Method for finely synthesizing ilmenite-structured ZnTiO3 nano powder by using water-soluble sol-gel process

A sol-gel method and sol-gel technology, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve problems such as difficulties in solid-phase synthesis, and achieve stable and single phase, no impurity interference, and fine particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

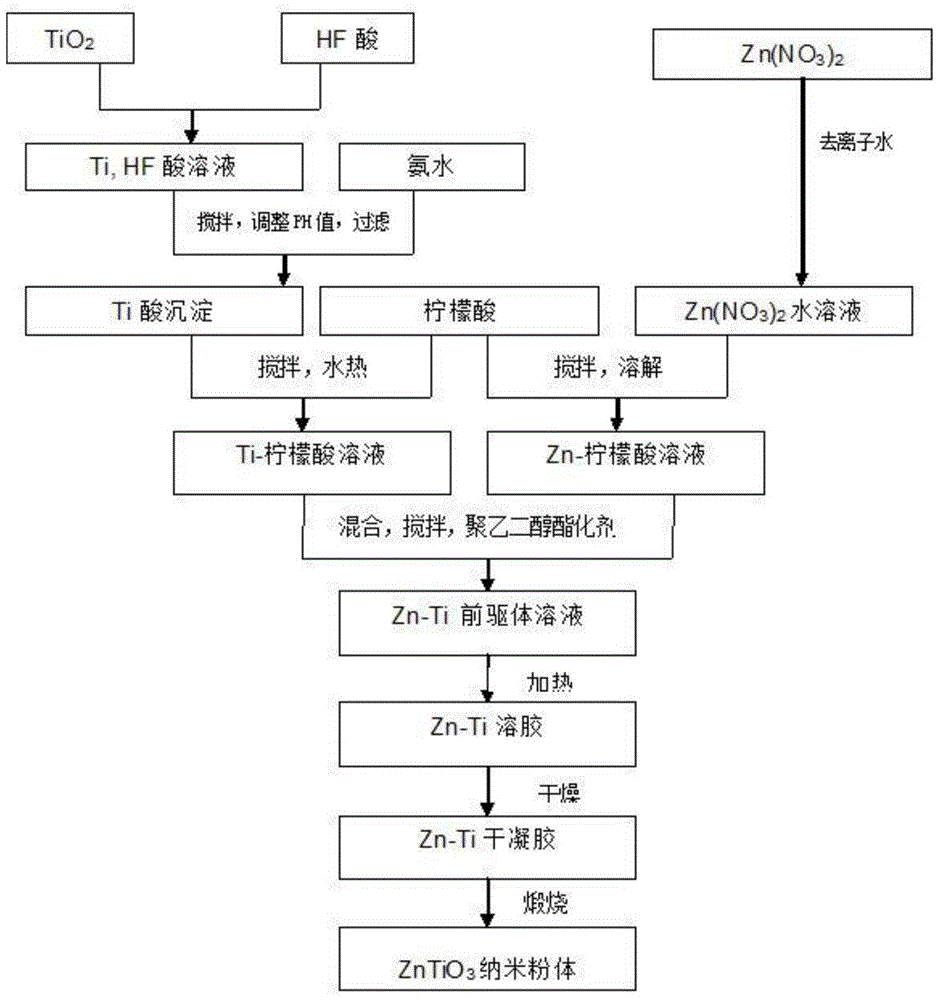

[0033] according to figure 1 Preparation of ZnTiO by Sol-Gel Process 3 The process flow chart of ceramic nano-precursor powder has the following steps:

[0034] 1) prepare the citric acid aqueous solution of Zn ion

[0035] (a) According to ZnTiO 3 The stoichiometric ratio of the microwave ceramic phase, adjust ZnO (or Zn (NO 3 ) 2 .6H 2 O) / TiO 2 The molar ratio is 1+x / 1 (03 ) 2 .6H 2 A total of 8.9247 grams, dissolved in 200ml of ionized water, magnetically stirred to form a colorless and transparent solution;

[0036] (b) take by weighing 34.58 grams of citric acid, add in the above-mentioned solution and stir, impel citric acid and Zn ion to form complex, make colorless transparent Zn ion citric acid aqueous solution;

[0037] 2) prepare the aqueous citric acid solution of Ti

[0038] (a) According to ZnTiO 3 For the stoichiometric ratio of the microwave ceramic phase, 0.8029 grams of titanium dioxide were weighed, placed in a ceramic medium reactor, sealed after...

Embodiment 2

[0047] according to figure 1 Preparation of ZnTiO by Sol-Gel Process 3 The process flow chart of ceramic nano-precursor powder has the following steps:

[0048] 1) prepare the citric acid aqueous solution of Zn ion

[0049] (a) According to the stoichiometric ratio of ZnTiO3 microwave ceramic phase, adjust ZnO / TiO 2 The molar ratio is 1+x / 1 (03 ) 2 .6H 2 A total of 14.8745 grams of O was dissolved in 100ml of ionized water and stirred magnetically to form a colorless and transparent solution;

[0050] (b) take by weighing 38.428 grams of citric acid, add in the above-mentioned solution and stir, impel citric acid and Zn ion to form complex, make colorless transparent Zn ion citric acid aqueous solution;

[0051] 2) prepare the aqueous citric acid solution of Ti

[0052] (a) According to ZnTiO 3 For the stoichiometric ratio of microwave ceramic phases, weigh 1.4935 grams of titanium dioxide, place them in a ceramic medium reactor, add 90ml of hydrofluoric acid, seal them...

Embodiment 3

[0061] according to figure 1 Preparation of ZnTiO by Sol-Gel Process 3 The process flow chart of ceramic nano-precursor powder has the following steps:

[0062] 1) prepare the citric acid aqueous solution of Zn ion

[0063] (a) According to ZnTiO 3 Stoichiometric ratio of microwave ceramic phases, adjustment of ZnO / TiO 2 The molar ratio is 1+x / 1 (03 ) 2 .6H 2 A total of 29.747 grams of O was dissolved in 100ml of ionized water and stirred magnetically to form a colorless and transparent solution;

[0064] (b) take by weighing 96.07 grams of citric acid, add in the above-mentioned solution and stir, impel citric acid and Zn ion to form complex, make colorless transparent Zn ion citric acid aqueous solution;

[0065] 2) prepare the aqueous citric acid solution of Ti

[0066] (a) According to ZnTiO 3 For the stoichiometric ratio of the microwave ceramic phase, 2.987 grams of titanium dioxide were weighed, placed in a ceramic medium reactor, sealed after adding 80ml of hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com