Patents

Literature

54results about How to "Control curing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

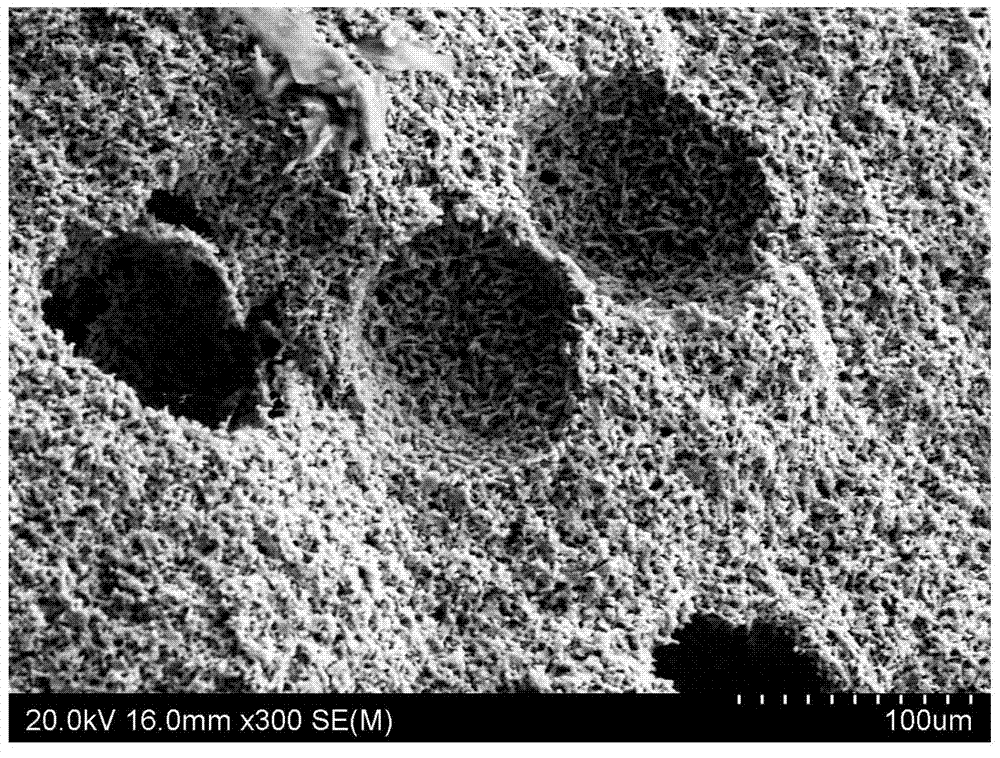

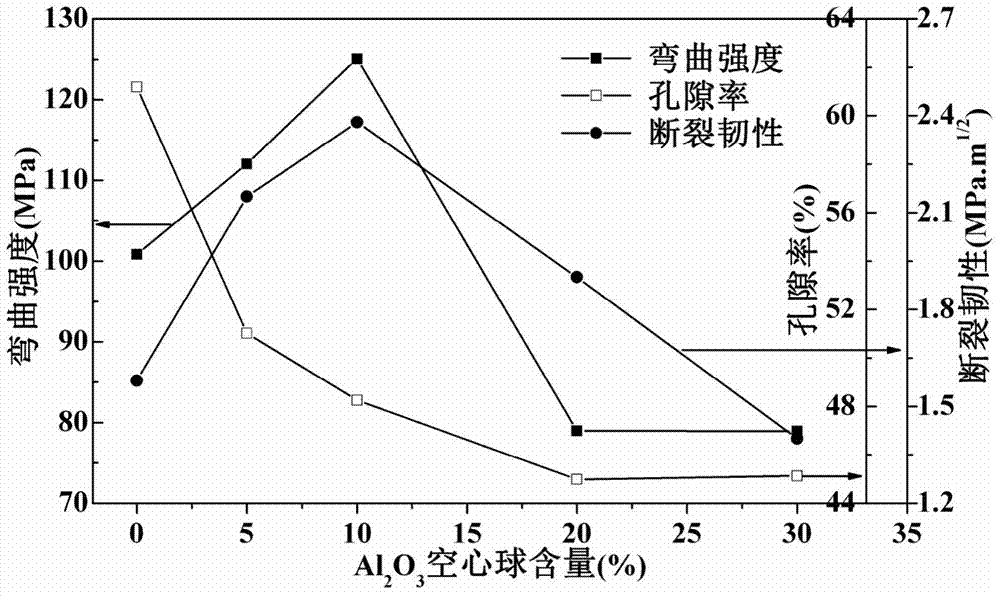

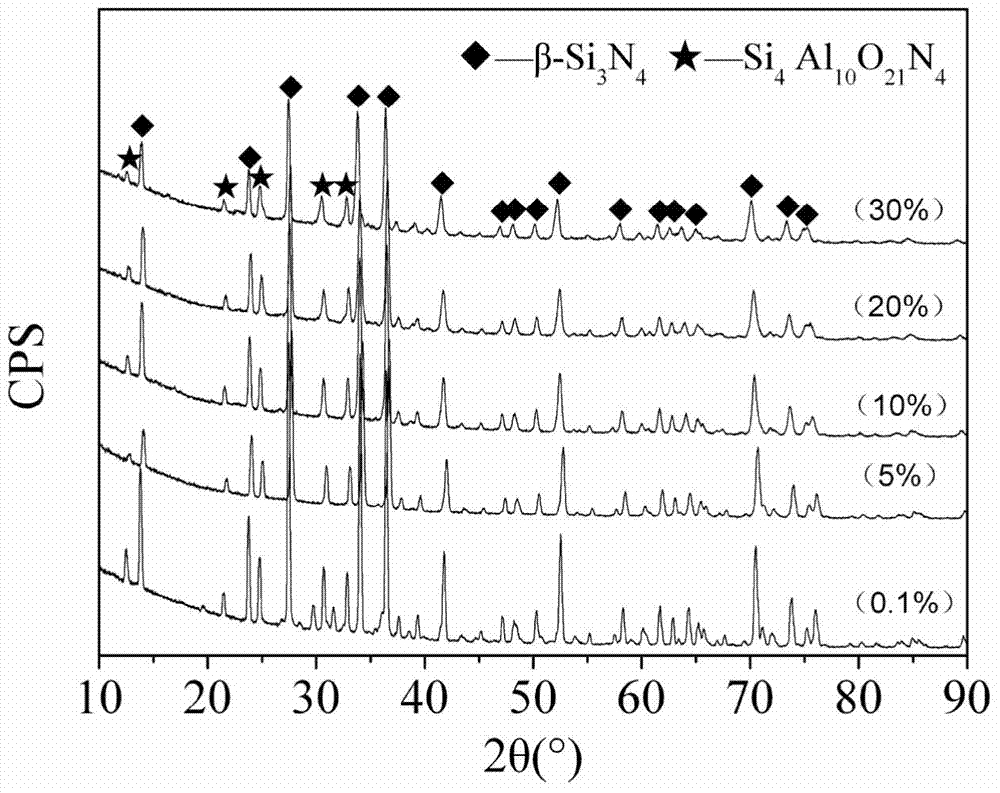

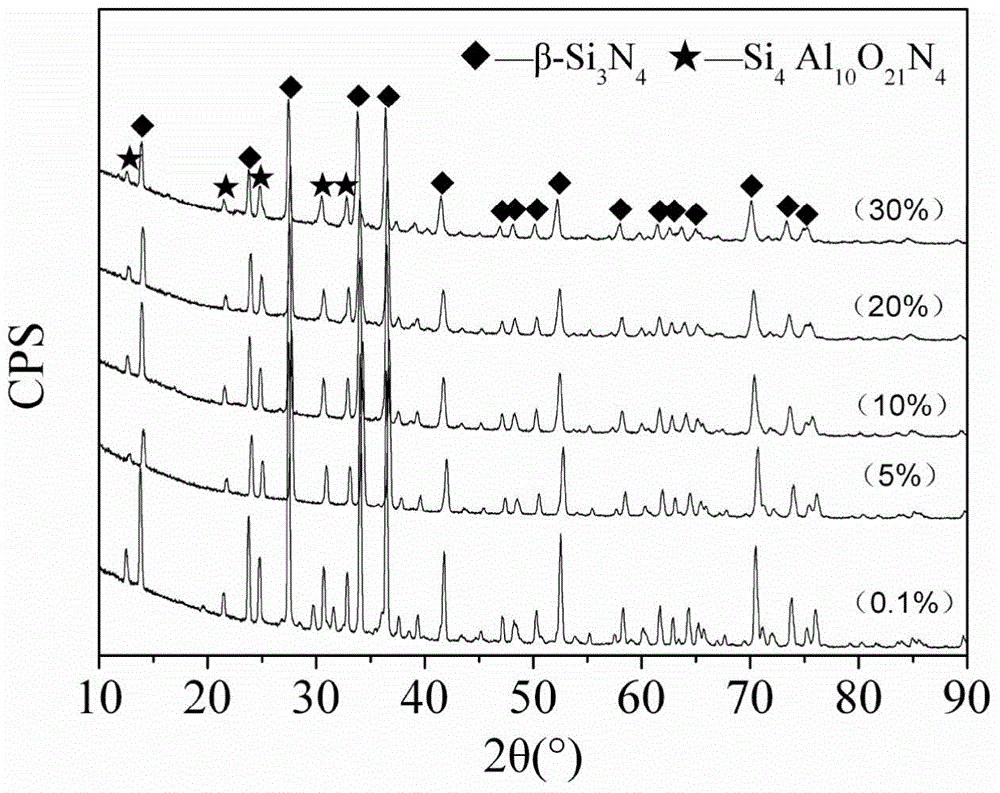

Preparation method for porous silicon nitride ceramic

The invention provides a preparation method for porous silicon nitride ceramic. The preparation method comprises the following steps: preparation of gel; addition of a pore forming agent; molding of a green body; drying of the green body; sintering of the green body; etc. The method combines a gel-casting and a pore forming agent addition process together and has the advantages of simple process, low cost and substantially shortened gel discharge time; and the prepared porous silicon nitride ceramic has great porosity, high bending strength and good mechanical properties.

Owner:HOHAI UNIV

Polymer-type water glass curing agent and application in water glass chemical grouting materials

InactiveCN101885591AResolution timeSolve the strength problemOther chemical processesBuilding constructionsSolubility(Hydroxyethyl)methacrylate

The invention relates to a polymer-type water glass curing agent with easily-controlled curing time and high toughness. The curing agent is mainly formed by polymerizing and copolymerizing double bonds-containing acids such as crylic acid, methacrylic acid and the like and double bonds-containing esters such as butyl methacrylate, vinyl acetate, hydroxy-ethyl methacrylate and the like by latex. The polymer-type water glass curing agent of the invention is a novel water-soluble water glass curing agent, which can control the curing time of the water-soluble grouting materials by controlling the content of carboxyl and ester group in a polymer. By using the curing agent, a water glass consolidating body has vey high compressive strength and toughness, synthetically overcomes the shortages of too fast curing time, high corrosiveness, low consolidating body strength and the like of an acid curing agent which is commonly used in the water glass grouting materials and the shortages of poor water solubility, slow curing time and the like of an organic ester curing agent, and can be widely applied in the field of anti-seepage stoppage engineering.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

High-transparency and high-strength room temperature vulcanization organosilicon electron pouring sealant and preparation method and application thereof

ActiveCN101787211AGood optical performanceImprove affordabilityOther chemical processesVulcanizationSealant

The invention discloses a high-transparency and high-strength room temperature vulcanization organosilicon electron pouring sealant, which comprises two components of A and B, wherein the component A comprises: hydroxyl terminated polydimethylsiloxane, simethicone and synthetized strengthening agent, and the weight ratio thereof is 100:20-60:10-40; the component B comprises vulcanizer and catalyst, the weight ratio thereof is 4-20:0.8-2.4; and the weight ratio of the component A to the component B is 1-9:9-1. The invention ensures that the room temperature vulcanization pouring sealant forms a super large three-dimensional skeleton structure after the vulcanization by adopting the synthetized strengthening agent, effectively improves the mechanical property and optical property of the pouring sealant; at the same time the preparation method of the pouring sealant is simple, is suitable for the industry production, saves energy consumption and reduces the cost.

