Patents

Literature

37results about How to "Achieve epitaxial growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

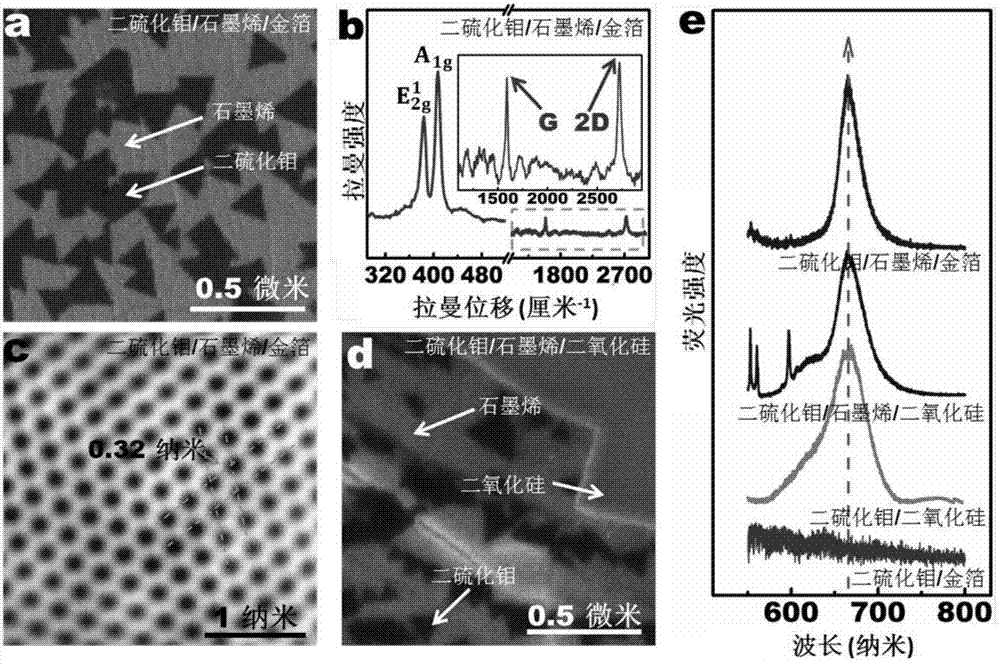

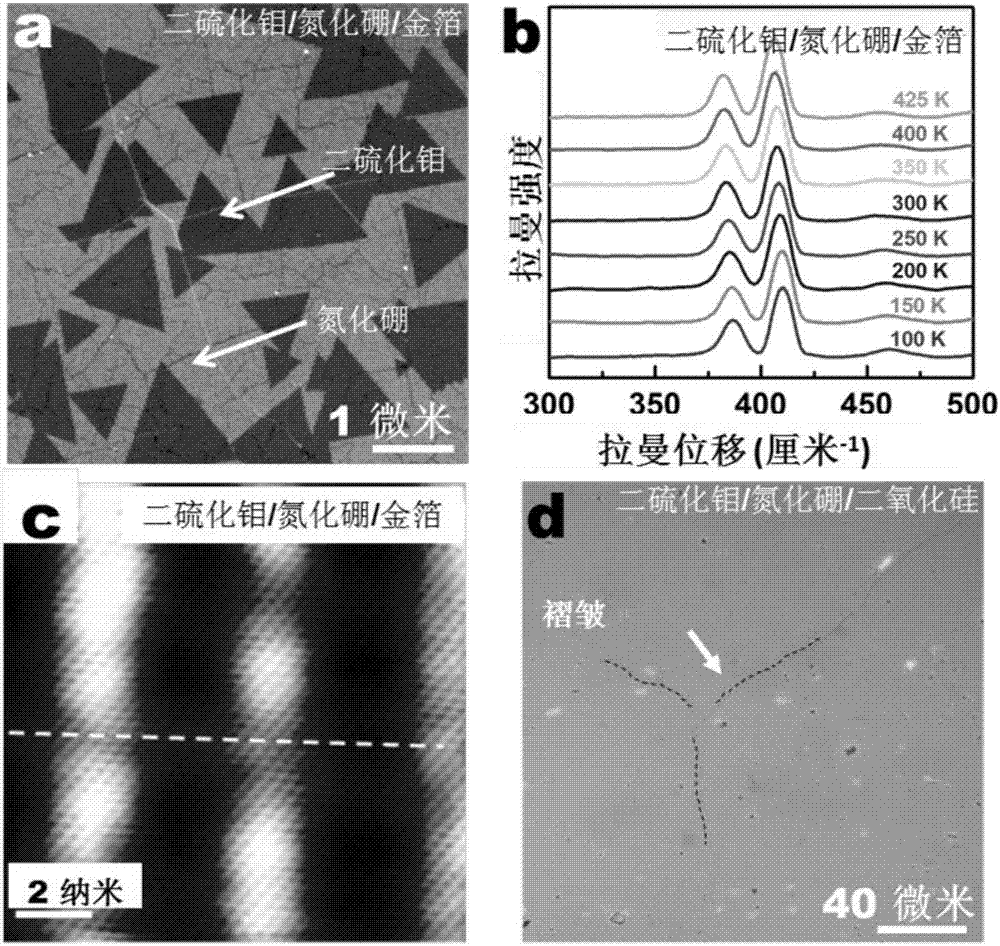

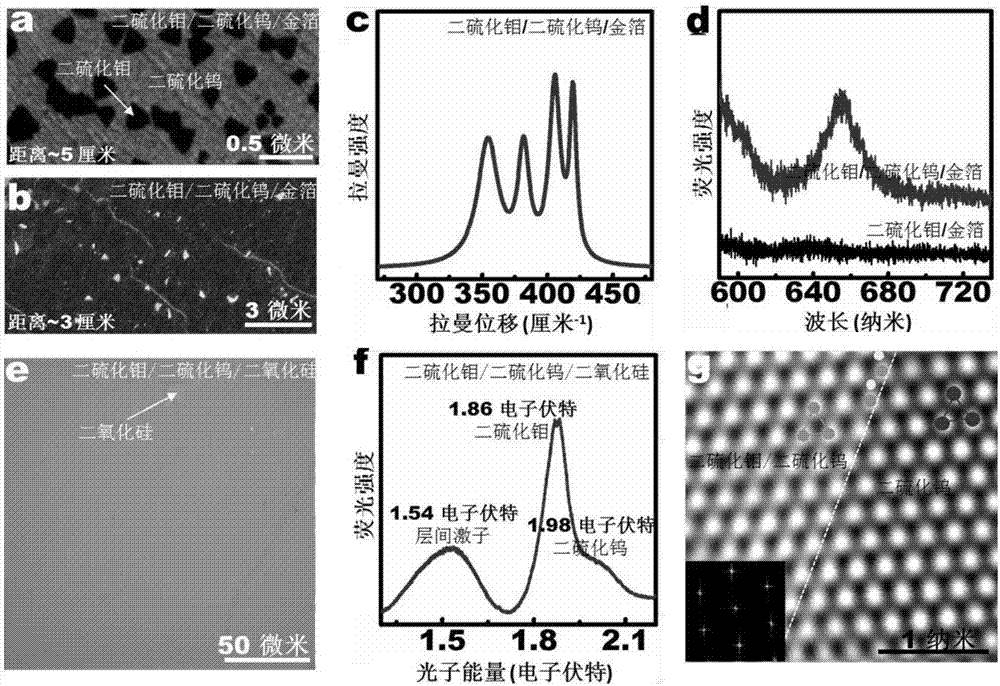

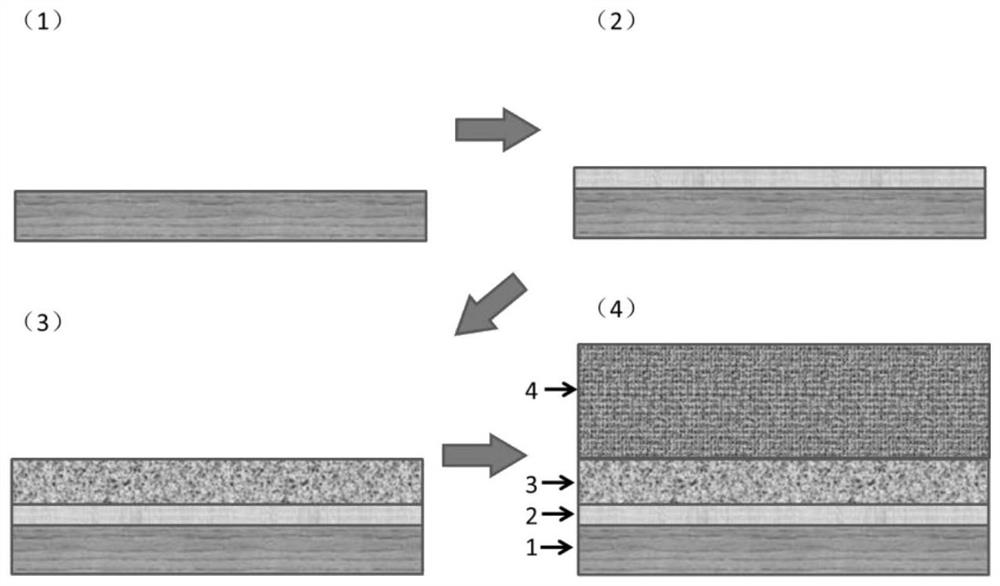

Method for preparing transition metal chalcogenide/two-dimensional layered material interlayer heterogeneous structure through two-step chemical vapor deposition method

InactiveCN107447200AAchieve epitaxial growthAvoid pollutionChemical vapor deposition coatingChemical vapor depositionGold foil

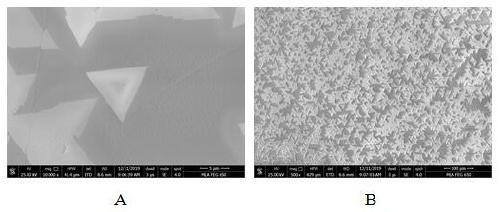

The invention discloses a method for preparing a transition metal chalcogenide / two-dimensional layered material interlayer heterogeneous structure through a two-step chemical vapor deposition method. The method comprises the following steps that (1) gold foil is cleaned and subjected to high-temperature pre-annealing treatment; (2) the annealed gold foil is placed in a high-temperature tube furnace, a two-dimensional layered material is grown on the gold foil through the low-pressure chemical vapor deposition method, and a two-dimensional layered material / gold foil sample is obtained after the temperature is lowered to the room temperature; (3) the two-dimensional layered material / gold foil sample is put into a second high-temperature tube furnace, and powdered sulfur, molybdenum oxides and the two-dimensional layered material / gold foil are sequentially arranged according to the order from the upstream portion to the downstream portion; (4) argon and hydrogen are pumped into a reaction chamber, and molybdenum disulfide is grown; and (5) after growing of molybdenum disulfide is finished, the molybdenum disulfide / two-dimensional layered material interlayer heterogeneous structure on the gold foil is obtained.

Owner:PEKING UNIV

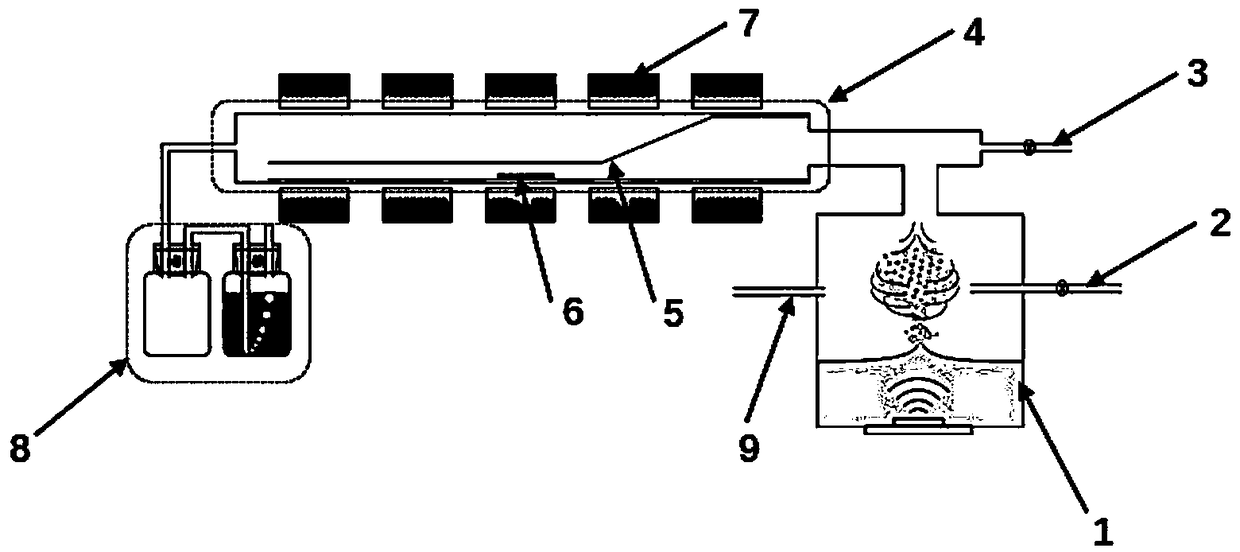

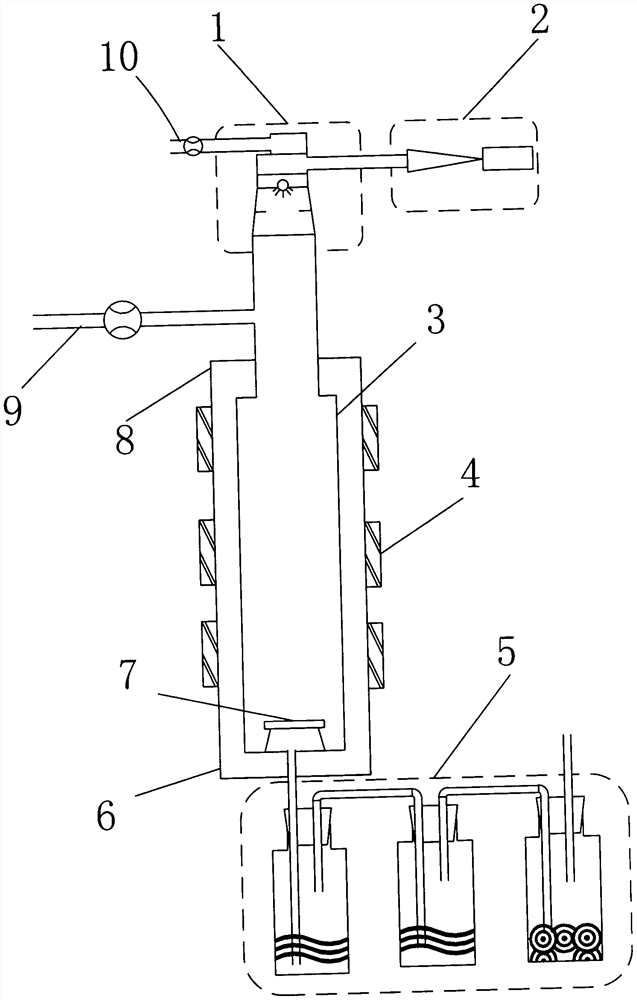

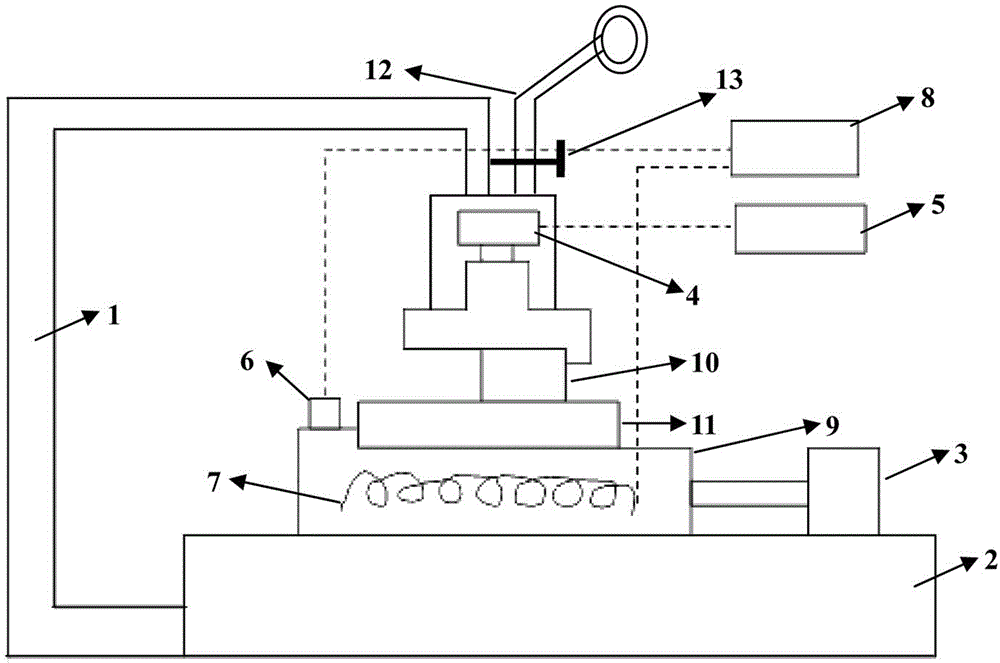

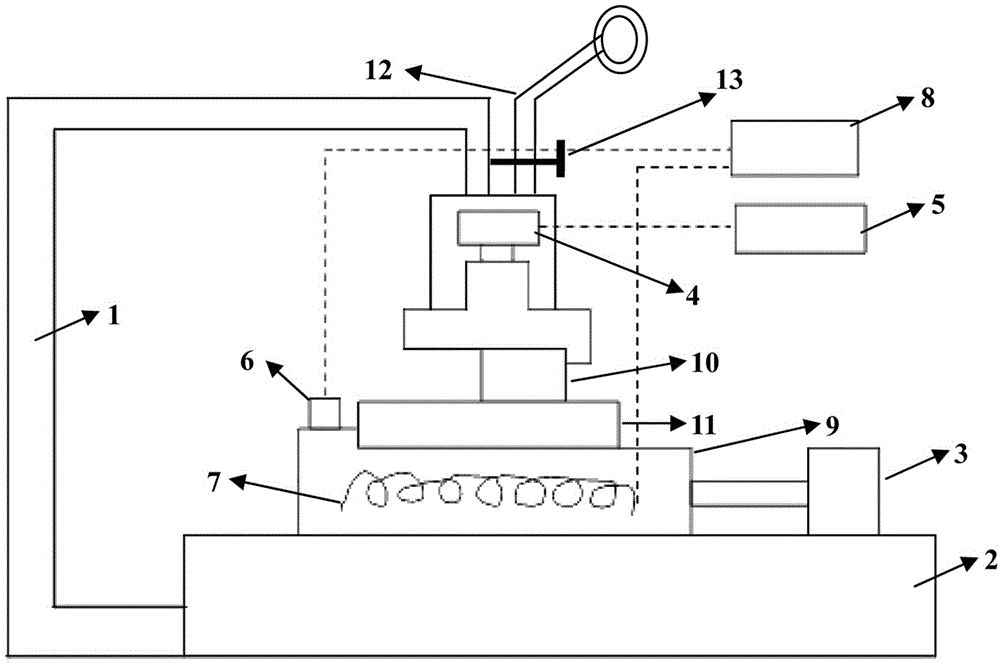

System for growth of gallium oxide by means of ultrasound-assisted fog-phase transport chemical vapor deposition

