Ultrasonic probe adapter, ultrasonic testing method and ultrasonic testing system

A technology of ultrasonic probes and testing methods, applied in the testing of machines/structural components, the analysis of solids using sonic/ultrasonic/infrasonic waves, and the material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as the need for personnel and time-intensive processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

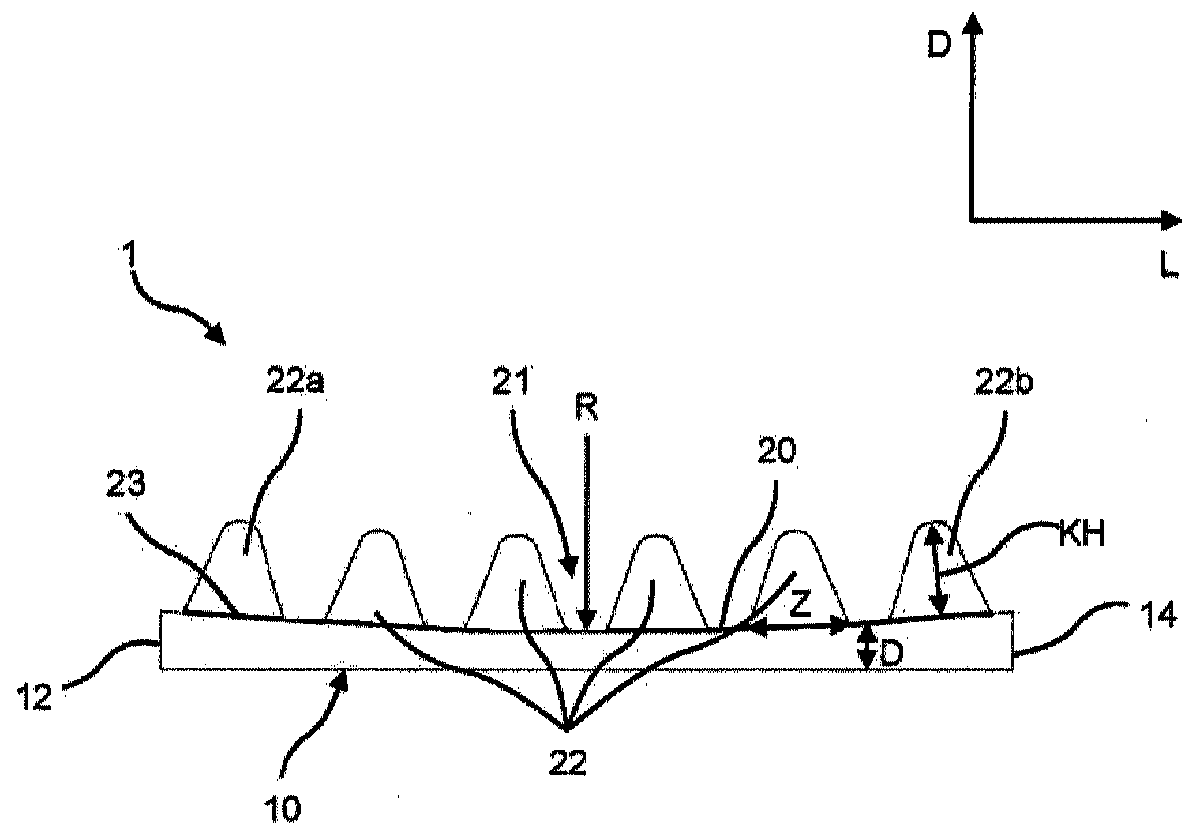

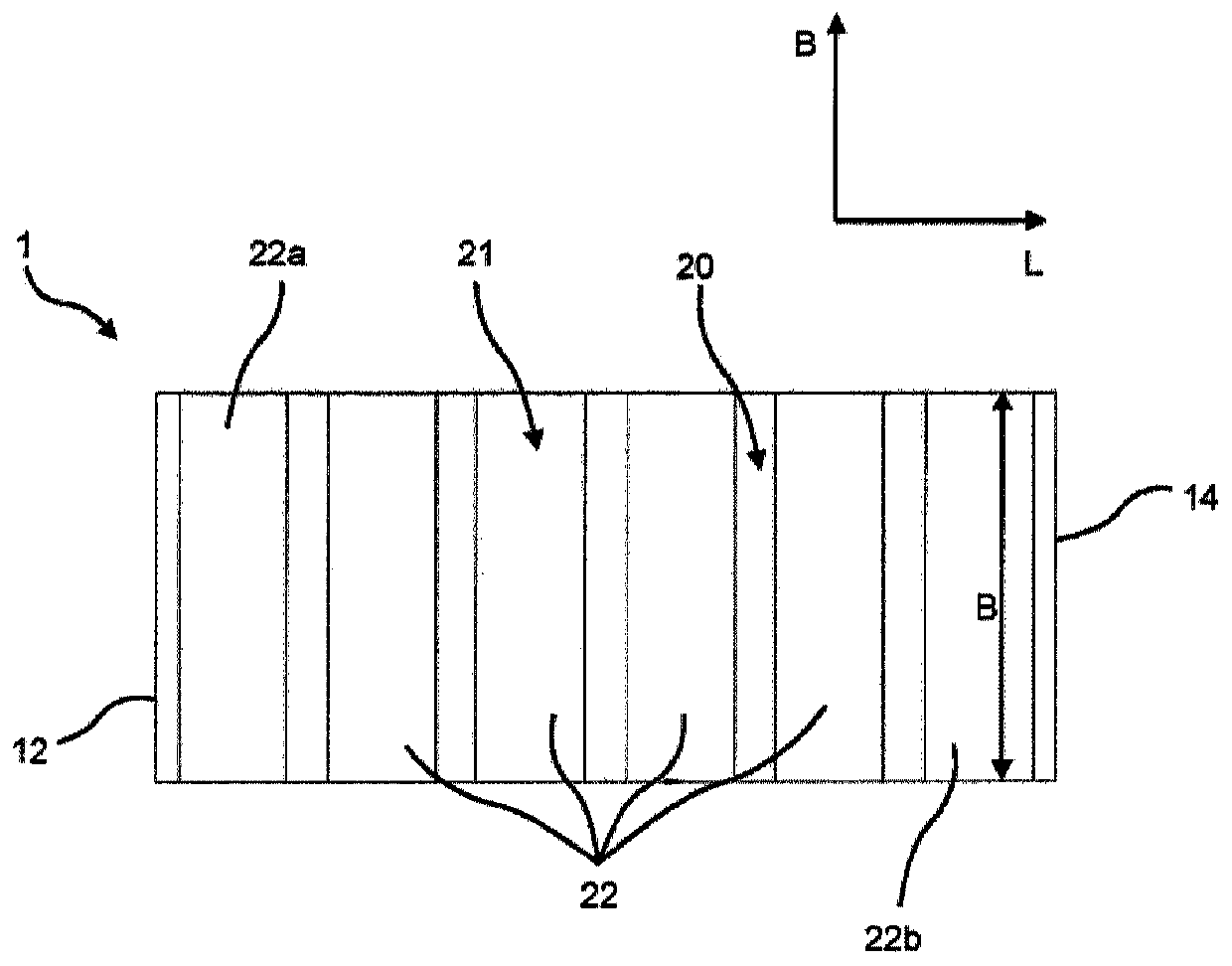

[0048] figure 1 A schematic side view of an exemplary embodiment of an ultrasound probe adapter 1 according to the invention is shown. The ultrasonic probe adapter 1 includes a base body and a test spline 21 . The substrate is defined by a longitudinal length L, a thickness D and a width B (not shown here). The longitudinal length L of the ultrasound probe adapter 1 extends from the first end 12 to the second end 14 . Orthogonal to the longitudinal length L, the ultrasound probe adapter 1 additionally has a thickness D. The thickness D extends from the probe side 10 to the root diameter 23 of the test toothing 21 . The thickness D varies in dimension along the longitudinal length L such that the concave test specimen side 20 is defined by a width B oriented normal to the thickness D and normal to the longitudinal length L and a root diameter 23 extending generally longitudinally.

[0049] On the test specimen side 20 a test toothing 21 is arranged. The test toothing 21 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com