Organic polymer material, Portland cement containing same and preparation method of Portland cement

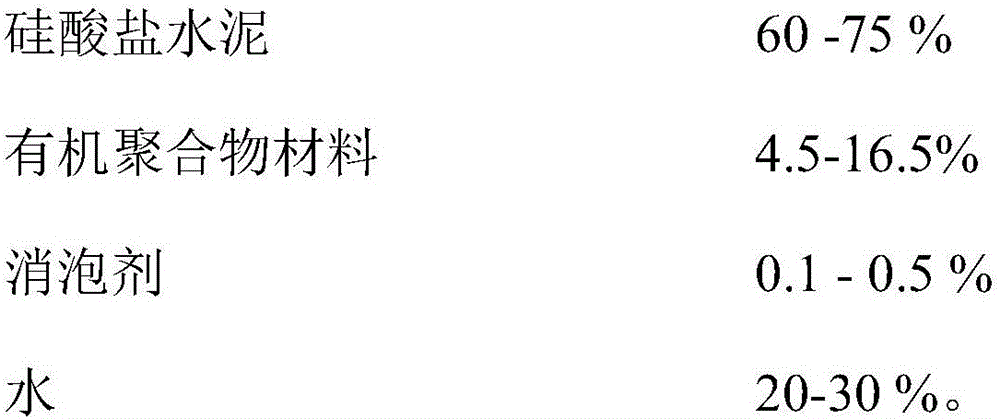

A polymer material, Portland cement technology, used in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor stability, temperature resistance and anti-corrosion performance, and achieve good toughness and anti-corrosion performance. , Improve rheology and thickening properties, the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

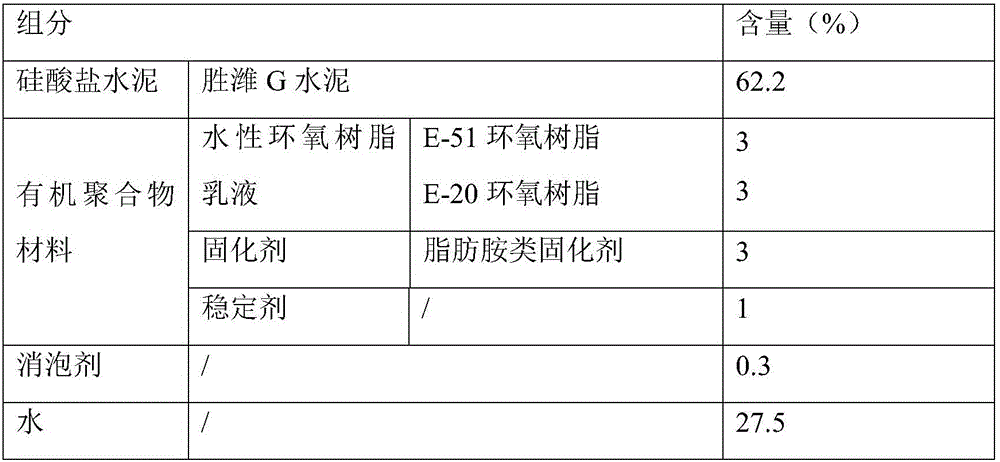

Embodiment 1-5

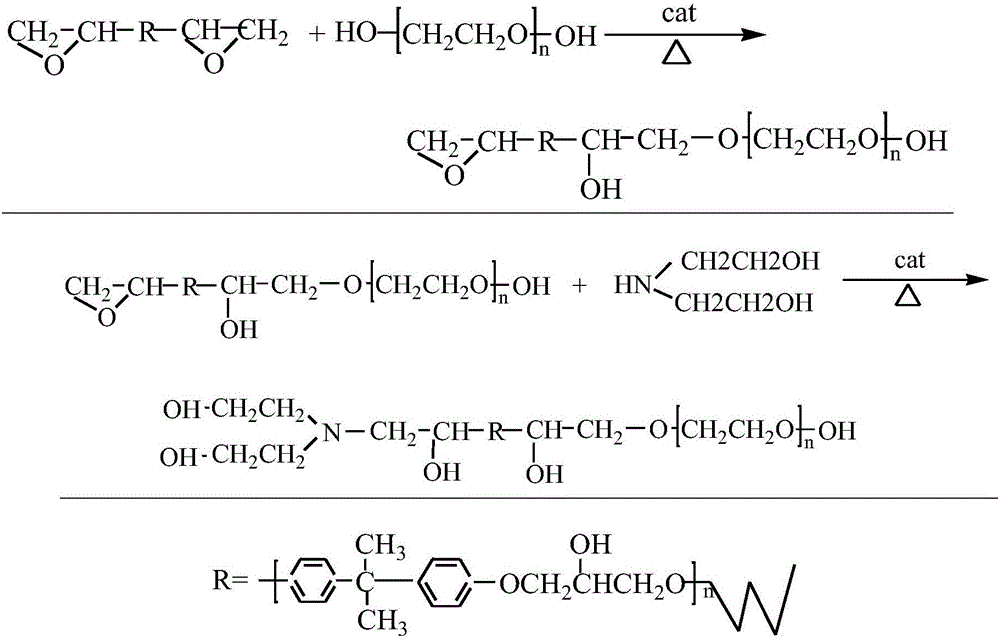

[0031] 1. The preparation method of water-based epoxy resin emulsion is as follows:

[0032] (1) Preparation of epoxy resin emulsifier: In the reactor, add 200g epoxy resin and 200g polyethylene glycol PEG-1000, stir and react at a constant temperature of 80℃~100℃ for 2h to obtain a transparent solution, then stir down Continue to add 400g of diethanolamine, continue to react at a constant temperature for 2h, after the reaction, a yellow epoxy emulsifier is obtained;

[0033] (2) Preparation of water-based epoxy emulsion: Mix 40g of the epoxy resin emulsifier prepared above, 490g epoxy resin and 50g organic solvent according to the stoichiometric ratio. The temperature is raised to 40℃~60℃ and stirred at high speed. Slowly add 420g of deionized water, and continue to stir for 30min-60min after the reverse rotation occurs to obtain a milky white non-ionic aqueous epoxy emulsion.

[0034] The aqueous epoxy resin emulsion obtained above has a solid content of 53%, a viscosity of 600 mP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com