PendingCN109056066AEasy to dopeControl growth ratePolycrystalline material growthFrom chemically reactive gasesGas phaseNitrogen gas

The invention relates to a system for growth of gallium oxide by means of ultrasound-assisted fog-phase transport chemical vapor deposition. An ultrasound-assisted fog-phase transport chemical vapor deposition method adopts a water-soluble gallium salt ultrasonic atomization source as a raw material and is performed in a reaction chamber; the part, having gas flow, of a confinement device portionin the reaction chamber is used as a growth region, and the whole reaction chamber is used as a horizontal structure; after being atomized by using an ultrasonic atomizer, an aqueous solution of a gallium source is transported by using inert gas (nitrogen gas) as carrier gas, is mixed with dilution gas and then enters the reaction chamber; the reaction chamber is internally provided with a gas flow confinement structure; reaction products and unreacted raw materials are absorbed with water at an output position of the rear end of the reaction chamber, and an anti-inverse-suction structure is arranged at the output position; after a reaction is finished, the exhaust gas is treated by means of an exhaust gas treatment device.

Owner:NANJING UNIV

Method for preparing beta-FeSi2 semiconductor film by femtosecond pulsed laser

InactiveCN1664989AAvoid secondary pollutionShine wellVacuum evaporation coatingSemiconductor/solid-state device manufacturingFemtosecond pulsed laserPeak value

The invention provides a method for preparing belta-FeSi2 semiconductor film by flysecond pulse laser, vacuumizing pulse-laser film depositing device to an air pressure of 10<-5> to 10<-3>, using FeSi2 alloy as target material, placing the target material and a substrate in the pulse-laser film depositing device, where the target material and the substrate, mutually parallel, are 20-50mm apart from each other, heating the substrate to 20 DEG C to 700 DEG C and then keeping warm, irradiating the target material by laser beam with a peak power density of 10<12> to 10<15> W / sq cm<2>, which makes the ejective plasma is deposited on the substrate and epitaxially grows along the crystal face of the substrate to form the film. The invention is suitable for different substrates to synthesize a large-area, uniform, monophasic beta- FeSi2 semiconductor film at lower temperature in a short time, and the prepared film is provided with better light emitting and photovoltaic properties, which solves the technical difficulty in being a high quality beta-FeSi2 film needed by infrared light emitting diode and solar battery.

Owner:HUAZHONG UNIV OF SCI & TECH

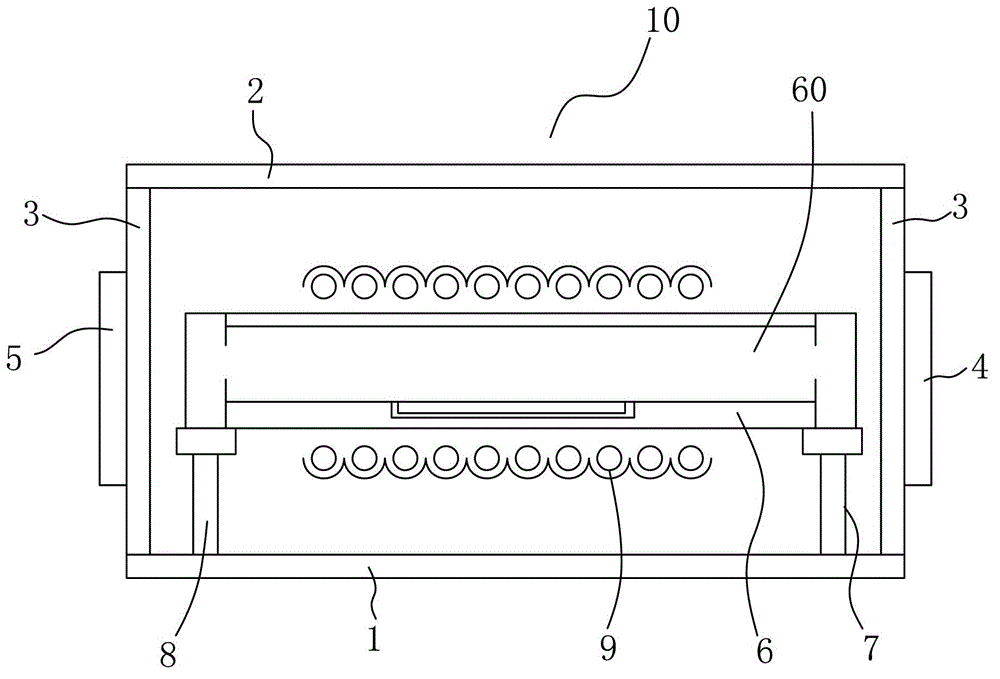

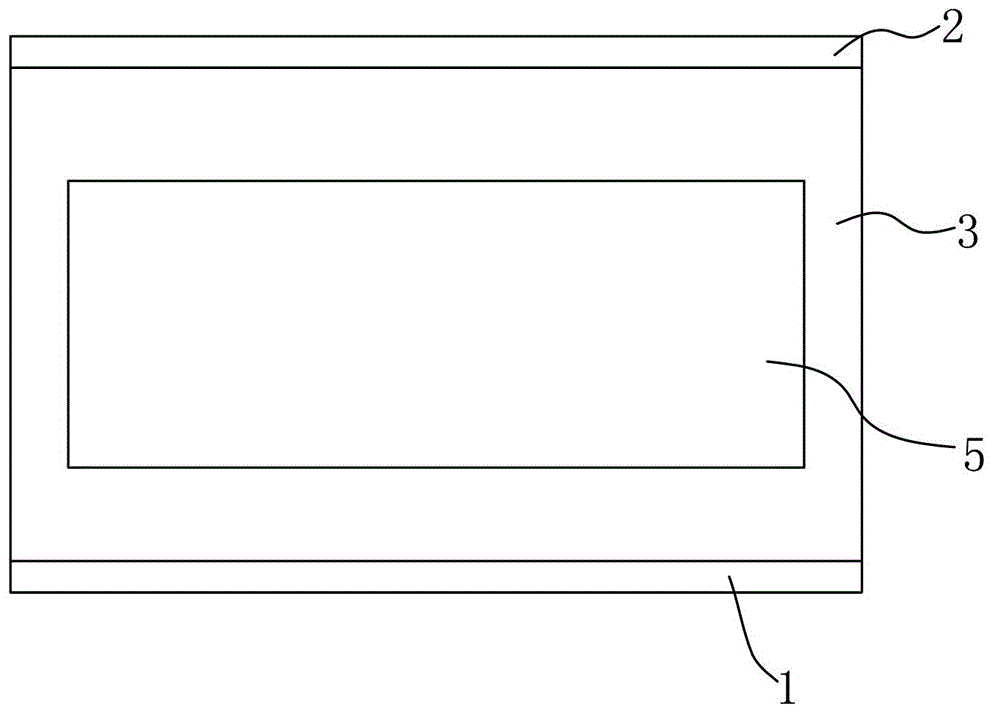

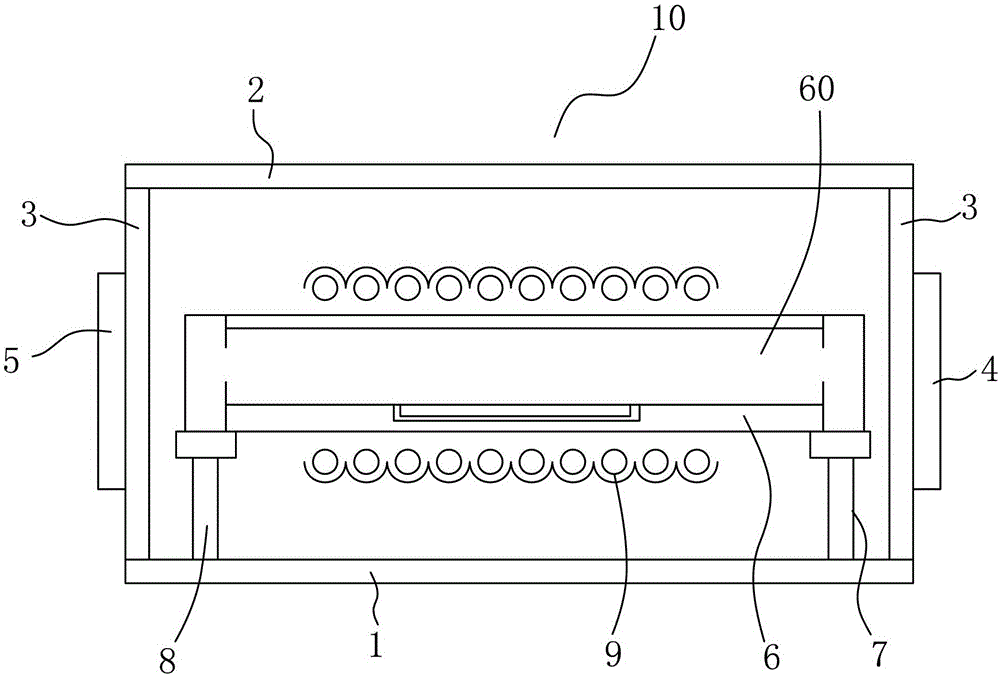

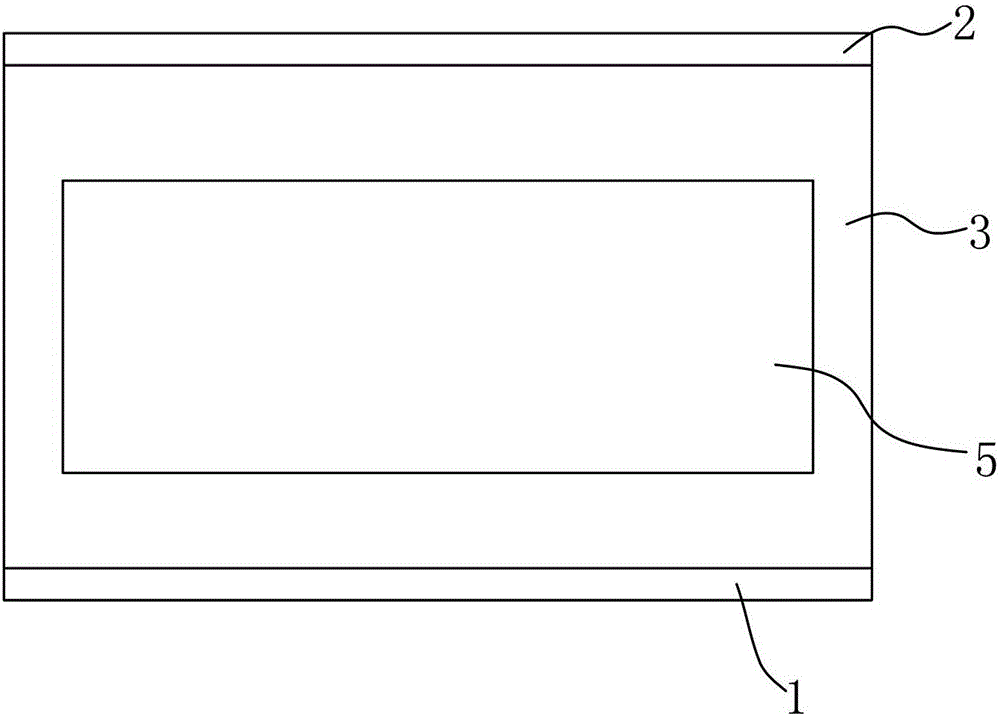

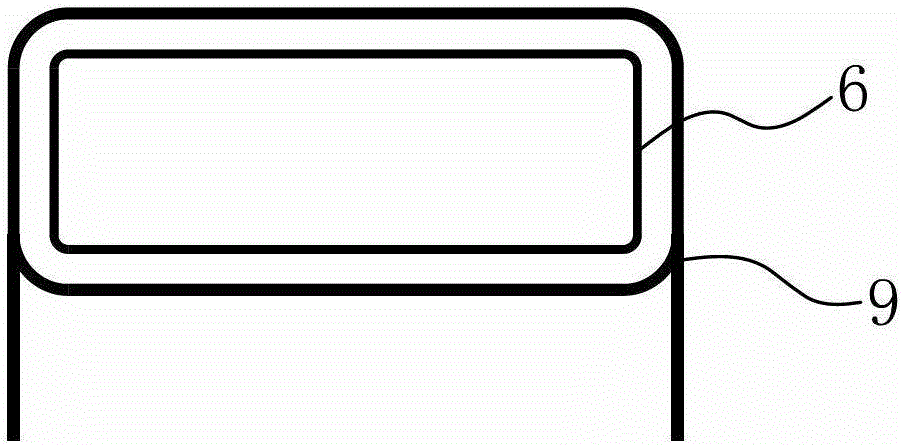

High-temperature large area silicon carbide epitaxial growth device and treatment method

ActiveCN102747418AKeep constantAchieve epitaxial growthPolycrystalline material growthFrom chemically reactive gasesGraphiteOptoelectronics

The invention discloses a high-temperature large area silicon carbide epitaxial growth device and a treatment method. The high-temperature large area silicon carbide epitaxial growth device comprises a closed working chamber made of stainless steels, a graphite reaction cavity chamber arranged in the working chamber and a heating component arranged at the periphery of the reaction cavity chamber, wherein a tray groove is arranged in the reaction cavity chamber, a tray which bears a silicon carbide substrate is arranged in the tray groove, the reaction cavity chamber is provided with a penetrating channel, and a gas inlet device and a gas outlet device are respectively arranged at two ends of the channel. During treatment, the silicon carbide substrate is put into the reaction cavity chamber and then vacuumized and heated, reaction gas is introduced into the reaction cavity chamber so as to allow epitaxial growth of the silicon carbide, and then the silicon carbide taken out. Compared with the traditional quartz tube structure, the high-temperature large area silicon carbide epitaxial growth device has a simple structure, is relatively easy to manufacture, is convenient to process and can be used for treating the silicon carbide with a larger area. In addition, according to the high-temperature large area silicon carbide epitaxial growth device disclosed by the invention, the working chamber is in a water-cooling stainless steel structure, has higher strength and is not easy to damage.

