Preparation method of graphene oxide/konjac glucomannan degradable composite film material

A konjac glucomannan and composite film technology, which is applied in the field of preparation of graphene oxide/konjac glucomannan degradable composite film materials, can solve the problems of poor mechanical properties and thermal stability, and achieve good hydrophilicity and Excellent mechanical properties, good material regularity, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

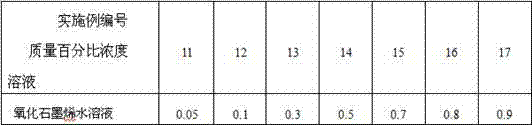

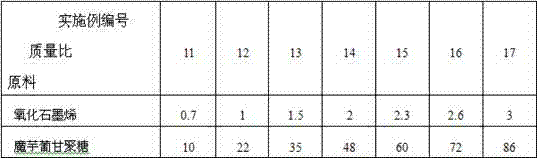

Examples

Embodiment 1

[0018] Add a certain amount of graphene oxide into 200mL deionized water, stir ultrasonically for 1 hour, and prepare a graphene oxide solution with a concentration of 5mg / mL; add 2g konjac glucomannan to the above solution while stirring, and stir at 30°C for 0.5 After 1 hour, the film solution was prepared and left to stand for 12 hours; the film solution was poured into the film-making mold, the film solution and the mold were placed in a drying oven, and vacuum-dried at 30°C for 24 hours, taken out, cooled to room temperature, and peeled off the film . Place the membrane in 10% ammonia solution, treat it at 30°C for 2 hours, take it out, and dry it at 50°C.

[0019] The test results are: tensile strength: 183 MPa, elongation at break: 45.5%.

Embodiment 2

[0021] Add a certain amount of graphene oxide into 200mL of deionized water, stir ultrasonically for 1 hour, and prepare a graphene oxide solution with a concentration of 3mg / mL; add 2g of konjac glucomannan to the above solution while stirring, and stir at 40°C for 1.5 After 1 hour, the film solution was prepared and left to stand for 12 hours; the film solution was poured into the film-making mold, the film solution and the mold were placed in a drying oven, and vacuum-dried at 40°C for 24 hours, taken out, cooled to room temperature, and peeled off the film ; Place the film in 5% glutaraldehyde aqueous solution, treat it at 40°C for 2 hours, take it out, and dry it at 40°C.

[0022] The test results are: tensile strength: 175MPa, elongation at break: 50.3%.

Embodiment 3

[0024] Add a certain amount of graphene oxide into 200mL of deionized water, stir ultrasonically for 3 hours, and prepare a graphene oxide solution with a concentration of 1mg / mL; add 2g of konjac glucomannan to the above solution while stirring, and stir at 40°C for 2.5 After 24 hours, the film solution was prepared and left to stand for 24 hours; the film solution was poured into the film-making mold, the film solution and the mold were placed in a drying oven, and vacuum-dried at 40°C for 24 hours, taken out, cooled to room temperature, and peeled off the film ; Place the film in 1% aqueous sodium hydroxide solution, treat it at 45°C for 3 hours, take it out, and dry it at 50°C.

[0025] The test results are: tensile strength: 164 MPa, elongation at break: 68.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com