer

The invention discloses a preparation method of an antistatic filter material, and belongs to the technical field of filter materials. The preparation method comprises the following steps: depositing a first conductive layer on a base cloth layer; loading second conductive layers on the surfaces of fiber layers by using an electrostatic spinning process; placing the treated base cloth layer between the two fiber layers, and fixedly binding the base cloth layer and the fiber layers together through needling or spunlacing. The filter material prepared by the preparation method is high in filter efficiency, antistatic property and high-temperature resistance.

Owner:江苏三元环保科技有限公司

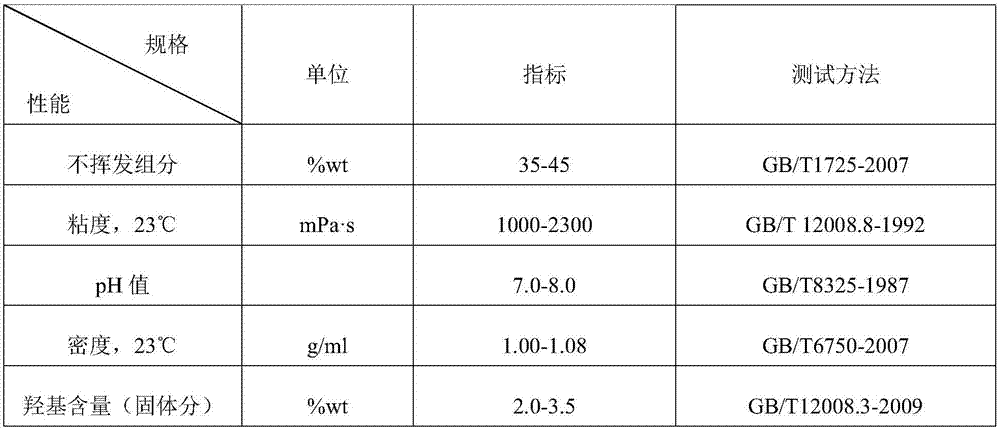

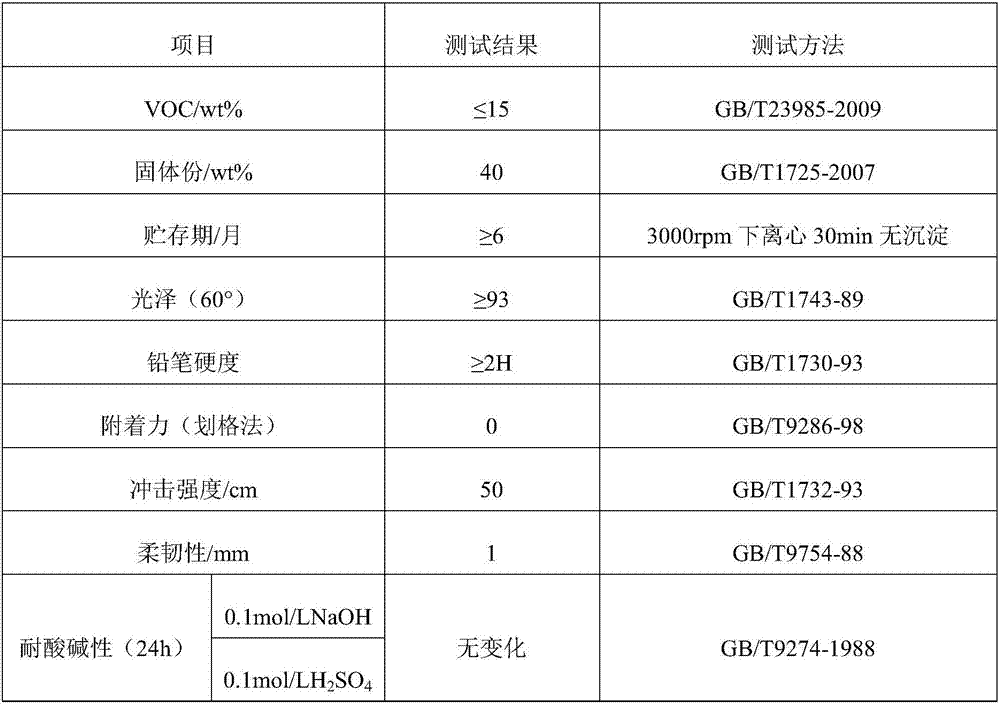

Preparation of graphene oxide nanometer modified acrylate aqueous dispersion and application of same to waterborne automobile coating

ActiveCN107501467AHigh specific surface energyGood mechanical propertiesFireproof paintsSolventAcrylate

The invention relates to preparation of graphene oxide nanometer modified acrylate aqueous dispersion and application of the same to waterborne automobile coating, belongs to series of waterborne automobile coating, and discloses a method for preparing graphene oxide nanometer modified acrylate aqueous dispersion. The preparation and the application have the advantages that special physical and chemical performance of nanometer materials and merits of acrylate are sufficiently combined with one another, accordingly, the graphene oxide nanometer modified acrylate aqueous dispersion is excellent in performance in the aspects of mechanical properties, solvent resistance, stability and the like, formed paint films are high in gloss, good in fullness and solvent resistance and excellent in mechanical performance, the comprehensive performance can be greatly improved, environments can be protected, energy can be saved, and the graphene oxide nanometer modified acrylate aqueous dispersion is high in operability and convenient to popularize and apply and has a broad market prospect.

Owner:QINGYUAN HAOYU CHEM TECH

Preparation method for high-coercivity sintered neodymium-iron-boron

ActiveCN103956244AAccurate ingredientsExtend the life cycleInorganic material magnetismDehydrogenationNitrogen gas

The invention discloses a preparation method for high-coercivity sintered neodymium-iron-boron. The method specifically comprises the following steps: batching raw materials proportionally, and preparing a thin alloy sheet by using a medium-frequency vacuum rapid-hardening melt-spinning furnace; performing normal-temperature hydrogen absorption and heating dehydrogenation on the thin alloy sheet in a reaction kettle of a hydrogen decrepitating furnace to prepare coarse particles of which the particle size is 60-80 meshes; milling hydrogen-decrepitated coarse powder by using a jet mill to form fine powder of which the average particle size is 2.0-4.0 mu m; adding one or more rare-earth nano additives into the powder by using a jet method, and performing uniform mixing in the atmosphere of argon shielding; performing oriented molding and isostatic pressing on the mixed powder under the argon shielding through a 1.8-3.0T magnetic field; filling a green neodymium-iron-boron body into a vacuum sintering furnace in a closed glove box full of nitrogen, continuously sintering the green neodymium-iron-boron body for three times, quickly cooling the green neodymium-iron-boron body, and finally, aging the green neodymium-iron-boron body twice to prepare a corresponding neodymium-iron-boron magnet of which the performance meets the national standard. The method is low in cost, simple in process, energy-saving, environmentally-friendly, and high in rare-earth utilization rate.

