3PE anticorrosive paint epoxy bottom layer for outer wall of deep sea oil and gas transmission steel pipe and preparation method of 3PE anticorrosive paint epoxy bottom layer

An anti-corrosion coating, oil and gas technology, applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of poor toughness of epoxy resin, and achieve the effects of reducing pollution, good processability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

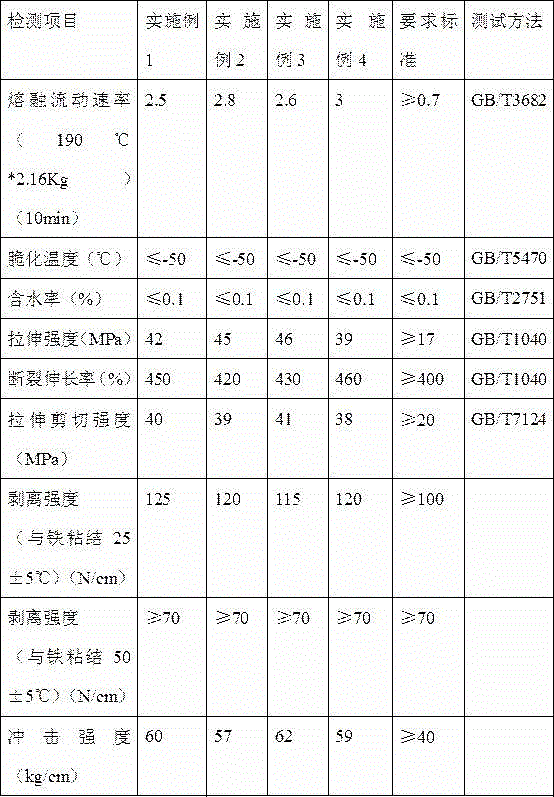

Examples

preparation example Construction

[0045] The preparation method of the 3PE anti-corrosion coating epoxy primer on the outer wall of the deep-sea oil and gas transmission steel pipe includes the following steps:

[0046] Step a. Mix epoxy resin, graphene oxide and coupling agent evenly, place them in an ultrasonic oscillator, and use 50Hz, 1000W ultrasonic treatment for 7 to 8 hours;

[0047] Step b. Mix the well-mixed raw materials in step a with gas-phase SiO 2 Mix and stir for 20 to 30 minutes, the speed of the mixer is 700 to 900 rpm, so that the gas phase SiO 2 Evenly dispersed;

[0048] Step c. The product in step b is mixed with a curing agent for the preparation of tensile shear samples and impact samples, and the samples are cured at 80° C. for 6 hours to obtain the epoxy bottom layer.

Embodiment 1

[0051] (1) Raw materials:

[0052] Epoxy resin: bisphenol F type epoxy resin

[0053] Silane coupling agent: KH-550

[0055] Vapor SiO 2

[0056] Curing agent: T-31 curing agent

[0057] According to the mass percentage, the ratio of the above raw materials is: epoxy resin 60%, silane coupling agent 5%, graphene oxide 1.5%, gas phase SiO 2 3.5%, curing agent 30%.

[0058] (2) Preparation method:

[0059] a. Mix epoxy resin, graphene oxide and coupling agent evenly, place in an ultrasonic oscillator, and use 50Hz, 1000W ultrasonic treatment for 7 hours;

[0060] b. Combine the well-mixed raw materials in step a with gas-phase SiO 2 Mix and stir for 30 minutes to make the gas phase SiO 2 Evenly disperse, the speed of the mixer is set to 800 rpm during the mixing process;

[0061] c. The product in step b is mixed with a curing agent for the preparation of tensile shear samples and impact samples, and the samples are cured at 80° C. for 6 hours to...

Embodiment 2

[0063] (1) Raw materials:

[0064] Epoxy resin: bisphenol F type epoxy resin

[0065] Silane coupling agent: KH-550

[0066] Graphene oxide

[0067] Vapor SiO 2

[0068] Curing agent: T-31 curing agent

[0069] According to the mass percentage, the ratio of the above raw materials is: epoxy resin 65%, silane coupling agent 10%, graphene oxide 0.5%, gas phase SiO 2 2%, curing agent 22.5%.

[0070] (2) Preparation method:

[0071] a. Mix epoxy resin, graphene oxide and coupling agent evenly, place in an ultrasonic oscillator, and use 50Hz, 1000W ultrasonic treatment for 8 hours;

[0072] b. Combine the well-mixed raw materials in step a with gas-phase SiO 2 Mix and stir for 20 minutes to make the gas phase SiO 2 Evenly disperse, the speed of the mixer is set to 700 rpm during the stirring process;

[0073] c. The product in step b is mixed with a curing agent for the preparation of tensile shear samples and impact samples, and the samples are cured at 80° C. for 6 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com