Manufacturing method for heating material uniformly heating used for thermal battery and application thereof

A technology for heating materials and thermal batteries, which is applied in the use/maintenance of primary batteries, primary batteries, electrochemical generators, etc. It can solve the problems of excessive decomposition of active substances in positive electrode materials and low utilization of positive electrode materials, and achieve initial redox The temperature value is advanced, the specific surface energy is increased, and the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

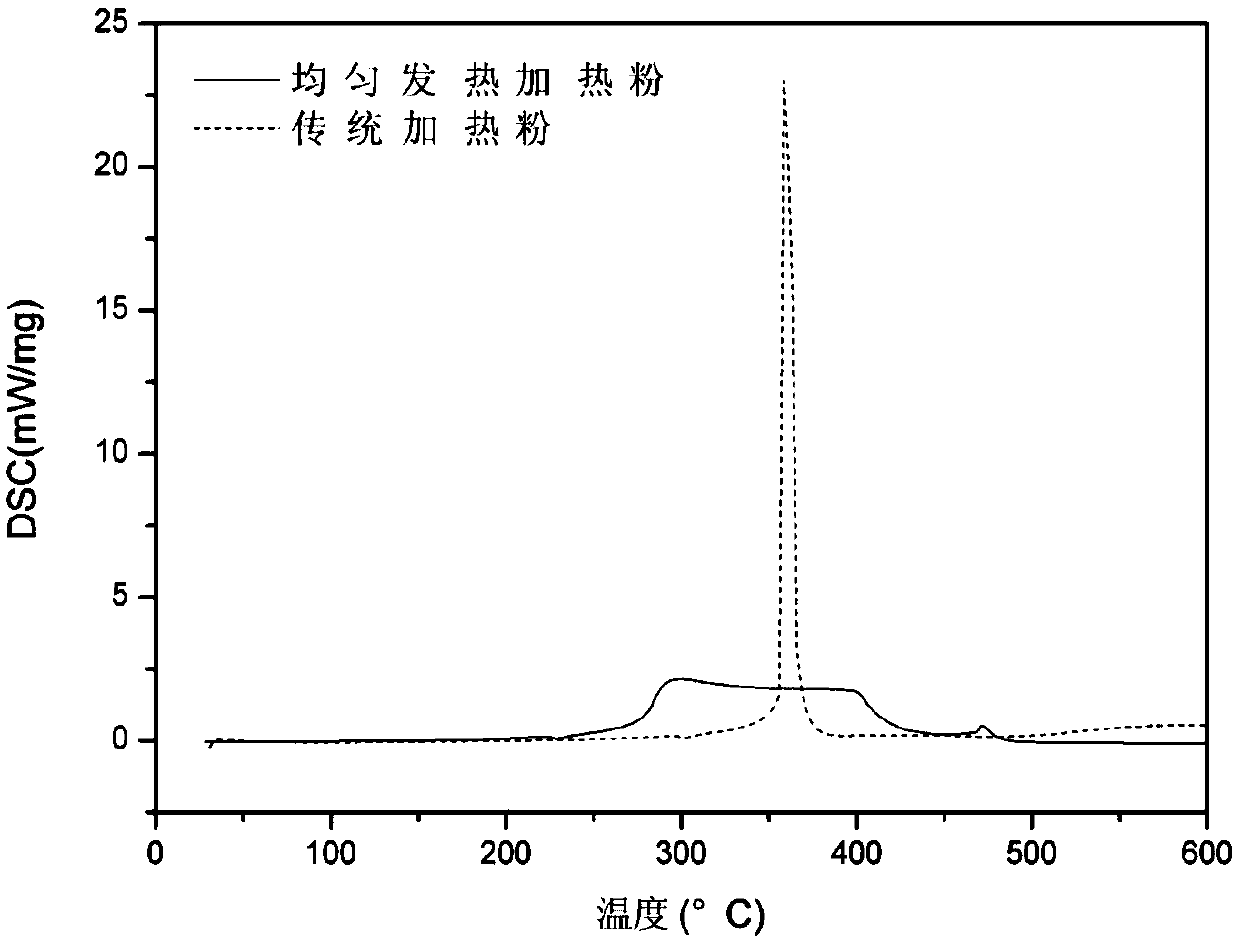

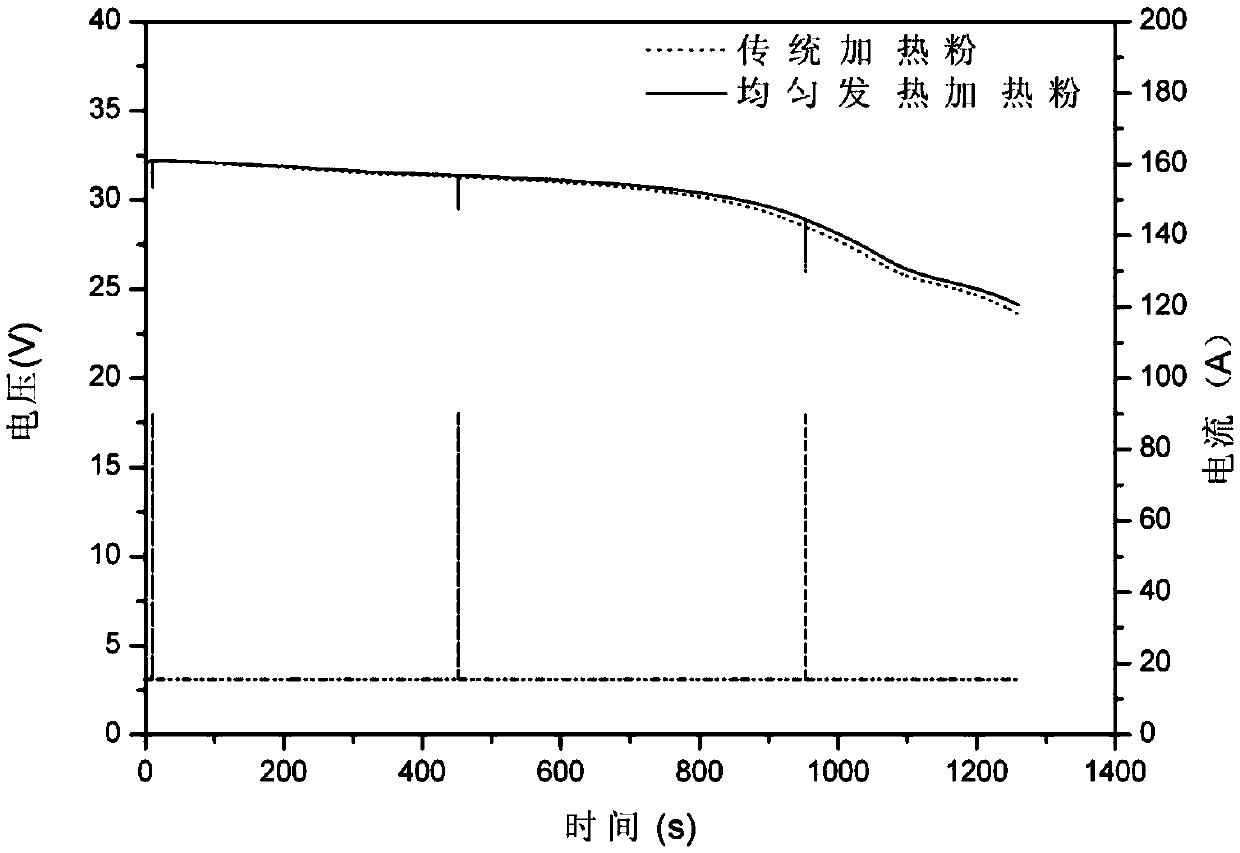

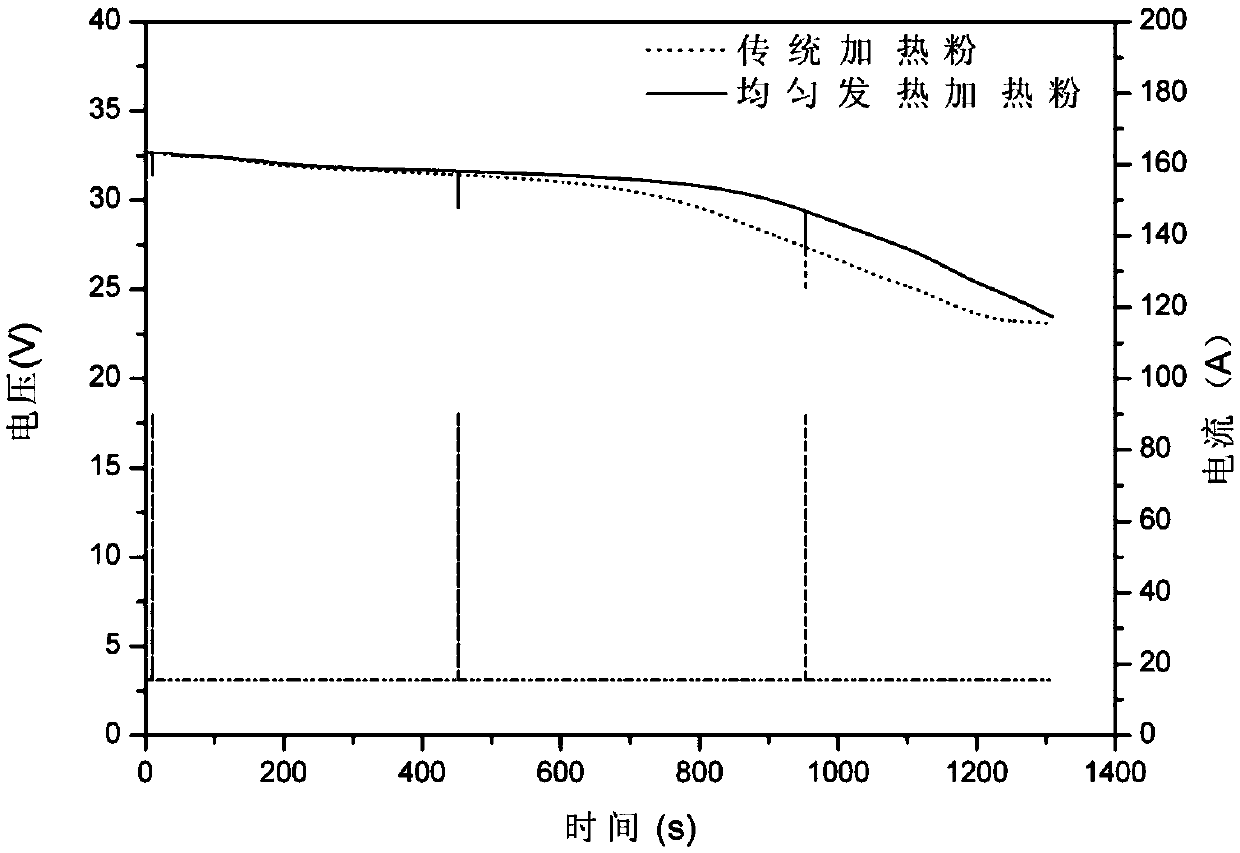

[0017] see Figure 1 to Figure 4 , the preparation method of the uniform heating material provided in this embodiment includes: pouring analytically pure grade potassium perchlorate into a high-energy ball mill cup, adding appropriate water to make a slurry, putting a certain number of zirconia balls, and setting the rotation speed to be greater than 3000r / min for high-energy ball milling, the high-energy ball milling time is 30s~2min, then stop running, cool for more than 10min, and then run the high-energy ball mill, repeat this