Owner:DONGGUAN TIANYU SEMICON TECH

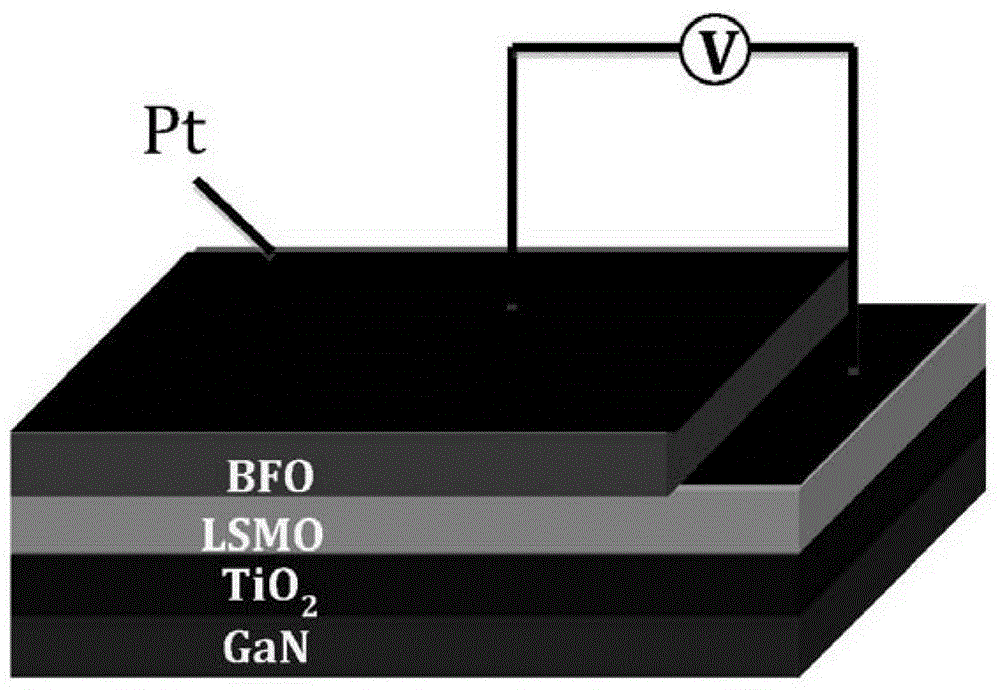

Gallium nitride-based bismuth ferrite ferroelectric thin film and preparation method thereof

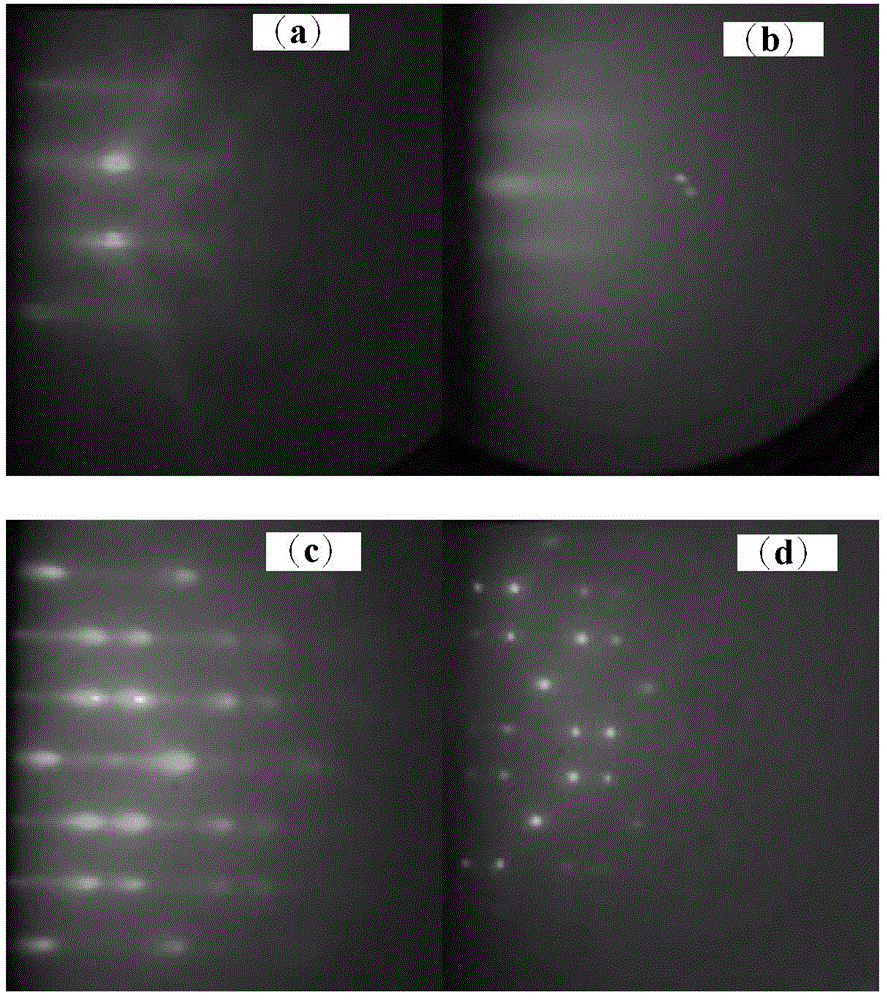

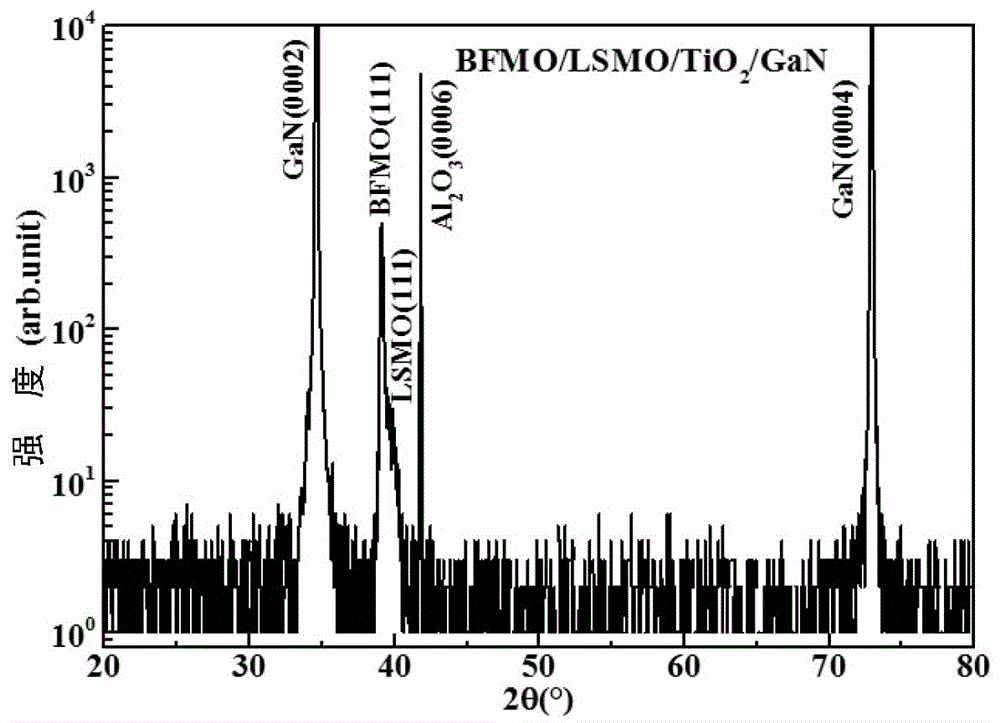

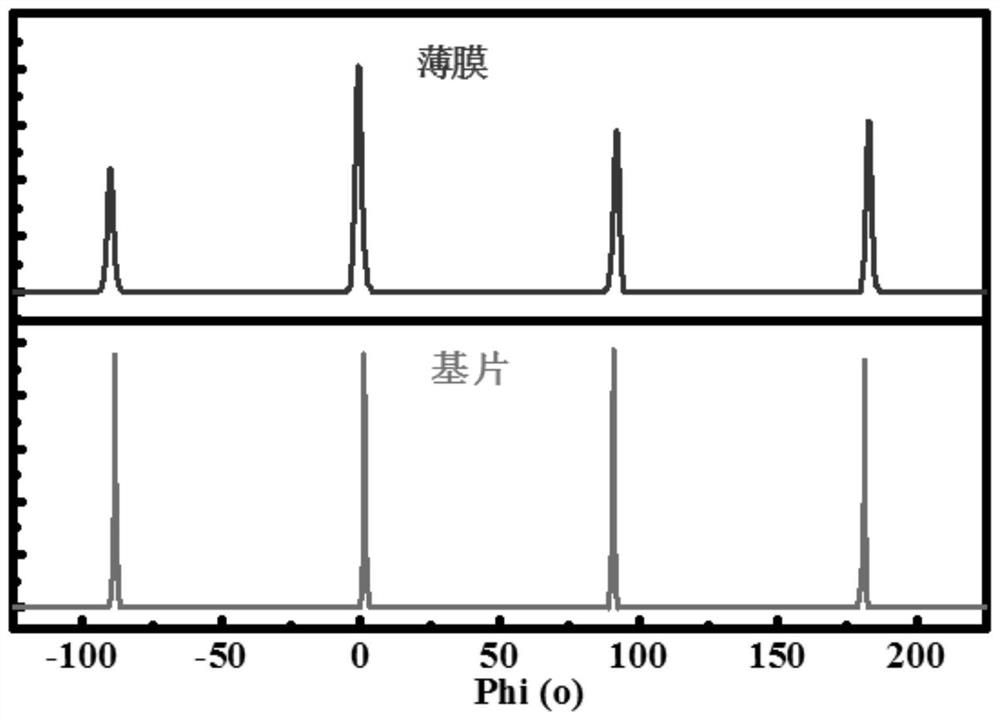

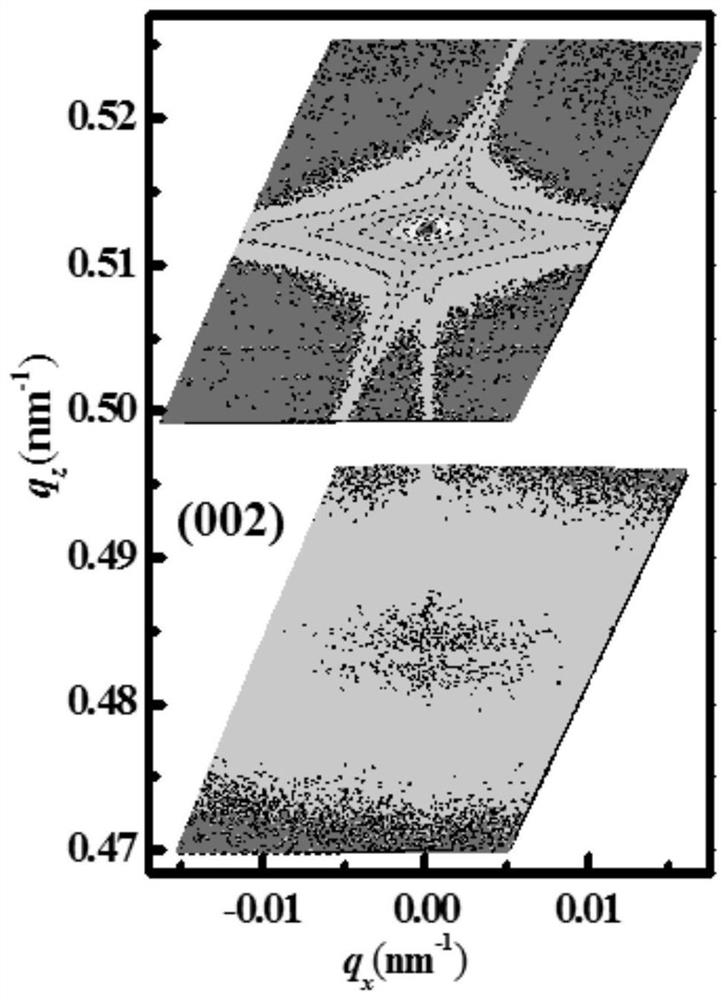

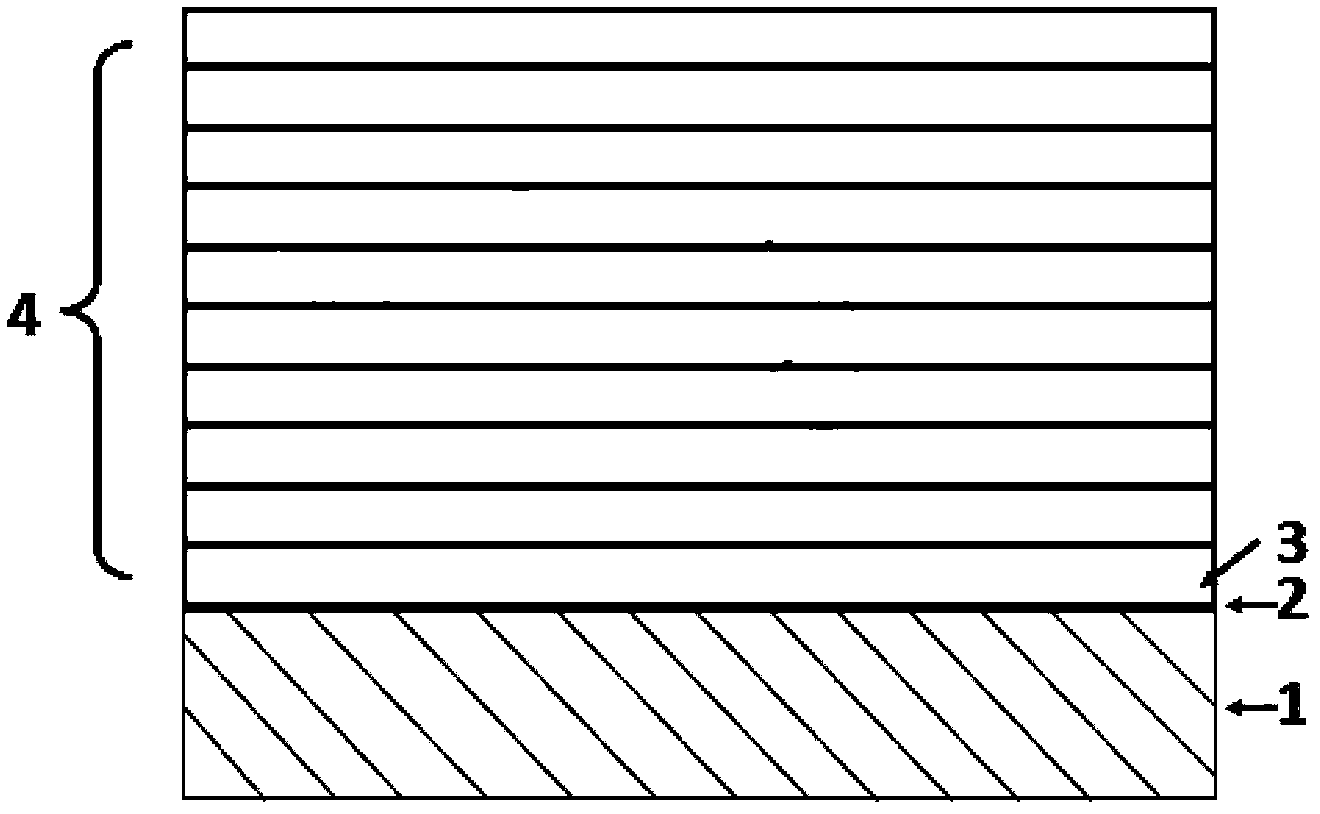

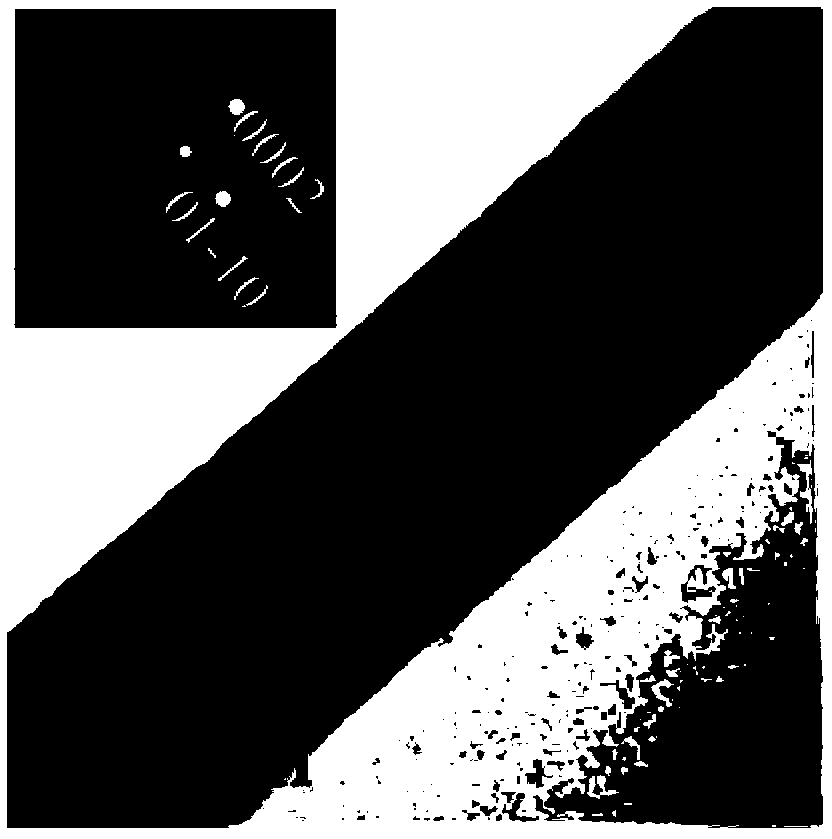

InactiveCN106129243ASmall lattice mismatchAchieve epitaxial growthPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionCrystallographyFerroelectric thin films

The invention relates to a gallium nitride-based bismuth ferrite ferroelectric thin film and a preparation method thereof. The gallium nitride-based bismuth ferrite ferroelectric thin film comprises a TiO<2> buffer layer, a strontium lanthanum manganate buffer layer and a bismuth ferrite ferroelectric thin film which are formed on a gallium nitride semiconductor thin film substrate in sequence through a pulse laser deposition technology. The gallium nitride-based bismuth ferrite ferroelectric thin film and the preparation method thereof have the following beneficial effects: the LSMO / TiO<2> dual buffer layers are adopted, so that the lattice mismatching degree between bismuth ferrite and gallium nitride is reduced; the epitaxial growth of the bismuth ferrite ferroelectric thin film on the gallium nitride semiconductor thin film is realized; the (111) single-oriented bismuth ferrite thin film is obtained; and the epitaxial integration of the bismuth ferrite ferroelectric thin film and the gallium nitride semiconductor is realized.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

