Medical titanium or titanium alloy surface activation modifying method

A technology of surface activation and surfactant, which is applied in medical science, prosthesis, coating, etc., can solve the problems of narrow selection range of matrix materials and reliability problems, and achieve rich physical and chemical properties, improve biological activity, and large ratio The effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

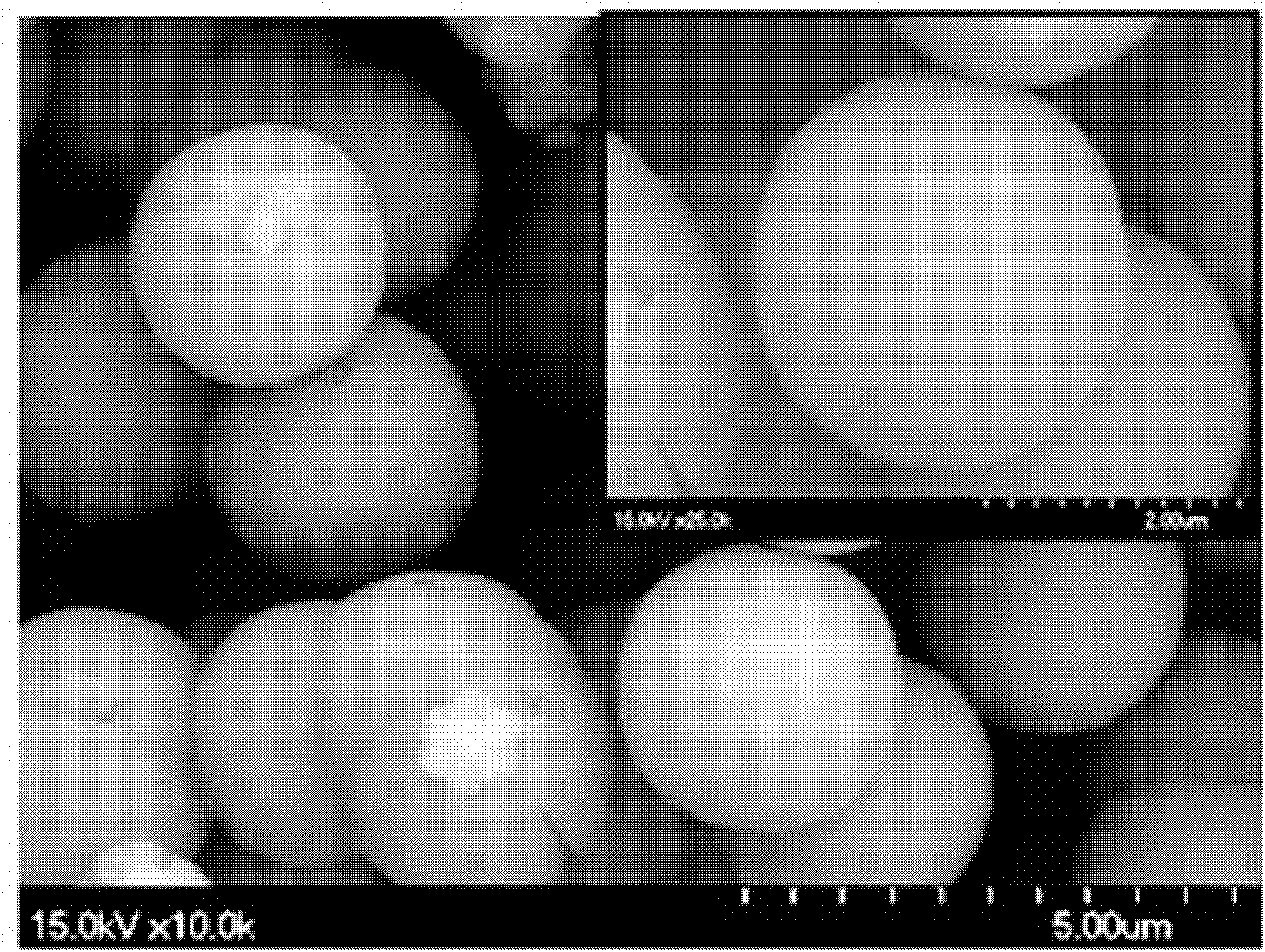

[0037] 350ml of surfactant sodium styrene sulfonate (PSS) and 21g of polystyrene microspheres (PS) were thoroughly ultrasonically mixed to obtain a 0.06g / ml modified polystyrene microsphere dispersion.

