Solder paste for dipping as well as preparation technology and use method of solder paste

A preparation process and technology of solder paste, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as insufficient strength, affecting product quality and reliability, and blockage of metal orifice plates to achieve cost savings and bonding The effect of high strength and consistency, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

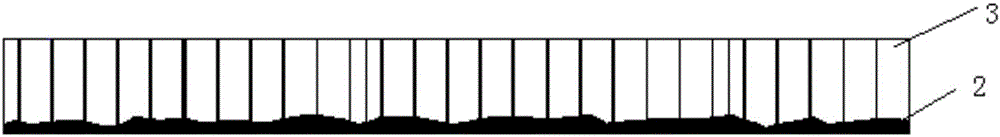

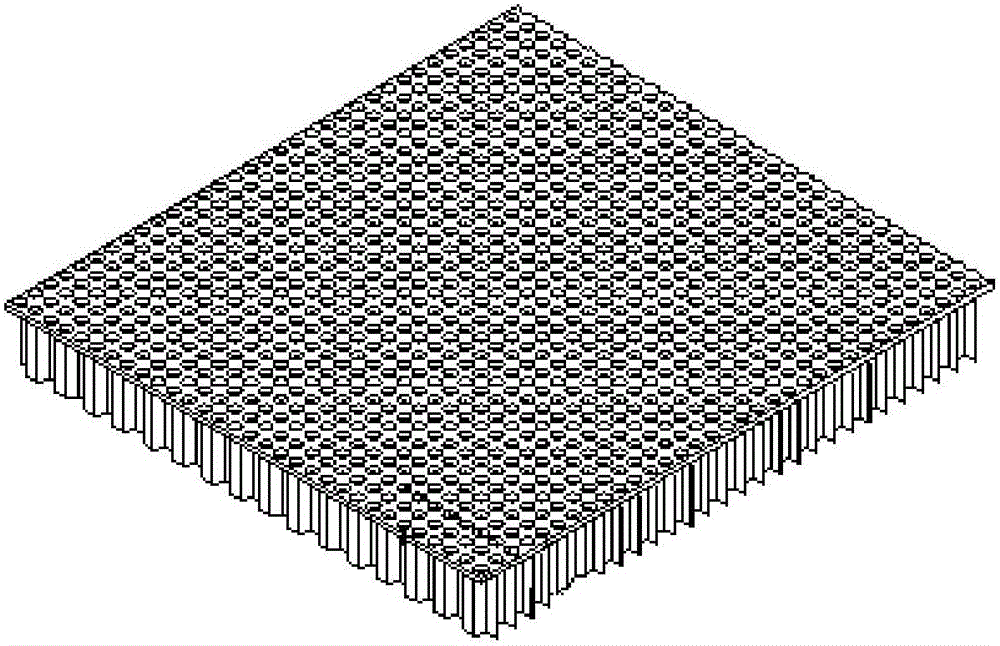

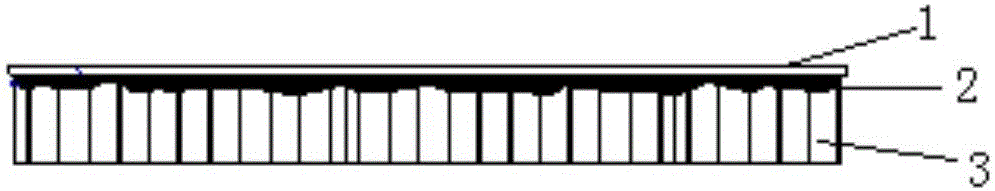

Method used

Image

Examples

Embodiment 1

[0030] The solder paste for dipping, the components it contains and the respective parts by weight are as follows:

[0031] 5.7 parts of water-based binder

[0032] BN 2 63.6 parts of solder powder

[0033] 30.7 parts of water.

[0034] Metal and alloy powder wherein mainly adopt nickel base, copper base brazing material, adopt BNi in the present embodiment 2 Brazing filler metal powder, its main components are calculated by weight percentage: Cr 7.0%, B 3%, Si 4.5%, Fe3%, C 0.04%, P 0.01%, Ni balance. The brazing temperature of the solder powder is 1010-1175°C.

[0035] The average particle size of the metal and alloy powder in this embodiment is 140-325 mesh, wherein the water-based binder adopts Cememt 650 adhesive has a viscosity of 275-350CPS at 25°C, CPS is the viscosity unit, 1CPS=1mpa˙s.

Embodiment 2

[0037] The solder paste for dipping, the components it contains and the respective parts by weight are as follows:

[0038] 5 parts water-based binder

[0039] BN 2 Solder powder 50 parts

[0040] 20 parts of water.

[0041] Metal and alloy powder wherein mainly adopt nickel base, copper base brazing material, adopt BNi in the present embodiment 2 The brazing filler metal powder, its main composition by weight percentage is: Cr 6.0%, B 2.75%, Si 4.0%, Fe 2.5%, C 0.02%, P 0.015%, Ni balance. The brazing temperature of the solder powder is 1010-1175°C.

[0042] The average particle size of the metal and alloy powder in this embodiment is 140-325 mesh, wherein the water-based binder adopts Cememt 650 adhesive has a viscosity of 275-350 CPS at 25°C.

Embodiment 3

[0044] The solder paste for dipping, the components it contains and the respective parts by weight are as follows:

[0045] 10 parts of water-based adhesive

[0046] BN 2 Solder powder 75 parts

[0047] 40 parts of water.

[0048] Metal and alloy powder wherein mainly adopt nickel base, copper base brazing material, adopt BNi in the present embodiment 2 The brazing material powder, its main components are calculated by weight percentage: 8.0% Cr, 3.5% B, 5.0% Si, 3.5% Fe, 0.06% C, 0.02% P, Ni balance. The brazing temperature of the solder powder is 1010-1175°C.

[0049] The average particle size of the metal and alloy powder in this embodiment is 140-325 mesh, wherein the water-based binder adopts Cememt 650 adhesive has a viscosity of 275-350 CPS at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com