Owner:SHENYANG SHENGSHI WUHUAN TECH CO LTD

Low-impedance interface processing method of solid-state lithium battery positive electrode and positive electrode structure

ActiveCN109768215AImprove securityAvoid punctureNon-aqueous electrolyte accumulator electrodesSolid state electrolyteEngineering

The invention discloses a low-impedance interface processing method of a solid-state lithium battery positive electrode and a positive electrode structure. By the method, impedance of two interfaces between active material particle in a positive electrode plate and solid-state electrolyte particle and between the positive electrode plate and an electrolyte piece can be effectively reduced, so thatthe capacity of active positive electrode particle in the solid-state lithium battery can be effectively developed. The dual-layer structure ceramic piece comprising a solid-state electrolyte layer and a positive electrode layer and fabricated by the method is excellent in performance and has favorable application prospect in the field of solid-state lithium batteries.

Owner:杭州阳名新能源设备科技有限公司

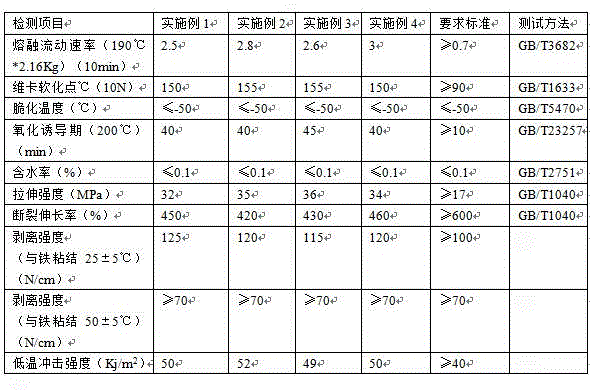

Adhesive for anticorrosive paint for deep-sea oil-gas delivery steel tube outer walls and preparation method thereof

InactiveCN104087211AHigh temperature limitImprove adhesionNon-macromolecular adhesive additivesPolymer sciencePolyolefin

The invention provides an adhesive for an anticorrosive paint for deep-sea oil-gas delivery steel tube outer walls and a preparation method thereof. The adhesive is prepared from the following raw materials in percentage by mass: 55-70% of polypropylene, 20-30% of functional polyolefin, 2-6% of reactive monomer, 1-3% of graphene, 2-5% of nano CaCO3, 0.1-0.6% of initiator, 0.4-0.8% of nucleating agent and 0.1-1.5% of antioxidant. The preparation method comprises the following steps: mixing the raw materials, stirring uniformly, putting in a double screw extruder, carrying out compounding and plastifying, drawing, cooling with water, airing, granulating, extruding for granulation, and packaging to obtain the adhesive. The adhesive has excellent mechanical properties, higher low-temperature impact resistance and wide application range.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