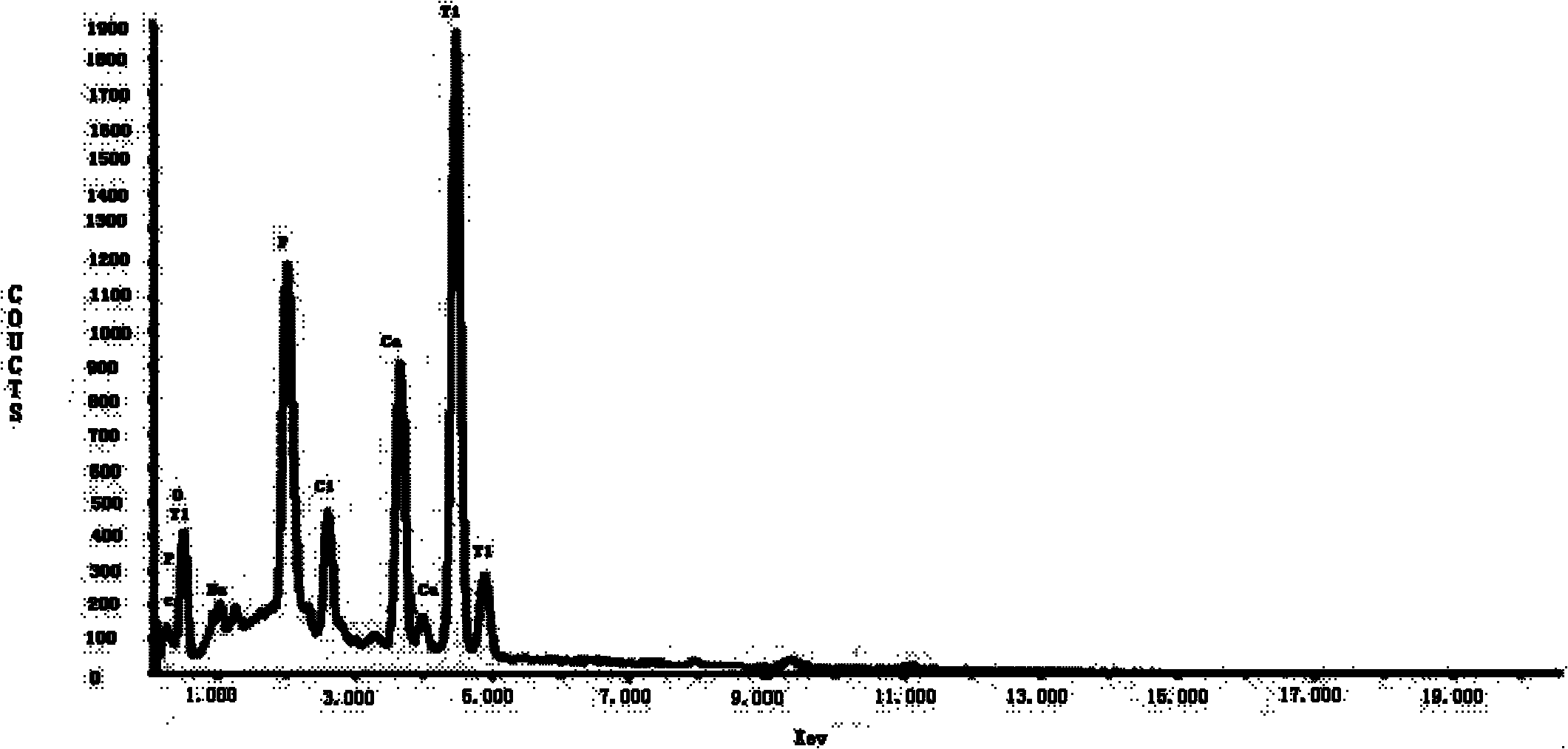

[0038] 1.02g of H 2 o 2 (30%wt) was added into 300ml deionized water and mixed well to obtain 0.03mol / L of H 2 o 2 aqueous solution. Take 1.44g of TiOSO 4 Add 0.03mol / L of H to the powder 2 o 2 Aqueous solution, prepared 0.03mol / L TiOSO 4 , 0.03mol / L H 2 o 2 mixture.

