A kind of preparation method of bismuth vanadate composite material coated with mesoporous silica on the surface

A technology of mesoporous silica and composite materials, which can be used in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problem of not forming a core-shell structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

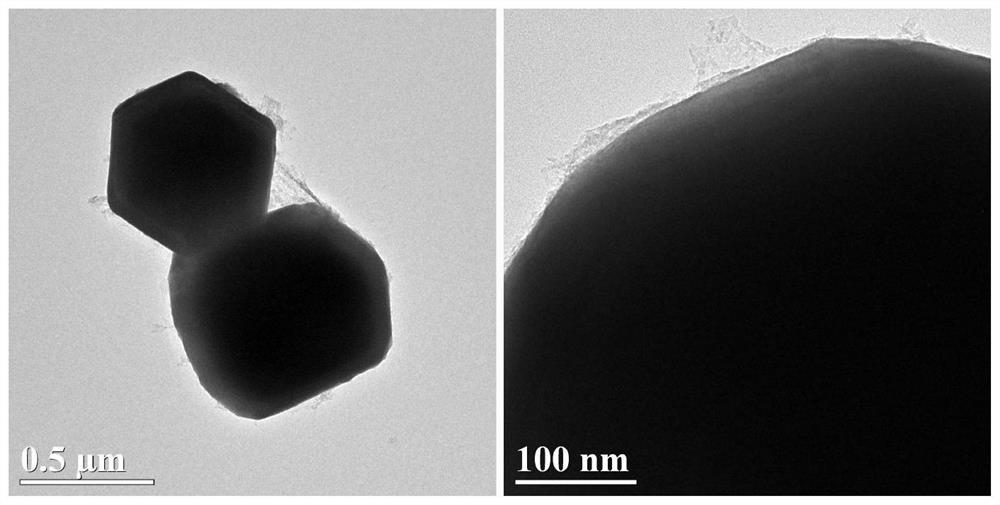

[0028] BiVO 4 The sample preparation steps are as follows:

[0029] Step A: get the bismuth salt of 0.02mol and be dissolved in the concentrated nitric acid of 20mL to obtain homogeneous solution, stir 2h; Described bismuth salt is Bi(NO 3 ) 3 ·5H 2 O or BiCl 3 ; The vanadium-containing compound is NH 4 VO 3 or Na 3 VO 4 ;

[0030] Step B: 0.02mol of vanadium-containing compound was dissolved in 20mL of 6M NaOH aqueous solution;

[0031] Step C: Add the solution obtained in step B to the solution obtained in step A, then add 0.1 to 0.5 g of cetyltrimethylammonium bromide (CTAB) into the obtained solution, stir for 2 hours, then slowly add 30 mL of 6M NaOH Aqueous solution, to obtain a uniform suspension, stirred for 2h;

[0032] Step D: Add the solution obtained in step 3 into a 100 mL stainless steel reaction kettle lined with polytetrafluoroethylene, keep it at 180 ° C for 48 h, centrifuge the obtained product with deionized water for several times, and then dry it...