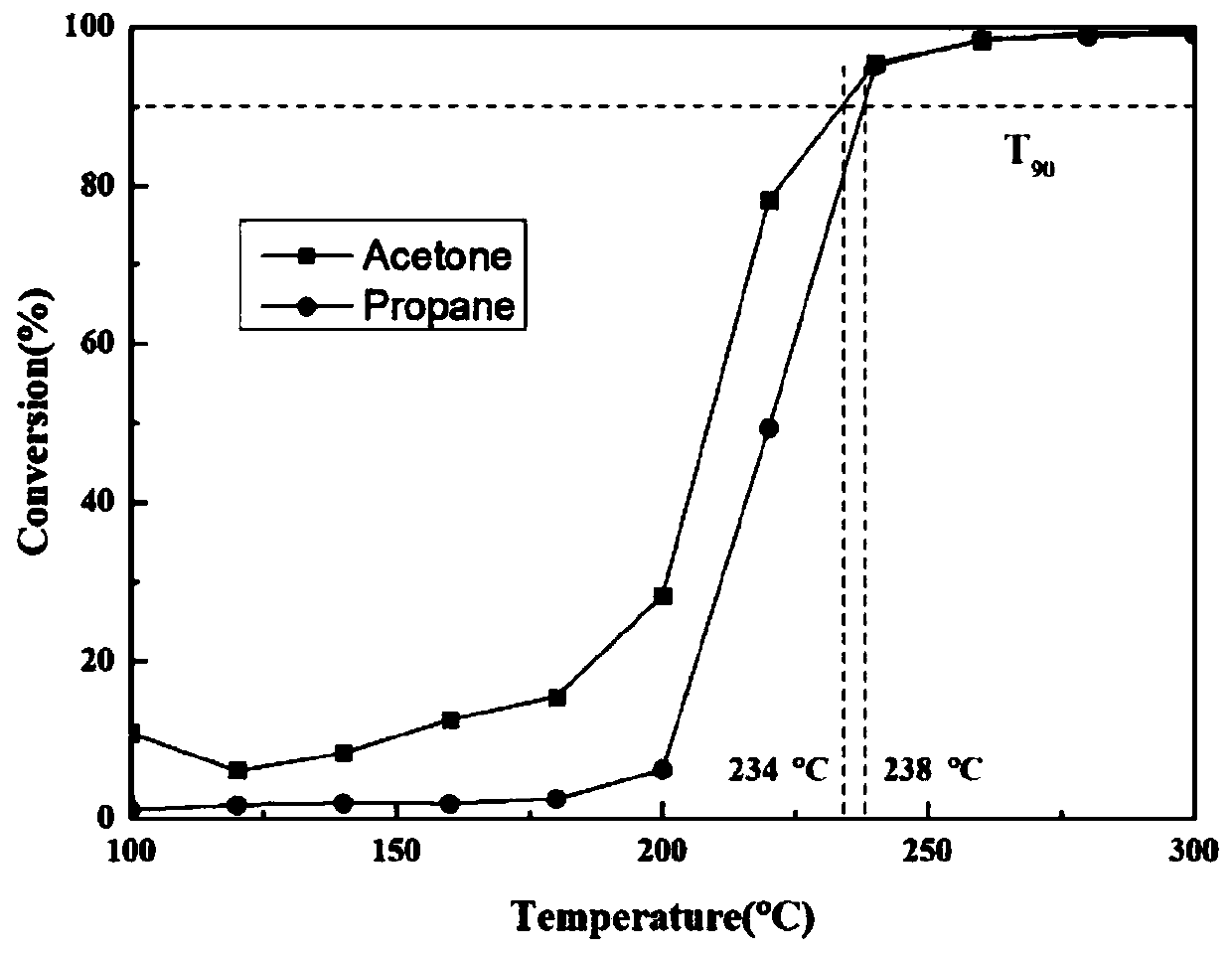

Volatile organic compound catalytic oxidation catalyst with high chlorine poisoning resisting efficiency, and preparation method thereof

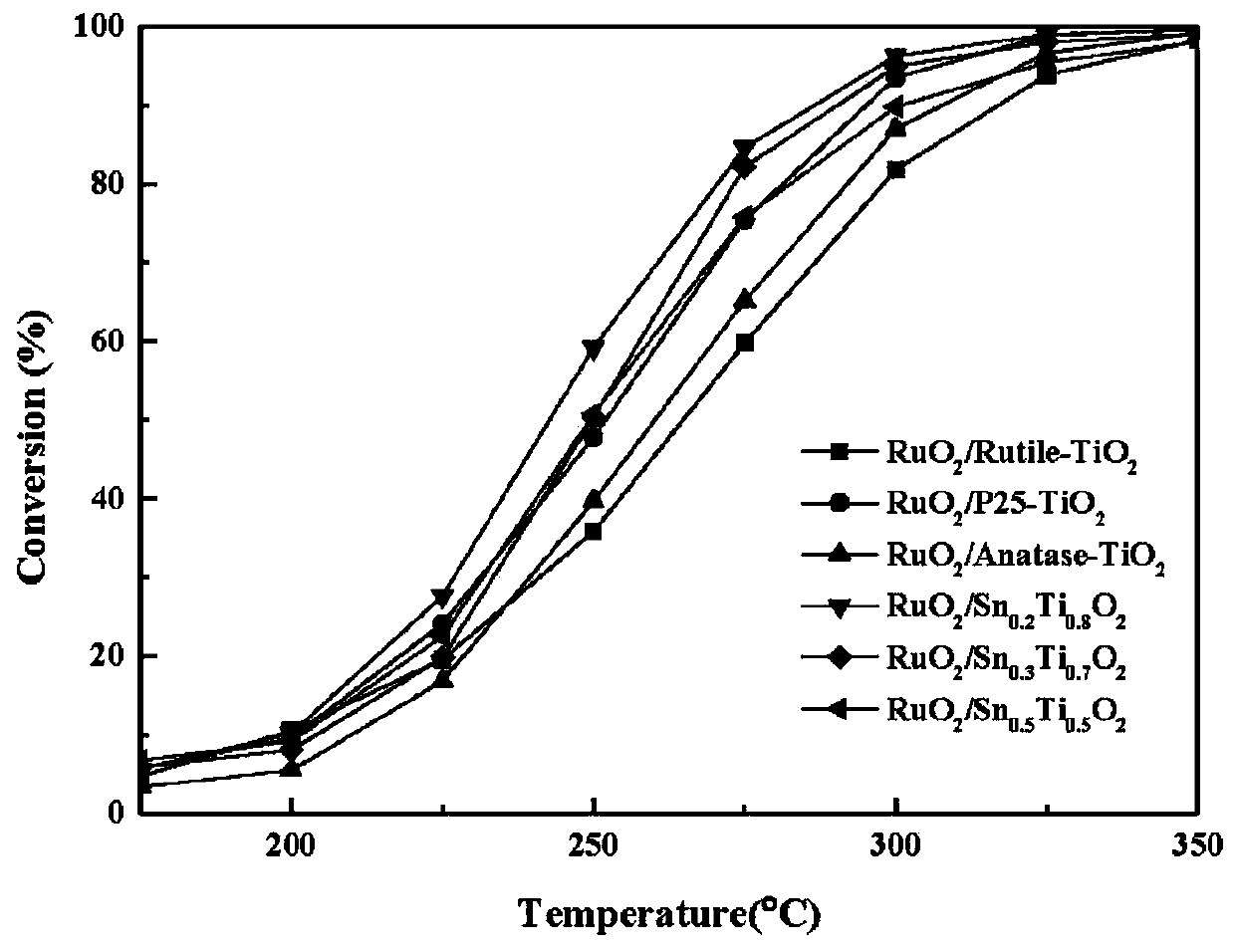

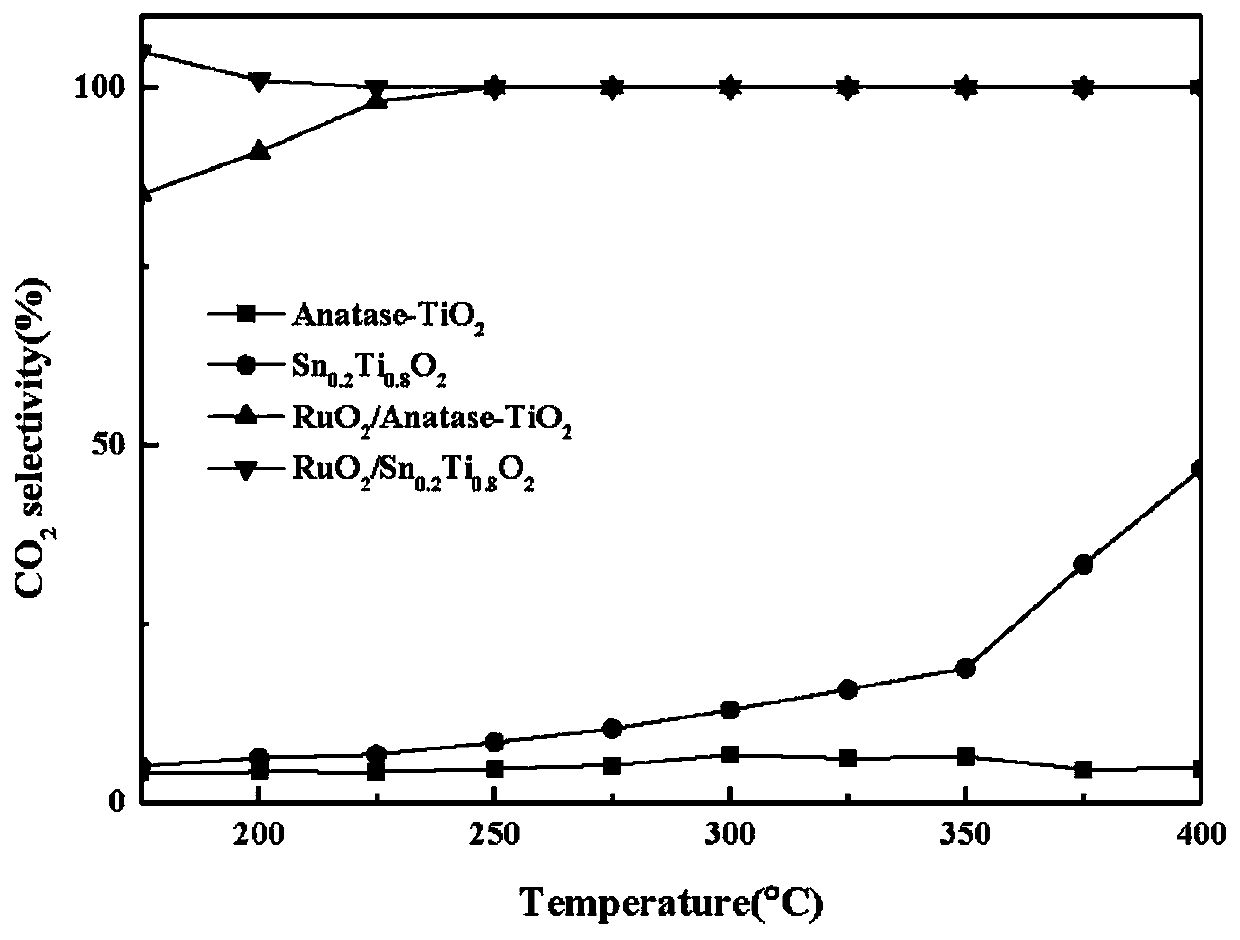

ActiveCN110404534AGood dispersionRealize regulationGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsHigh activationOrganic synthesis

The invention relates to a volatile organic compound catalytic oxidation catalyst with a high chlorine poisoning resisting efficiency, and a preparation method thereof. The catalyst adopts RuO2 as anactive component, and adopts a SnyTi1-yO2 or MOx-SnyTi1-yO2 mixed metal oxide as a carrier. TiO2 is doped with Sn to realize the regulation of the crystal form of the carrier oxide, so the dispersiondegree of RuO2 on the surface of the carrier is greatly improved while constructing the tin-titanium-based catalyst carrier with a high activation performance; and the catalyst has the characteristicsof high catalytic activity to chlorine-containing volatile organic compounds, strong chlorine poisoning resistance, and high selectivity of the product to CO2, has a good removal effect on common volatile organic compounds, and can be widely used in treatment of chlorine-containing organic waste gases in the fields of pharmaceutical, organic synthesis and paint spraying.

Owner:ZHEJIANG UNIV

Electrostatic atomization chemical vapor deposition gallium oxide film system

PendingCN112111783AAchieve epitaxial growthControl growth ratePolycrystalline material growthFrom chemically reactive gasesChemical reactionPhysical chemistry

The invention discloses an electrostatic atomization chemical vapor deposition gallium oxide film system, which belongs to the field of chemical vapor deposition material growth, and mainly solves theproblems of droplet particle size and motion control in the process of atomized vapor deposition of a gallium oxide film. The electrostatic atomization chemical vapor deposition method comprises thefollowing steps of carrying out electrostatic atomization on a gallium salt solution as a gallium source, and carrying out chemical reaction in a reaction cavity, using a loading support part in a reaction cavity as a growth area, transporting a gallium salt aqueous solution by carrier gas after electrostatic atomization, mixing with reaction gas and then transporting to the reaction cavity, and conducting a reaction in the growth area. The whole reaction cavity is of a vertical structure, a heating device is arranged on the periphery of the reaction cavity to provide required heat for reaction, a waste gas purification treatment device is arranged at the output position of the tail end of the reaction cavity, and reacted tail gas is treated by the waste gas purification treatment device.

Owner:TIANJIN POLYTECHNIC UNIV

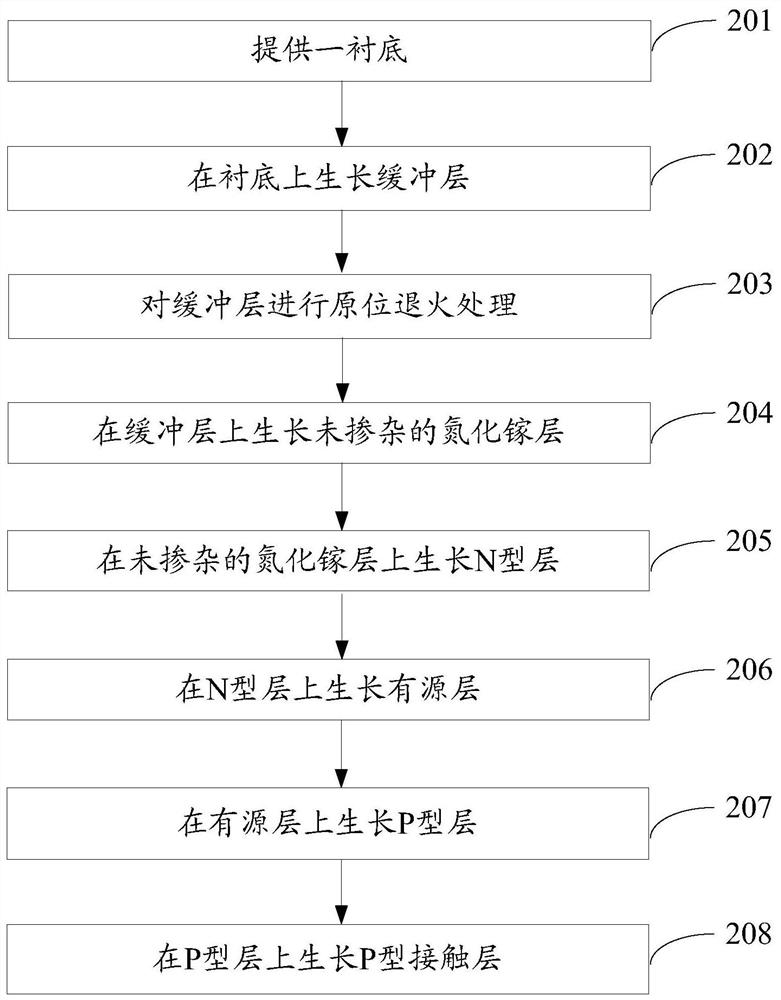

Preparation method of distributed Bragg reflector and vertical cavity surface emitting laser

InactiveCN110165550AAvoid warpingStress reliefLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserLattice mismatch

The invention relates to the technical field of semiconductor lasers, and particularly discloses a preparation method of a distributed Bragg reflector and a vertical cavity surface emitting laser. Themethod comprises the steps: providing a substrate; and alternately growing the first refractive index layer and the second refractive index layer of the distributed Bragg reflector on the substrate in turn, wherein the lattice constant of the substrate is located between the lattice constant of the first refractive index layer and the lattice constant of the second refractive index layer. The substrate having the lattice constant between the lattice constant of the first refractive index layer and the lattice constant of the second refractive index lay is used so that the stress of the firstrefractive index layer and the second refractive index layer grown on the substrate is enabled to cancel each other, i.e. the stress caused by lattice mismatch is eliminated by using the strain compensation mode so that the growth of the strain-free Bragg reflector is realized, and the problem of warping of the epitaxial wafer is avoided.

Owner:度亘核芯光电技术(苏州)有限公司

Heterotopic multi-metal oxide film epitaxial growth and continuous preparation method

InactiveCN108588648AEvenly distributedAchieve crystallizationVacuum evaporation coatingSputtering coatingEvaporationAmorphous metal

The invention provides a heterotopic multi-metal oxide film epitaxial growth and continuous preparation method. According to the characteristics of a metal target, the initial component evaporation isperformed; after nanoparticles evaporated from the target the high vacuum state reach the substrate, the nanoparticles are deposited into an amorphous metal precursor film; after deposition, the precursor film is transported to low-pressure atmospheres with different oxygen partial pressures; and at different temperatures, crystallization and epitaxial growth are performed. By the method, co-evaporation of multi-metal elements with different melting points and sublimation temperatures is realized, the evaporation technology and conditions of the elements can be selected according to characteristics of the constituent elements, and the dynamic baseband can help realize the uniformity of the precursor component; the later oxidation treatment starts with the highly-refined nano-scale precursor, nucleation centers of later crystallization growth are many, and growth is fast and density is high; and by controlling the oxygen partial pressure, the reaction heat-treatment can be realized ata lower temperature, and then crystallization and epitaxial growth can be achieved at low temperature. The preparation method is simple.