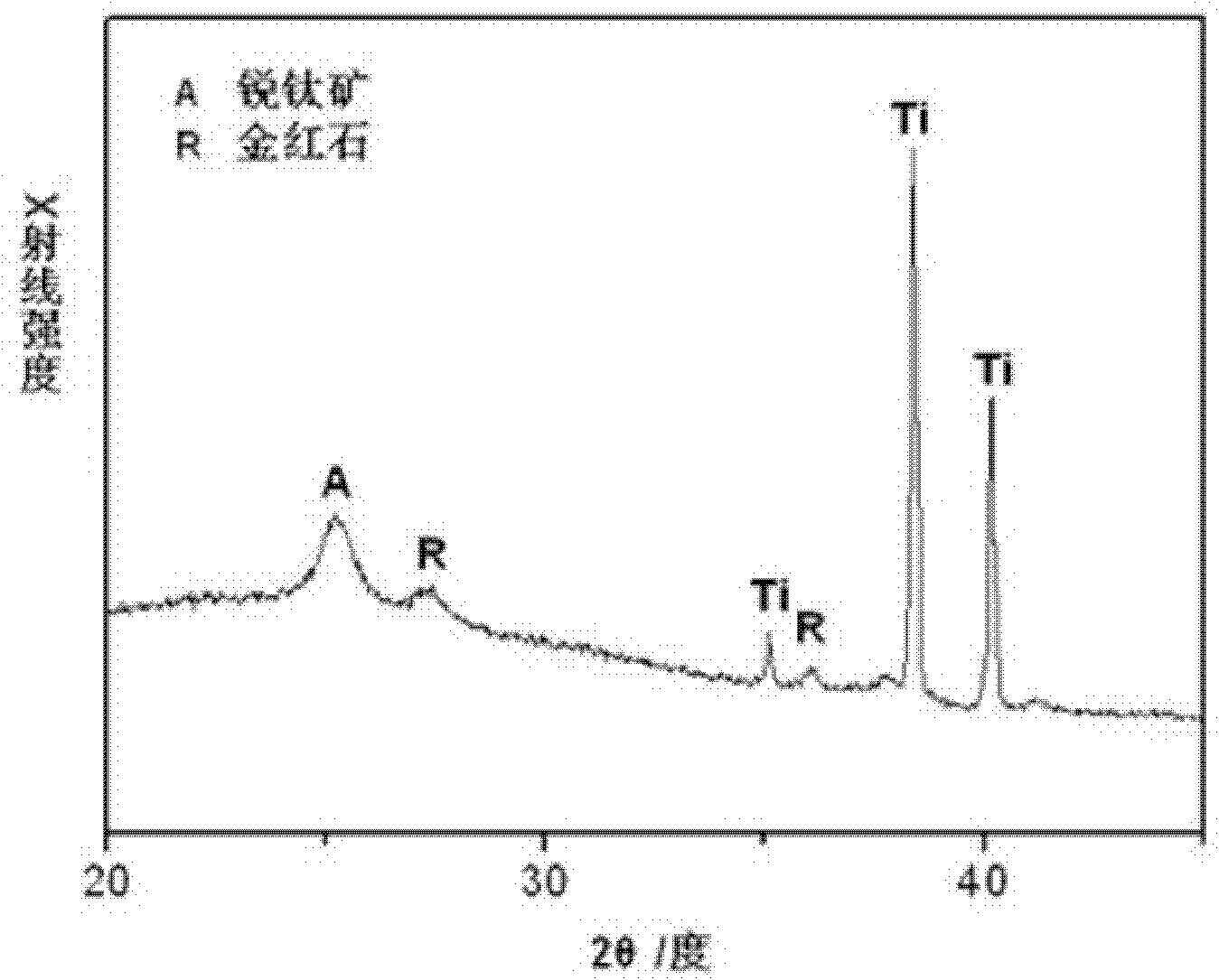

[0039] The sample is pure titanium with a size of 10×10×1 mm, which is cleaned and used for later use. Take the above 0.03mol / L TiOSO 4 , 0.03mol / L H 2 o 2 30 ml of the mixed solution was added, 20 ml of the above-mentioned polystyrene microsphere (PS) dispersion modified with the surfactant sodium styrene sulfonate was added, and the treatment solution was obtained by fully ultrasonically mixing. Heat the treatment solution to 100°C and keep it at this temperature, immerse the titanium sheet in th...

Embodiment 2

[0041] The sample is pure titanium with a size of 10×10×1 mm, which is cleaned and used for later use. Get the 0.03mol / LTiOS0 that makes in embodiment 1 4 , 0.03mol / L H 2 o 2 30ml of the mixed solution was added to 20ml of the polystyrene microsphere (PS) dispersion modified with the surfactant sodium styrene sulfonate prepared in Example 1, and fully ultrasonically mixed to obtain a treatment solution. Heat the treatment solution to 80°C and keep it at this temperature, immerse the titanium sheet in the treatment solution for 0.5 hours, and use a high-pressure mercury lamp with a power of 1000W and a light intensity of 65±5w / m at 254nm 2 , irradiated with ultraviolet light for 0.5 hours, then removed the ultraviolet light source, then soaked the titanium sheet in the treatment solution at 80°C for 35.5 hours, took it out and immersed it in 50ml of tetrahydrofuran for 0.5 hours to remove polystyrene, took it out to remove polystyrene The ethylene substrate was washed with d...

Embodiment 3

[0043] The sample is pure titanium with a size of 10×10×1 mm, which is cleaned and used for later use. Get the 0.03mol / LTiOS0 that makes in embodiment 1 4 , 0.03mol / L H 2 o 2 30ml of the mixed solution was added to 20ml of the polystyrene microsphere (PS) dispersion modified with the surfactant sodium styrene sulfonate prepared in Example 1, and fully ultrasonically mixed to obtain a treatment solution. Heat the treatment solution to 60°C and keep it at this temperature, immerse the titanium sheet in the treatment solution for 0.5 hours, and use a high-pressure mercury lamp with a power of 1000W and a light intensity of 65±5w / m at 254nm 2 , irradiated with ultraviolet light for 0.5 hours, then removed the ultraviolet light source, then soaked the titanium sheet in the treatment solution at 60°C for 35.5 hours, took it out and soaked it in 50ml of tetrahydrofuran for 0.5 hours to remove polystyrene, took it out to remove polystyrene The ethylene substrate was washed with dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com