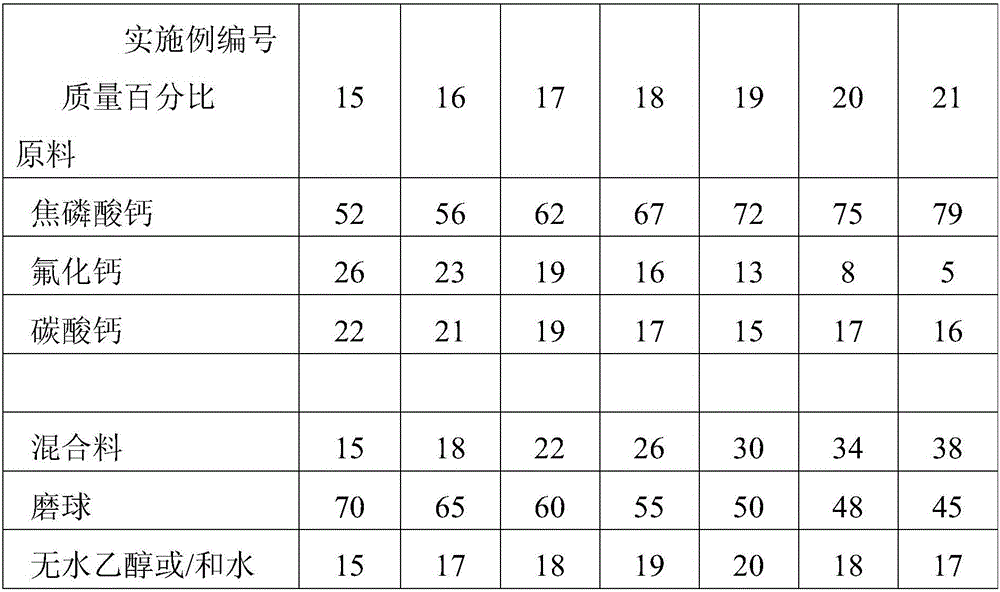

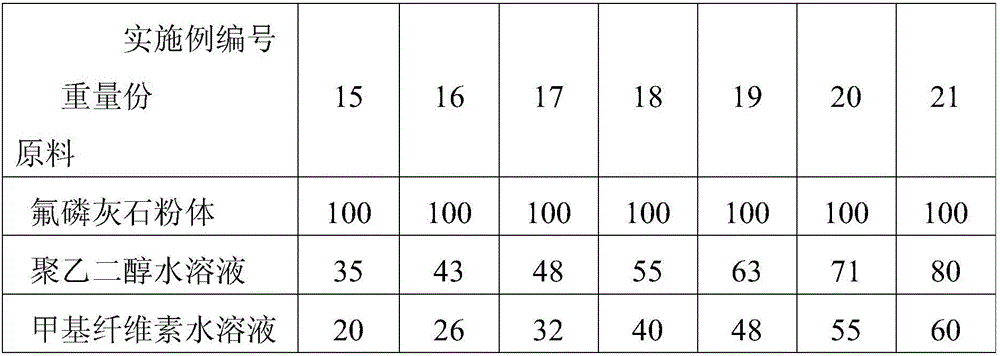

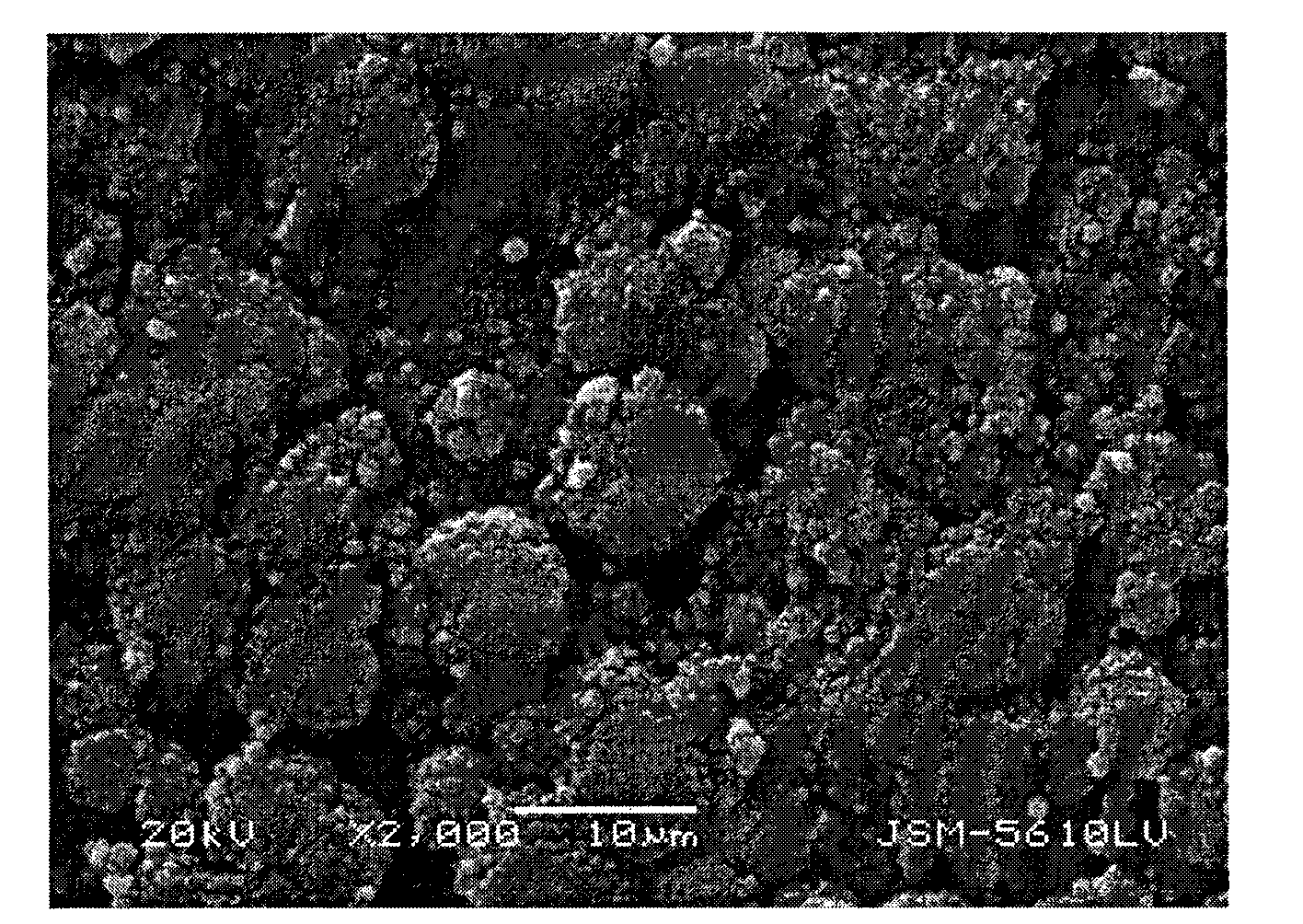

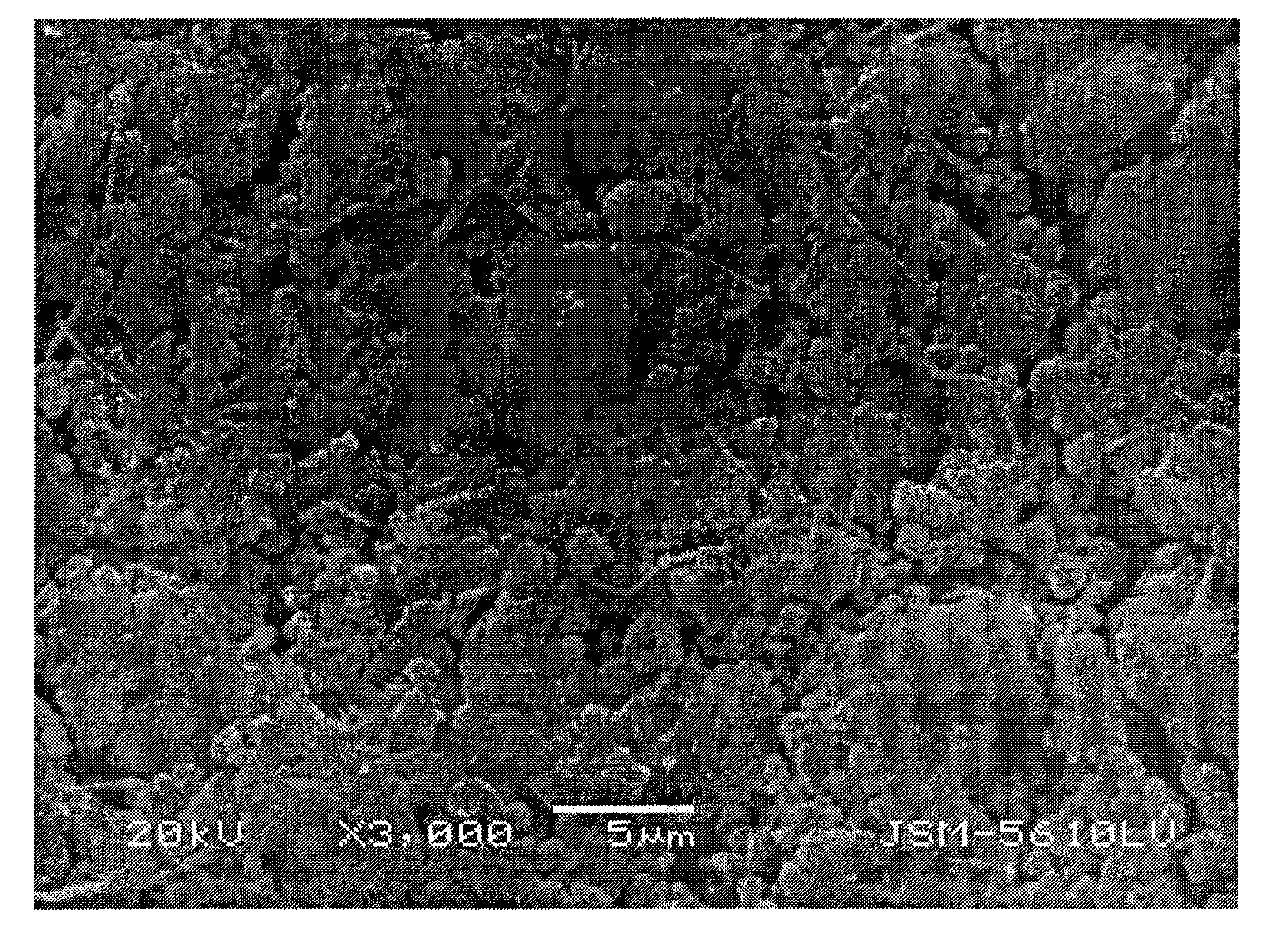

Method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide

ActiveCN106045495AGood chemical stabilityReduce solubilityRadioactive decontaminationCeramicwareEcological environmentPolyethylene glycol

