Rotor disk

A technology of rotor disk and disk body, which is applied in the direction of mixer with rotating stirring device, mixer, transportation and packaging, etc., to achieve the effect of high running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

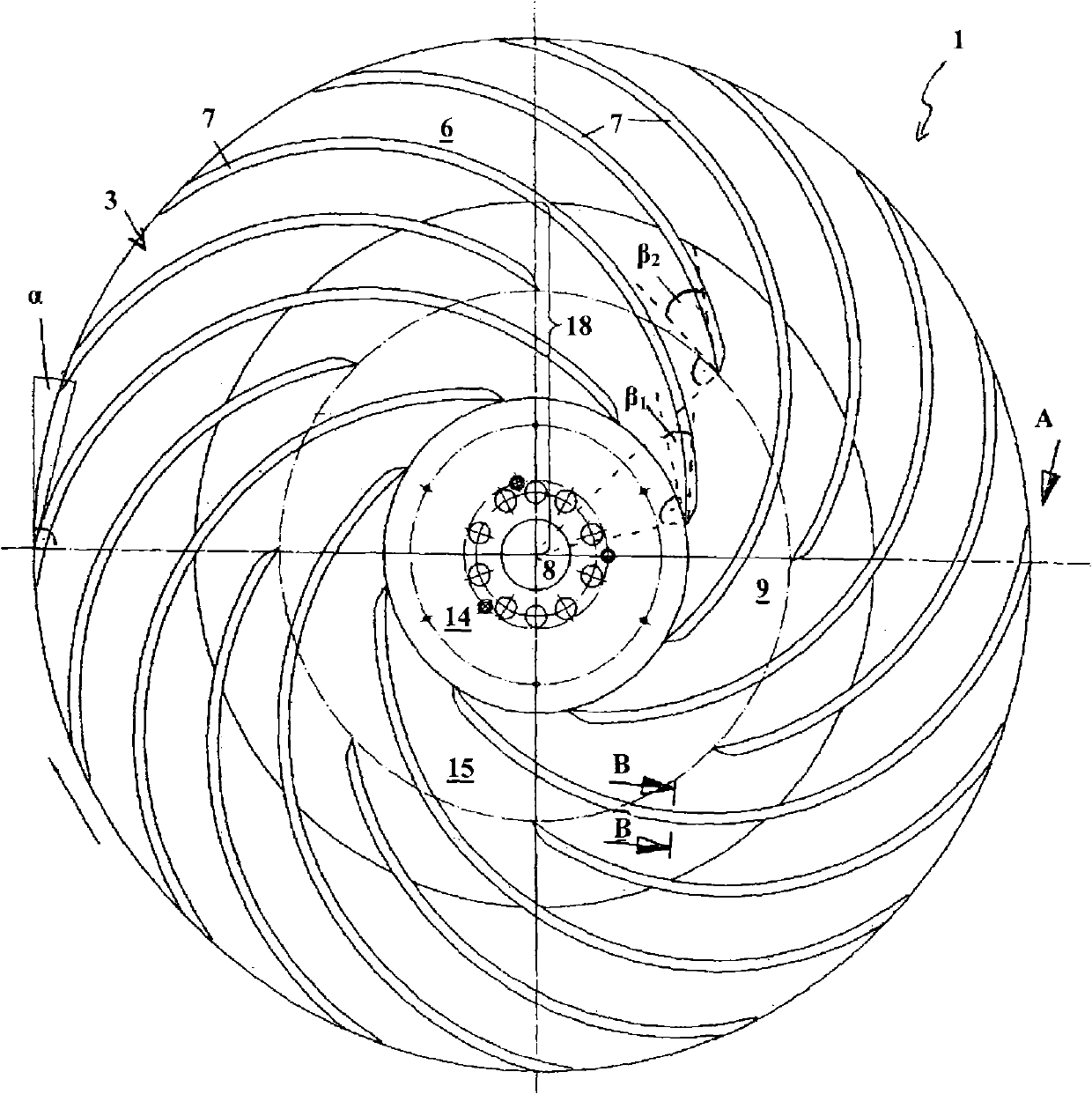

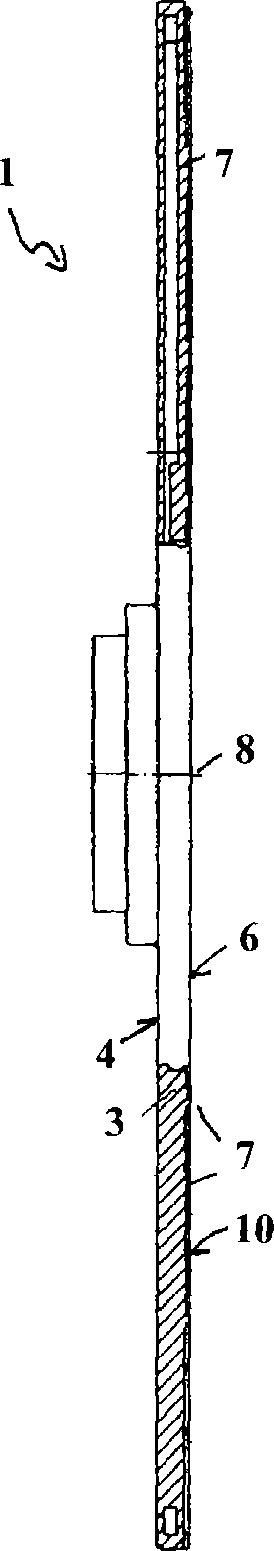

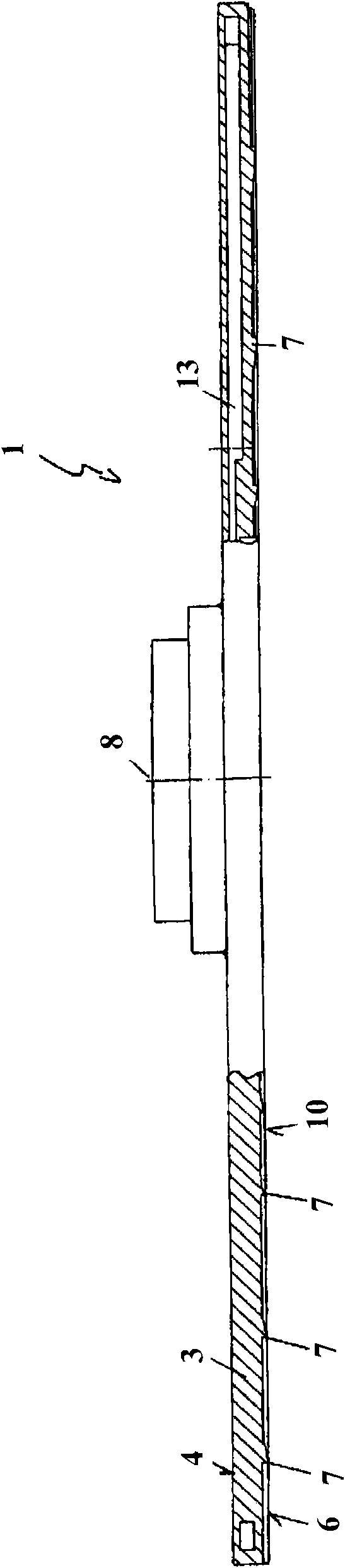

[0047] exist figure 1 A particularly efficient and advantageous rotor disk 1 is exemplarily shown in , wherein figure 1 The rotor disk 1 is shown viewed from below, ie from the storage base 17 during operation. In practice, such a rotor disk 1 is usually inserted into a large-volume holding store 2 in which a lot of polymer material with a correspondingly high weight is present. A correspondingly high pressure acts on the rotor disk 1 . In this case, the diameter of such a rotor disk 1 is in the range of approximately 2 m or more.

[0048] The rotor disk 1 has a disk body 3 on which mixing and / or grinding tools 5 can be arranged on an upper side 4 . A number of conveying ribs 7 extending from the inside to the outside are arranged on the opposite underside 6 of the tray body 3 . All conveying ribs 7 are curved concavely in the direction of travel of the disk 1 , wherein the curvature runs uniformly in the shape of a circular arc. The radius of curvature of the conveying r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com