Owner:SHANGHAI UNIV

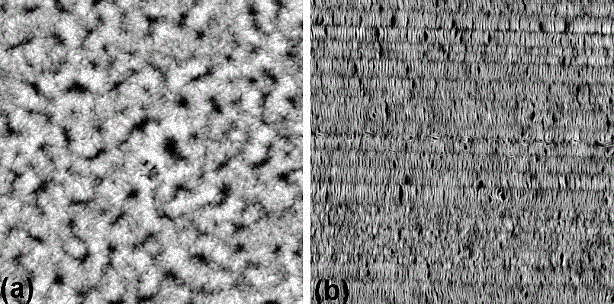

Nano doping structure and preparation method thereof

ActiveCN102953048AGood extension relationshipPrecise thickness controlMaterial nanotechnologyChemical vapor deposition coatingDopantReaction temperature

The invention provides a nano doping structure and a preparation method thereof. The preparation method comprises the following steps of: 1) placing a nano material into a reaction chamber of an atom layer depositing system; 2) utilizing an atom layer depositing method to deposit a dopant material with the thickness of 1-2 cycles; 3) depositing a base material of a nano material with the thickness of X cycles; and 4) alternatively and circularly depositing dopants and substrate material layers obtained in the steps 2) and 3) with the thickness of Y cycles, wherein the selection of the X is determined according to an actual doping ratio; when the X is smaller, a doping ratio is larger; and the selection of the Y is determined according to the thickness of an actually-needed doping layer, and the doping layer is thicker when the Y is greater. According to the nano doping structure and the preparation method thereof, an in-situ atom layer depositing technology is adopted, a process is simple and is easy to realize, a reaction temperature is low and an applicable material range is wide.

Owner:青岛艾斯达特新材料科技有限公司

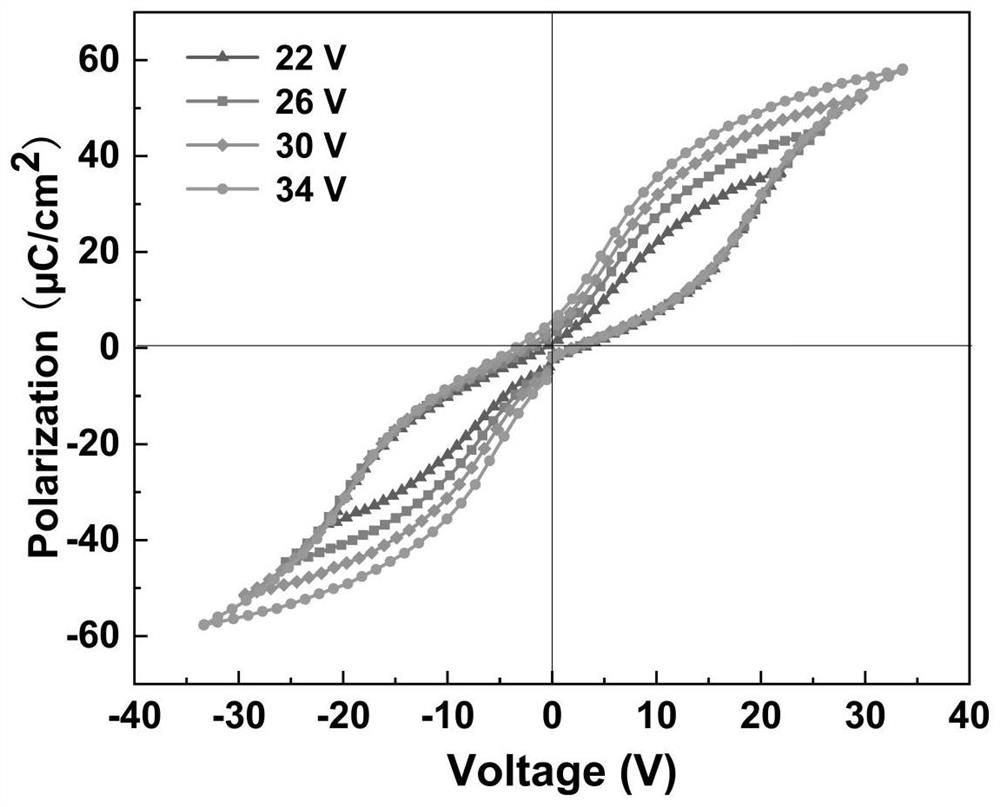

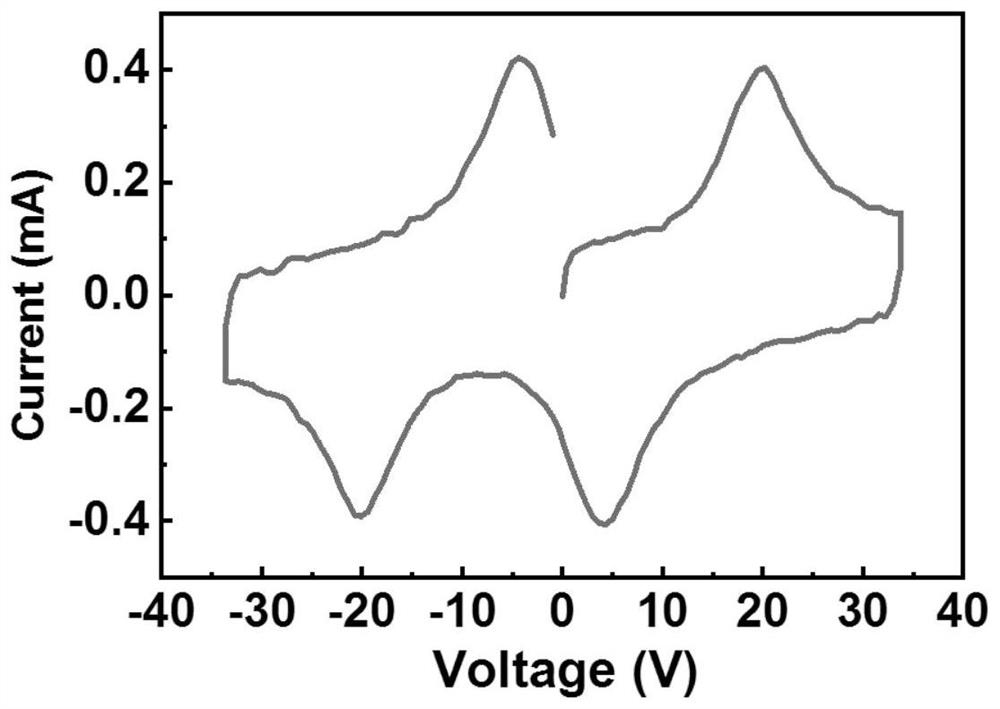

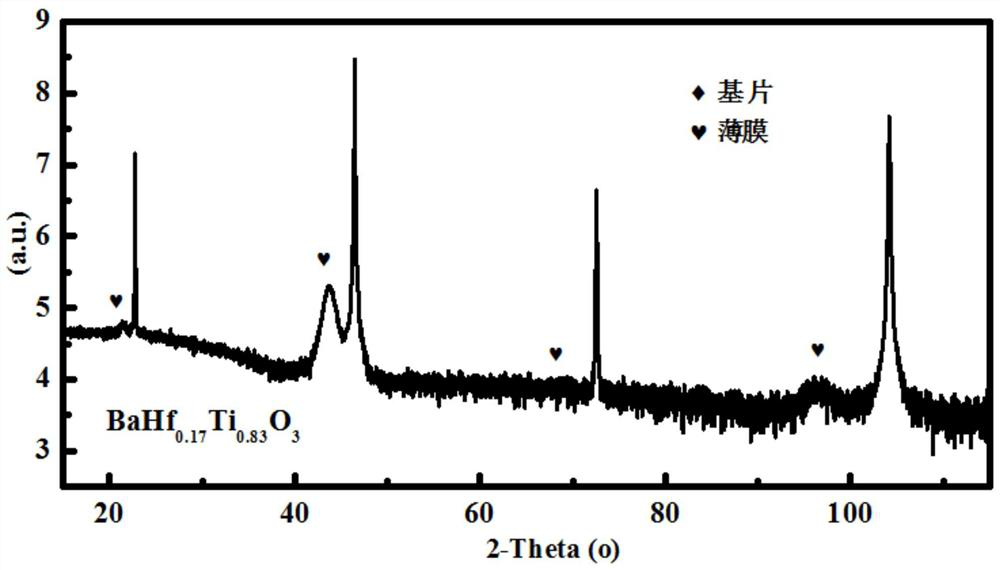

Rare earth element modified wide temperature film energy-storage capacitor and preparation method thereof