A method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide is characterized by including: using the materials in percent by weight: 50-80% of calcium pyrophosphate, 4-26% of calcium fluoride and 16-45% of calcium carbonate, and mixing, ball-milling, drying, press-forming, calcining, grinding, and screening to obtain fluorapatite powder; mixing the fluorapatite powder with polyethylene glycol solution, methyl cellulose solution and hydrogen peroxide solution, and performing microwave assisted pore-forming, drying and the like to obtain a porous fluorapatite ceramic blank; preparing porous fluorapatite ceramic adsorbing material via normal pressure sintering. The porous fluorapatite ceramic adsorbing material prepared herein has the advantages of high radiation stability, good thermal stability, high mechanical and chemical stability and the like, also has high specific surface energy and nuclide adsorbing capacity and may be used as an efficient adsorbing material for radioactive nuclide in high-radioactive waste liquid, thus effectively protecting human health and ecological environment.

Owner:SOUTHWEAT UNIV OF SCI & TECH

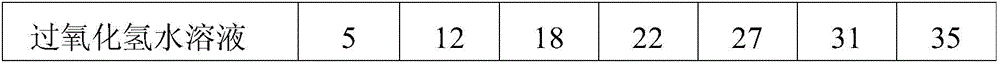

Method for removing sulfate and Zn(II) wastewater by virtue of synergism of spongy iron and microorganisms

ActiveCN106007001ALarge specific surface areaHigh specific surface energyTreatment with anaerobic digestion processesRisk strokeSolid phases

The invention relates to a method for removing sulfate and Zn(II) wastewater by virtue of synergism of spongy iron and microorganisms. The method comprises the following steps of: mixing a spongy iron solution A, a bacterial suspension B of sulphate reducing bacteria and a bacterial suspension C of ferric reducing comamonas at a volume ratio of (1:1:1) to (1:3:4), aging the mixture for 40-60 minutes, repeatedly washing with deoxidization deionized water after reaction is finished, and soaking a product in a stroke-physiological saline solution, thereby obtaining a mixture of spongy iron and sulphate reducing bacteria / iron-reducing bacteria; mixing the mixture of spongy iron and sulphate reducing bacteria / iron-reducing bacteria with the sulfate and the Zn(II) wastewater, performing reaction at a room temperature for 20 hours or more, and purifying the wastewater sulfate and the Zn(II) at the same time. The method is capable of achieving the Zn(II) removal rate not less than 91%, required equipment is simple, the operation is convenient, reaction is finished at the normal temperature and a normal pressure, products are in a solid phase, the reaction system is in a liquid phase, the products are easy to separate, and the method is suitable for large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of nano palladium oxide catalyst

ActiveCN103381364AShape is easy to controlConsistent sizeMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAlumina composite

A preparation method of nano palladium oxide catalyst comprises following steps: (1) preparing a nano palladium array and an alumina composite structure; (2) extracting the nano palladium array; (3) subjecting the nano palladium array to a heat treatment to obtain a nano palladium oxide array. The operation of the preparation method is simple. The pH value is adjusted through controlling the ammonia liquor concentration in the electro-deposition solution. The electro-deposition current density, the electro-deposition time, and the temperature and time during the heat treatment process are controlled to prepare a nano-grade palladium oxide array, which has a relatively high specific surface energy and catalyzing ability. The morphology of the nano palladium oxide is controllable, the size of the nano palladium oxide is the same, the application range is wide, and the nano palladium oxide is especially suitable for applications of tailing gas purifying technology in the automobile industry.

Owner:HUNAN JIANTE TECH CO LTD

Hexadecyl trimethyl ammonium bromide expansive soil improvement agent

InactiveCN1850702AImprove the nature of the projectReduce negative chargeSoil propertiesRoom temperature

The invention is a palmityl trimethyl ammonium bromide expansive soil modifier, characterized in comprising the preparing steps of: (1) at room temperature, preparing saturated lime water solution; (2) weighing the needed palmityl trimethyl ammonium bromide in the mass ratio of palmityl trimethyl ammonium bromide to dry soil = 0.5 : 99.5; (3) dissolving the palmityl trimethyl ammonium bromide in the saturated lime water solution, where it needs to notice that the dosage of the saturated lime water solution is able to completely dissolve the palmityl trimethyl ammonium bromide. And the advantages: making the soil property still able to reach the specified standard under the water influence; improving engineering property of expansive soil; unable to cause environmental pollution. And its construction method uses osmotic modification principle and fully uses multi-crack property of expansive soil and is simple and convenient.