Owner:深圳市钧泰丰新材料有限公司

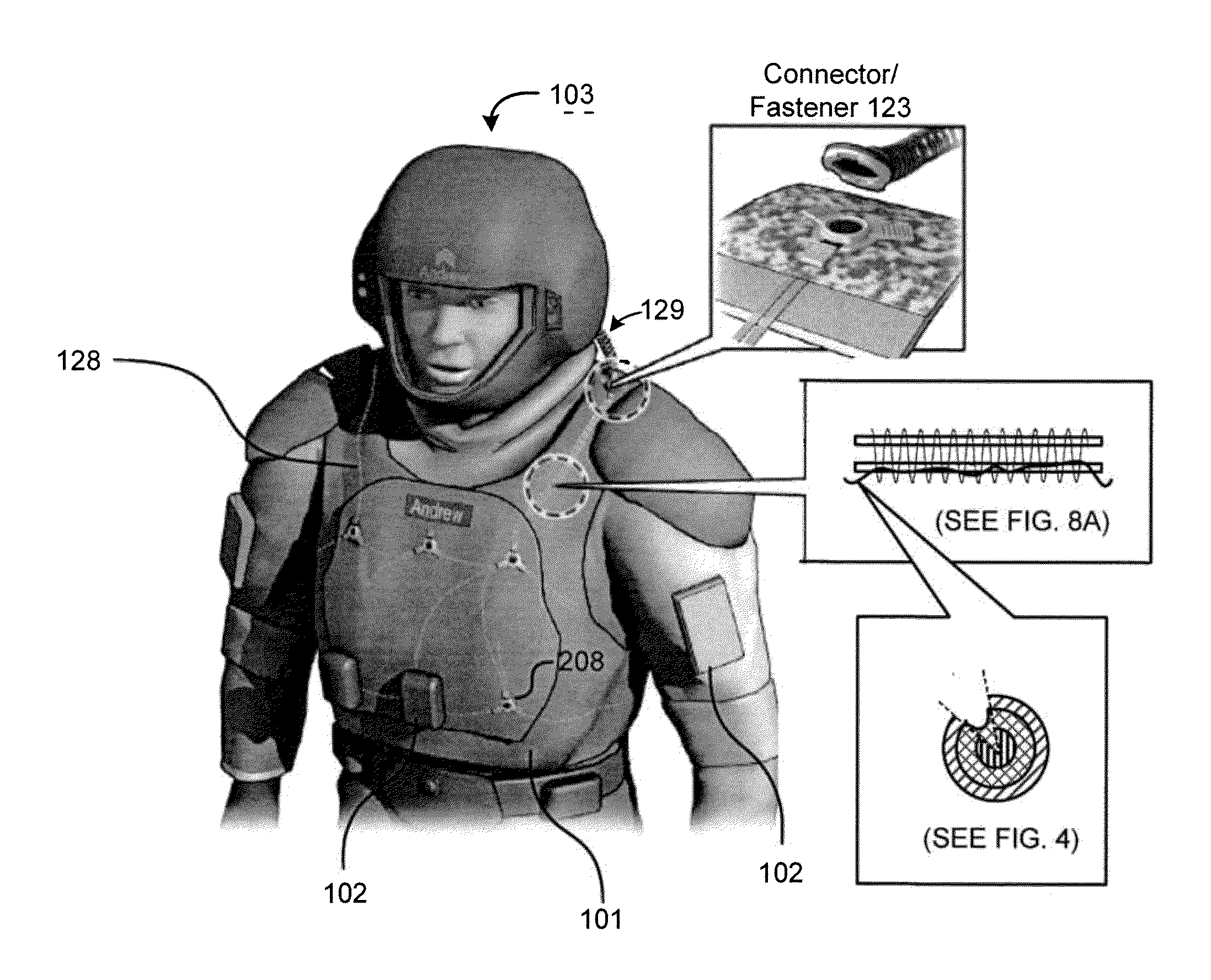

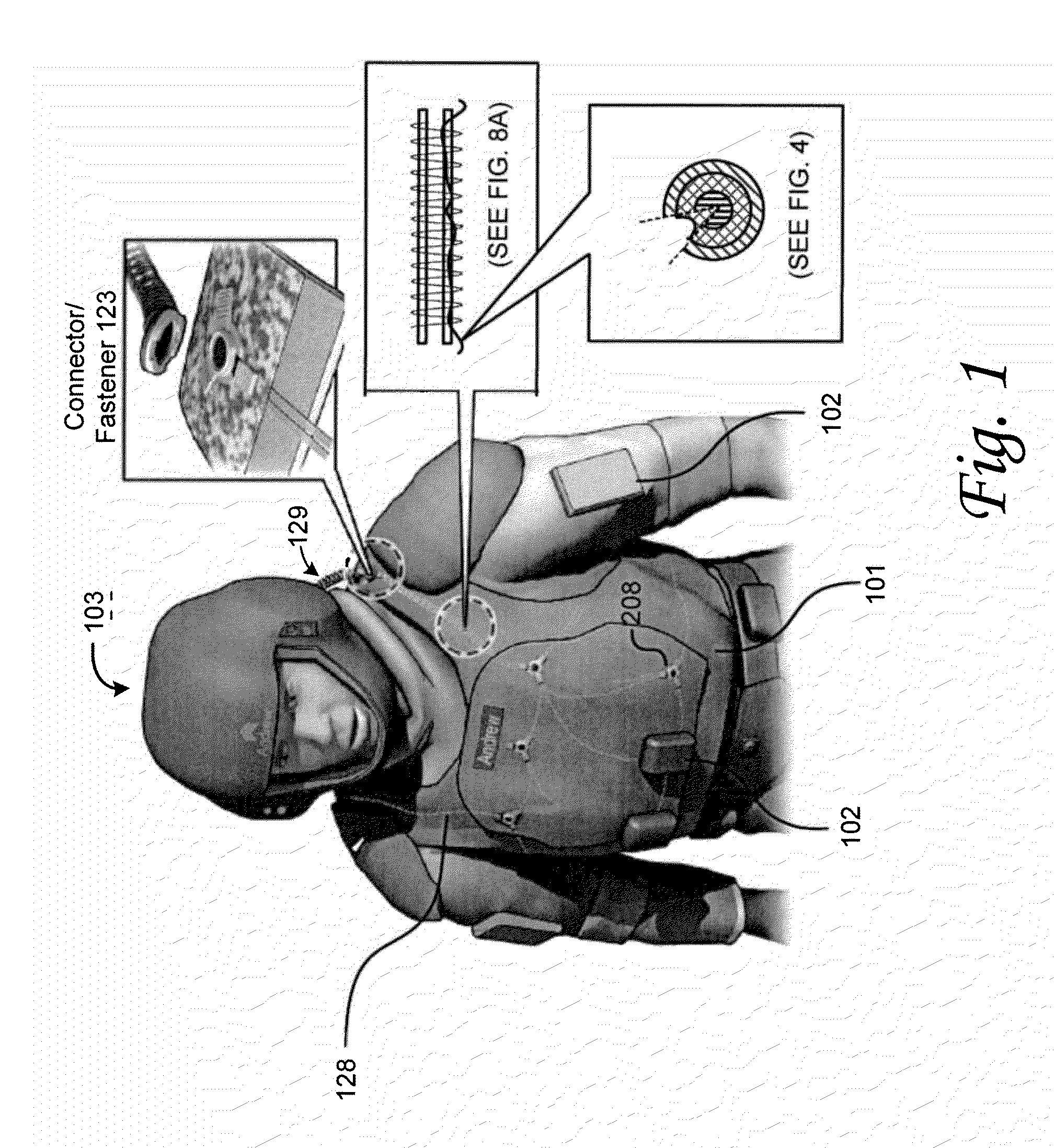

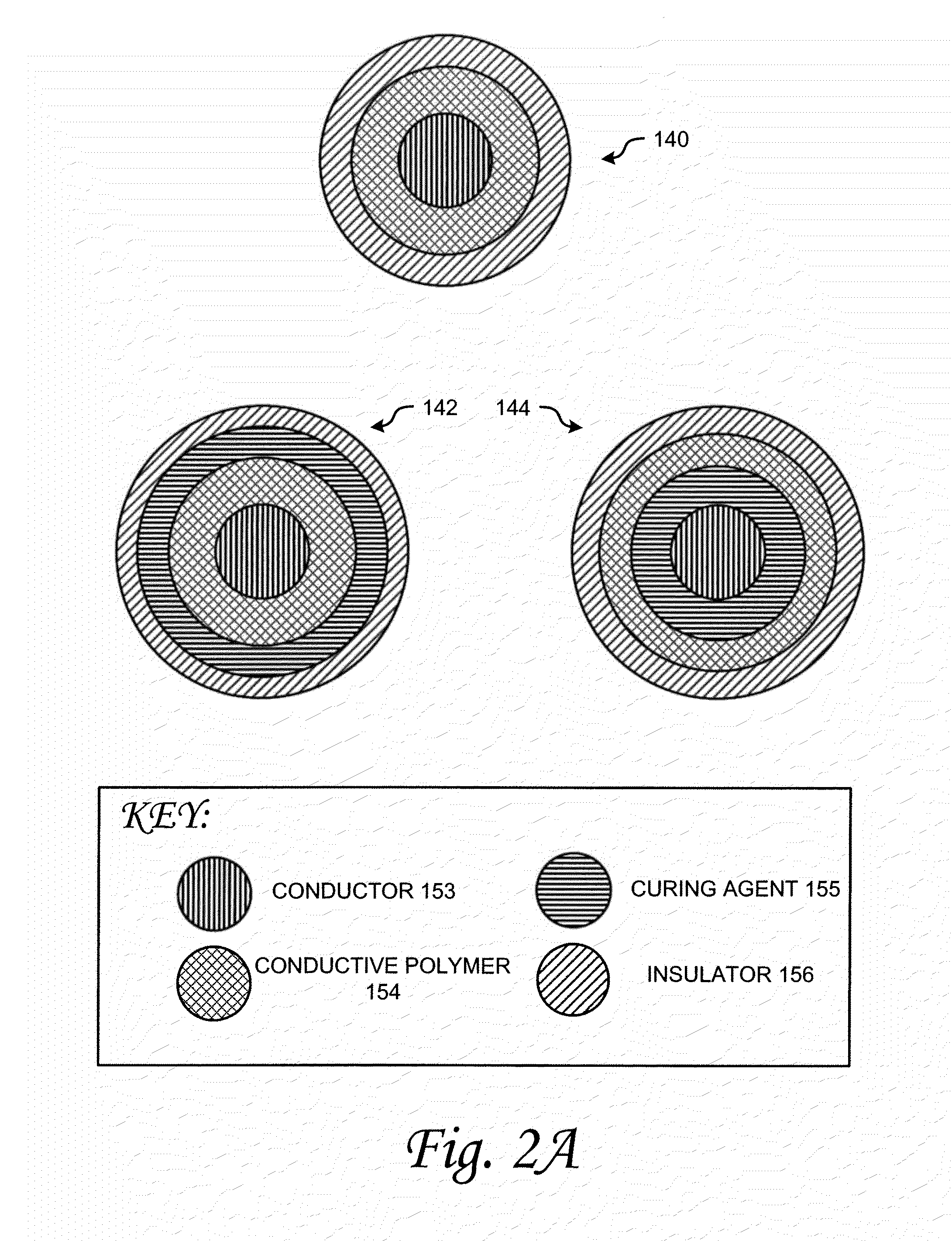

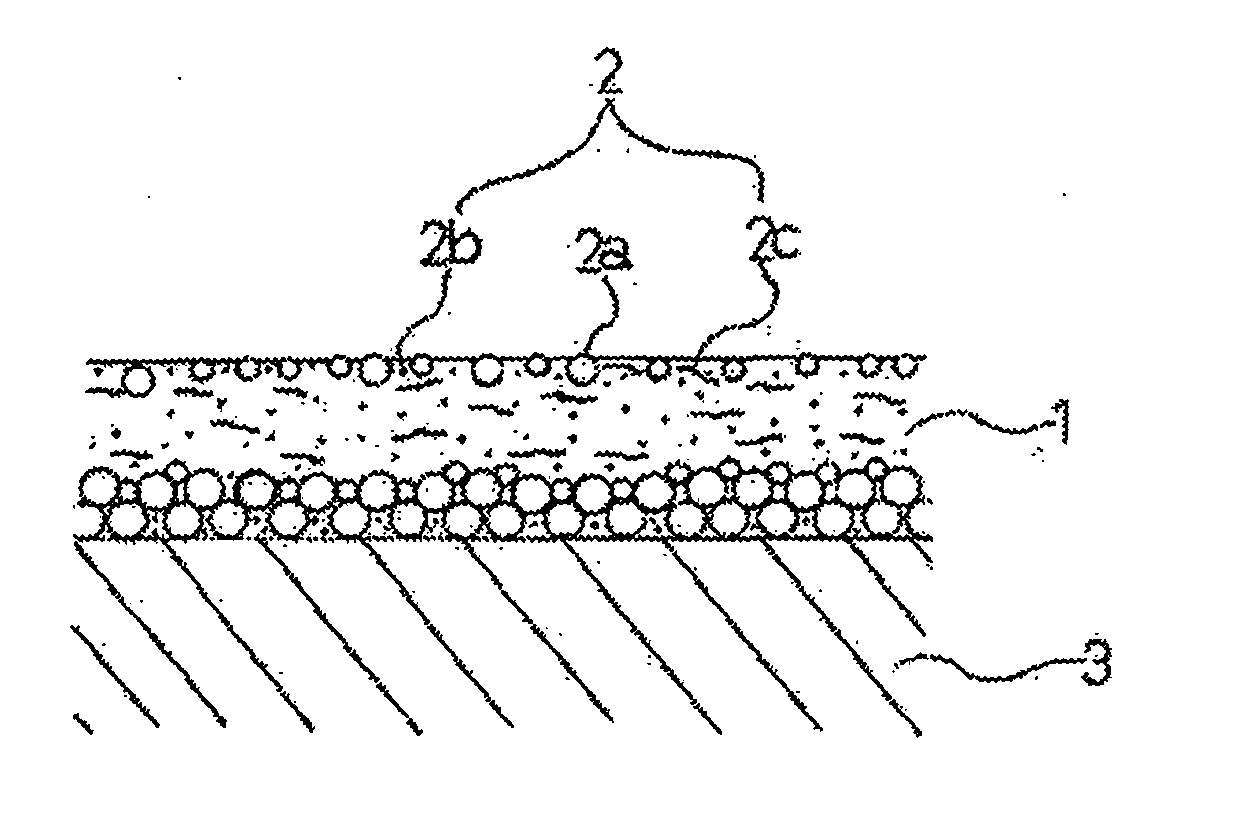

Self-healing electrical communication paths

ActiveUS20100122832A1Low viscosityEnough timePlastic/resin/waxes insulatorsDigital data processing detailsFiberSelf-healing

Self-healing electrical garments and self-healing electrical conductors and components for use in electrical garments are provided. A communication medium of various forms is integrated into a garment seam that is used to join two or more portions of a garment. The communication media can be used to provide electrical or other electromagnetic connection for coupling among a plurality of electrical devices associated with the garment. The self-healing electrical conductor may be used as part of a garment portion or may be used as a joining fiber in a variety of techniques to join garment portions together. The self-healing electrical conductor comprises an electrical conductor, a conductive polymer immediately surrounding or adjacent to the electrical conductor, an insulator enclosing the electrical conductor and the conductive polymer.