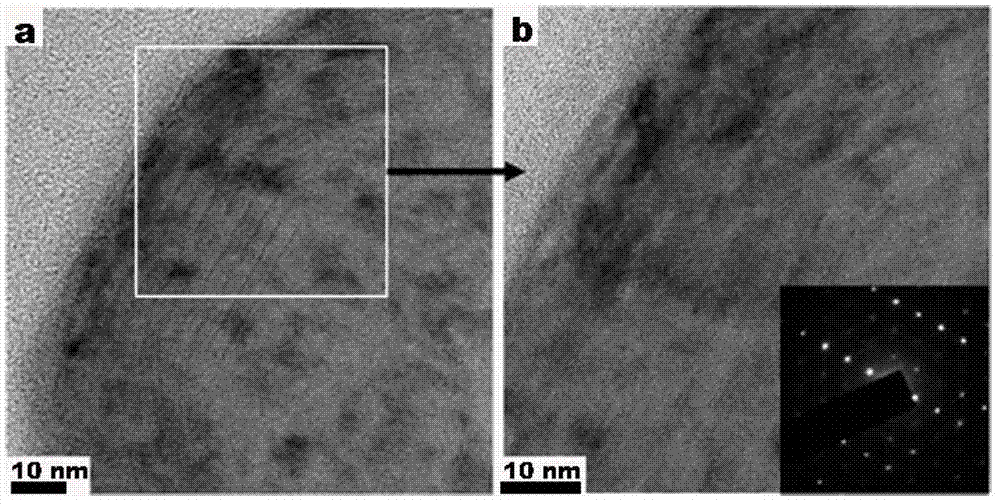

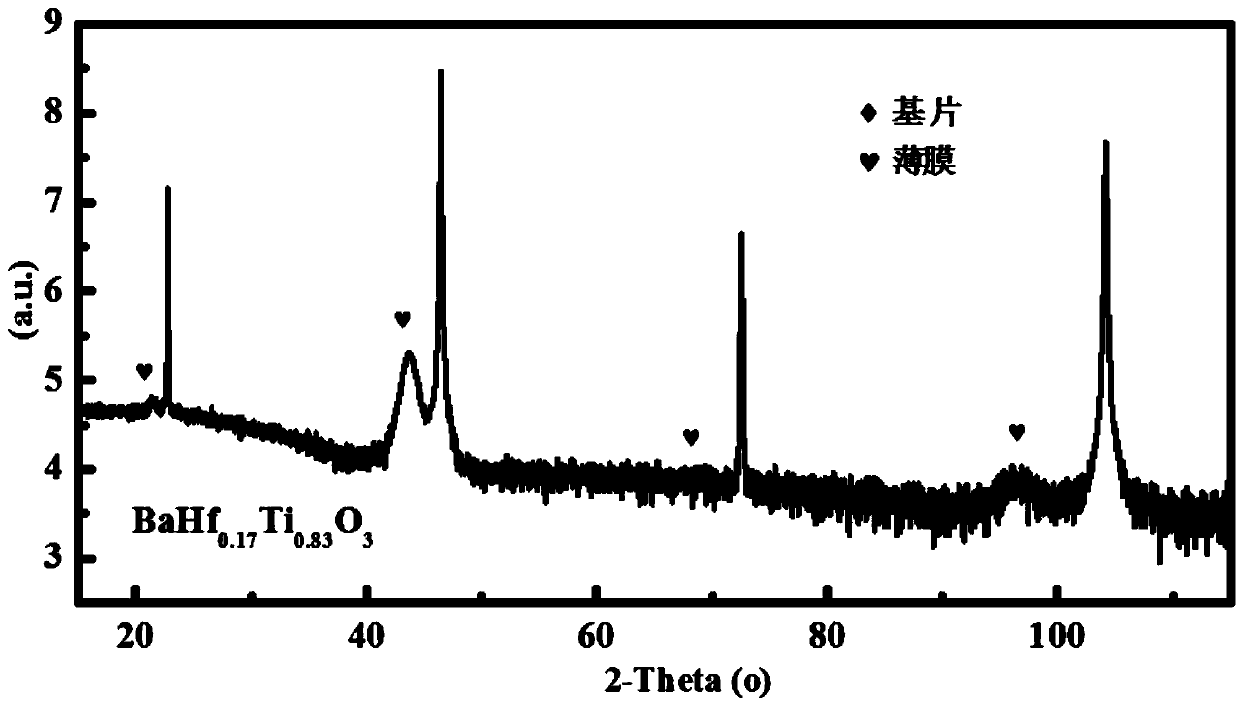

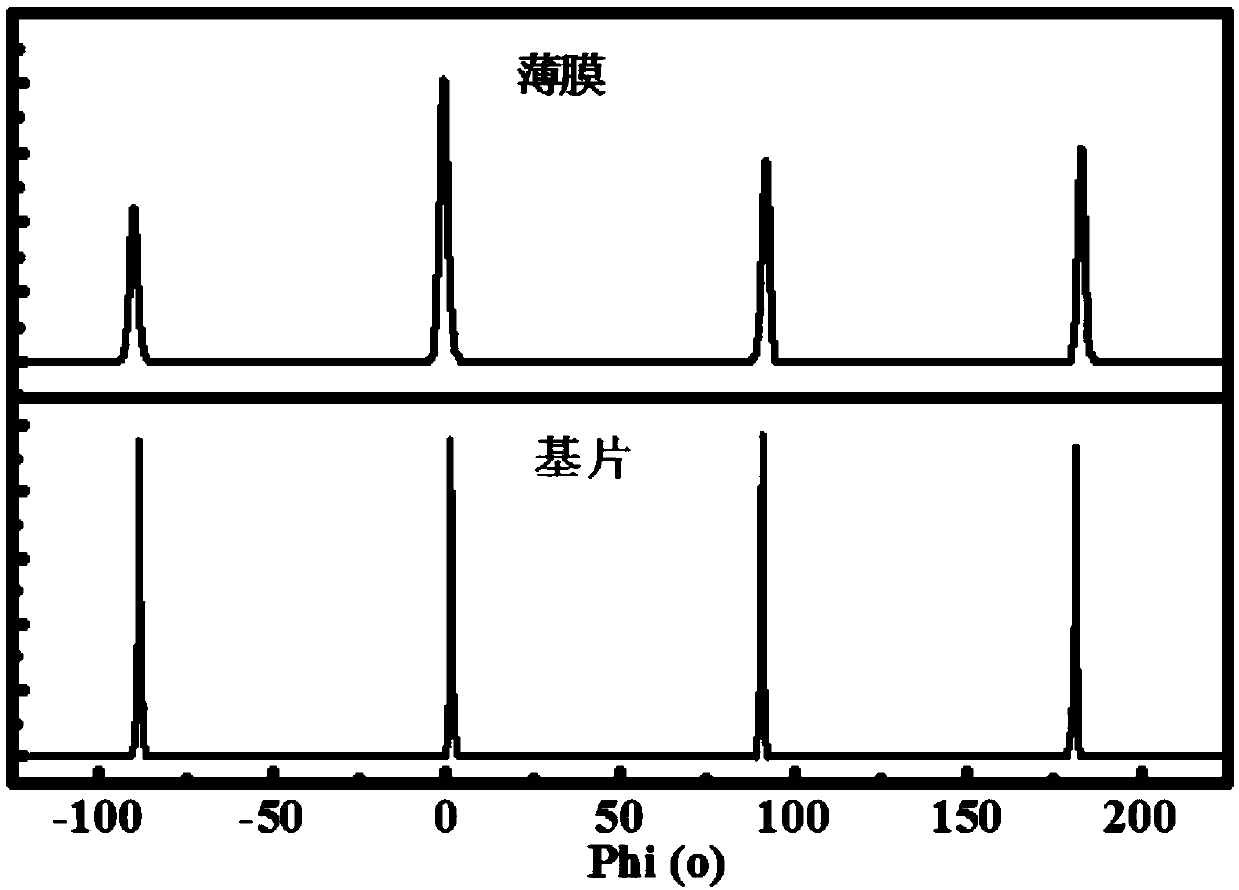

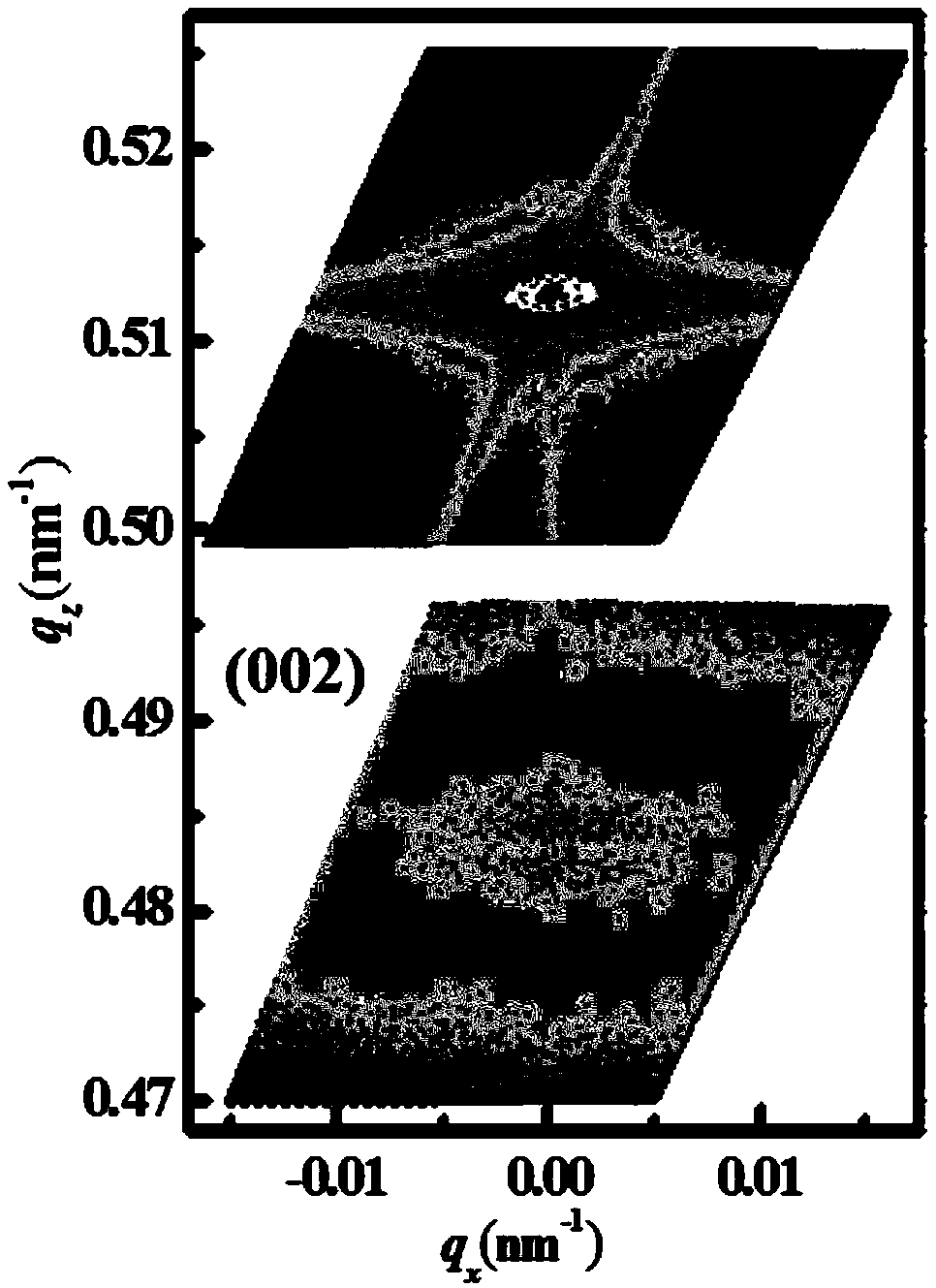

ActiveCN109545548AExcellent epitaxyImprove energy storage characteristicsThin/thick film capacitorFixed capacitor dielectricRare-earth elementRadio frequency magnetron sputtering

The invention relates to the field of energy storage thin film materials, and discloses a rare earth element modified wide temperature film energy-storage capacitor and a preparation method thereof. The preparation method is characterized by adopting an ultrahigh vacuum radio frequency magnetron sputtering technology, in the high temperature and high oxygen pressure environment, by performing bombardment on a target material through a plasma to enable the particles of the target material to be deposited on a substrate, realizing epitaxial growth, and then obtaining a BHT epitaxial film. Due tocharacteristics of the radio frequency magnetron sputtering technology, the growing speed of the film is slower relatively, so that the film prepared by the preparation method is uniform in the crystal grain size, is flat in the surface of the film, has high degree of crystallization, and further enhances the energy storage feature of the ceramic target material taken as the BT-base energy storage material.

Owner:XI AN JIAOTONG UNIV

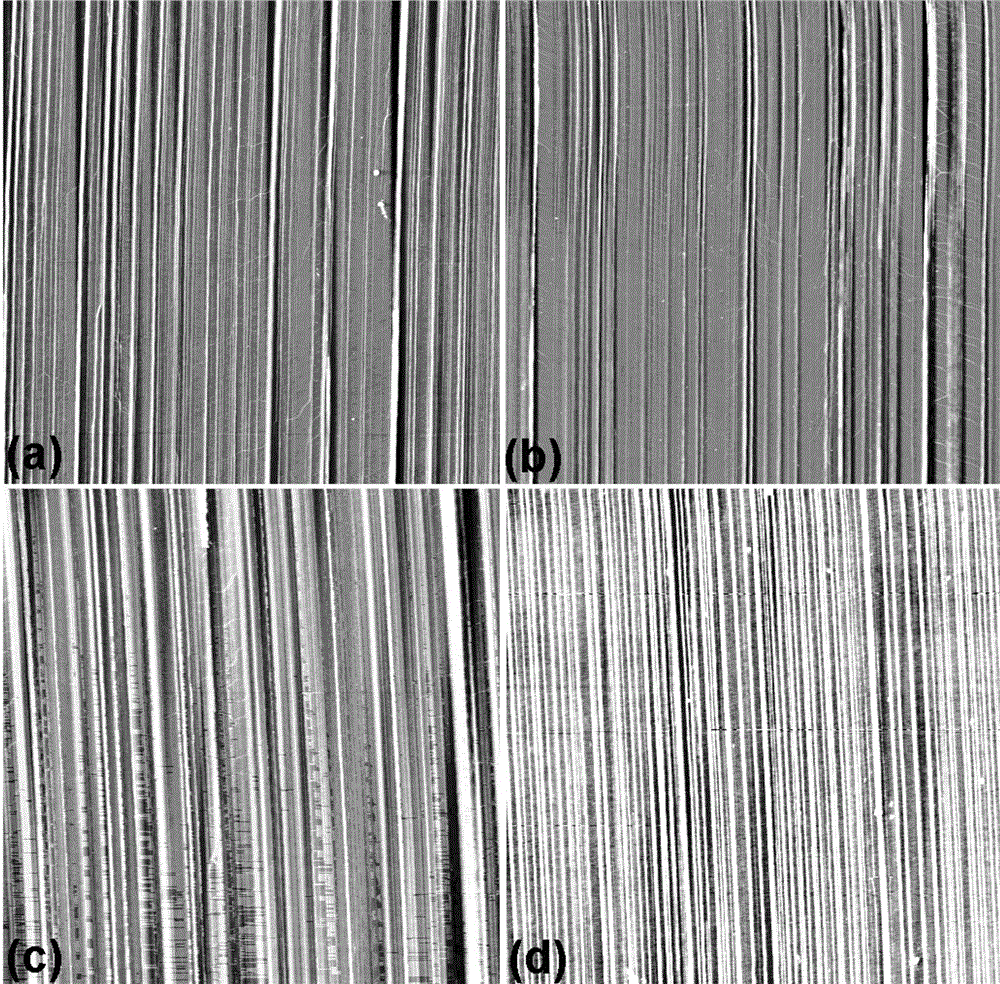

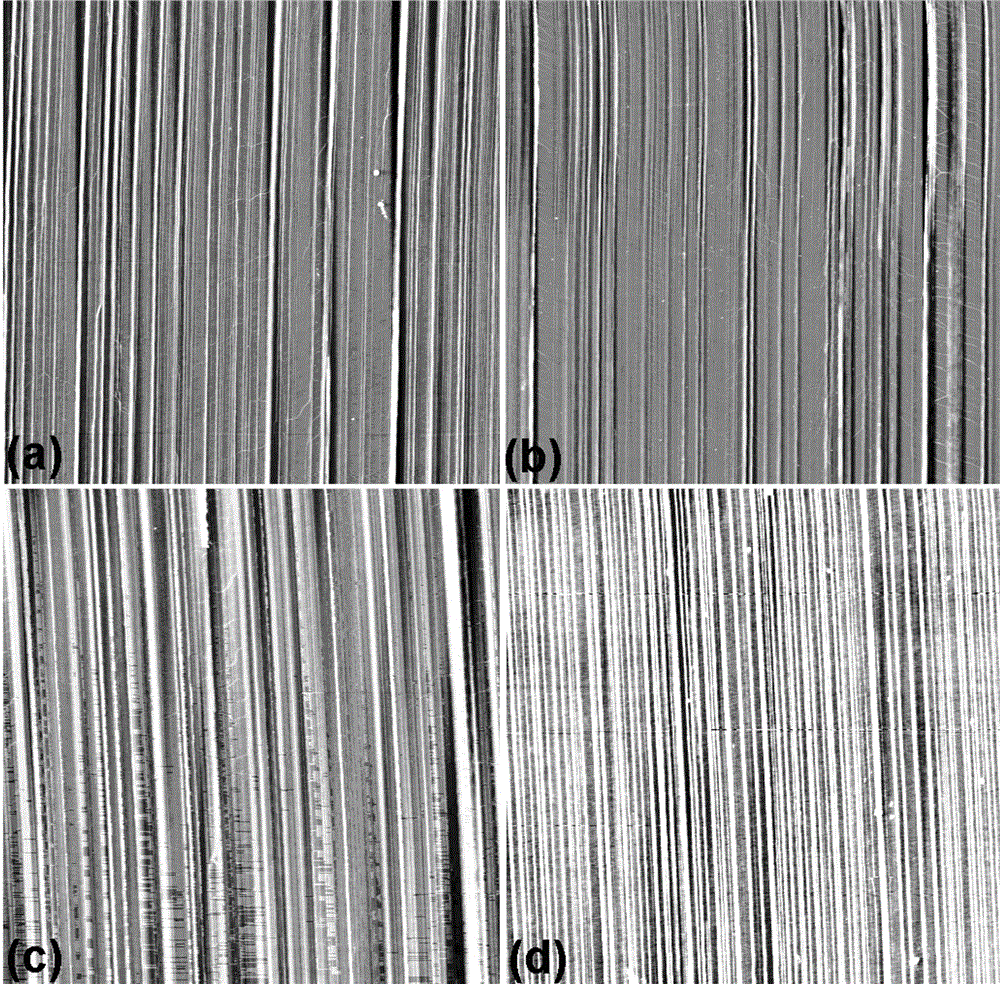

Method for preparing polytetrafluoroethylene ordered template based on temperature-controllable, pressure-controllable and friction film forming device

ActiveCN104875402AEasy to manufactureThickness is easy to controlFlat articlesFerroelectric polymersNumerical control

The invention relates to a method for preparing polytetrafluoroethylene (PTFE) ordered template based on temperature-controllable, pressure-controllable and friction film forming device. The device consists of a numerical control motor, a temperature control module and a pressure control module. Due to the adoption of the device, ordered PTFE templates are prepared on various rigid substrate materials such as glass, ITO and a silicon wafer, and the PTFE templates with different film thicknesses are acquired by controlling the parameters such as temperature, pressure and friction film forming speed; the templates have ordered heights, and can be used for epitaxial growth of various organic semiconductors and ferroelectric polymer films.

Owner:FUDAN UNIV

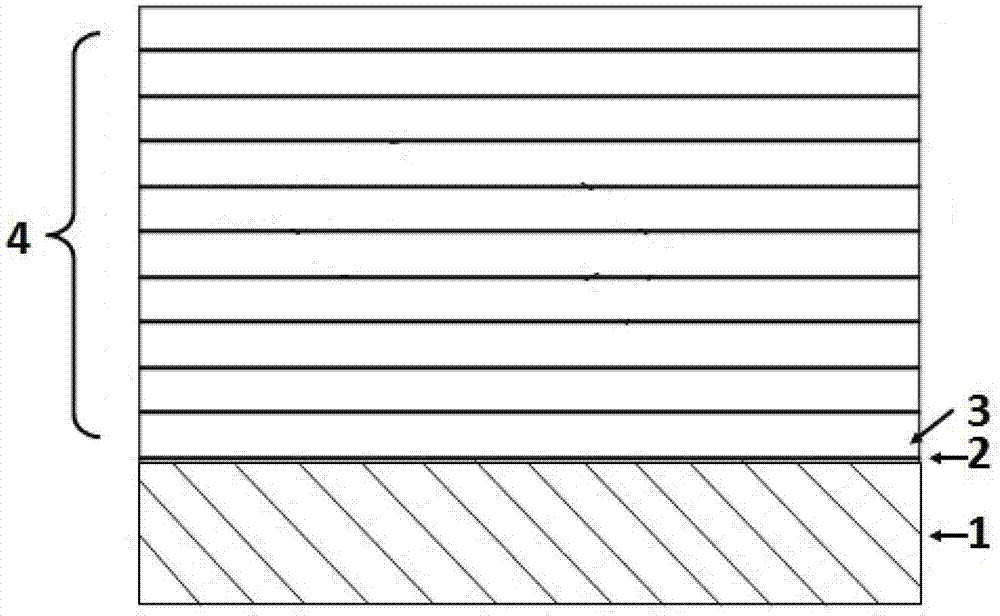

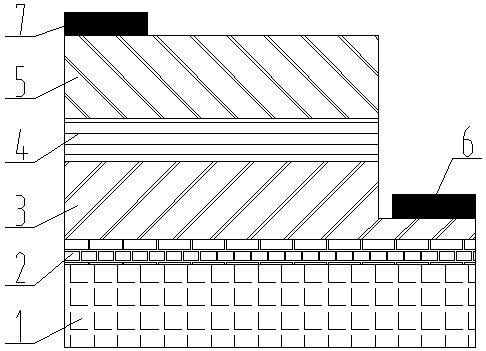

Flexible ferroelectric film containing defect dipole and manufacturing method

PendingCN114665003AMaximum polarizationGuaranteed flexibilityThermoelectric device with dielectric constant thermal changeVacuum evaporation coatingFerroelectric thin filmsThin membrane

The invention discloses a flexible ferroelectric film containing a defect dipole and a manufacturing method. The film mainly comprises a mica substrate, a buffer layer CoFe2O4 film, a bottom electrode layer SrRuO3 film and a ferroelectric functional layer Pb (Zr0. 2Ti0. 8) O3 film, wherein the buffer layer CoFe2O4 film, the bottom electrode layer SrRuO3 film and the ferroelectric functional layer Pb (Zr0. 2Ti0. 8) O3 film sequentially grow on the mica substrate. In the manufacturing method, a pulse laser deposition process is adopted, and volatilization of Pb ions in the Pb (Zr0. 2Ti0. 8) O3 ferroelectric film is controlled by using different process parameters, so that Pb ion vacancies are introduced into the ferroelectric film to be combined with O vacancies to form defect dipoles. A ferroelectric domain overturning process can be effectively regulated and controlled by introducing a defect dipole into the ferroelectric functional layer, so that the change quantity of a polarization state is improved, a giant electrocaloric effect is generated near the room temperature, and the change quantity of polarization intensity before and after an external electric field is applied and removed can reach 50 [mu] C / cm < 2 >; wide application prospects are realized in the field of solid-state refrigeration.