Embodiment 2

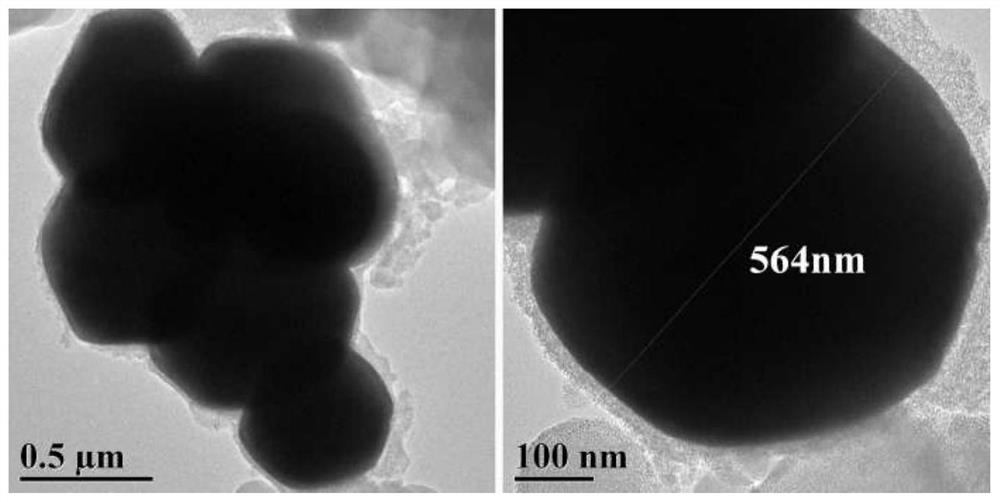

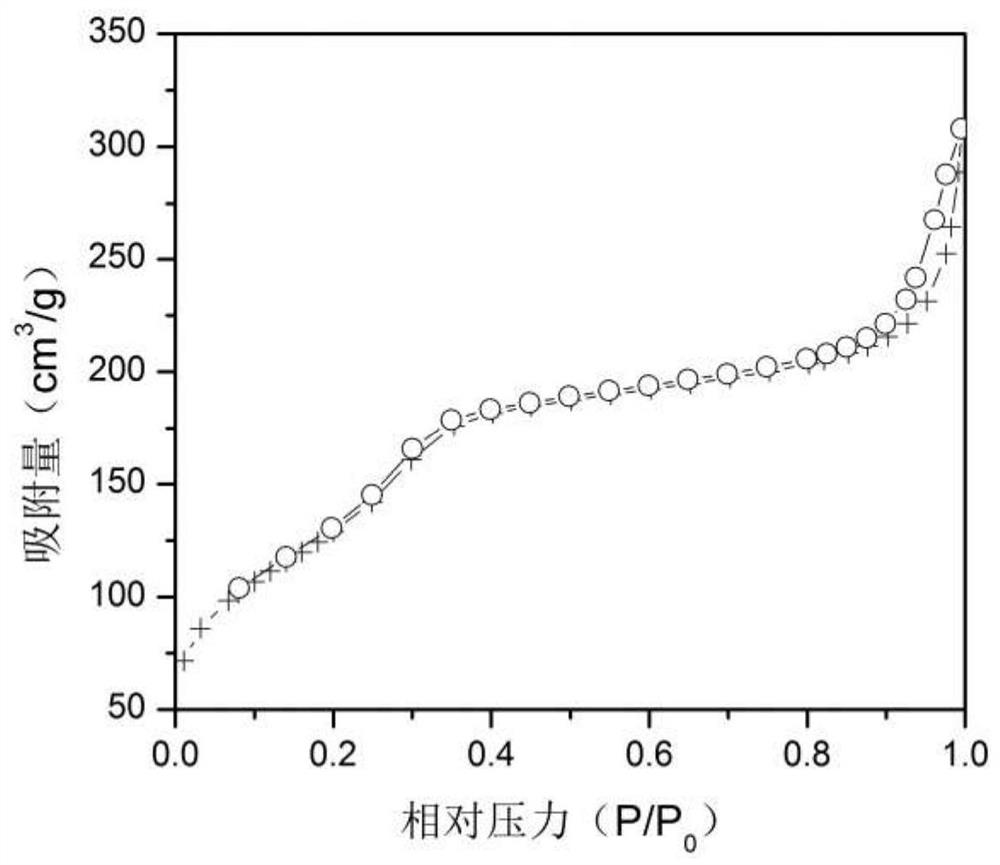

[0034] Weigh the 1.23mmol BiVO that embodiment 1 obtains 4 (0.4g) sample, add 1.23mmol gallic acid (0.21g) according to molar ratio n (gallic acid: bismuth vanadate)=1:1, add 15mL deionized water and mix well, then according to ferric chloride: bismuth vanadate sample The molar ratio is 0.5:1, adding 0.615mmol ferric chloride (0.1g), stirring at room temperature for 24 hours, the resulting product is separated, washed and dried to obtain bismuth vanadate@iron-gallic acid complex core-shell structure composite material ( Marked as 0.5BiVO 4 @Fe Ⅲ -GA). The obtained bismuth vanadate@iron-gallic acid product was added to a solution containing CTAB and ammonia water for 10 minutes of ultrasonication, then TEOS was added dropwise to the above mixed solution and crystallized at 80°C for 2 hours, the obtained product was washed with water and ethanol and dried dry, and finally calcined at 550° C. for 6 hours in an air atmosphere to obtain the bismuth vanadate composite material wh...

Embodiment 3

[0037] Weigh the 1.23mmol BiVO that embodiment 1 obtains 4 (0.4g) sample, add 0.75mmol tannic acid (1.28g) according to molar ratio n (tannic acid: bismuth vanadate)=0.61:1, add 15mL deionized water and mix well, then according to ruthenium chloride: vanadate The molar ratio of the bismuth sample is 0.02:1, add 0.025mmol ruthenium chloride (0.005g), and stir at room temperature for 24h. The resulting product is separated, washed and dried to obtain the target product bismuth vanadate@ruthenium-tannic acid complex core-shell structure composite material (marked as 0.02BiVO 4 @Ru Ⅲ-TA). The obtained bismuth vanadate@ruthenium-tannic acid product was added to a solution containing CTAB and ammonia water for 10 minutes, and then TEOS was added dropwise to the above mixture and crystallized at 80°C for 2 hours. The obtained product was washed with water and ethanol and drying, and finally calcining at 550° C. for 6 hours in an air atmosphere to obtain the bismuth vanadate compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com