Preparation method and application of Ag/carbon quantum dot/phosphotungstic acid composite material

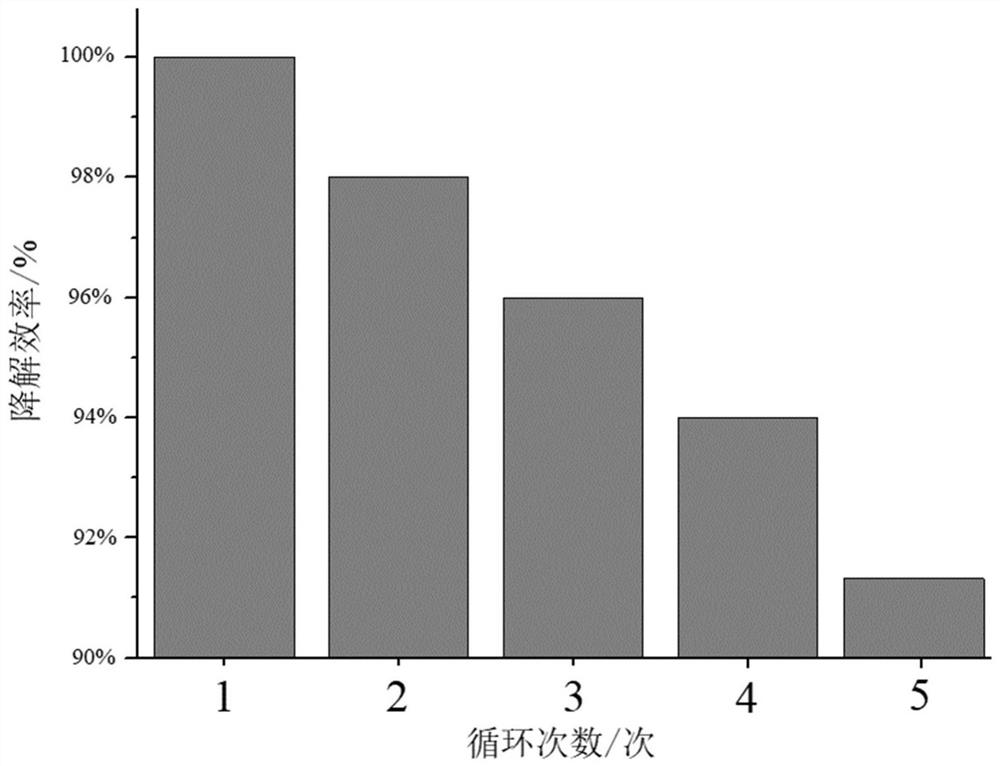

A technology of carbon quantum dots and composite materials, which is applied in chemical instruments and methods, water/sludge/sewage treatment, molecular sieve catalysts, etc., can solve the problems of complex and cumbersome preparation methods of nano-composite materials, and the photocatalytic effect cannot be reused. , to achieve the effect of low cost, simple process and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

