Preparation of graphene oxide nanometer modified acrylate aqueous dispersion and application of same to waterborne automobile coating

A technology of acrylate and nano-modification, which is applied in the direction of fireproof coatings, coatings, etc., can solve problems such as environmental pollution, severe, and human hazards, and achieve the effects of no pollution to the environment, enhanced dispersion stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

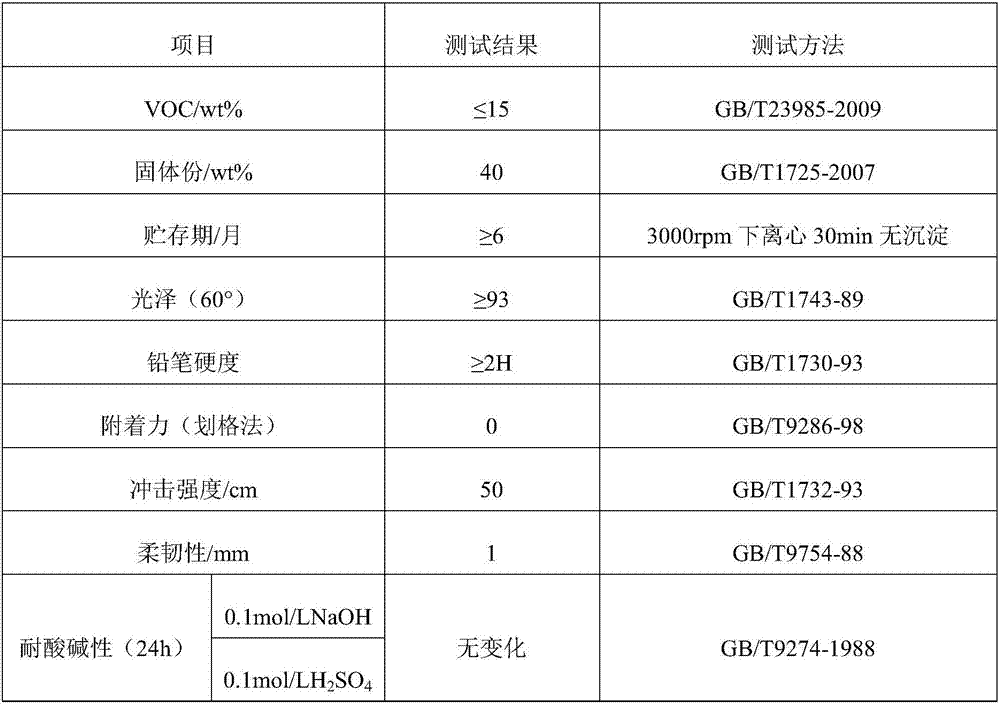

Embodiment 1

[0033] In the reactor equipped with stirring paddle, thermometer and condenser, add 15 parts by weight of glycidyl tertiary carbonic acid ester Cardura E10P, 5 parts by weight of dimethylformamide (DMF), 0.8 parts by weight of graphene oxide, under nitrogen protection After heating up to 100°C and keeping the high-speed dispersion state for 0.5h, 18 parts by weight of ethyl methacrylate, 25 parts by weight of butyl acrylate, 12 parts by weight of hydroxyethyl methacrylate, and 10 parts by weight of formaldehyde were added dropwise. Acrylic acid, 15 parts by weight of styrene, 1.5 parts by weight of azobisisobutyronitrile, and 0.2 parts by weight of mercaptoethanol were added dropwise within 2.5 hours, kept warm for 1 hour, and then added 0.6 parts by weight of the above-mentioned initiator When the temperature drops to 70°C, add the neutralizing agent N, N-dimethylethanolamine to carry out the neutralization reaction under the dispersion condition of 1200r / min, the reaction tim...

Embodiment 2

[0036] In the reactor equipped with stirring paddle, thermometer and condenser, add 15 parts by weight of glycidyl tertiary carbonic acid ester Cardura E10P, 3-5 parts by weight of dimethylformamide (DMF), 0.5 parts by weight of graphene oxide, in nitrogen Under protection, the temperature was raised to 100°C, and after maintaining the high-speed dispersion state for 0.5h, 15 parts by weight of methyl methacrylate, 20 parts by weight of ethyl acrylate, 10 parts by weight of hydroxyethyl acrylate, and 5 parts by weight of acrylic acid were added dropwise. , the mixed solution that the acrylonitrile of 10 weight parts, the dibenzoyl peroxide of 1 weight part and the dodecyl mercaptan of 0.05 weight part form, dropwise in 2-, keep warm for 0.5-1h, then add 0.5 parts by weight of the above initiator, heat preservation for 1.5h; when the temperature drops to 60°C, add neutralizing agent N,N-dimethylethanolamine to carry out neutralization reaction under the dispersion condition of 1...

Embodiment 3

[0038]In a reactor equipped with a stirring paddle, a thermometer, and a condenser, add 15 parts by weight of glycidyl tertiary carbonic acid ester Cardura E10P, 3-5 parts by weight of dimethylformamide (DMF), and 1 part by weight of graphene oxide under nitrogen Under protection, the temperature was raised to 100°C, and after maintaining the high-speed dispersion state for 0.5h, 25 parts by weight of methyl methacrylate, 30 parts by weight of ethyl acrylate, 15 parts by weight of hydroxyethyl acrylate, and 15 parts by weight of acrylic acid were added dropwise. , the mixed solution that the acrylonitrile of 20 weight parts, the dibenzoyl peroxide of 2 weight parts and the dodecyl mercaptan of 1 weight part form, dropwise in 3h, keep warm for 1h, then add 1 weight part of the above initiator, keep it warm for 2.5h; when the temperature drops to 80°C, add the neutralizing agent N,N-dimethylethanolamine to carry out the neutralization reaction under the dispersion condition of 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com