Owner:MERCURY MISSION SYST LLC

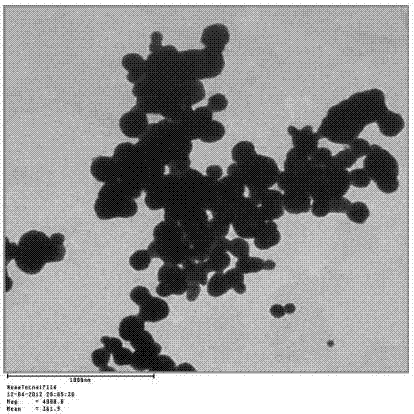

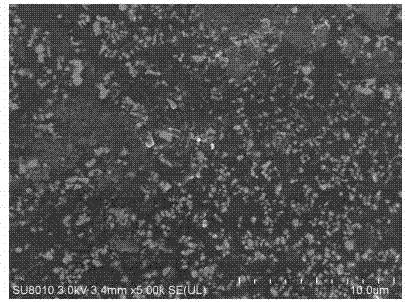

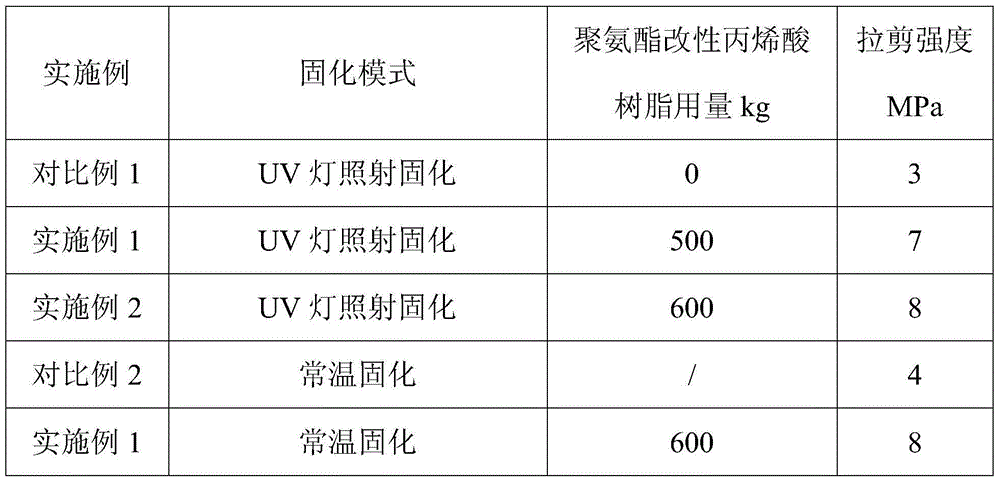

Silver/graphene low-temperature curing conductive rubber, conductive film, conductor and preparation method thereof

ActiveCN107502257AControl curing timeHigh specific surface energyNon-macromolecular adhesive additivesElectrically conductive adhesive connectionsFilling materialsLow temperature curing

The invention discloses a preparation method of low-temperature curing high-conductivity slurry and a conductive film. The low-temperature curing high-conductivity slurry is prepared by blending organic carriers with purpose-made nanometer stage silver powder mixed with a small amount of graphene as conductive filling materials. The conductive filling materials use nanometer stage silver powder compounding graphene, has the characteristic of high compactness, and enables the conducive rubber to form a better conductive path when being applied to the conductive rubber. The conductive slurry comprises double ingredients, and has the advantage of long storage period. Compared with the prior art, the preparation method has the advantages of low-temperature curing, high conductivity, high anti-shearing intensity, long storage period and the like and can be widely applied to printing circuit and LED (light emitting diode) chip bonding in electronic devices.

Owner:JINLING INST OF TECH

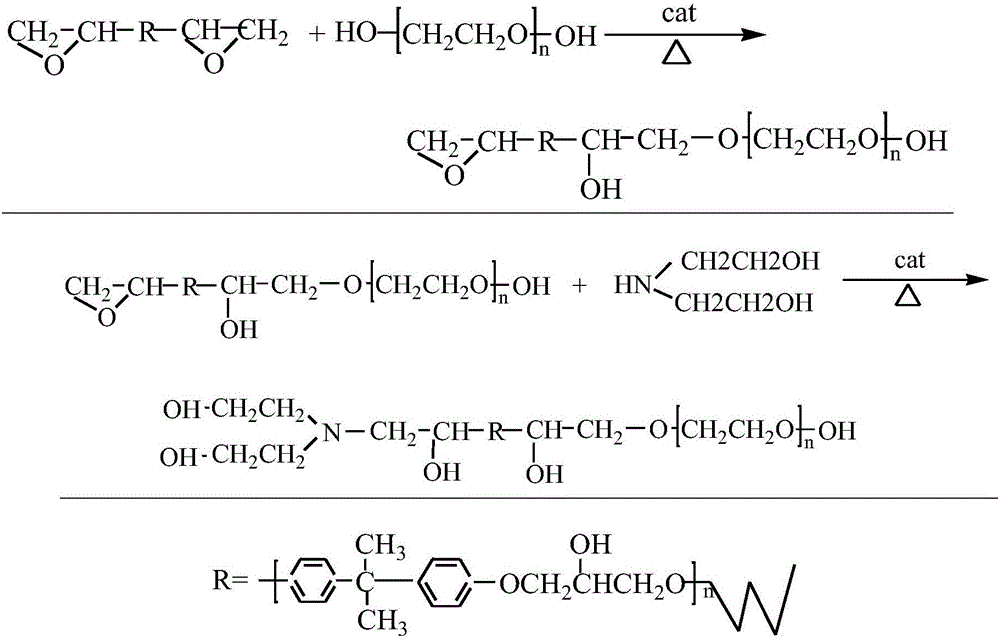

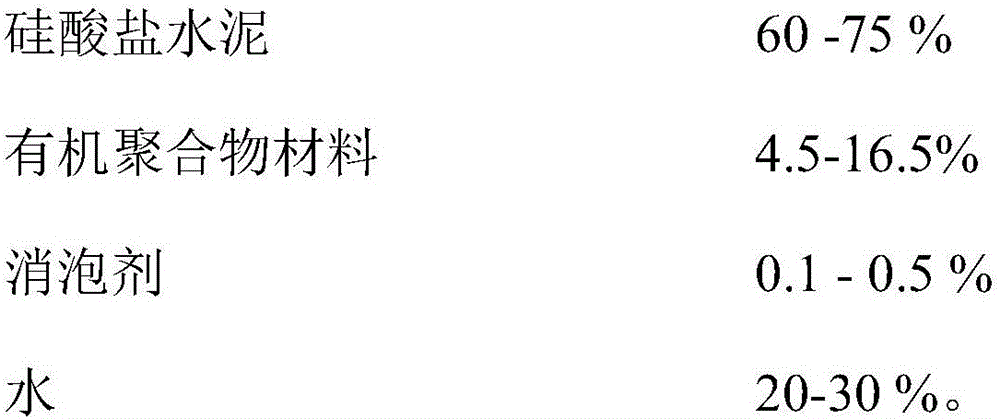

Organic polymer material, Portland cement containing same and preparation method of Portland cement

The invention relates to the technical field of cement preparation and particularly relates to an organic polymer material, Portland cement containing the same and a preparation method of the Portland cement. The organic polymer material is prepared from an aqueous epoxy resin emulsion, a curing agent and a stabilizer, wherein the weight ratio of the aqueous epoxy resin emulsion to the curing agent is (3-10):(1-5), and the weight ratio of the aqueous epoxy resin emulsion to the stabilizer is (3-10):(0.5-1.5). The organic polymer material can not only protect cement slurry under the well cementing conditions of high temperature and high mineralization degree, but also improve the compressive strength and toughness of cement stone and also improve the corrosion resistance of the cement stone.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

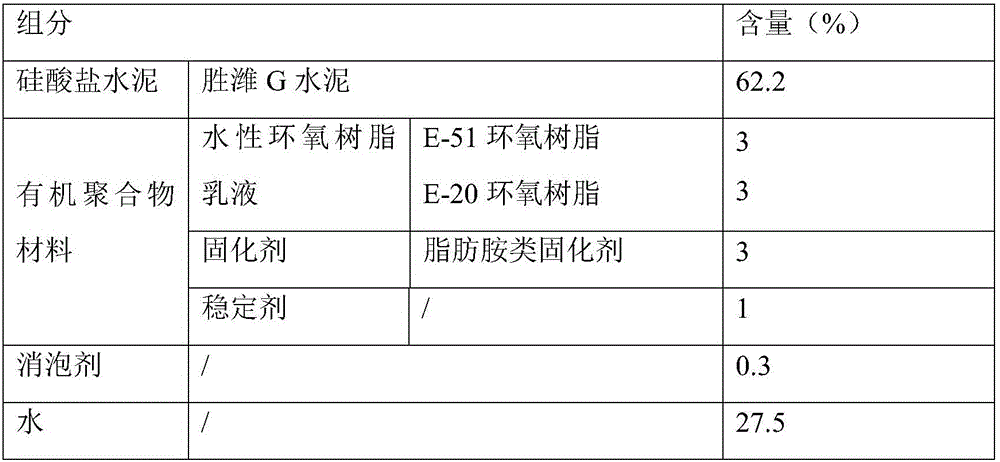

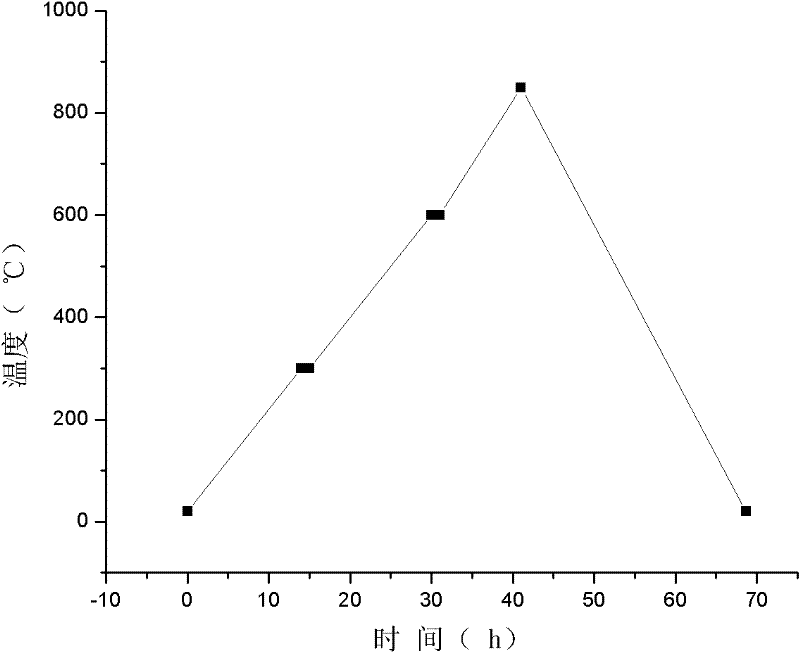

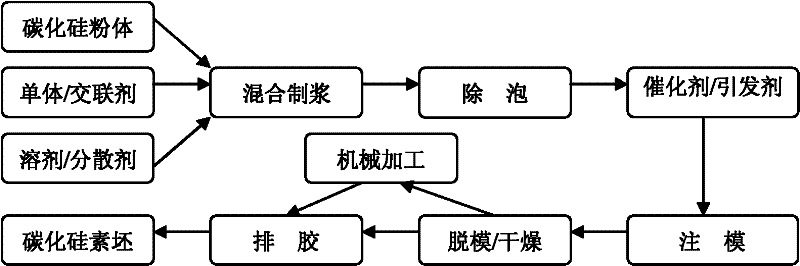

Gel injection molding technology of large-sized and complicated-shape silicon carbide ceramic biscuit

InactiveCN101941231BIncrease contentControl curing timeCeramic shaping apparatusMaterials preparationSlurry

The invention relates to a gel injection molding technology of a large-sized and complicated-shape silicon carbide ceramic biscuit, belonging to the technical field of a material preparation. In the technology, the large-sized and complicated-shape SiC ceramic biscuit can be prepared by seven steps of preparing premixing liquid, preparing slurry, defoaming the slurry, adding an initiating agent and a catalyst, injecting and molding, drying a biscuit body and degreasing the biscuit. The invention can ensure that a plurality of technological difficulties of difficult preparation of high-solid-phase content slurry, difficult gelation time control of the slurry, difficult demolding and drying and the like in the course of preparing the large-sized and complicated-shape SiC ceramic biscuit by adopting the gel injection molding technology are solved; and the preparation of the complicated-shape SiC ceramic biscuit of 1m of magnitude order is realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Old pipeline repairing process

InactiveCN102788222AControllable curing timeEasy to manufacturePipe elementsEngineeringMechanical engineering

The invention relates to an old pipeline repairing process. The old pipeline repairing process comprises the steps of: first, soaking a barrel composite sandwich felt in UV resin to form a hose, and sticking an inner film and an outer film respectively on the inner and outer surfaces of the composite sandwich felt; then, dragging the hose into the oil pipeline with cleaned inner wall; placing a UV (ultraviolet) lamp in an end socket at one end of the hose, and connecting a traction rope and a power supply; and second, sealing both ends of the hose by the end socket, and pulling the UV lamp to move slowly to irradiate the hose by the traction rope to cure the hose. The hose provided by the invention is made of composite sandwich felt soaked in the UV resin, the curing time of the hose can be controlled, and the hose can be manufactured in a workshop, so that the construction time in a construction site is shortened, the curing time and speed of the UV resin can be effectively controlled, the success rate is improved, and the liner repairing quality is ensured.

Owner:HENAN ZHONGTUO PIPELINE ENG

Resin mortar composition for construction and floor operating method using the same

InactiveUS20060155004A1Improve liquidityIncreased durabilityCosmetic preparationsImpression capsGlass fiberCrack resistance

The present invention relates to a resin mortar composition, which has excellent flowing property, storage property, excellent self-leveling property when constructed, and excellent abrasion resistance, surface scratch resistance, crack resistance and durability after construction, which can be easily constructed and easily control curing time, and is economical. According to the present invention, there are provided a resin mortar composition for construction, which comprises, on the basis of solid content, a) 100 parts by weight of room temperature curable organic liquid phase resin; b) 10 to 200 parts by weight of glass bead, c) 10 to 400 parts by weight of glass powder, and d) 0.1 to 50 parts by weight of glass fiber, and a method for constructing a floor that has beautiful surface and does not show crack using the same.