Owner:XIANGTAN UNIV

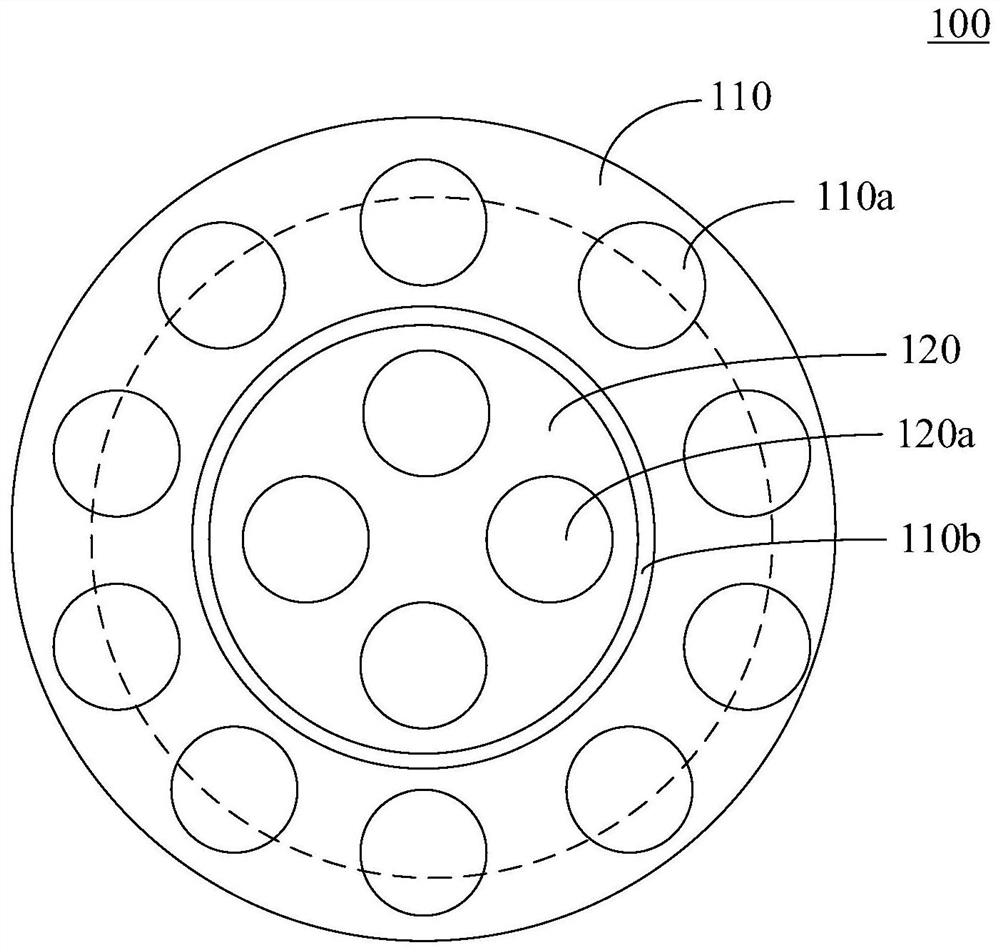

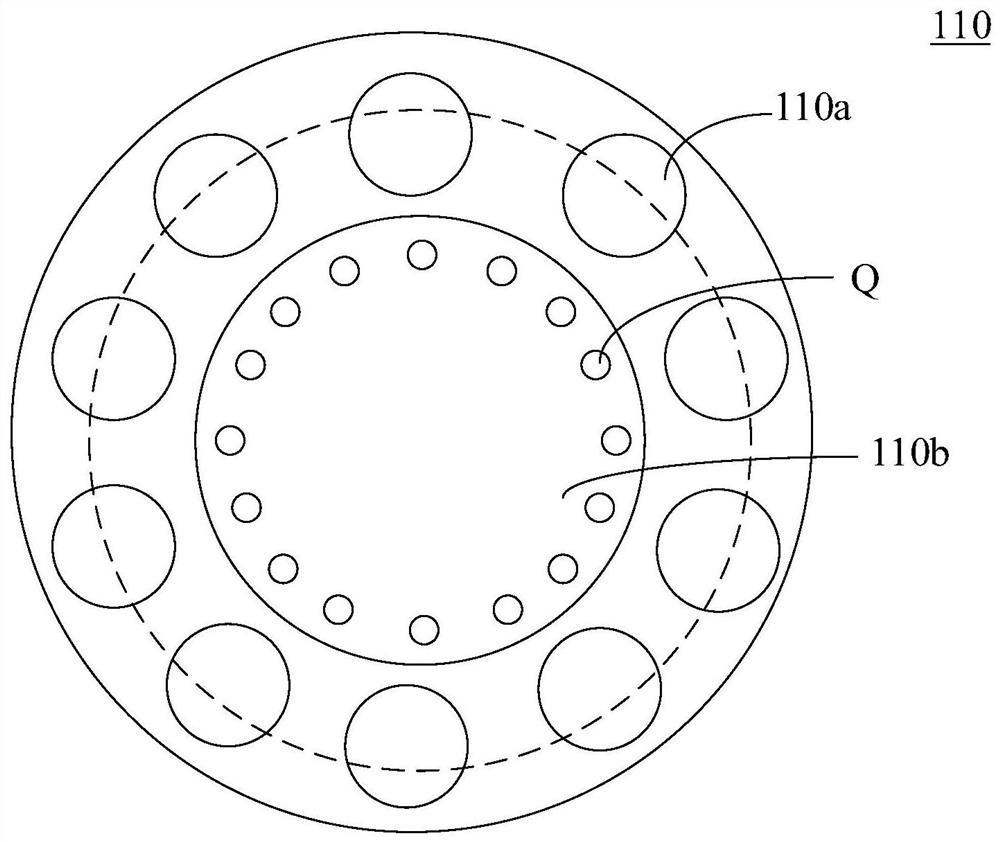

Graphite substrate for improving wavelength uniformity of epitaxial wafer

PendingCN114134563AReduce volumeEvenly distributedFrom chemically reactive gasesCircular discEngineering

The invention provides a graphite substrate for improving the wavelength uniformity of an epitaxial wafer, and belongs to the technical field of semiconductors. The graphite base plate comprises a first base plate, a second base plate and an exhaust device, and the first base plate and the second base plate are both discs; the upper surface of the first substrate is provided with a plurality of circles of first grooves for accommodating substrates, the middle part of the first substrate is provided with a circular pit, and the bottom of the circular pit is provided with a plurality of air holes; the second substrate is coaxially arranged in the circular pit, and the upper surface of the second substrate is provided with a plurality of circles of second grooves for accommodating the substrate; and the exhaust device is configured to provide gas with set flow for the plurality of gas holes in different working states, so that the second substrate is suspended in the circular pit and is separated from the first substrate, and the second substrate and the first substrate rotate in the same direction or in the opposite direction at a set rotating speed. The epitaxial wafer grows on the graphite substrate provided by the invention, so that the wavelength uniformity of the epitaxial wafer growing in each groove of the graphite substrate can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

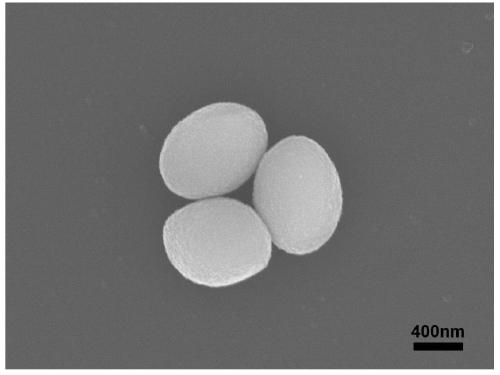

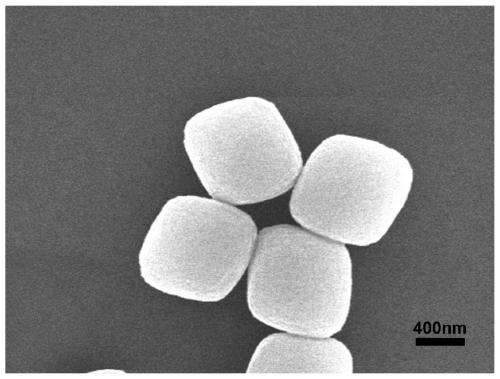

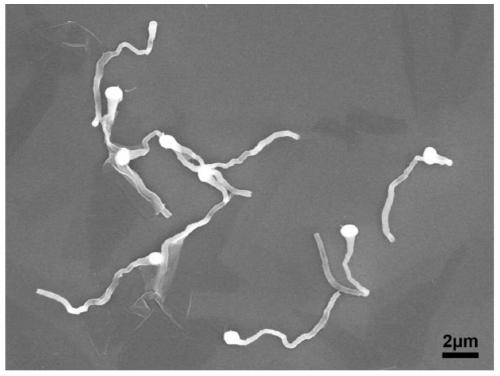

Silicon dioxide coated ferric oxide composite materials and preparation method thereof

InactiveCN111204816ALow costEasy to makeSilicaChemical industryTetraethyl orthosilicateCitrate sodium

The invention discloses silicon dioxide coated ferric oxide composite materials and a preparation method thereof. The preparation method comprises the following steps: adding Fe2O3 colloidal particles, ethanol, water, a sodium citrate solution, ammonia water and tetraethyl orthosilicate into a solution containing polyvinylpyrrolidone pentanol, standing in an environment of 30-60 DEG C, washing anddrying. According to the preparation method, a series of composite materials with various morphologies can be simply, effectively and stably prepared by changing the reagent addition amount and reaction conditions, so that an idea is provided for morphology design research of hybrid particles, and possibility is provided for exploring new nano particles and nano structures; the inherent defects of Fe2O3 magnetic particles are modified, and a silicon dioxide rod structure which is low in cost and wide in application is introduced, so that the composite structure has certain potential application value in the fields of photon / plasma devices, nano-electronics, high-efficiency conversion / energy storage, micro diagnosis systems, drug / gene transfer, hierarchical structure catalysts and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing beta-FeSi2 semiconductor film by femtosecond pulsed laser

InactiveCN1312734CReduce thermal effectsAvoid it happening againVacuum evaporation coatingSemiconductor/solid-state device manufacturingFemtosecond pulsed laserPeak value

The invention provides a method for preparing belta-FeSi2 semiconductor film by flysecond pulse laser, vacuumizing pulse-laser film depositing device to an air pressure of 10<-5> to 10<-3>, using FeSi2 alloy as target material, placing the target material and a substrate in the pulse-laser film depositing device, where the target material and the substrate, mutually parallel, are 20-50mm apart from each other, heating the substrate to 20 DEG C to 700 DEG C and then keeping warm, irradiating the target material by laser beam with a peak power density of 10<12> to 10<15> W / sq cm<2>, which makes the ejective plasma is deposited on the substrate and epitaxially grows along the crystal face of the substrate to form the film. The invention is suitable for different substrates to synthesize a large-area, uniform, monophasic beta- FeSi2 semiconductor film at lower temperature in a short time, and the prepared film is provided with better light emitting and photovoltaic properties, which solves the technical difficulty in being a high quality beta-FeSi2 film needed by infrared light emitting diode and solar battery.

Owner:HUAZHONG UNIV OF SCI & TECH

A method for preparing polytetrafluoroethylene ordered templates based on a temperature-controllable, pressure-controlled, and friction film-forming device

ActiveCN104875402BEasy to manufactureThickness is easy to controlFlat articlesTemperature controlNumerical control

