Shadowless glue with high adhesion and preparation method thereof

A high-adhesive, shadowless adhesive technology, applied in the direction of adhesives, can solve the problems of adverse effects on the environment and human health, uncontrollable curing time, unfavorable operation safety, etc., to achieve good adhesion, control curing time, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

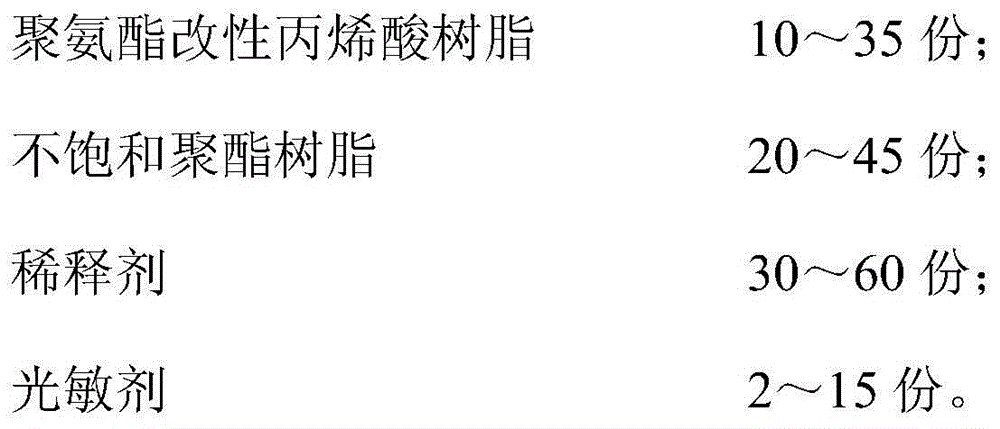

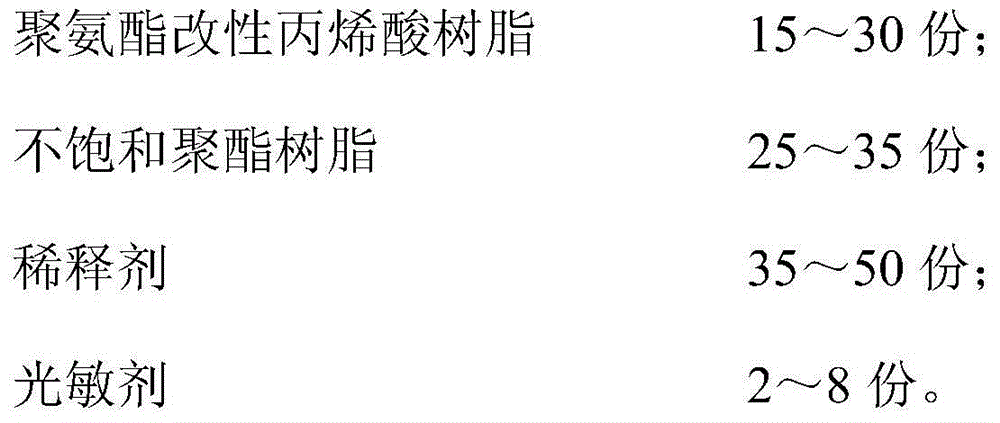

Method used

Image

Examples

Embodiment 1

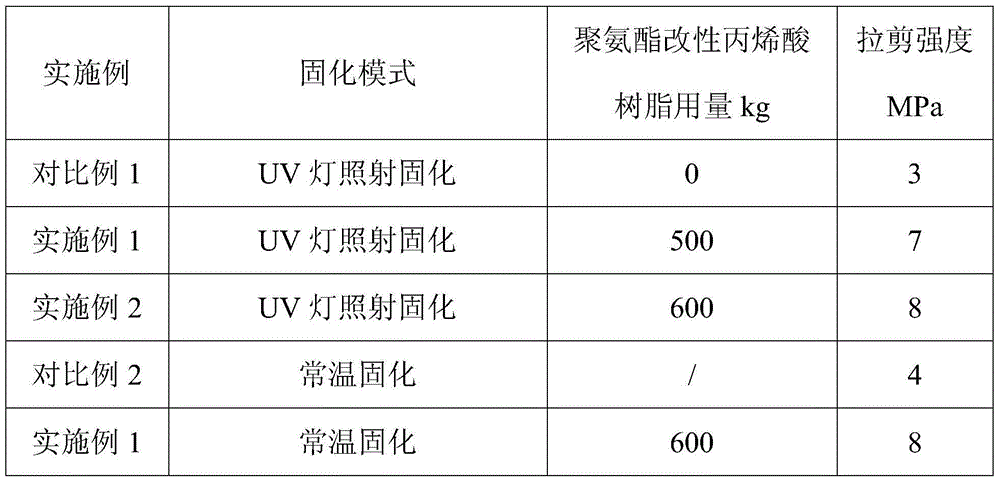

[0027] Weigh 600 kg of polyurethane modified acrylic resin, 900 kg of 191 type unsaturated polyester resin, 600 kg of diluent HEMA and DPGDA. Put the polyurethane modified acrylic resin, 191 type unsaturated polyester resin, diluent HEMA, DPGDA into the reaction kettle in order to mix and stir. During the stirring process, the temperature is controlled at normal temperature, and the stirring time is about 30 minutes, and the stirring is in a uniform state. to stop. Weigh 90kg of photosensitizer 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and put it into the reaction kettle for stirring. During the stirring process, the temperature is controlled at normal temperature and stirred at normal pressure for about 30 minutes, and the stirring is uniform. The colloid was obtained as a shadowless glue.

[0028] The tensile and shear strength of the colloid was measured after curing at room temperature, and the experimental results are shown in Table 1; UV lamps were used for curing....

Embodiment 2

[0030] Weigh 500 kg of polyurethane modified acrylic resin, 900 kg of 191 type unsaturated polyester resin, 600 kg of diluent HDDA and IBOA. Put polyurethane modified acrylic resin, 191-type unsaturated polyester resin, thinner HDDA, and IBOA into the reaction kettle in order to mix and stir. During the stirring process, the temperature is controlled at normal temperature and stirred under normal pressure. The time is about 30 minutes, and the stirring is in a uniform state. to stop. Take by weighing photosensitizer 2-phenylbenzyl-2-dimethylamino-1-(4-morpholine benzylphenyl) butanone 90kg, put into reaction kettle and stir, temperature is controlled at normal temperature in stirring process, stirs under normal pressure, time For about 30 minutes, stir to form a uniform colloid to obtain a shadowless glue.

[0031] Using UV lamp irradiation, the length of UV lamp tube is 10cm, the tube diameter is Φ2cm, and the irradiation distance is 5cm as the standard. The power density of...

Embodiment 4

[0042] Take the colloid prepared in Example 1, cure at room temperature, record the curing time, and see Table 2 for the experimental results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com