Owner:HOHAI UNIV

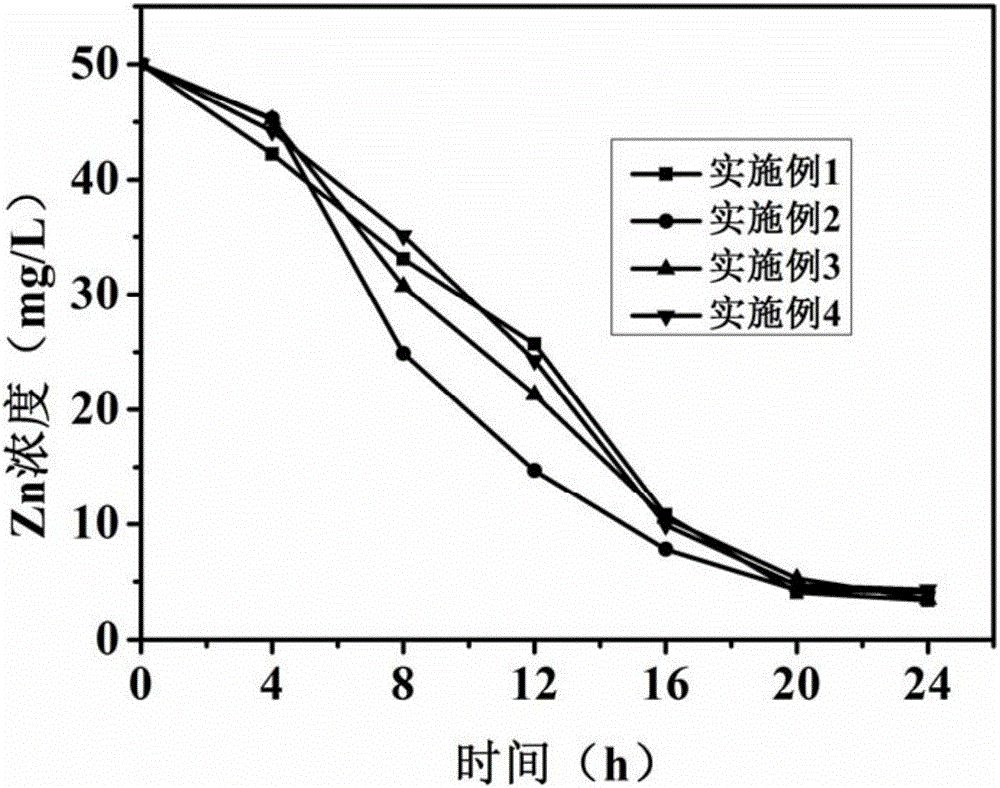

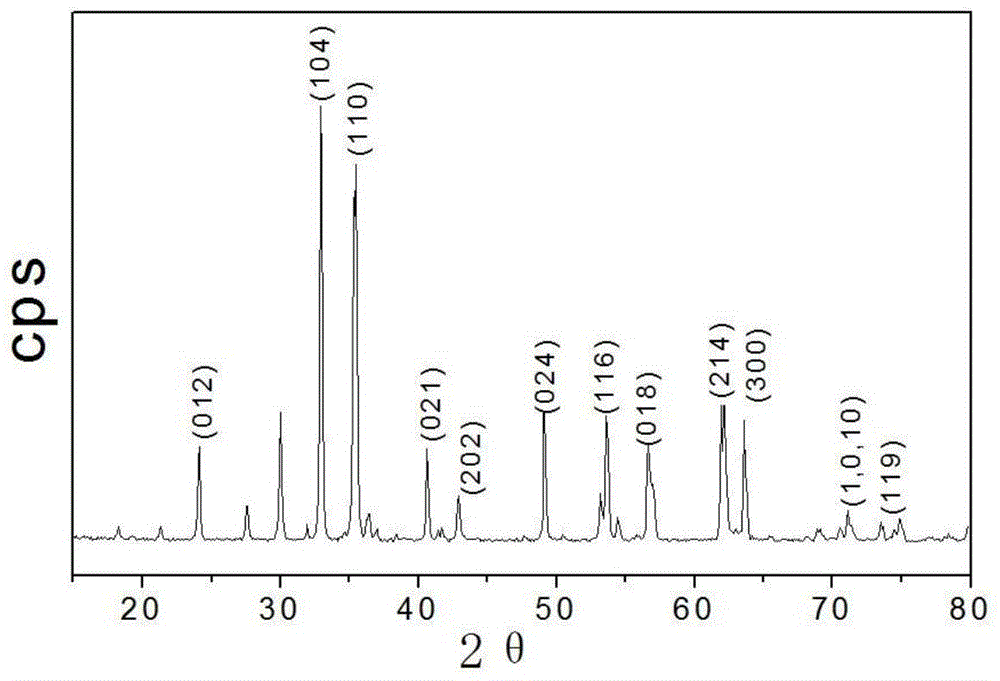

Method for finely synthesizing ilmenite-structured ZnTiO3 nano powder by using water-soluble sol-gel process

InactiveCN104609466ASynthesis temperature is lowSimple processTitanium compoundsDispersityDielectric

The invention belongs to the technical field of electronic ceramic preparation and application, and in particular relates to a method for finely synthesizing ilmenite-structured ZnTiO3 series microwave dielectric ceramic nano powder by using a water-soluble sol-gel process. The method comprises the following steps: 1) preparing a citric acid solution of Zn ions; 2) preparing a citric acid solution of Ti; 3) synthesizing a ZnTiO3 microwave dielectric ceramic nano precursor. As oxides and inorganic nitrate which are low in price are taken as raw materials, and expensive alkoxides are not used, the synthesized powder has the remarkable advantages that the synthesis temperature is low, the ceramic particles are uniform, good dispersity is achieved, the phase is pure, various elements can be finely doped and modified, the prepared powder has the nano particle size (about 30nm), is high in specific surface property and is relatively high in activity, later low-temperature sintering can be achieved, and LTCC application requirements can be possibly met.

Owner:JINAN WEIBO NEW MATERIAL

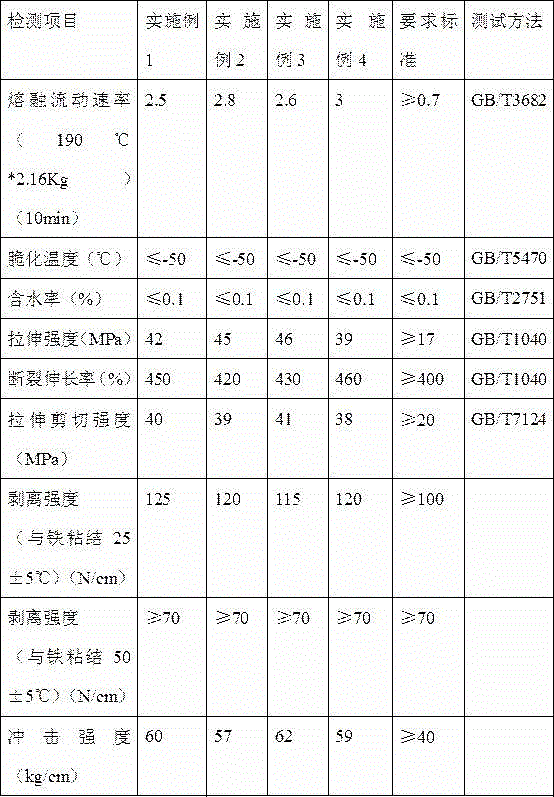

3PE anticorrosive paint epoxy bottom layer for outer wall of deep sea oil and gas transmission steel pipe and preparation method of 3PE anticorrosive paint epoxy bottom layer

InactiveCN104449208AImprove adhesionGood mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsGas phaseFirming agent

The invention provides a 3PE anticorrosive paint epoxy bottom layer for an outer wall of a deep sea oil and gas transmission steel pipe and a preparation method of the epoxy bottom layer. The epoxy bottom layer comprises the following raw materials in percentage by mass: 60%-75% of epoxy resin, 5%-10% of a silane coupling agent, 0.5%-1.5% of graphene oxide, 2%-5% of gaseous phase SiO2 and 15%-30% of a curing agent. The preparation method comprises the following steps: mixing the raw materials evenly; carrying out ultrasonic treatment; putting into a stirrer and stirring evenly; and heating and solidifying, so as to obtain the epoxy bottom layer. The epoxy bottom layer has excellent mechanical property and wide application; and particularly, the anti-tensile shearing strength and the impact strength are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