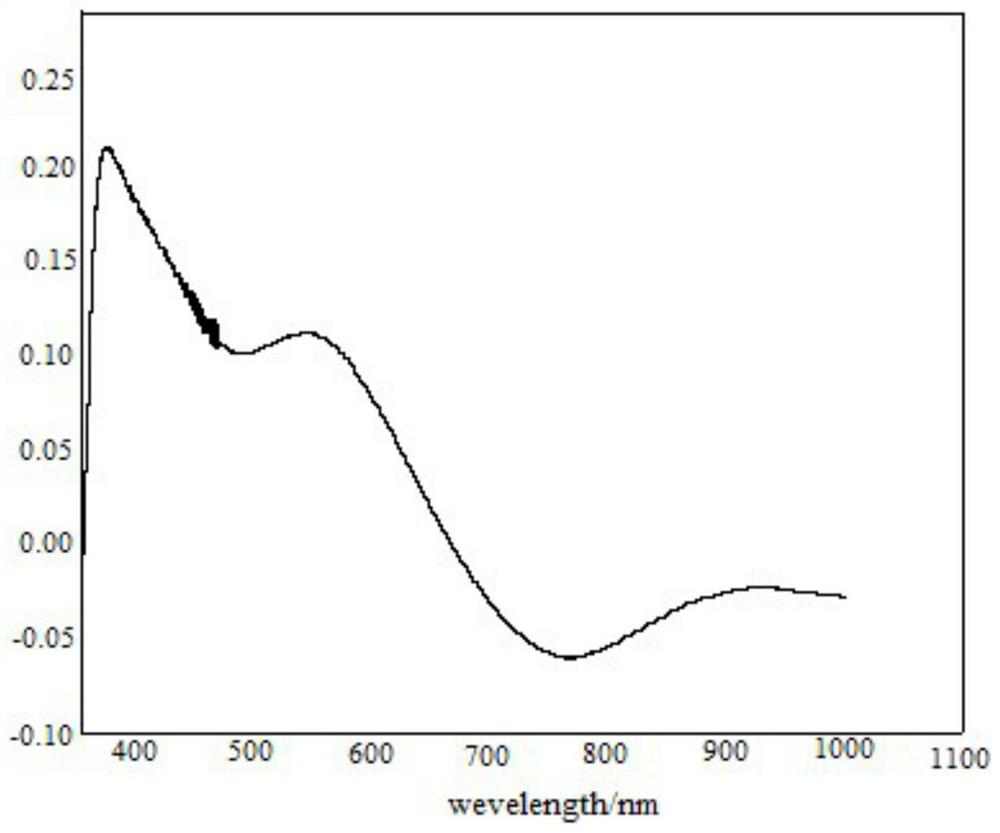

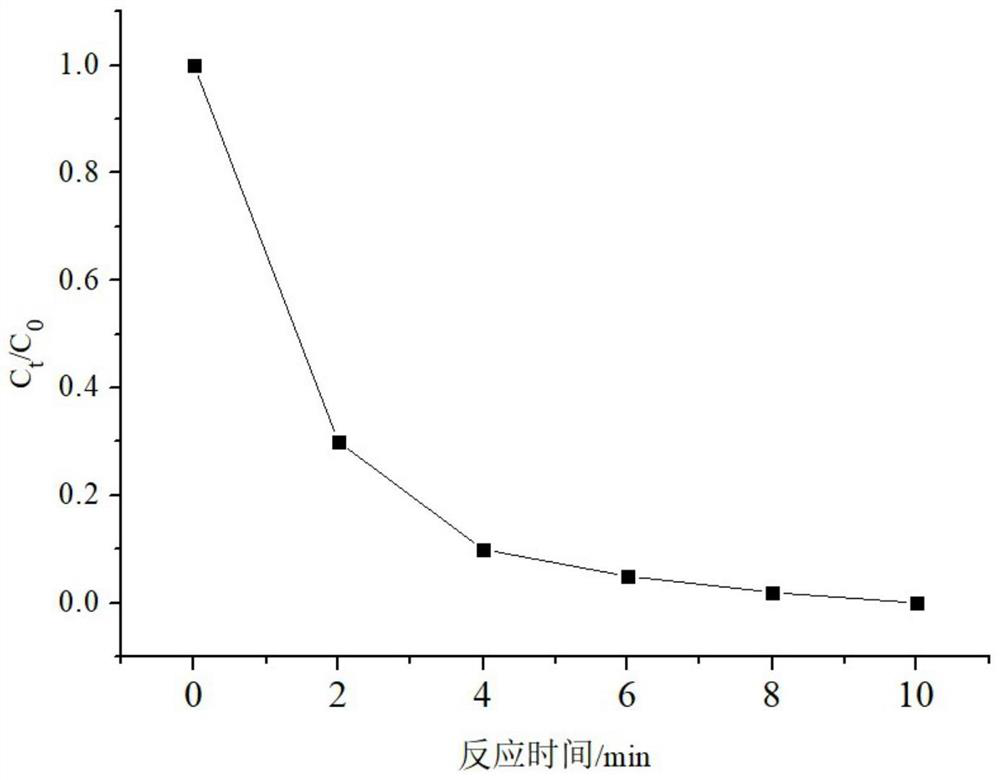

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: A preparation method of Ag / carbon quantum dots / phosphotungstic acid composite material in this embodiment is completed according to the following steps:

[0021] 1. Add the aqueous solution of phosphotungstic acid and carbon quantum dots into distilled water, and ultrasonically disperse to obtain a mixed solution;

[0022] 2. Transfer the mixed solution to a reaction kettle lined with tetrafluoroethylene, then immerse the zeolite in the reaction kettle, raise the temperature to carry out a hydrothermal reaction, the hydrothermal reaction ends, take out the zeolite, wash, and dry to obtain carbon quantum dots / phosphotungstic acid coated zeolite;

[0023] 3. Immerse the carbon quantum dots / phosphotungstic acid-coated zeolite into AgNO under UV light irradiation 3 In the solution, a reaction product is obtained through an in-situ photoreduction reaction; the reaction product is washed and then dried to obtain an Ag / carbon quantum dot / phosphotungstic acid c...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the concentration of the carbon quantum dot aqueous solution described in step 1 is 6 mg / mL to 7 mg / mL. Other steps are the same as in the first embodiment.

[0025] The preparation method of the carbon quantum dot aqueous solution described in this embodiment is as follows: put a graphite rod into water, continuously electrolyze it at 30V for 120 hours, then filter and wash it.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of the phosphotungstic acid described in step 1 to the volume ratio of the carbon quantum dot aqueous solution is (3g~5g): (7mL~ 8mL); the volume ratio of the carbon quantum dot aqueous solution described in step 1 to distilled water is (7mL~8mL): (30mL~40mL). Other steps are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com