Gel injection molding technology of large-sized and complicated-shape silicon carbide ceramic biscuit

A technology for gel injection molding and shape silicon carbide, which is applied in the field of gel injection molding technology to achieve the effects of tight packing, increased content and consistent drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0019] SiC powder is provided by Shandong Weifang Huamei Fine Technology Ceramics Co., Ltd., with a median diameter of d 50 They are 0.5μm, 10μm and 40μm, respectively, with a purity of 99.7%. Various chemical reagents used in the preparation process are provided by Beijing Chemical Reagent Co., Ltd., all of which are analytically pure.

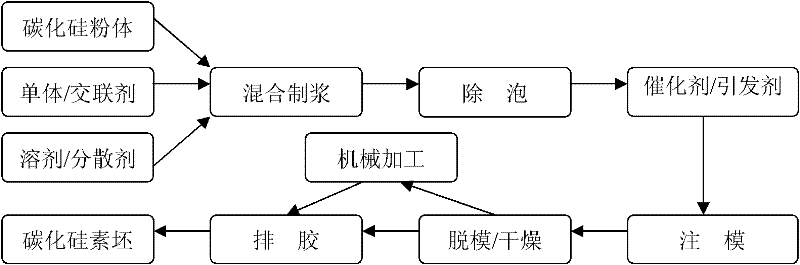

[0020] according to figure 1 The gel injection molding process flow chart of the large-size and complex-shaped silicon carbide ceramic green body shown, the process of the specific embodiment is as follows:

[0021] Dissolve 75g of acrylamide and 5g of methylenebisacrylamide in 301.7ml of deionized water, add 7ml of glycerol and 2ml of isopropanol, and add 14ml of tetramethylammonium hydroxide to adjust the pH of the premix to about 11.5 .

[0022] Add 2640g of SiC powder to the premix, the weight ratios of the three parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com