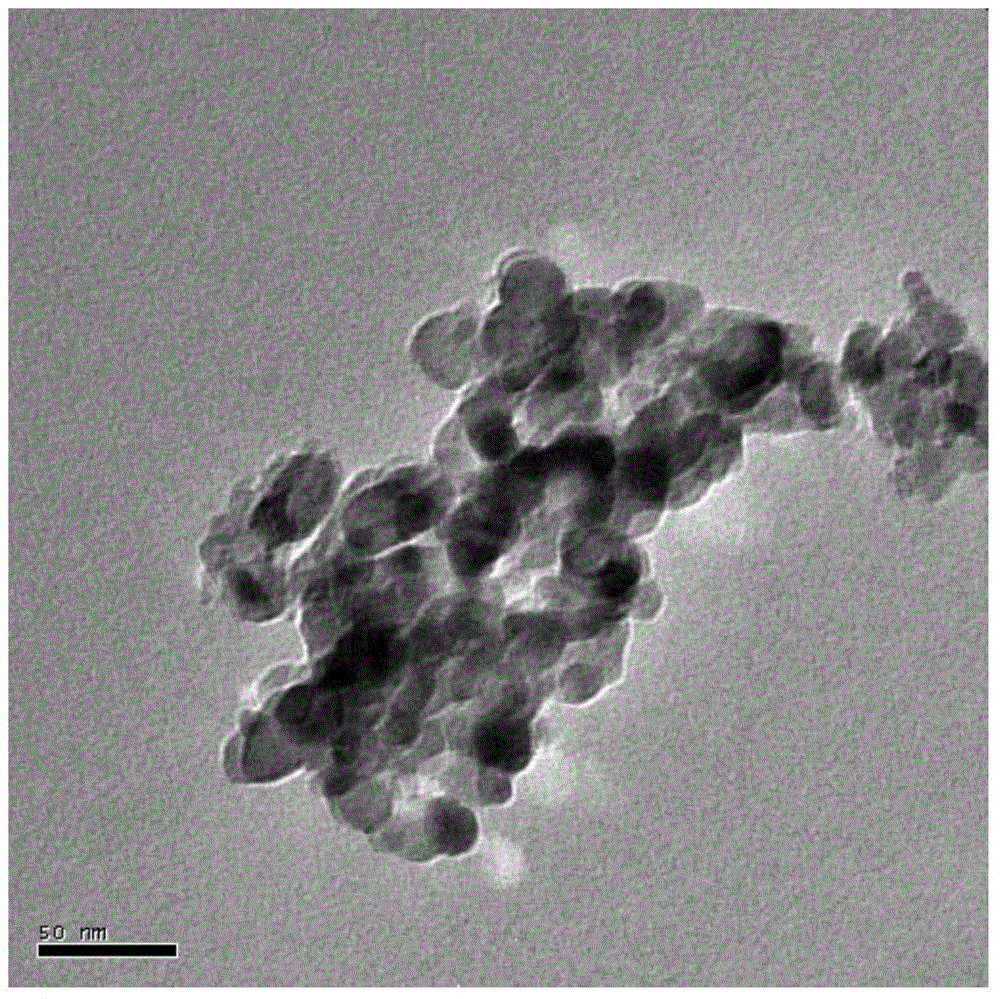

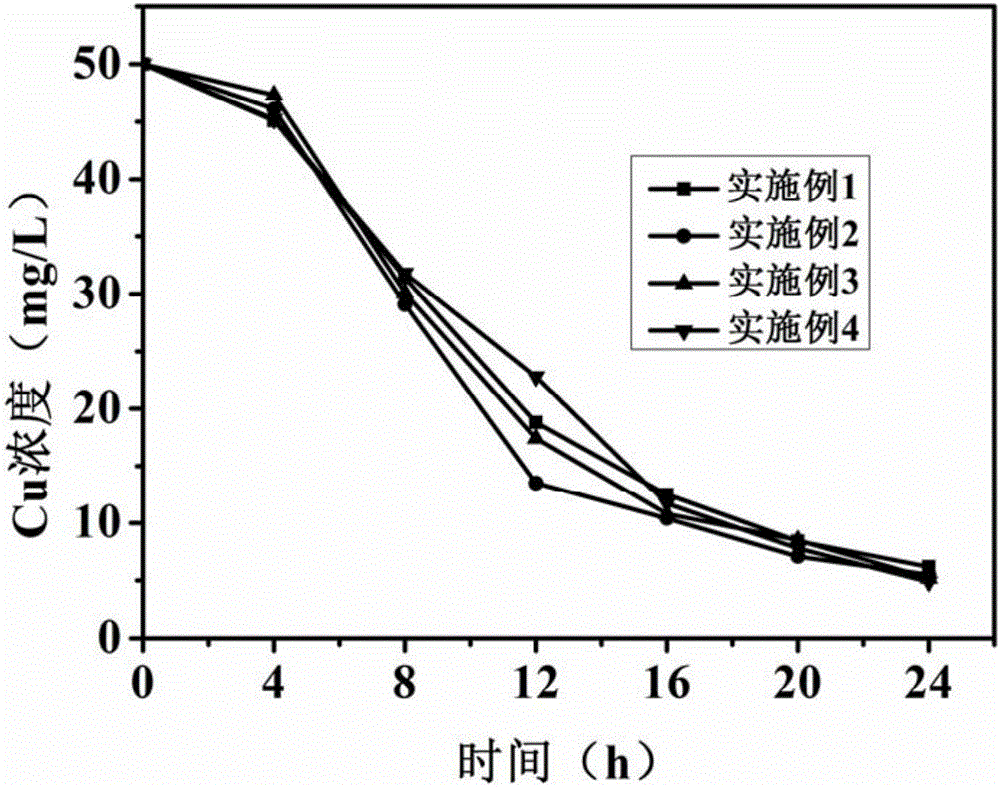

A method of removing sulfates and Cu (II) in waste water through combining sponge iron and microbes

ActiveCN106396124ALarge specific surface areaHigh specific surface energyWater contaminantsBiological water/sewage treatmentSulfate-reducing bacteriaSolid phases

A method of removing sulfates and Cu (II) in waste water through combining sponge iron and microbes is disclosed. The method includes mixing a sponge iron solution A, a sulfate reducing bacterium suspension B and an iron-reducing comamonas bacterium suspension C in a volume ration of 1:1:1-1:3:4 under anaerobic conditions, ageing for 40-70 min, repeatedly washing with deoxygenated deionized water after the reaction is finished, and soaking in sterile physiological saline to obtain a mixture of the sponge iron and the sulfate reducing bacteria / iron-reducing bacteria. The mixture is mixed with the waste water containing the sulfates and the Cu (II), and reacted at room temperature for 20 h or more to simultaneously purify the sulfates and Cu (II) in the waste water. The removing rate of the Cu (II) by the method is 87% or above. The method is simple in required device and convenient to operate. Reactions are finished at room temperature under atmospheric pressure. A product is a solid phase, and a reaction system is a liquid phase so that the product is easy to separate. The method is suitable for large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Medical titanium or titanium alloy surface activation modifying method

InactiveCN102100926ARich physical and chemical propertiesHigh specific surface energyCoatingsProsthesisIonSalt water

The invention relates to a medical titanium or titanium alloy surface activation modifying method which comprises the steps of: 1, with a surfactant modified monodisperse polystyrene (PS) sphere as a template and an inorganic titanium salt water solution as a precursor solution, preparing a processing solution; 2, with pure titanium or titanium alloy as a matrix, immersing the pure titanium or titanium alloy in the processing solution, and keeping the temperature of the processing solution to be 60-100 DEG C for 24-50h, wherein UV-irradiation is carried out within at least 0.25-2h, and the matrix is soaked in the processing solution with the temperature of 60-100 DEG C; and taking the soaked matrix out, immersing into an organic solvent capable of dissolving the PS for soaking to remove the PS, soaking and crystallizing in deionized water, and completing the deposition of a film. The self-assembling nano crystal titanium dioxide microcapsule biological film is prepared by using the monodisperse polystyrene sphere as the template and the low-price inorganic titanium salt as the raw material at low temperature through a hydrolysis-sol method, and has better bioactivity.

