Bridge expansion joint protective pouring system

A technology of expansion joints and systems, applied in the direction of non-polymer adhesive additives, adhesive types, adhesives, etc., can solve the problems of reduced deformation capacity of bridge expansion joints, closed traffic for a long time, reduced traffic efficiency, etc., to achieve shortening Time to open traffic, excellent elasticity, and short surface-drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

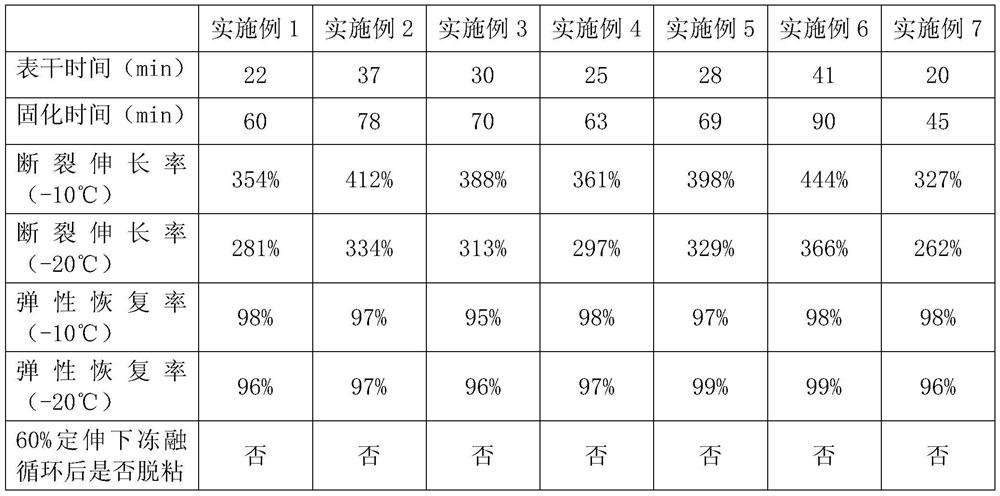

Examples

Embodiment 1

[0055] Step 1, the preparation of polyurethane prepolymer

[0056] 10 parts by mass of polyethylene glycol (Mn=2000) and 10 parts by mass of polyether polyol (Mn=3000) were heated in vacuum to remove water, then added to the reaction kettle, and 5 parts by mass of iso Phorone diisocyanate, 0.5 parts by mass of dibutyltin dilaurate, and 0.5 parts by mass of ethanolamine were reacted at 60°C for 1 hour to obtain a polyurethane prepolymer;

[0057] Step 2, the preparation of A component

[0058] Add 5 parts by mass of dibutyl phthalate, 1 part by mass of BYK070, 7 parts by mass of talcum powder and calcium carbonate powder into a vacuum reactor to remove water, and then add 1 part by mass of Dibutyltin dilaurate, 0.5 parts by mass of trimethyl orthoformate, and 30 parts by mass of polyurethane prepolymer prepared in step 1 are mixed in a vacuum environment, sealed and stored to obtain component A;

[0059] Step 3, preparation of component B

[0060] Mix 10 parts by mass of bis...

Embodiment 2

[0065] Step 1, the preparation of polyurethane prepolymer

[0066] 50 parts by mass of polyethylene glycol (Mn=2000) and 40 parts by mass of polyether polyol (Mn=3000) were heated in a vacuum to remove water, then added to the reactor, and 20 parts by mass were added under nitrogen protection. The equivalent blend of toluene diisocyanate and diphenylmethane diisocyanate, 1 mass part of diethanolamine, and 1 mass part of stannous octoate were reacted at 70°C for 2 hours to obtain a polyurethane prepolymer;

[0067] Step 2, the preparation of A component

[0068] 10 parts by mass of dioctyl phthalate, an equal blend of ethyl acetate, 5 parts by mass of BYK024 and an equal amount of HX-2085, 20 parts by mass of kaolin and silica powder The blend is added in a vacuum reactor to dewater, then add 5 mass parts of dibutyltin dilaurate, 2 mass parts of trimethyl orthoformate, the polyurethane prepolymer of 60 mass parts that step 1 makes, in a vacuum Mix under ambient conditions, se...

Embodiment 3

[0075] Step 1, the preparation of polyurethane prepolymer

[0076] 45 parts by mass of polyethylene glycol (Mn=4000) and 25 parts by mass of polyether polyol (Mn=5000) were heated in a vacuum to remove water, then added to the reactor, and 15 parts by mass were added under nitrogen protection. 1,6-hexamethylene diisocyanate, 1 mass part of dibutyltin dilaurate, and 0.6 mass part of ethanolamine were reacted at 80°C for 1 hour to obtain a polyurethane prepolymer;

[0077] Step 2, the preparation of A component

[0078] Add 8 parts by mass of ethyl acetate, butyl acetate and an equal blend of butyl acetate, 3 parts by mass of BYK024, 7 parts by mass of talcum powder, and 6 parts by mass of diatomaceous earth into a vacuum reactor for removal. Water, then add 3 mass parts of dibutyltin dilaurate, 1 mass part of trimethyl orthoformate, the polyurethane prepolymer of 45 mass parts that step 1 makes, mix under vacuum environment, seal and preserve promptly to get A components;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com