Owner:KWAK SANG WOON

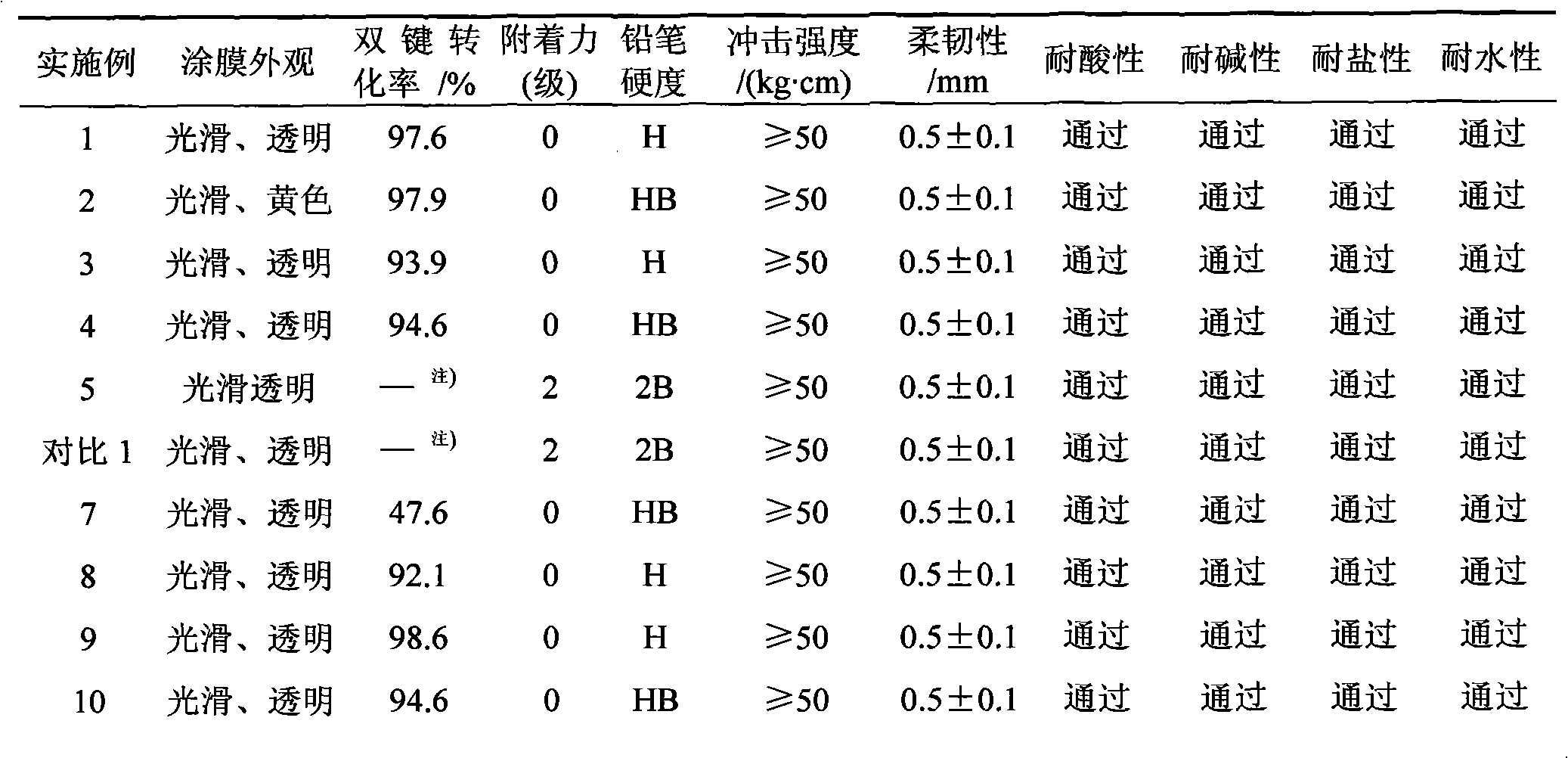

Abietic resin allyl propionate photo-curing material and preparation method thereof

InactiveCN101870754AFully embodies and exerts excellent performanceControl curing timeCoatingsPliabilityDouble bond

The invention discloses an abietic resin allyl propionate photo-curing material, which comprises the following components in parts by mass: 1 part of abietic resin allyl propionate, 0.01 to 0.1 part of conventional photoinitiator, 5 to 100 parts of diluent or active diluent, wherein the abietic resin propionate uses colophony as a structure unit and contains vinyl double bonds. When the material is matched with monomer for conventional photo-curing, dosage of the monomer for conventional photo-curing is between 0 and 99 parts, and is not equal to zero. When the abietic resin allyl propionate is applied in photo-curing material prepolymer, the curing time and the surface effect can be controlled by regulating the photo-curing condition. The prepolymer has the characteristic of high curing speed, and the obtained film has good flexibility, impact strength resistance and adhesion, and has high hardness, acid resistance, alkali resistance, salt resistance and water resistance.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

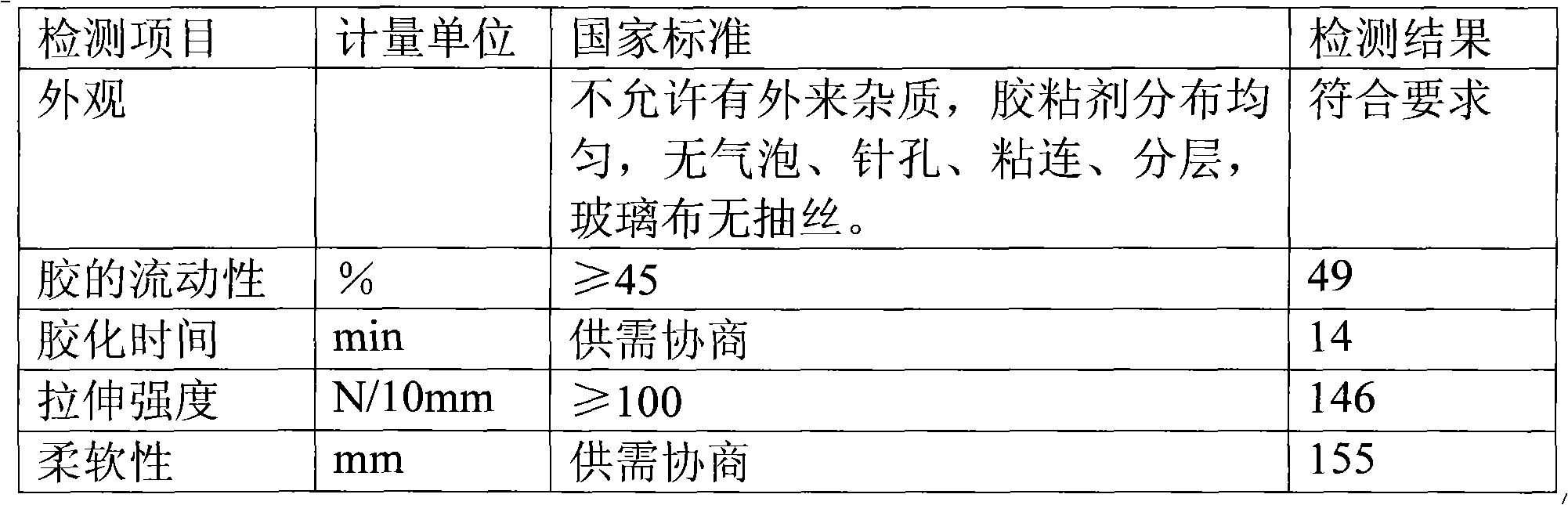

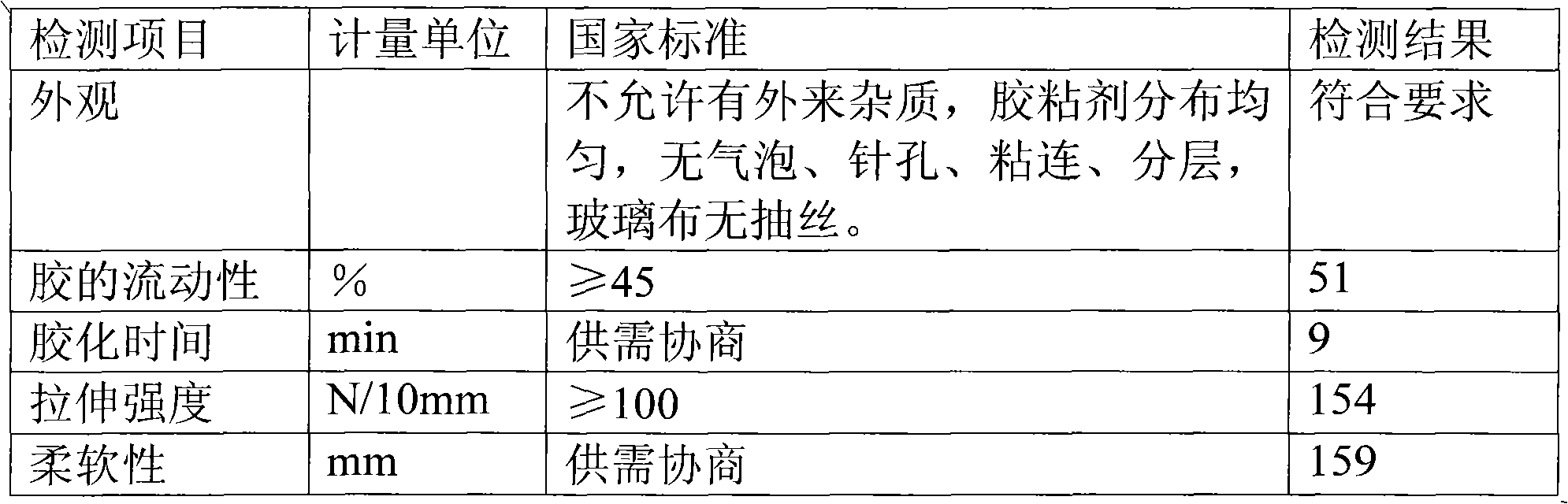

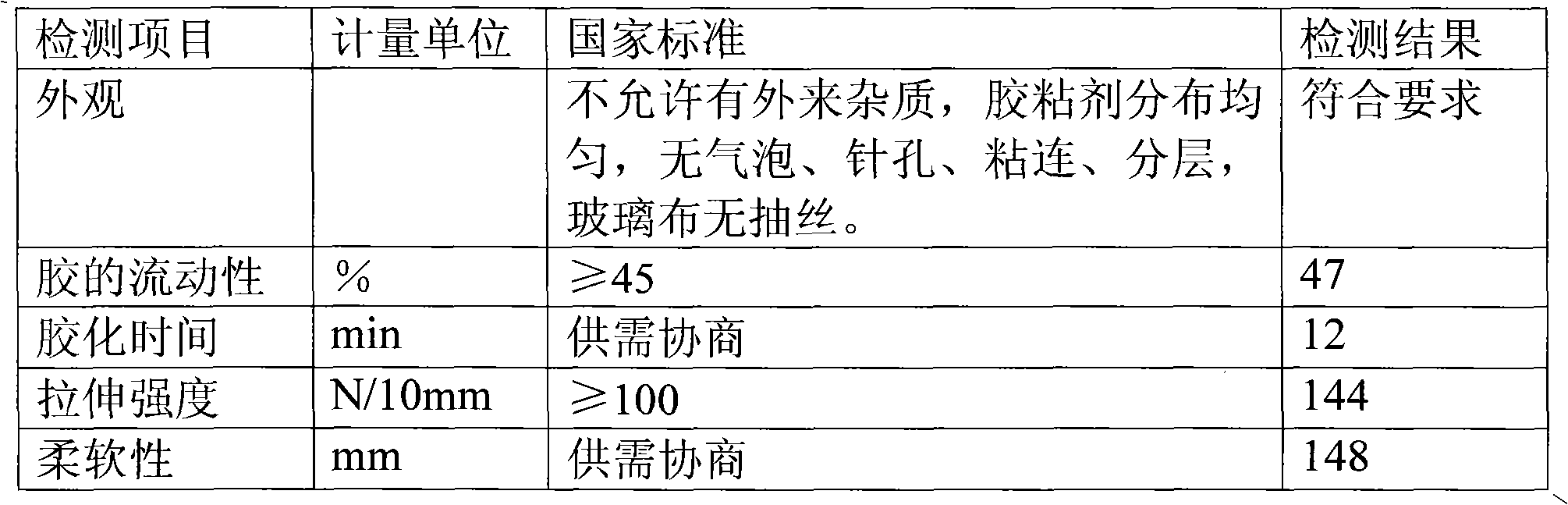

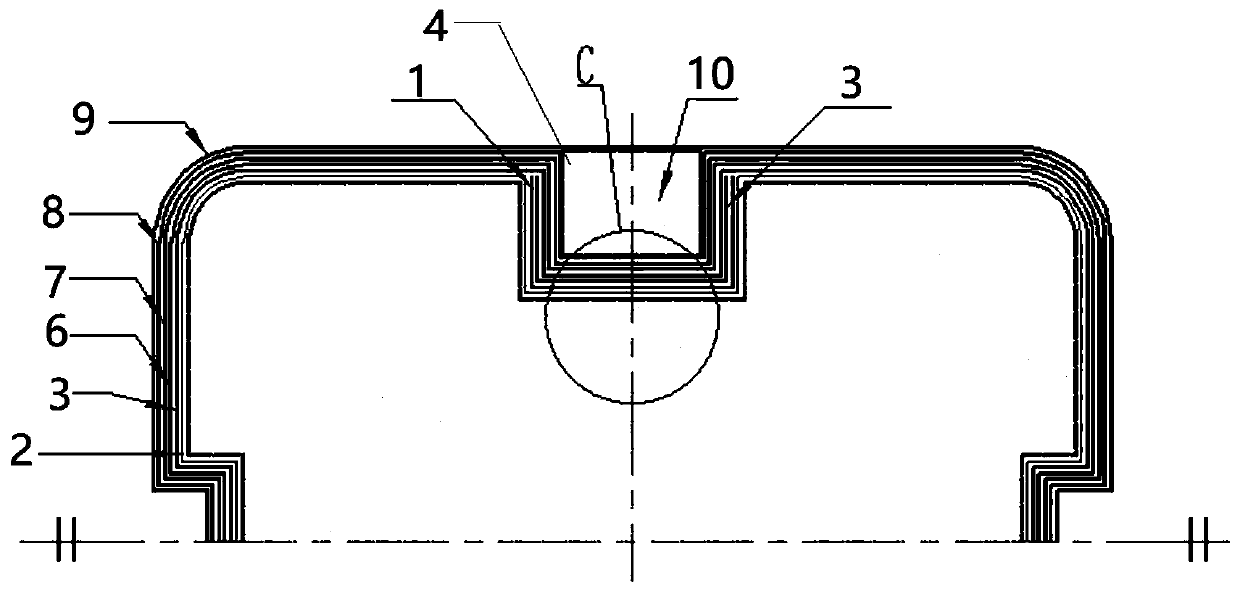

Epoxy glass powder mica belt and preparation method thereof

InactiveCN102081989AImprove product qualityImprove heat resistanceInorganic insulatorsInsulating bodiesSolventEpoxy adhesive

The invention discloses an epoxy glass powder mica belt and a preparation method thereof. The epoxy powder mica belt is formed by laminating mica paper, glass cloth and epoxy adhesive, wherein the epoxy adhesive is prepared from tung oil, maleic anhydride, bismaleimide, epoxy resin, a solvent, a complexing agent and a catalyst. The production quality of the epoxy glass powder mica belt prepared by a unique method can be ensured, the curing time during use can be accurately controlled according to customer demands; and the invention has the advantages of simple process, simple operation, reliable use performance and the like.

Owner:STATE GRID CORP OF CHINA +1

Composite material emission box and preparation method thereof

ActiveCN111421858AMeet wall thickness requirementsGuaranteed bonding effectRocket launchersAmmunition storageMold removalInterface bonding

The invention provides a composite material emission box and a preparation method thereof. The preparation method comprises the following steps of spraying a heat-protection layer material on the surface of a mold, precuring the heat-protection layer material, and obtaining a heat-protection layer; overlaying a first stitched fabric on the heat-protection layer, infusing a resin material by vacuum, then co-curing the resin material and the heat-protection layer for forming, and forming a composite material inner layer on the heat-protection layer; overlaying a second stitched fabric on the composite material inner layer, infusing a resin material by vacuum, then curing and forming, and forming a composite material outer layer on the composite material inner layer; and separating a productfrom the mold, and obtaining the composite material emission box. According to the method, the construction method for preparing the small-bore composite material emission box with the heat-protectionlayer and a large slenderness ratio is simple; and according to the prepared emission box, an interface bonding effect of the heat-protection layer and the composite material layer is high, and the heat-protection layer can be demolded without damage.