step, the high-energy ball mill runs for a total of 4~6h. Afterwards, put the ball-milled powder into a freeze dryer, run the freeze dryer to remove excess water by sublimation, and then use a pulverizer to pulverize and pass through a 400-mesh sieve to obtain ultrafine potassium perchlorate. Pour the active iron powder into the inert atmosphere glove box, add a certain mass ratio of inorganic potassium salt, and then mix the two by physical or chemi...

Embodiment 2

[0027]The preparation method of the uniform heating material for thermal batteries provided in this embodiment includes: pouring analytically pure grade potassium perchlorate into a high-energy ball mill cup, adding appropriate water to prepare a slurry, and putting a certain number of zirconia balls, Set the rotation speed to be greater than 3000r / min for high-energy ball milling. The high-energy ball milling time is 30s~2min. After that, stop the operation, cool for more than 10min, and then run the high-energy ball mill. Repeat this step. Put it into a freeze dryer, run the freeze dryer to use sublimation to remove excess water, and then use a pulverizer to crush it. After passing through a 400-mesh sieve, ultra-fine potassium perchlorate is obtained, and the active iron powder is poured into the inert atmosphere glove box , add a certain mass ratio of inorganic potassium salt, and then use physical or chemical methods to mix the two to form potassium-containing iron powder,...

Embodiment 3

[0037] The preparation method of the uniform heating material for thermal batteries provided in this embodiment includes: pouring analytically pure grade potassium perchlorate into a high-energy ball mill cup, adding appropriate water to prepare a slurry, and putting a certain number of zirconia balls, Set the rotation speed to be greater than 3000r / min for high-energy ball milling. The high-energy ball milling time is 30s~2min. After that, stop the operation, cool for more than 10min, and then run the high-energy ball mill. Repeat this step. Put it into a freeze dryer, run the freeze dryer to use sublimation to remove excess water, and then use a pulverizer to crush it. After passing through a 400-mesh sieve, ultra-fine potassium perchlorate is obtained, and the active iron powder is poured into the inert atmosphere glove box , add a certain mass ratio of inorganic potassium salt, and then use physical or chemical methods to mix the two to form potassium-containing iron powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com