Owner:ZHEJIANG UNIV OF TECH

Composite toughened grouting cement mortar and preparation method thereof

ActiveCN105541202AEffectively exert the effect of synergistic tougheningThe preparation conditions are metEpoxyCrack resistance

The invention discloses a composite toughened grouting cement mortar and a preparation method thereof. The composite toughened grouting cement mortar is prepared from the following raw materials in parts by weight: 80-100 parts of cement, 120-180 parts of 50-200-mesh fine sand, 20-50 parts of water, 5-10 parts of polyurethane solution, 5-10 parts of epoxy resin emulsion, 10-15 parts of toughening additive, 1.5-6 parts of early-strength admixture, 2-9 parts of methacrylic acid, 2-6 parts of calcium formate, 2-8 parts of neopentyl glycol, 0.2-0.8 part of sodium dodecyl benzene sulfonate and 0.9-2.4 parts of water reducing agent. A modified composite carbon nano material, activated wood meal and isotactic polypropylene are combined to form the unique toughening additive under the surface modification actions of a coupling agent and a compatilizer; and when the toughening additive is used for preparing the cement mortar, the prepared cement mortar has the advantages of favorable toughness, favorable fatigue resistance and favorable isotropy, and is beneficial to enhancing the crack resistance of the grouting mortar and reducing the engineering maintenance cost in the later period.

Owner:福建省东霖建设工程有限公司

Sintering aid for preparing silicon nitride ceramics, application of sintering aid and preparation method of silicon nitride ceramics

InactiveCN113105252AReduced high temperature creep resistanceImprove high temperature mechanical propertiesMischmetalCeramic

The invention relates to the technical field of silicon nitride ceramics, and in particular, relates to a sintering aid for preparing silicon nitride ceramics, an application of the sintering aid and a preparation method of the silicon nitride ceramics. The invention provides the sintering aid for preparing the silicon nitride ceramics. The sintering aid comprises a component A, a component B and a component C; the particle size of the sintering aid is less than or equal to 100 nm; the mass ratio of the component A to the component B to the component C is (1-5):(1-10):(1-10); the component A comprises titanium dioxide; the component B comprises boric oxide, magnesium oxide or calcium oxide; and the component C comprises a rare earth metal oxide. The sintering aid can effectively improve the mechanical property of the silicon nitride ceramics.

Owner:SINOMA ADVANCED NITRIDE CERAMICS CO LTD

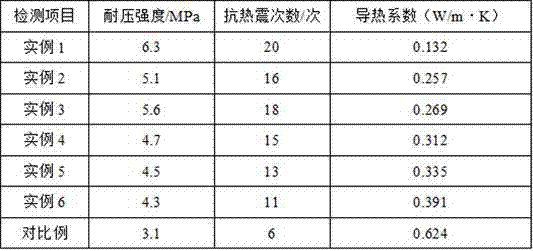

High-strength light-weight brick and preparation method of same

ActiveCN107963908AGood dispersionHigh specific surface energyCeramic materials productionCeramicwareFiberBrick

The invention discloses a high-strength light-weight brick and a preparation method of same and belongs to the technical field of building materials. The method includes steps of: 1) heating, stirringand mixing sepiolite and organic acid according to mass ratio of 1:50-1:100, and performing pressure reducing concentration, drying and crushing to prepare modified sepiolite; 2) stirring and mixingfly ash, a cementing material, bauxite, the modified sepiolite, coke, sawdust, gypsum, papermaking black liquid, a sodium fluoride solution, nano iron powder, sludge, fiber granular materials, agar liquid, magnesia, volcanic ash, magnesium chloride and water to prepare mixture slurry; 3) injecting the mixture slurry into a mould, allowing the mould to stand, demolding the mixture, and performing high pressure steam curing to obtain a brick green body; 4) performing nitrogen charging high-temperature sintering to the green body to obtain the high-strength light-weight brick. The high-strength light-weight brick has excellent mechanical performance, thermal shock resistance and heat preservation function; besides, wear resistance is also improved.

Owner:铜仁筱启环保科技有限公司

Activated carbon fiber based composite photocatalyst preparation method

InactiveCN109126761AStable chemical propertiesExtended service lifeGas treatmentWater/sewage treatment by irradiationFiberUltraviolet lights

The invention belongs to the technical field of pavement materials, discloses an activated carbon fiber based composite photocatalyst preparation method and solves the problem that conventional TiO2 only absorbs ultraviolet light and is high in surface energy, prone to agglomeration and difficult in gathering of pollutants on the TiO2 surface. The method includes: pretreating activated carbon fibers, adding methyl alcohol into a reactor, sequentially adding tetrabutyl titanate, glycol ether, lanthanum nitrate solution, glucose solution, lauric acid and activated carbon fibers, well mixing, performing reaction for 24h in the reactor, cooling to the room temperature, and cleaning and drying with absolute ethyl alcohol to obtain an activated carbon fiber based composite photocatalyst; finally, assessing effectiveness of the composite photocatalyst in catalytic degradation of main components in tail gas under simulated sunlight, adjusting the concentration of lanthanum nitrate and glucosesolution to determine optimum lanthanum and carbon doping quantity in TiO2 to prepare the activated carbon fiber based composite photocatalyst. The activated carbon fiber based composite photocatalystprepared according to the method is capable of absorbing visible light, and pollutant gathering promotion and photocatalytic efficiency improvement are realized.

Owner:NANJING FORESTRY UNIV

Battery electrode, preparation method thereof and battery

ActiveCN102054979ALower internal resistanceImprove rate charge and discharge performanceElectrode carriers/collectorsLi-accumulatorsMicro nanoPower flow

The invention provides a battery electrode, a preparation method thereof, and a battery. The battery electrode comprises a current collector and an active substance layer coated on the current collector; a micro-nano particle layer is adhered to the surface of the active substance layer; the active substance layer comprises electrode active substance and electrode binder; the micro-nano particle layer comprises micro-nano dry powder particles; and the micro-nano dry powder particles comprise dry powder particles of the micro-nano electrode active substance. Interface impedance between the electrode and electrolyte is reduced and rate discharge performance of the battery is improved; a micro-nano active material reduces serious volume effect of the material; and specifically, the micro-nano particle layer may not comprise the binder preferably, so that the large-current discharge characteristic of the battery is improved further. The method is simple and is easy to implement; and the combinability between the micro-nano particle layer and the active substance layer is high, and the surface of the active substance layer is not polluted by the substances of an upper layer.