Owner:北京玻钢院复合材料有限公司

Solder paste for dipping as well as preparation technology and use method of solder paste

InactiveCN106541221ALow viscosityHigh and consistent bond strengthWelding/cutting media/materialsSoldering mediaWater basedAlloy

The invention discloses solder paste for dipping. The solder paste is prepared from components in parts by weight as follows: 5-10 parts of a water-based binder, 50-75 parts of metal or alloy powder and 20-40 parts of water. A preparation technology of the solder paste comprises the steps as follows: the water-based binder, the metal or alloy powder and the water are weighed in parts by weight respectively; the water-based binder and the water are poured into a container and are evenly stirred; and the metal or alloy powder is added and is evenly stirred. A use method of the solder paste comprises the steps as follows: the solder paste with the certain height is placed in a container, and the surface of the solder paste is scraped flat; a to-be-soldered surface is dipped in the solder paste and is placed into a drying oven for drying or is air-dried naturally, and a to-be-soldered intermediate is obtained; and the to-be-soldered intermediate and a connecting piece are assembled, are soldered in a vacuum or furnace atmosphere and are connected into a whole. In the use process of the solder paste, holes are not blocked by solder, and the strength is high, uniform and consistent after soldering. The preparation technology is simple. With the adopted dipping method, the advantages of the solder paste can be exerted further.

Owner:BEIJING ANDER TECH

Highway environment-friendly epoxy biological asphalt material and preparation method thereof

ActiveCN108440981AImprove high temperature performanceGood compatibilityBuilding insulationsEpoxyCross-link

The invention relates to a highway environment-friendly epoxy biological asphalt material and a preparation method thereof, in particular to an epoxy biological asphalt material to repair a pavement and a preparation method thereof in order to solve the problem that existing biological asphalt materials have difficulty in balancing high- and low-temperature properties. The highway environment-friendly epoxy biological asphalt material is made from, by weight, 100 parts of biological asphalt, 35-60 parts of a curing agent, 1-2 parts of a strong base, 0.5-1 part of a defoaming agent, and 20-34 parts of epoxy resin. The preparation method includes: I, mixing the biological asphalt, the curing agent, the strong base and the defoaming agent to obtain biological asphalt mixture; II, mixing the epoxy resin with the biological asphalt mixture. The combination of the biological asphalt with the epoxy resin herein can balance the high- and low-temperature properties; the cured cross-linked epoxyresin is used to improve the high-temperature performance; the biological asphalt is used to fill the epoxy resin to provide toughening and to improve low-temperature performance; the curing time ofthe combination is well controlled, so that quick pavement repairing is achieved.

Owner:HARBIN INST OF TECH

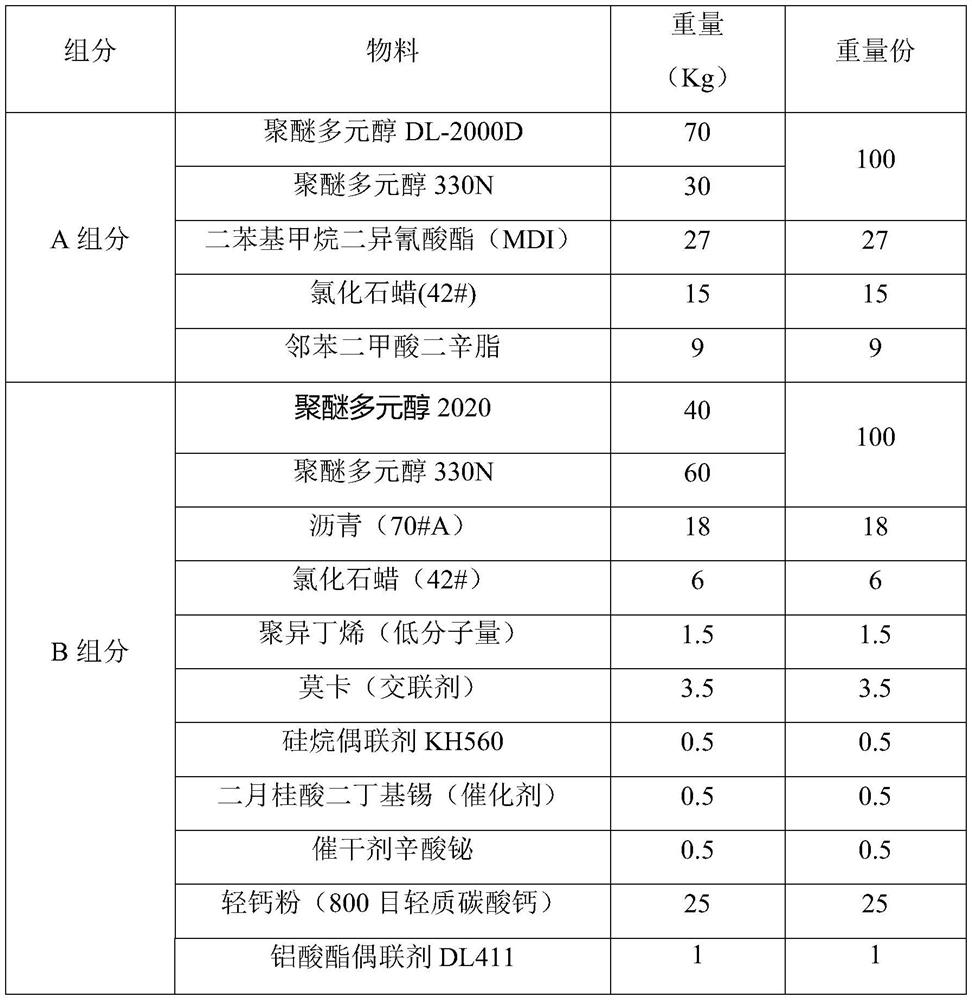

Normal temperature two-component liquid crack pouring sealant for pavements and preparation method thereof

ActiveCN110105911AAvoid damageHigh bonding strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemical synthesisAdhesive

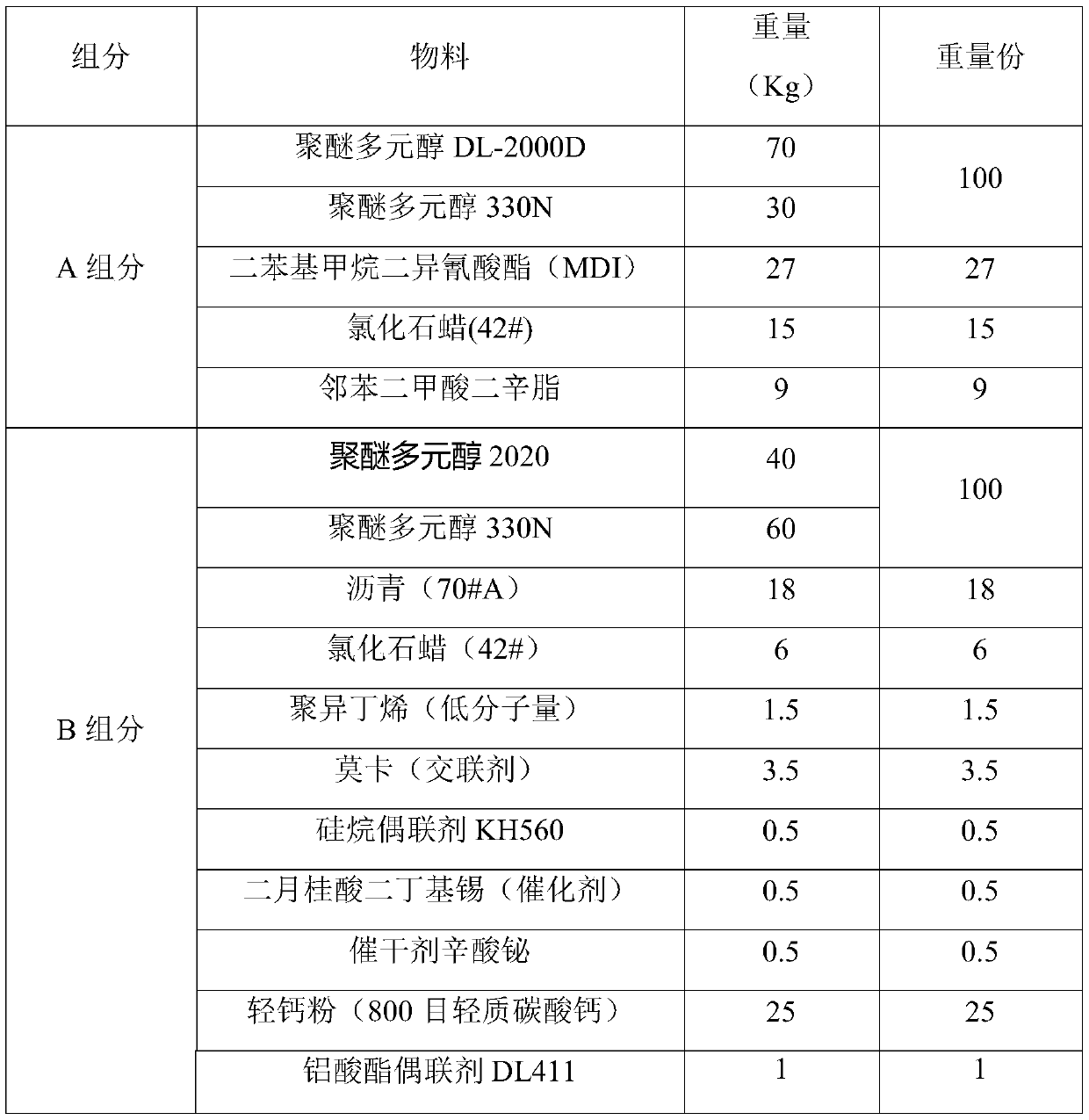

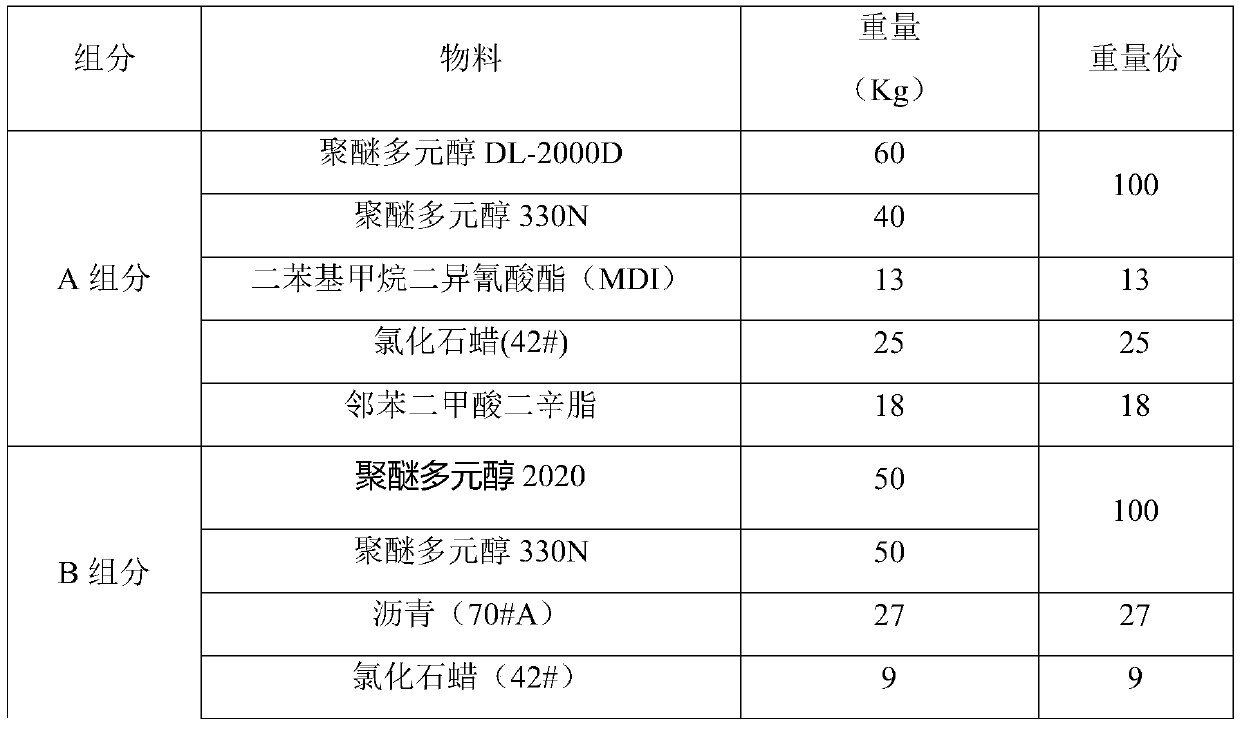

The invention provides a normal temperature two-component liquid crack pouring adhesive, which is a polyurethane two-component A-B type liquid crack pouring sealant. Specifically, the component A is aprepolymer prepared by chemical synthesis of a variety of materials including methylenediphenyl diisocyanate (MDI), polyether polyol, chlorinated paraffin, dioctyl phthalate, etc; the component B isa mixture of asphalt, polyether polyol, chlorinated paraffin, polyisobutylene, a crosslinking agent, a coupling agent, a catalyst, a drier, light calcium powder and other materials. During use, the component A and component B are fully mixed in certain proportion and then directly poured into pavement cracks, thus obtaining the pavement crack pouring and sealing material with the advantages of high cohesive force, high adhesion, high wear resistance, high weatherability and rapid curing. And the two-component liquid crack pouring sealant can be used for various cracks on asphalt and cement pavements.

