Method for clearing pollutant on standard wafer surface and emendation method for depth-measuring device

A technology for standard wafers and pollutants, applied in cleaning methods and tools, chemical instruments and methods, semiconductor/solid-state device testing/measurement, etc., can solve problems such as inability to accurately reflect the stability of testing equipment, unstable thickness testing results, etc. , to achieve the effect of maintaining stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

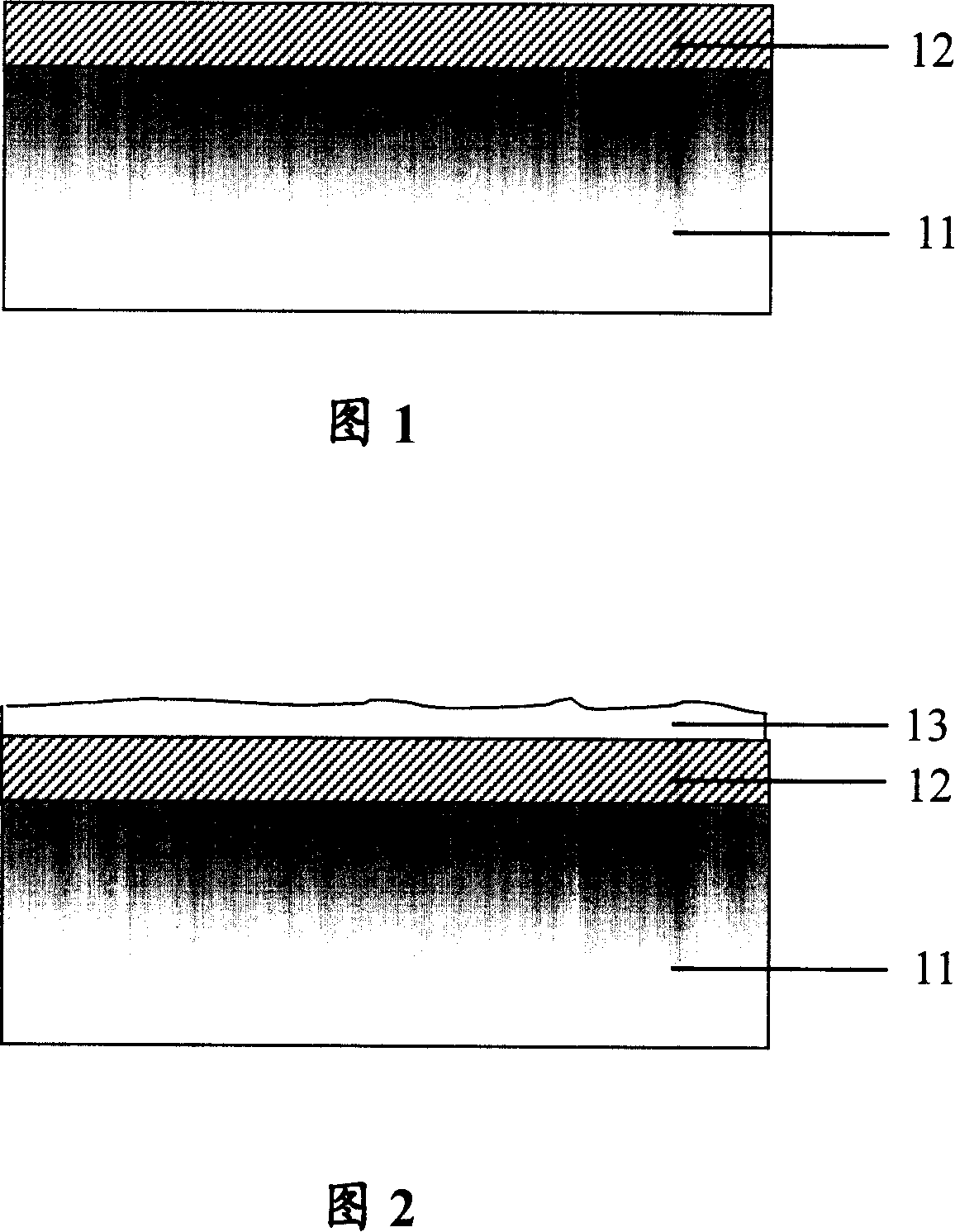

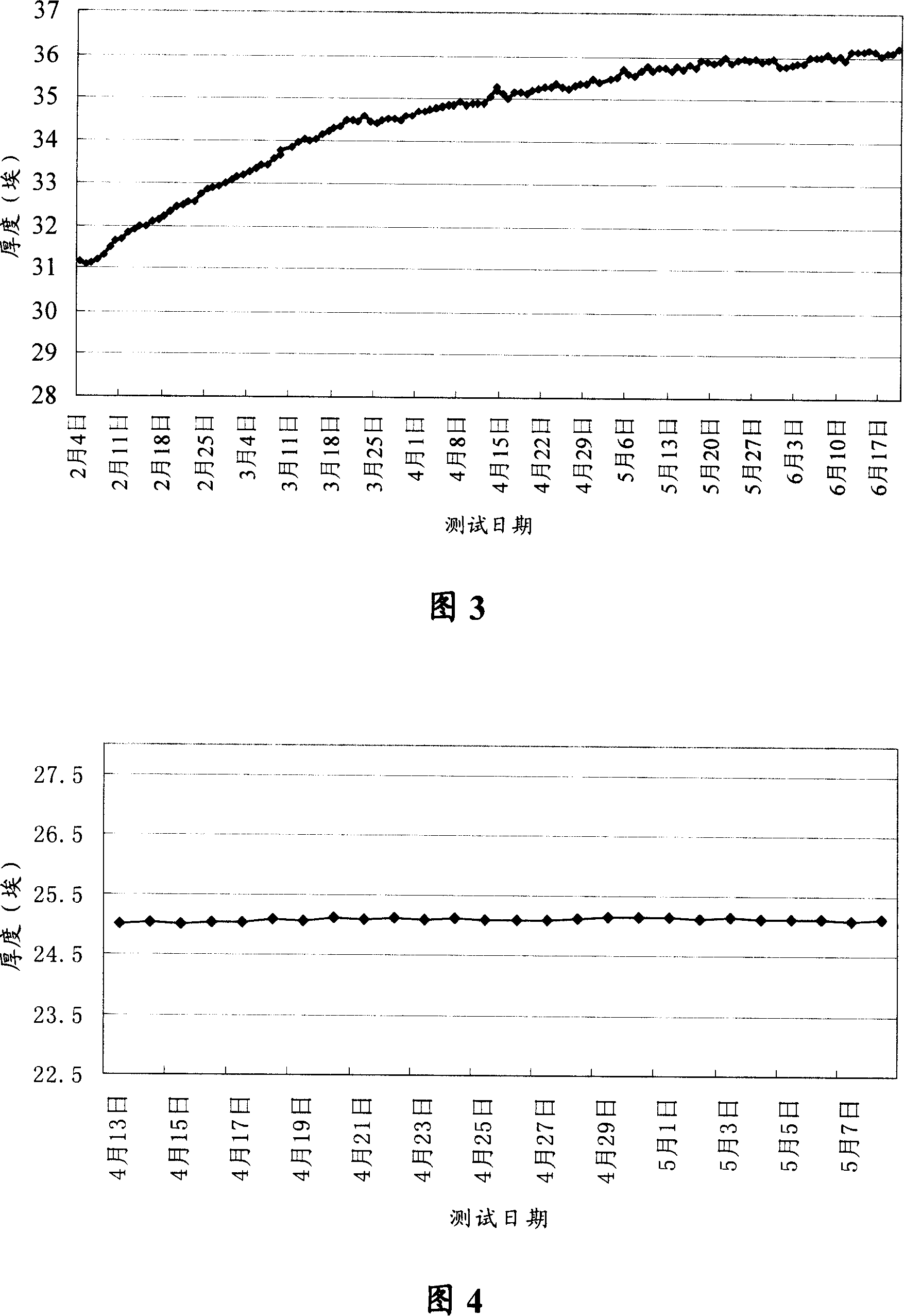

[0031] Referring to the accompanying drawing 1, it is a schematic diagram of the structure of a standard wafer. Among the figures, 11 is a semiconductor substrate. The standard wafer 11 can be a blank wafer or can be positioned at any stage of the semiconductor manufacturing process but has silicon oxide formed on its surface. Layer wafers, such as wafers with multiple film layers or multiple device layers but the surface layer is a silicon oxide layer. The wafer is pure semiconductor silicon or doped semiconductor silicon, and may also be semiconductor materials such as silicon-on-insulator or germanium. 12 is a film layer on the semiconductor substrate, and the film layer 12 can be various insulating materials such as oxides, nitrides, and oxynitrides, and can also be semiconductor materials such as polycrystalline silicon and monocrystalline silicon. The present invention is more suitable for The most important are insulating materials such as oxides such as silicon oxide. ...

