Epoxy glass powder mica tape

A technology of powder mica tape and epoxy glass, applied in mica, epoxy resin glue, quartz/glass/glass enamel, etc., to improve heat resistance level and high temperature mechanical strength, improve production quality, reliability and reliable life guarantee Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

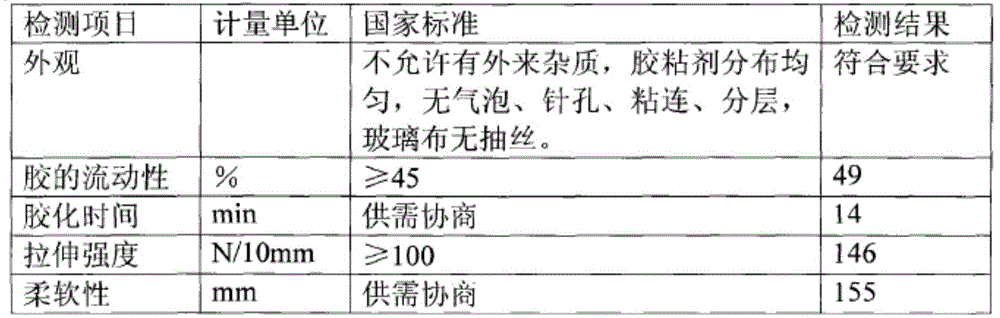

Embodiment 1

[0013] The epoxy glass powder mica tape is formed by laminating mica paper, glass cloth and epoxy adhesive, wherein the epoxy adhesive paint is prepared from the following raw materials in parts by weight: 30 parts of tung oil, 10 parts of maleic anhydride , 1 part of bismaleimide, 40 parts of epoxy resin, 40 parts of solvent, 1.5 parts of compounding agent and 0.05 part of catalyst. Among them, the solvent is prepared by mixing acetone and toluene in a weight ratio of 1:1; the composite agent is prepared by uniformly mixing HK550 and HK560 in a weight ratio of HK550:HK560=4.5:5.5; the catalyst is lead octoate.

[0014] The making of this epoxy glass powder mica tape is to carry out as follows:

[0015] Firstly, take tung oil and maleic anhydride according to the stated ratio, put them into the reaction kettle and stir evenly, and heat to 80°C for reaction, keep it warm for 20 minutes to make tung oil anhydride, then add bismaleic acid according to the described ratio Stir th...

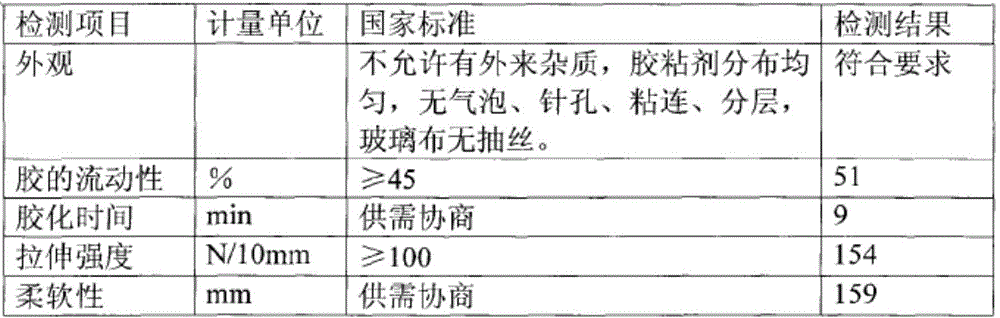

Embodiment 2

[0019] The epoxy glass powder mica tape is formed by laminating mica paper, glass cloth and epoxy adhesive, wherein the epoxy adhesive paint is prepared from the following raw materials in parts by weight: 35 parts of tung oil, 15 parts of maleic anhydride , 3 parts of bismaleimide, 50 parts of epoxy resin, 50 parts of solvent, 4 parts of compounding agent and 0.4 part of catalyst. Among them, the solvent is prepared by mixing acetone and toluene in a weight ratio of 1:1; the composite agent is prepared by mixing HK550 and HK560 in a weight ratio of HK550:HK560=4.5:5.5; the catalyst is manganese octoate.

[0020] The preparation method of this epoxy glass powder mica tape is basically the same as embodiment one, and the difference only lies in:

[0021] After putting tung oil and maleic anhydride into the reactor and stirring evenly, the heating temperature is 115°C, and the holding time is 14 minutes; For 12 minutes, the detection situation of the epoxy glass powder mica tap...

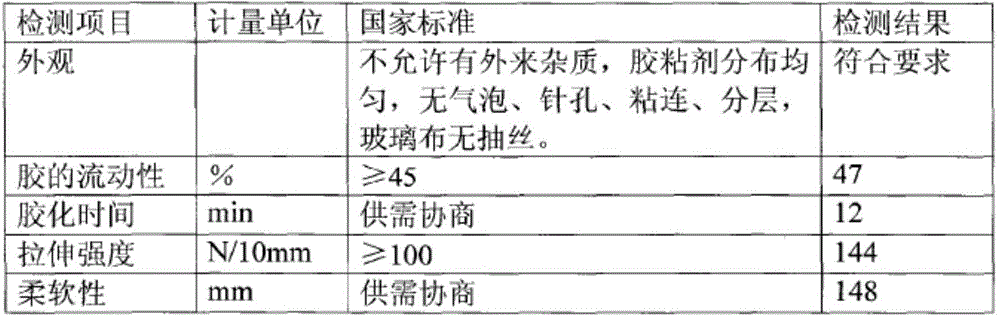

Embodiment 3

[0025] The epoxy glass powder mica tape is formed by laminating mica paper, glass cloth and epoxy adhesive, wherein the epoxy adhesive paint is prepared from the following raw materials in parts by weight: 40 parts of tung oil, 20 parts of maleic anhydride , 5 parts of bismaleimide, 60 parts of epoxy resin, 60 parts of solvent, 5 parts of compounding agent and 0.7 part of catalyst. Among them, the solvent is prepared by mixing acetone and toluene in a weight ratio of 1:1; the composite agent is prepared by mixing HK550 and HK560 in a weight ratio of HK550:HK560=4.5:5.5; the catalyst is zinc octoate.

[0026] The preparation method of this epoxy glass powder mica tape is basically the same as embodiment one, and the difference only lies in:

[0027] After putting tung oil and maleic anhydride into the reactor and stirring evenly, the heating temperature is 150°C for reaction, and the holding time is 8 minutes; ℃, and the holding time is 8 minutes. The detection status of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com