Owner:河北德瑞公路工程有限公司

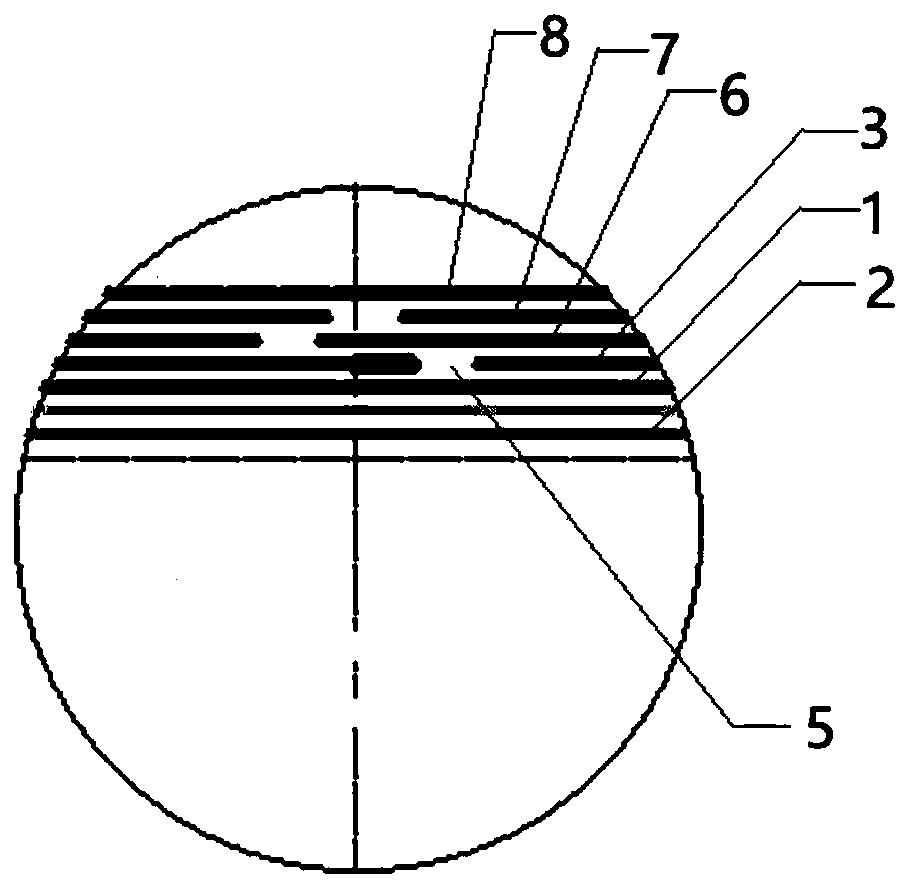

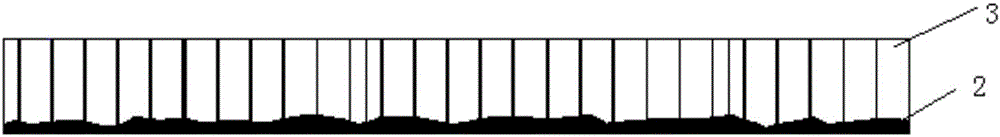

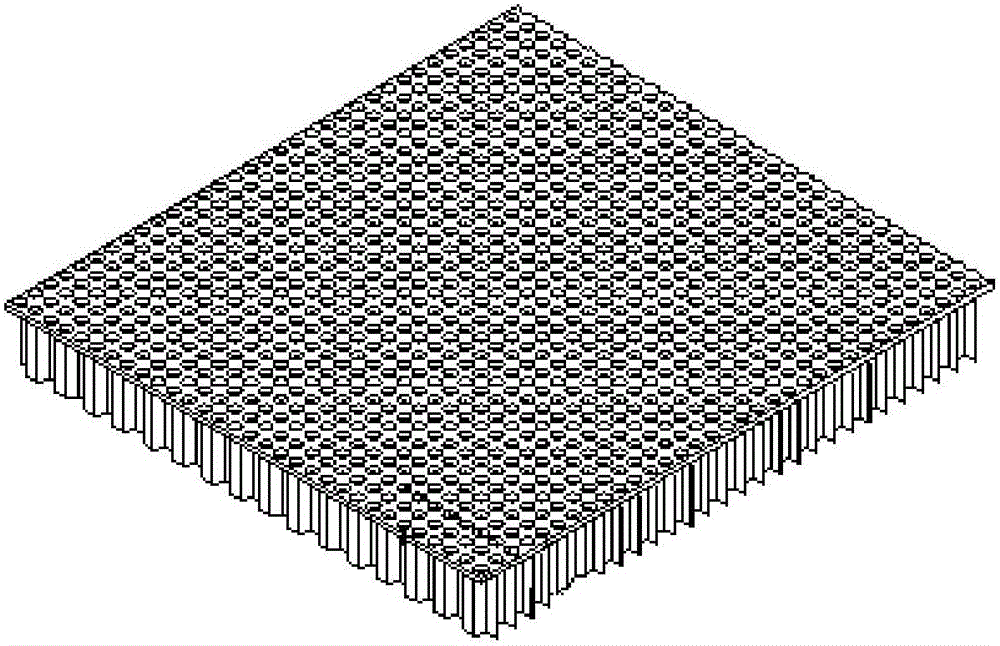

Industrial production method for electrostatic dust collection sheet

ActiveCN109591429AGood dust removal and purification effectIncrease productivityLamination ancillary operationsLaminationEngineeringPre treatment

The invention discloses an industrial production method for an electrostatic dust collection sheet and relates to the technical field of air purification. The industrial production method comprises asubstrate pretreatment step, a printing step, a drying step, a coating step and a cutting step. By selecting a PET coiled material as a substrate, a strip-like ink pattern is printed to the substrate,a PET film coats the dried substrate, the substrate is laminated by a laminating machine and is then tailored to obtain the electrostatic dust collection sheet. The industrial production method for the electrostatic dust collection sheet is simple in process, easily available in raw material, low in cost and high in efficiency.

Owner:DEYANG CARBONENE TECH

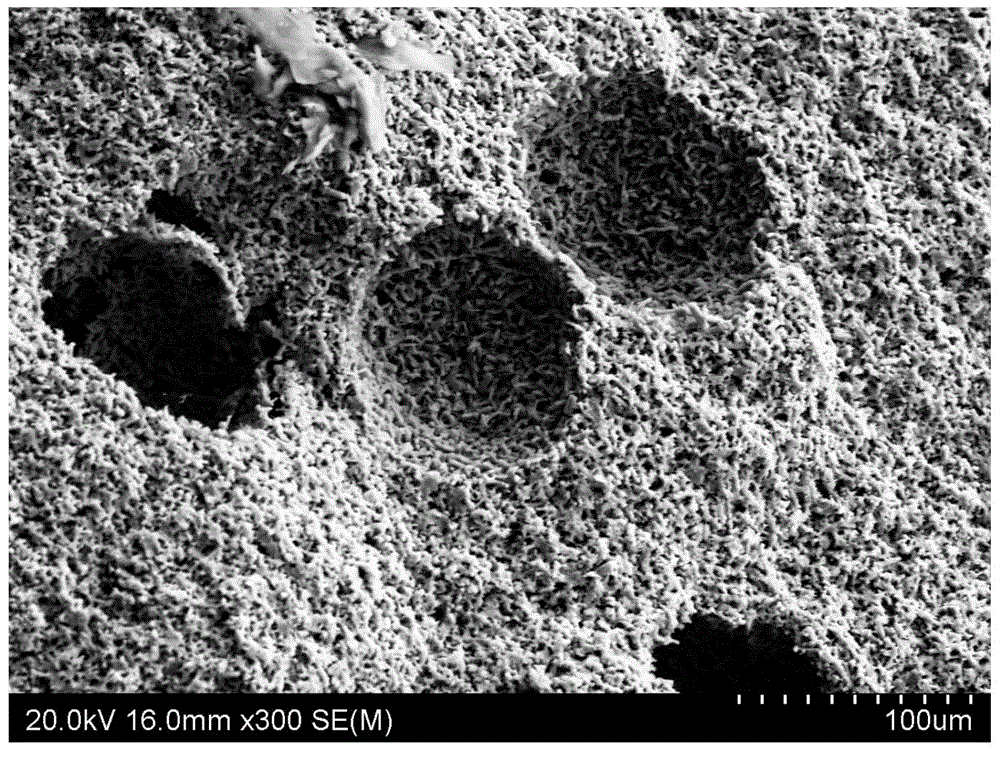

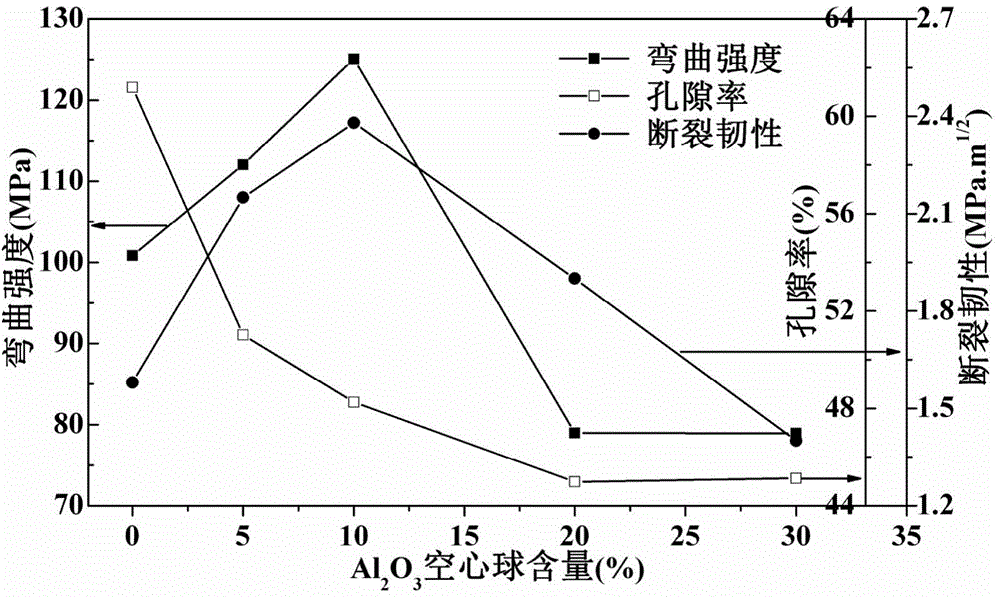

A kind of preparation method of porous silicon nitride ceramics

The invention provides a preparation method for porous silicon nitride ceramic. The preparation method comprises the following steps: preparation of gel; addition of a pore forming agent; molding of a green body; drying of the green body; sintering of the green body; etc. The method combines a gel-casting and a pore forming agent addition process together and has the advantages of simple process, low cost and substantially shortened gel discharge time; and the prepared porous silicon nitride ceramic has great porosity, high bending strength and good mechanical properties.

Owner:HOHAI UNIV

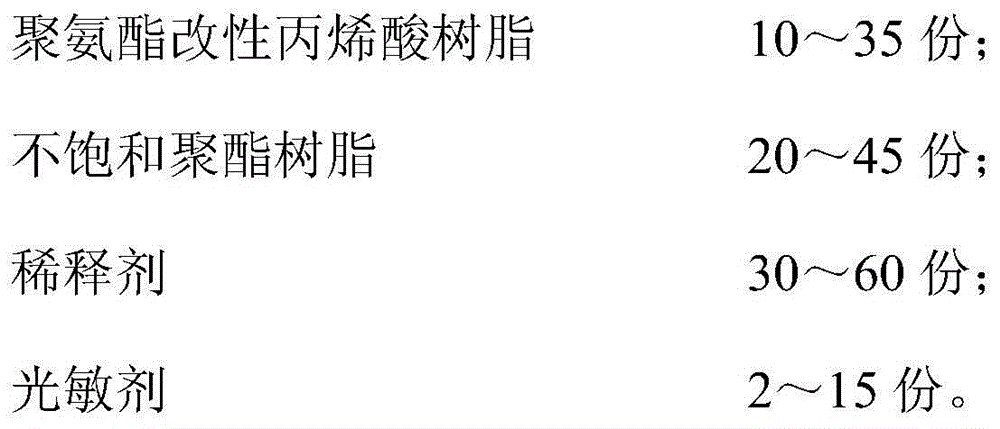

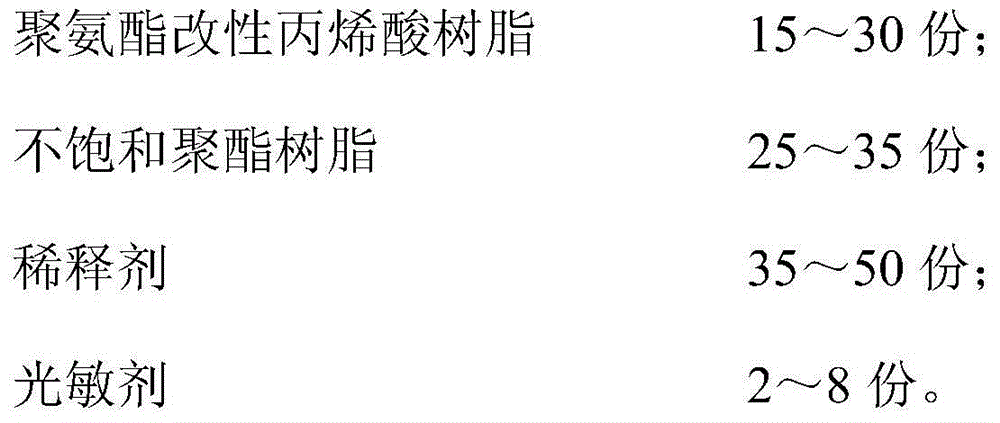

Shadowless glue with high adhesion and preparation method thereof

InactiveCN104629670AImprove adhesionGood flexibilityPolyureas/polyurethane adhesivesPhotosensitizerAcrylic resin

The invention discloses shadowless glue with high adhesion and a preparation method thereof. The shadowless glue comprises the following components in parts by mass: 10-35 parts of polyurethane modified acrylic resin, 20-45 parts of unsaturated polyester resin, 35-60 parts of a diluent and 2-10 parts of a photosensitizer. Since polyurethane modified acrylic resin and unsaturated polyester resin are blended, such advantages of polyurethane modified acrylic resin as high adhesion and good flexibility and such advantages of unsaturated polyester resin as room-temperature curing and normal-pressure molding properties as well as good processing property are combined; therefore, after being cured, the shadowless glue has excellent adhesion and can be operated under simple and convenient conditions.