Owner:SHANGHAI BYD

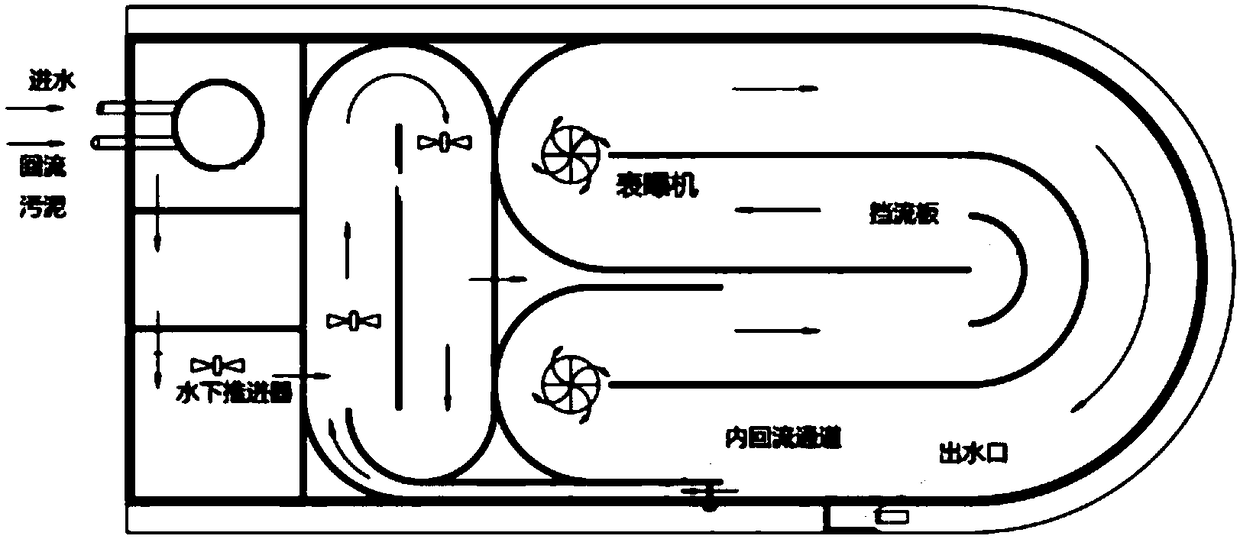

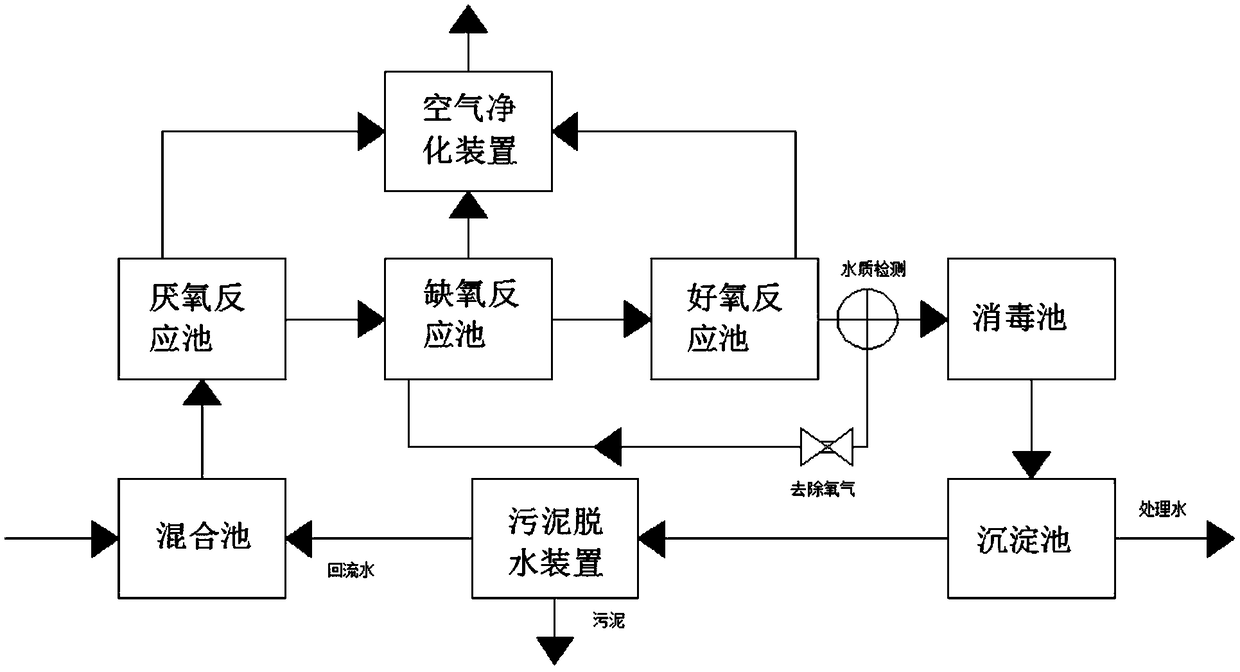

Denitrification and dephosphorization treatment technology for municipal sewage

InactiveCN108862828AHigh porosityLarge specific surface areaCombination devicesWater contaminantsOxygenPollution

The invention discloses a denitrification and dephosphorization treatment technology for municipal sewage. The technology comprises the following steps: firstly mixing and stirring after filtering domestic sewage, treating the sewage through an anaerobic reaction pool, an anoxic reaction pool and an aerobic reaction pool successively, entering a disinfecting pool for disinfecting and deodorizing after the sewage is treated to reach a standard, reflowing to the anoxic reaction pool for treating while the sewage does not reach the standard, discharging waste gases generated by the sewage treatment in the anaerobic reaction pool, the anoxic reaction pool and the aerobic reaction pool to the air after treated by an air purifying device, reducing air pollution, discharging the disinfected sewage after precipitating in a precipitating pool, performing dehydration treatment on sludge and feeding water to a mixing pool, and discharging the dehydrated sludge. The technology is low in cost, goodin water treatment effect, rapid in degradation speed, especially high in nitrogen and phosphorus element and organic matter removal rate in the sewage, safe and stable, and extensive in applicationrange, beneficial to promotion and popularization and capable of performing waste gas treatment, reducing secondary pollution and guaranteeing the effect of the sewage treatment.

Owner:即墨市污水处理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com