Embodiment 2

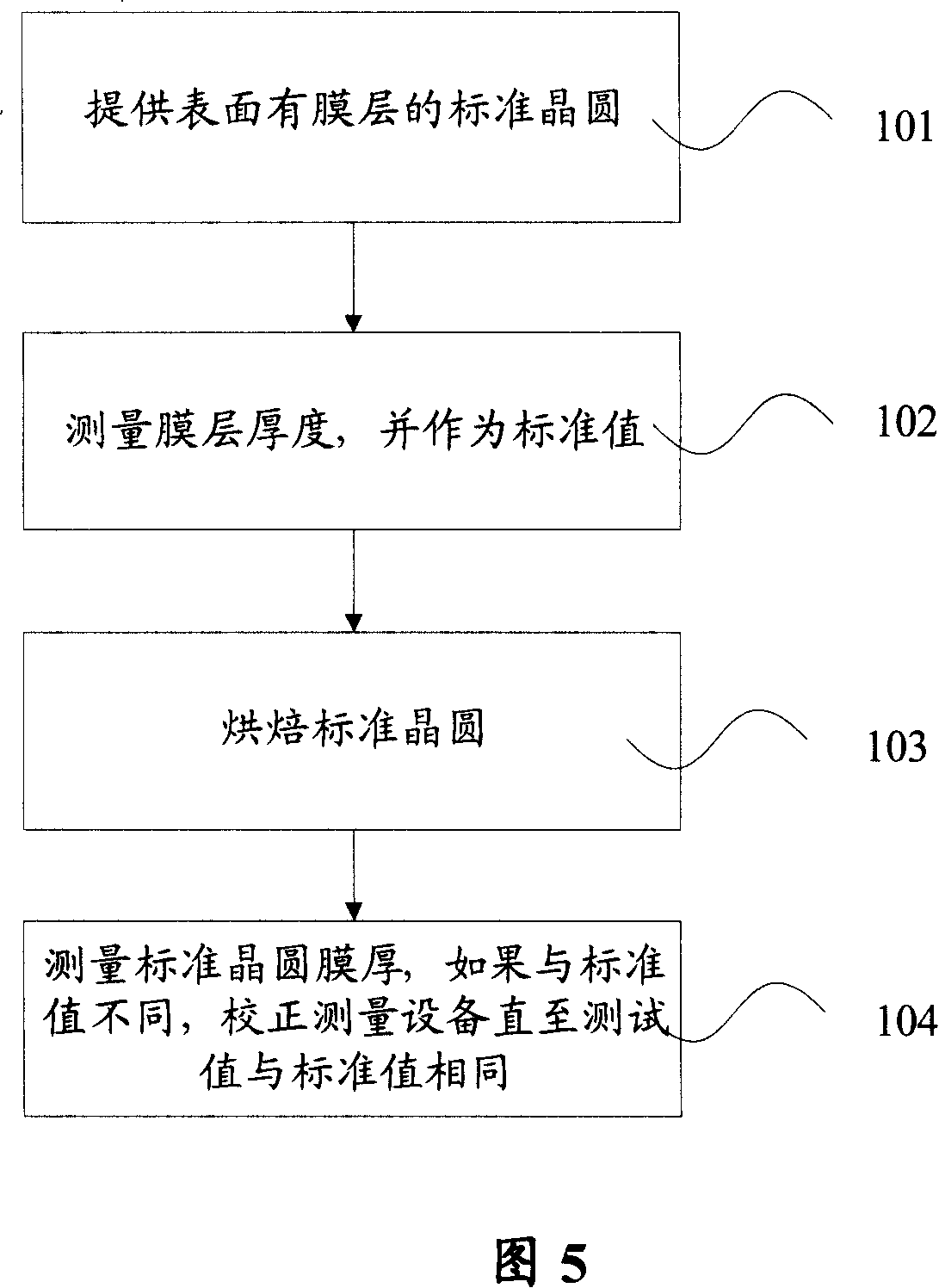

[0047] The present invention also provides a method for calibrating film thickness measuring equipment, comprising the following steps, referring to accompanying drawing 5, step 101, providing a standard wafer, the surface of the standard wafer has a film layer; step 102, detecting the film thickness and set it as a standard value; step 103, bake the standard wafer at a temperature of 50°C to 350°C; step 104, calibrate the film thickness measurement equipment, and place the baked standard wafer into The film layer measuring equipment measures its thickness, if the measured thickness does not match the standard value, correct the film layer thickness measuring device until the measured thickness is the same as the standard value.

[0048] The standard wafer described in this embodiment refers to the description in Example 1. At first, the film thickness on the standard wafer is detected and set as a standard value. After that, the standard wafer is heated at 50°C to 350°C. Baki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com