Owner:江苏大力士投资有限公司

A kind of two-component liquid joint glue for normal temperature pavement and preparation method thereof

ActiveCN110105911BSolve the problem of heating and polluting the environmentNo heating requiredNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesParaffin waxChemical synthesis

Owner:河北德瑞公路工程有限公司

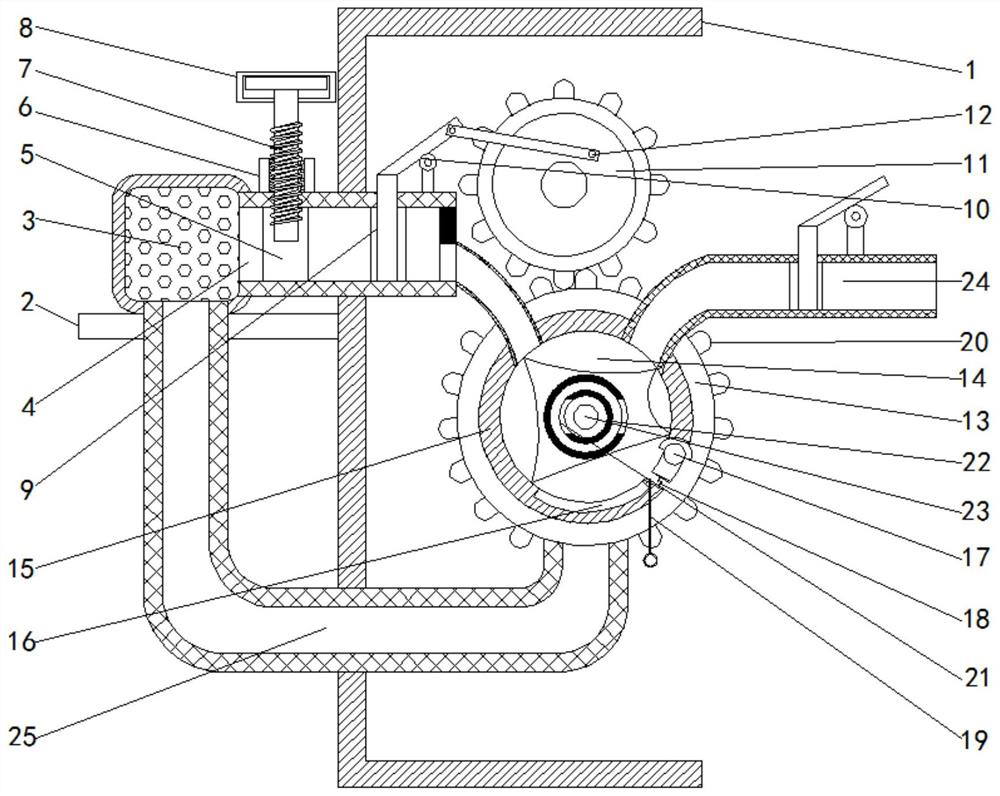

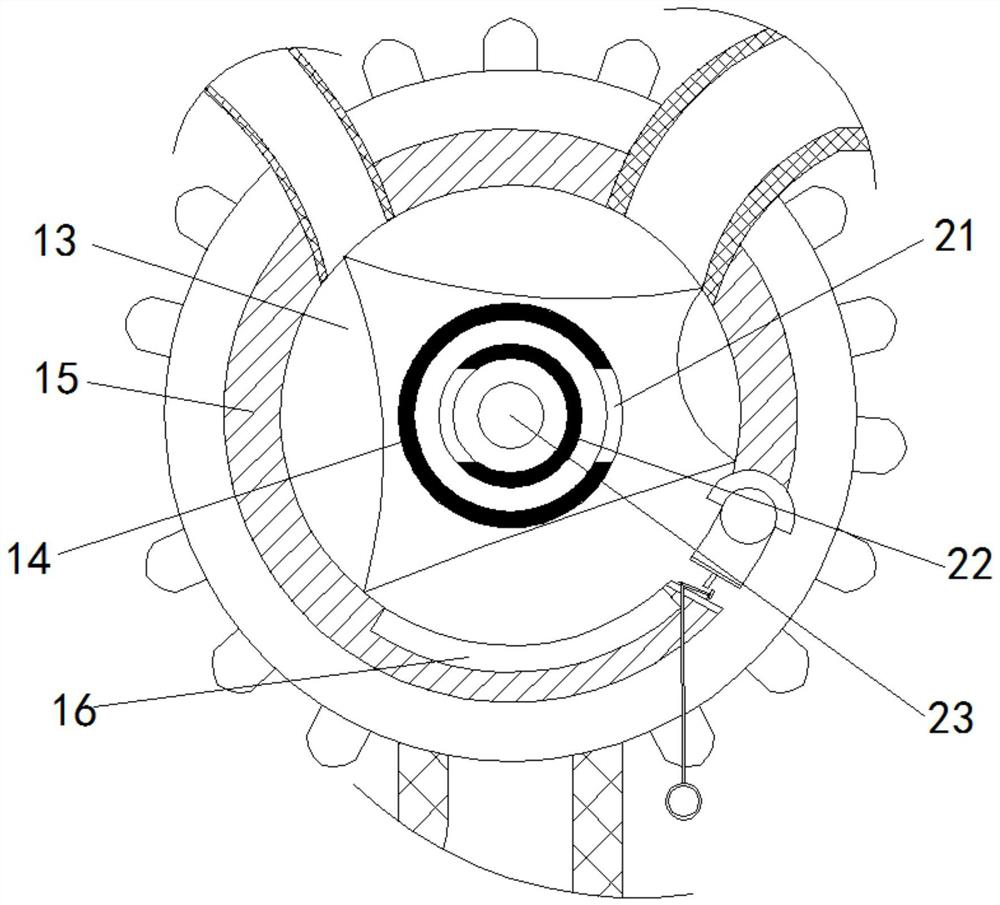

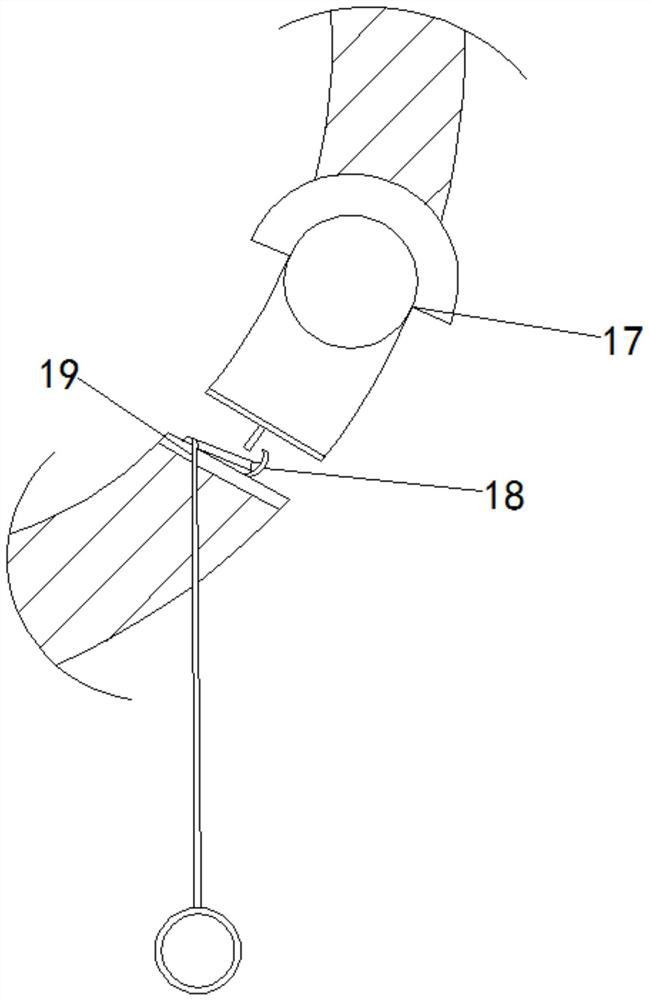

Device for carrying out vulcanization treatment on vamp rubber

The invention relates to the technical field of shoemaking, and discloses a device for carrying out vulcanization treatment on vamp rubber. The device for carrying out vulcanization treatment on the vamp rubber comprises a vulcanization treatment device main body, wherein a limiting groove is formed in a vulcanization gas pipeline; a threaded hole is fixedly formed in the top of the vulcanizationgas pipeline; a bolt rod is in threaded connection with the interior of the threaded hole; a rubber elasticity tester is fixedly installed at the top of the bolt rod; a valve is slidably connected into the limiting groove; and a rotary switch is movably connected to the top of the valve. The rubber elasticity tester is installed above a vulcanization gas pipeline, a rotating wheel drives a stop lever to compress the rubber, the rotating wheel stops rotating until compression is subjected to large resistance, and at the moment, due to the fact that the rotating wheel drives the bolt rod to rotate in the threaded hole in the rotating process, the bolt rod goes deep into the limiting groove; and thus, the vulcanization gas pipeline is further blocked, and the effect of determining the amountof introduced vulcanization gas according to the physical and chemical properties of the rubber is achieved.

Owner:广州宾聚科技有限公司

A polymer-loaded coagulant and its preparation method and cement slurry

ActiveCN107987813BPromote hydrationShort hardening timeDrilling compositionCompressive resistanceWell cementing

The invention relates to a polymer supported coagulant, a preparation method thereof and cement paste containing the polymer supported coagulant in the field of petroleum drilling and production. Thepolymer supported coagulant is prepared from a polymer supported organic component and inorganic matter in the weight ratio being 1:(0.1-100), preferably 1:(0.5-10). The polymer supported coagulant can be used as a cement coagulant for oil well cementation, particularly in a low-temperature environment. The polymer supported coagulant has good adaptability in the temperature range of 5-10 DEG C, has good dosage linearity, is compatible with multiple additive systems, has good compatibility, has the compressive strength larger than 3.5 MPa within 24 h for set cement and has no effects on comprehensive performance of the cement paste.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of leak repairing filling glue and house leak repairing method by using the filling glue

InactiveCN105400475ASmall shrinkageImprove shrinkageNon-macromolecular adhesive additivesBuilding repairsEpoxyAcetone

A Preparation method of leak repairing filling glue comprises the steps of: adding an amino silane coupling agent to absolute ethyl alcohol, adding acetic acid, adjusting the pH value to 1-7, conducting ultrasonic vibration to completely dissolve the amino silane coupling agent in the absolute ethyl alcohol to obtain a dispersed absolute ethyl alcohol mixed solution; modifying the nano SiO2 with the dispersed absolute ethyl alcohol mixed solution modified nano SiO2; mixing and reacting the obtained modified nano SiO2 with liquid epoxy resin to obtain modified epoxy resin; and mixing the modified epoxy resin product with acetone, adding a small amount of butyl acetate to completely dissolve the modified epoxy resin, then adding a curing agent, and uniformly stirring to obtain the leak repairing filling glue. The product provided by the present invention can greatly improve the permeability by controlling the viscosity of the material, and achieve the perfect leak repairing by controlling the curing time.

Owner:GUANGDONG UNIV OF TECH

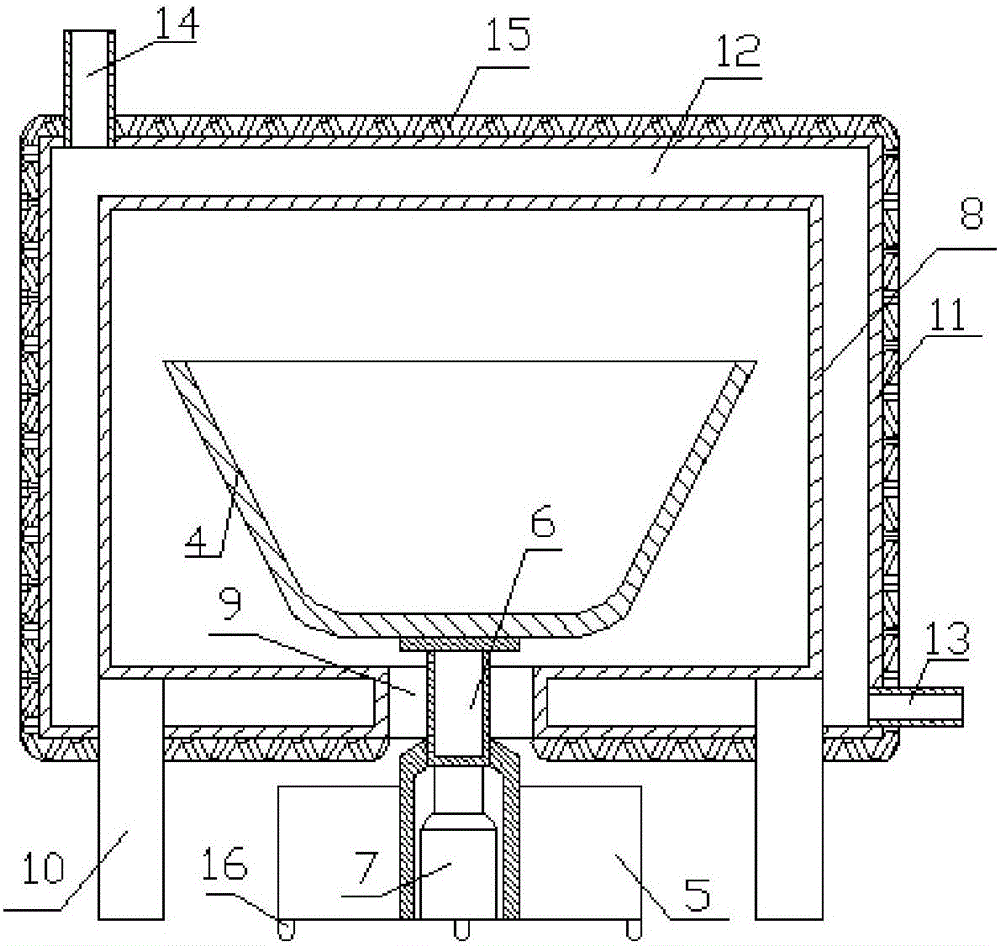

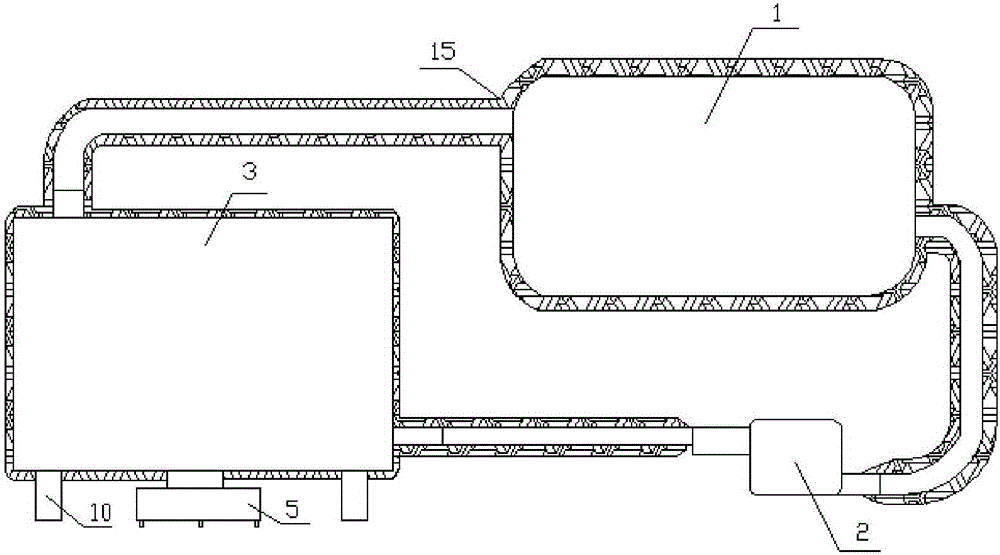

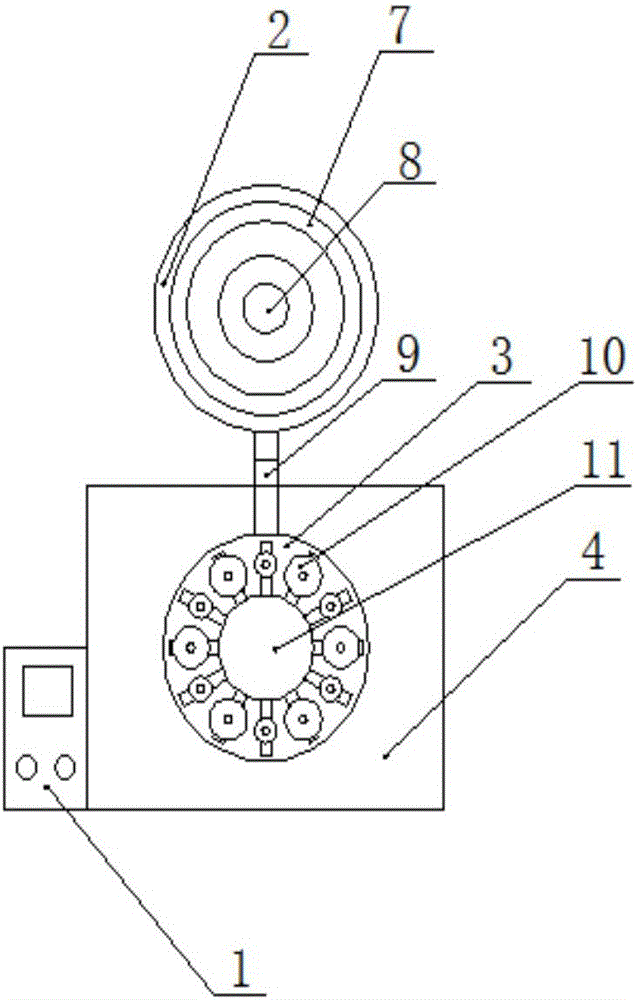

Device and method for promoting curing of fiberglass product

InactiveCN106182827ASolve the problem that production is affected by ambient temperatureEvenly heatedDrive shaftEngineering

The invention provides a device and method for promoting curing of a fiberglass product. The device for promoting curing of the fiberglass product comprises a constant-temperature water tank and a circulation device. A water outlet of the constant-temperature water tank is connected with a water inlet of the circulation device. The device for promoting curing of the fiberglass product further comprises a supporting device, a curing box and a rotating device. The rotating device is fixedly arranged at the bottom of a die frame and used for driving a drive shaft to rotate. The curing box comprises a box body, an opening and closing door arranged on one side of the box body and supporting feet arranged at the bottom of the box body. A box plate of the box body is of a double-layer structure, and a cavity is formed between an inner-layer plate body and an outer-layer plate body. The outer-layer plate body is fixedly provided with a water inlet pipe and a water outlet pipe which communicate with the cavity, wherein the water inlet pipe is connected with a water outlet of the circulation device, and the water outlet pipe is connected with a water inlet of the constant-temperature water tank. A channel for the drive shaft to get in and get out is formed in a bottom plate. The device for promoting curing of the fiberglass product has the beneficial effects that the structure is simple, the investment is small, heating is uniform, maintenance is convenient, and the heat energy utilization rate is high.

Owner:EULIKIND TIANJIN TECH

Thermoelectric power generation bituminous pavement structure and paving process thereof

PendingCN110396890AMeet driving requirementsExtended service lifeClimate change adaptationTemporary pavingsThermal energyInsulation layer

The invention discloses a thermoelectric power generation bituminous pavement structure and a paving process thereof. The process comprises the following steps of paving a rigid base layer on a subgrade; arranging a bonding layer on the rigid base layer; paving a heat insulation layer on the bonding layer; arranging an epoxy asphalt bonding layer on the heat insulation layer; arranging a heat conduction plate on the epoxy asphalt bonding layer; paving a asphalt mixture surface layer on the heat conduction plate; arranging an energy conversion module on the heat conduction plate; arranging a cooling module on the energy conversion module; and arranging a protection device on the cooling module. According to the structure and the process, the integration of the pavement performance and the power generation function of a pavement is achieved, the service life of the pavement is prolonged, the pavement temperature is effectively reduced, the urban heat island effect is relieved, the pavement high-temperature disease is relieved, a large amount of heat which is not easy to release by the bituminous pavement is utilized, thermal energy is converted into electric energy, the structure issimple, and the paving process is simple and convenient.

Owner:CHANGAN UNIV

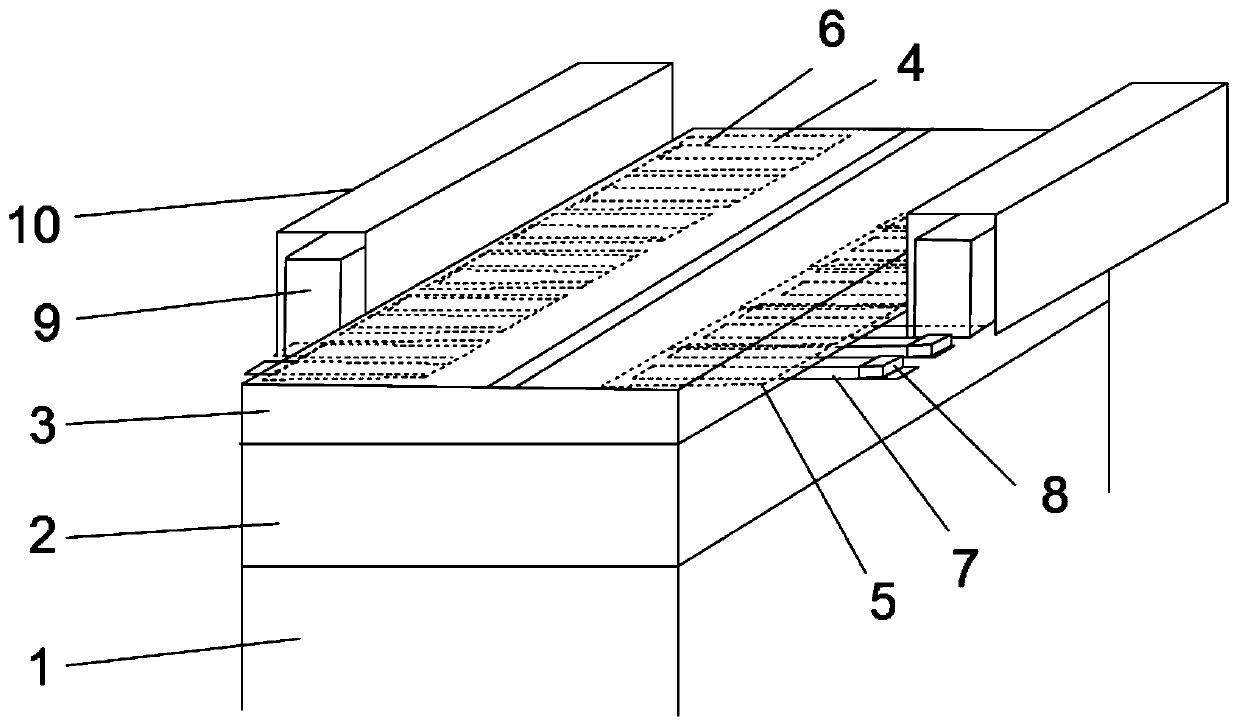

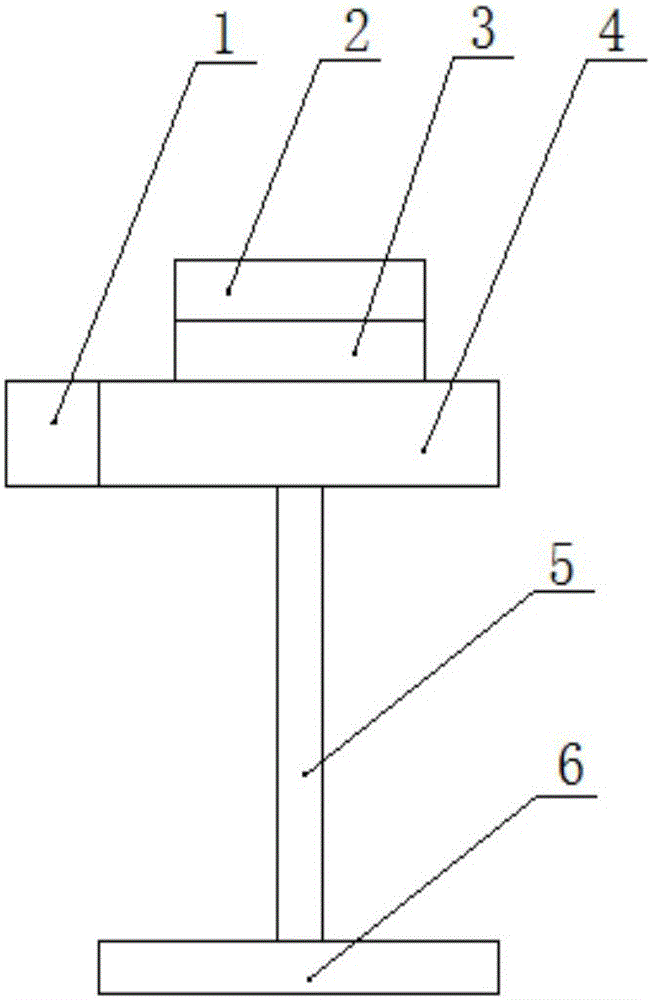

Fiber connector curing machine

ActiveCN106019480AEvenly heatedImprove curing effectCoupling light guidesOptical fiber connectorPliability

The invention relates to a fiber connector curing machine which comprises a pedestal, a rotary pole, an operating console, a curing disc and a controller, wherein the rotary pole is vertically inserted in the pedestal, the upper end of the rotary pole passes through the operating console, the curing disc is concentrically embedded in the center of the operating console, the upper end of the rotary pole is inserted in the center of the curing disc, and one side of the operating console is provided with the controller which controls the rotation of the rotary pole and timely sets curing temperature and time. The structure is simple, and operation is convenient. Curing temperature and curing time can be effectively controlled, so that optical cable connector is heated uniformly during a curing process. Gluing is rapid and accurate. Curing temperature and glue volatility are prevented from being affected by external environment. The product performance, machining efficiency and product quality are improved, hardness, flexibility, tension and anti-torsion performances of fiber connectors are effectively improved, production and use of fiber connectors are ensured, and the fiber connector curing machine is worthy of promotion.

Owner:天津立孚光电科技股份有限公司

Heat dissipating organic silicone coating for roofs

InactiveCN108329833AImprove high temperature resistanceImproves UV resistanceReflecting/signal paintsTemperature resistanceSilicone coating

The invention discloses a heat dissipating organic silicone coating for roofs. The coating comprises an A component and a B component, wherein the A component is formed by mixing of propyltriethoxysilane, dimethyldiethoxylsilane, alcohol, titanium dioxide, aluminum oxide, bentonite and water, and the B component is formed by mixing of a titanium complex, dibutyltin dilaurate and a coupling agent;and the A component and the B component are uniformly mixed when being used. The heat dissipating organic silicone coating for the roofs disclosed by the invention has good heat dissipation performance, strong adhesion, impact resistance, high-temperature resistance, convenient use, and curing time and effects which can be adjusted according to actual conditions.

Owner:JIANGXI PINHAN CHEM IND CO LTD

Bridge expansion joint protective pouring system

PendingCN113652191AImprove adhesionAvoid debondingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to a bridge expansion joint protective pouring system which is a mixture of a component A, a component B and a component C. The component A comprises, by mass, 30-60 parts of a polyurethane prepolymer, 5-10 parts of a plasticizer, 1-5 parts of a catalyst, 1-5 parts of a defoaming agent, 0.5-2 parts of a water removal agent and 7-20 parts of filler. The component B comprises 10-20 parts by mass of epoxy resin, 1-8 parts by mass of a diluent and 1-3 parts by mass of a thixotropic agent; the component C comprises 1-5 parts by mass of a high-activity curing agent; 1-5 parts by mass of a medium-activity curing agent; and 0.5-2 parts by mass of a coupling agent. After the component B and the component C are mixed, epoxy groups can react with amino groups for curing; the epoxy resin and the metal have excellent bonding performance, so that the component B and the component C can be firmly bonded with a steel structure of the expansion joint after being cured.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +1

Epoxy glass powder mica tape

InactiveCN105489323AImprove product qualityImprove heat resistanceNon-macromolecular adhesive additivesOil/fat/wax adhesivesSolventEpoxy adhesive

The invention discloses an epoxy glass powder mica tape. The epoxy glass powder mica tape is prepared from mica paper, glass cloth and an epoxy adhesive in a compounding manner, wherein the epoxy adhesive is prepared from tung oil, maleic anhydride, bismaleimide, epoxy resin, solvent, a complexing agent and a catalyst. The production quality of the mica tape can be ensured by the epoxy glass powder mica tape manufactured through a unique method; the curing time in the use process can be accurately controlled according to requirements of users; and in addition, the epoxy glass powder mica tape has the advantages of simple technological method, simple operation, reliable usability and the like.

Owner:HENAN XINGZHI PATENT SERVICE CO LTD

Brick breakage-free waterproof coating composition and ceramic tile waterproofing construction method

ActiveCN107245258AExcellent water swelling effectNot easy to lose waterCovering/liningsCement coatingsLithium carbonateSodium Acrylate

The invention belongs to the field of waterproof materials, in particular to a brick breakage-free waterproof coating composition. The brick breakage-free waterproof coating composition is prepared from a base layer coating, a middle layer coating and a surface layer coating, wherein the base layer coating is prepared from 0.6 to 0.8 weight part of sodium acrylate, 0.1 to 0.3 weight part of sodium silicate, 0.4 to 0.6 weight part of a lithium carbonate catalyst and 14 to 16 weight parts of a methyl ethidene diamine curing agent. The brick breakage-free waterproof coating composition has the beneficial effects of good waterproofing effect, long service life and external impact resistance.

Owner:广州艾偲尼建材科技有限公司

A low voc heat and humidity resistant zinc-containing construction machinery water paint

ActiveCN106883728BImprove adhesionLow VOC contentAnti-corrosive paintsEpoxy resin coatingsPhysical chemistryFirming agent

The present invention relates to the technical field of coatings, in particular to the technical field of water-based coatings, and specifically discloses a low-VOC moisture-heat-resistant zinc-containing water-based paint for engineering machinery. By selecting two water-based epoxy resins with different epoxy values and different reaction speeds and two Mixing water-based epoxy curing agents with different active hydrogen equivalents, and adding flaky zinc powder and shielding fillers, the prepared water-based paint is a zinc-rich primer, which has good ease of construction and good adhesion of the paint film. It has excellent physical and chemical properties, low VOC content, safety and environmental protection, can be used without intermediate coating, and reduces the construction process of construction machinery coating.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com