Owner:FUDAN UNIV

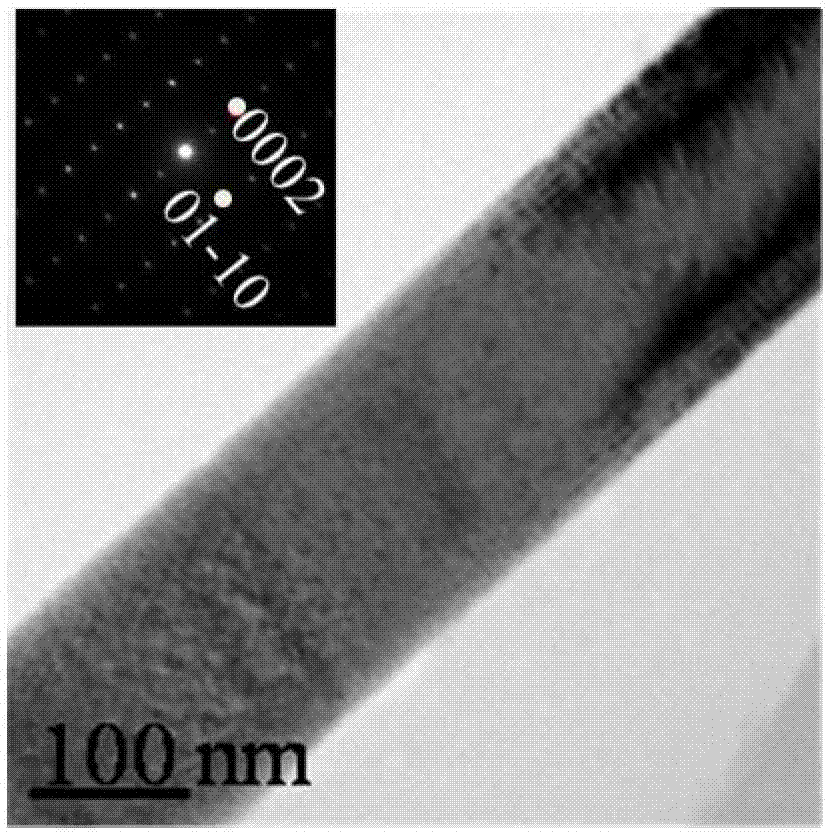

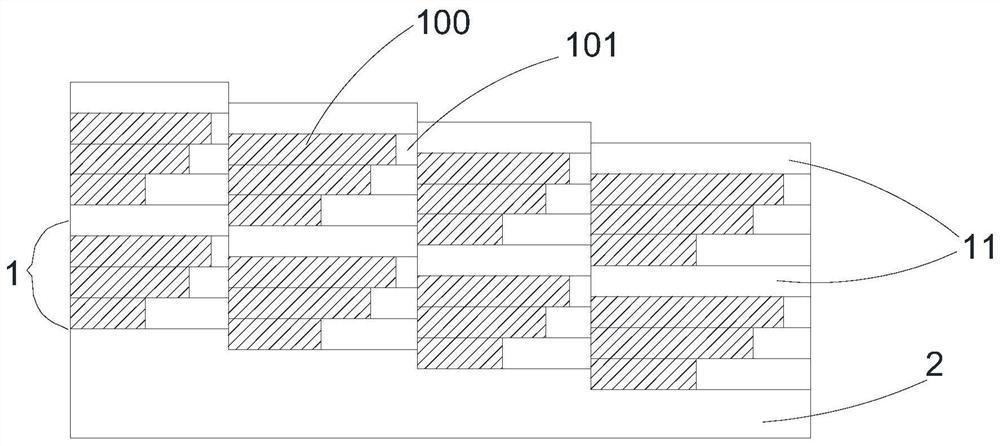

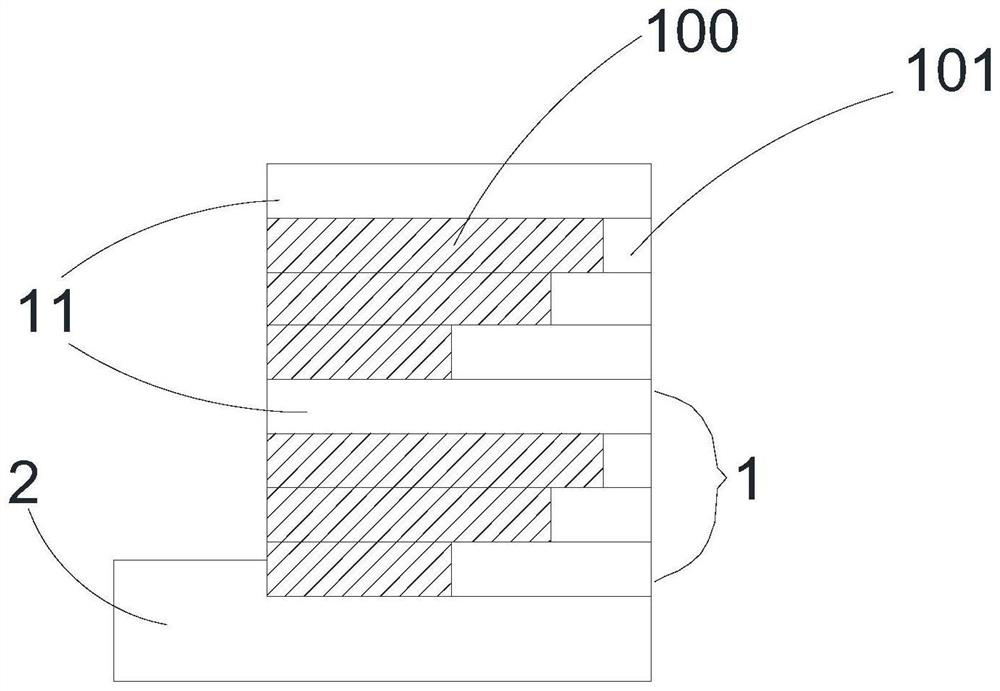

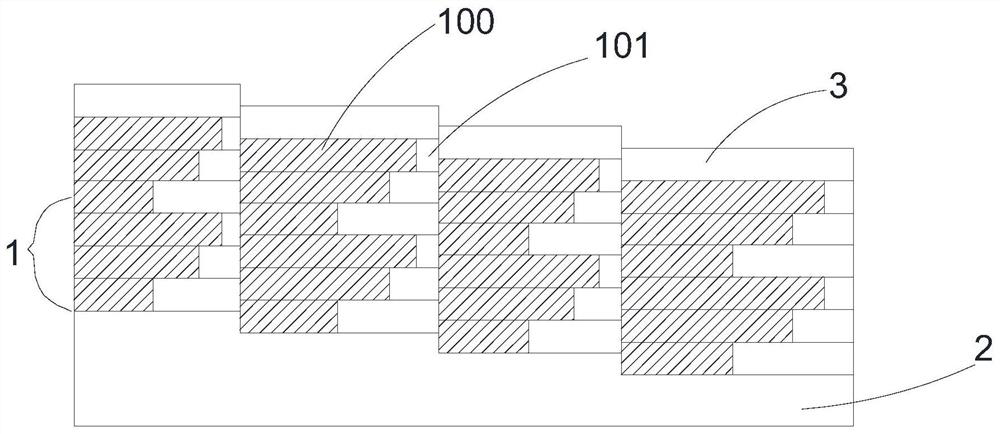

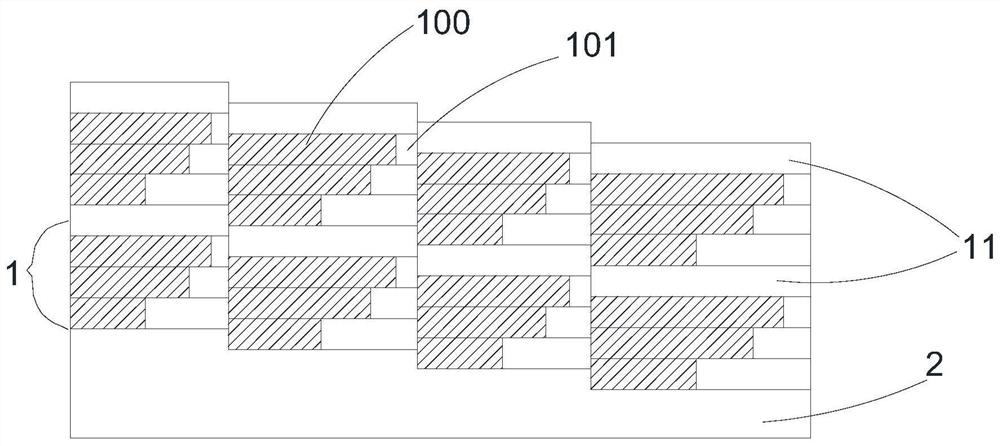

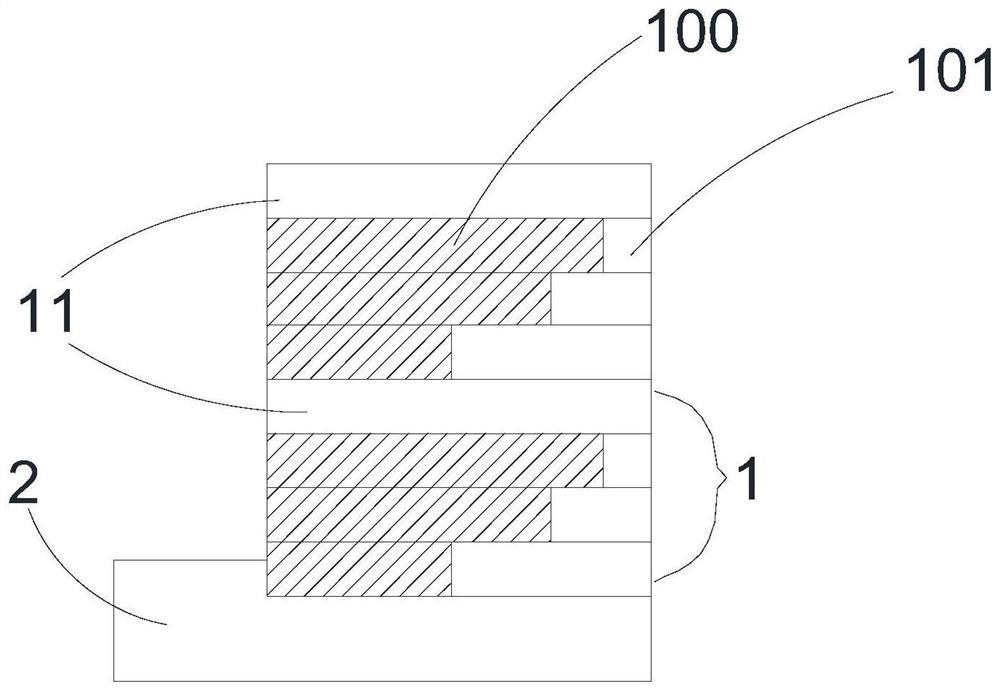

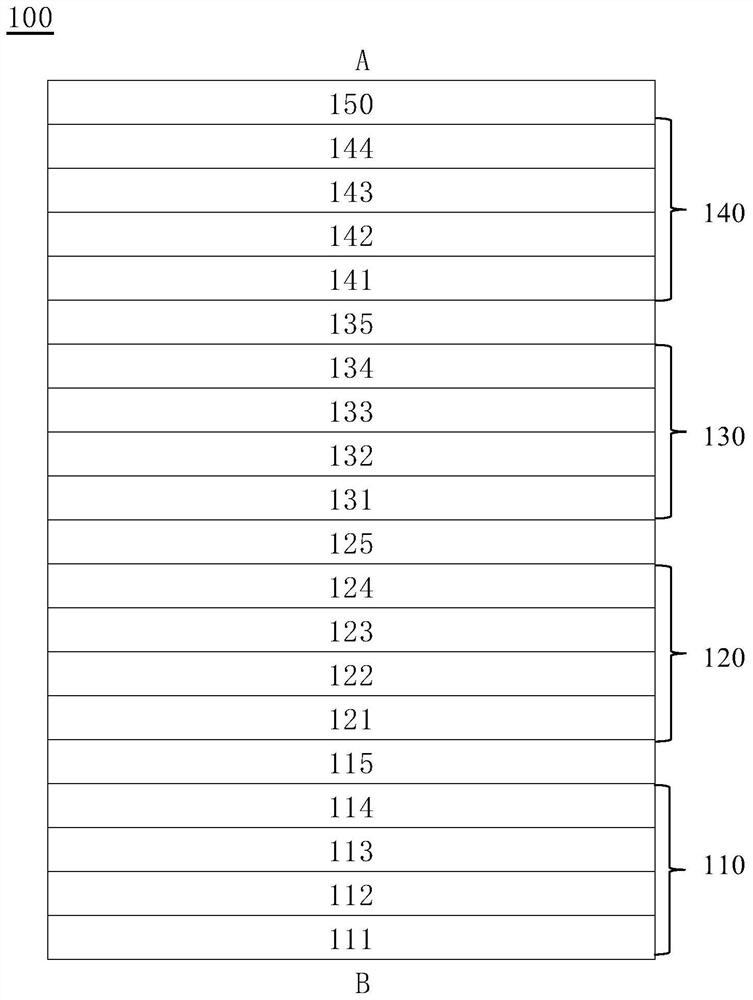

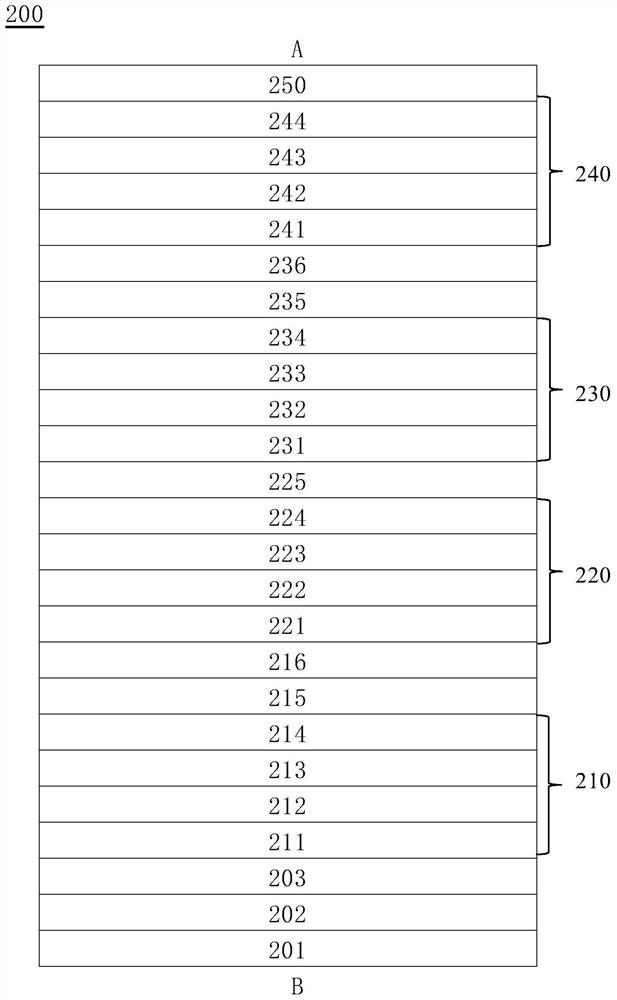

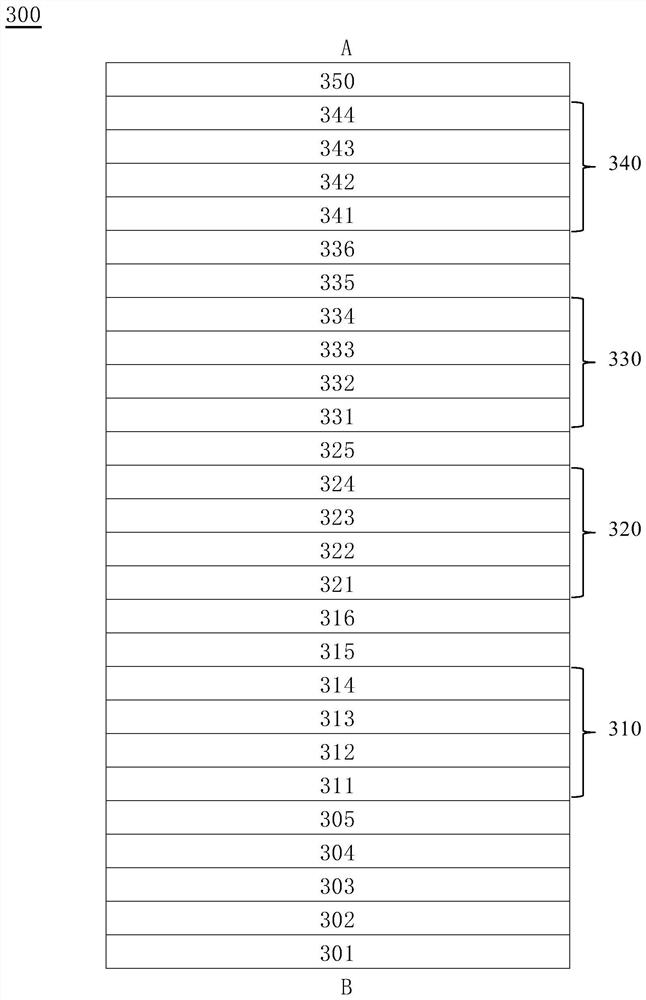

inas/gasb buffer layer, silicon-based antimonide semiconductor material and its preparation method and components

ActiveCN112688157BReduce lattice mismatchAchieve epitaxial growthSemiconductor laser structural detailsSemiconductor materialsLattice mismatch

The application provides an InAs / GaSb buffer layer, a silicon-based antimonide semiconductor material, a preparation method and components thereof. The InAs / GaSb buffer layer includes one or more basic buffer units, each basic buffer unit includes one or more basic unit layers, and each basic unit layer includes one or more sets of alternately arranged GaSb parts and InAs parts. The silicon-based antimonide semiconductor material includes a silicon substrate and a pure gallium antimony layer, and an InAs / GaSb buffer layer is arranged between the silicon substrate and the pure gallium antimony layer. The preparation method includes: growing GaSb part and InAs part on the silicon substrate to obtain multiple basic unit layers; and then growing pure gallium antimony layer. Components, whose raw materials include InAs / GaSb buffer layer or silicon-based antimonide semiconductor material. The InAs / GaSb buffer layer provided by the application can reduce the lattice mismatch between silicon and GaSb, thereby realizing high-quality antimonide epitaxial growth.

Owner:湖南科莱特光电有限公司

InAs/GaSb buffer layer, silicon-based antimonide semiconductor material, preparation method of silicon-based antimonide semiconductor material, and component

ActiveCN112688157AReduce lattice mismatchAchieve epitaxial growthSemiconductor laser structural detailsSemiconductor materialsLattice mismatch

The invention provides an InAs / GaSb buffer layer, a silicon-based antimonide semiconductor material, a preparation method of the silicon-based antimonide semiconductor material, and a component. The InAs / GaSb buffer layer comprises one or more basic buffer units, wherein each basic buffer unit comprises one or more basic unit layers, and each basic unit layer comprises one or more groups of GaSb parts and InAs parts which are alternately arranged. The silicon-based antimonide semiconductor material comprises a silicon substrate and a pure gallium antimony layer, where the InAs / GaSb buffer layer is arranged between the silicon substrate and the pure gallium antimony layer. The preparation method comprises the following steps: growing the GaSb parts and the InAs parts on the silicon substrate to obtain a plurality of the basic unit layers; and then growing the pure gallium antimony layer. Raw materials of the component comprise the InAs / GaSb buffer layer or the silicon-based antimonide semiconductor material. According to the InAs / GaSb buffer layer provided by the invention, lattice mismatch between silicon and GaSb can be reduced, so high-quality antimonide epitaxial growth is realized.

Owner:湖南科莱特光电有限公司

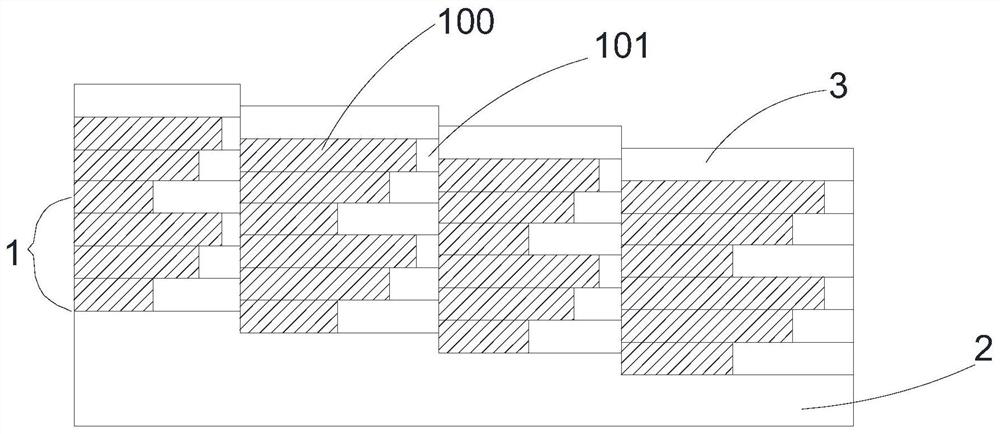

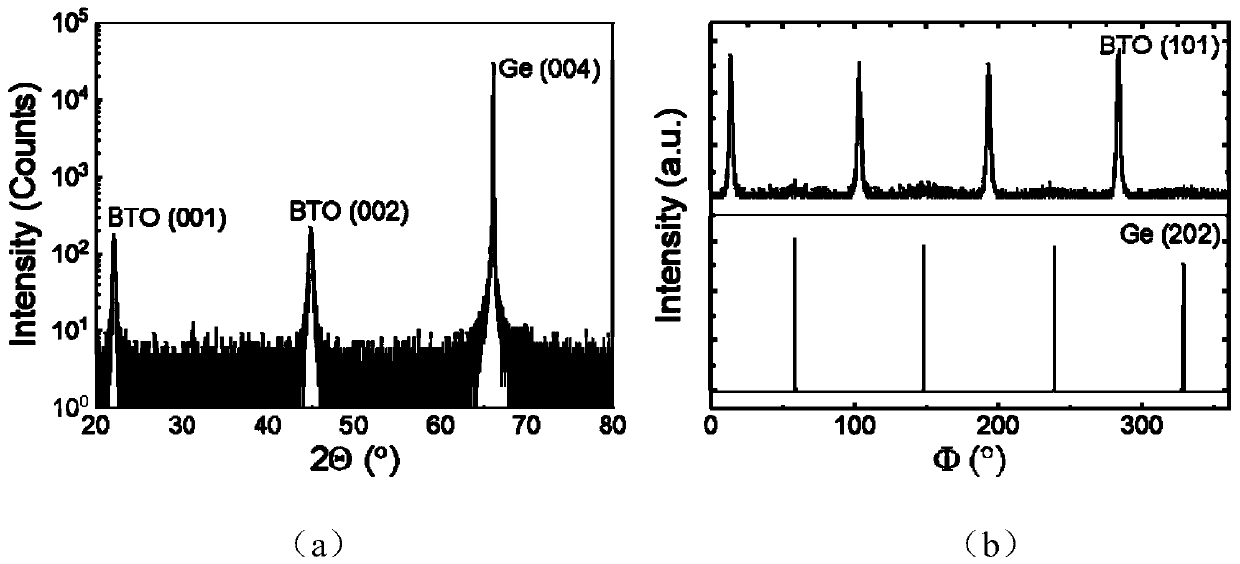

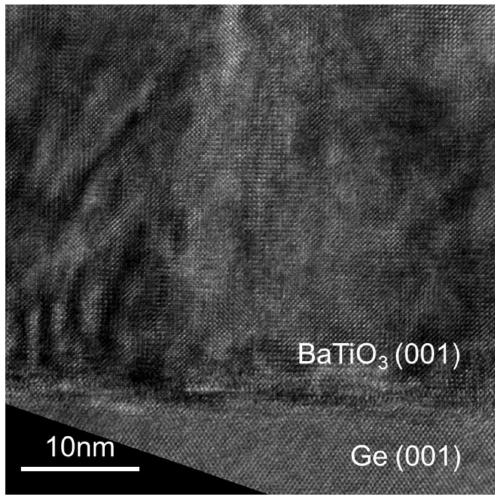

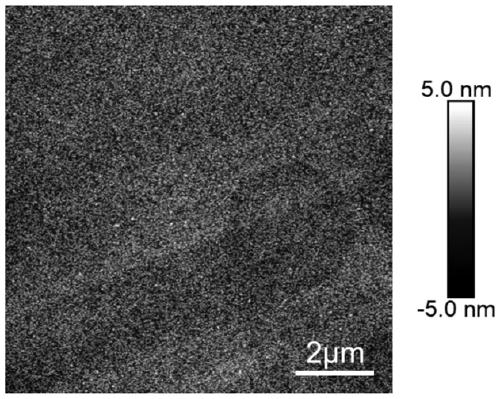

Method for epitaxial growth of monocrystalline barium titanate film on germanium substrate

ActiveCN109898138AEnables direct epitaxial growthAchieve epitaxial growthPolycrystalline material growthFrom condensed vaporsBarium titanateRoom temperature

The invention discloses a method for epitaxial growth of a monocrystalline barium titanate film on a germanium substrate, and belongs to the field of epitaxial preparation of monocrystalline films. The method comprises the following steps: ultrasonically cleaning a (001)-oriented Ge substrate, filling the chamber of a pulsed laser deposition system with the (001)-oriented Ge substrate, evacuatingthe chamber to the vacuum of the background, heating the substrate to 800 DEG C, maintaining a certain pressure and a certain temperature, annealing the substrate to reconstruct the surface in order to crystallize the film in the subsequent film growth process, adjusting the pressure and the temperature, controlling the temperature to be 500-800 DEG C, turning on a laser to grow a film, stopping the growth after the film grows to a certain degree, naturally cooling the substrate, introducing air into the chamber after the obtained sample is cooled to room temperature, opening the chamber, andtaking out the sample to complete growth. The method simply and cheaply realizes the epitaxial growth of the barium titanate film on Ge, and the obtained film has the characteristics of clear interface, monocrystalline epitaxial growth and smooth film surface.

Owner:XI AN JIAOTONG UNIV

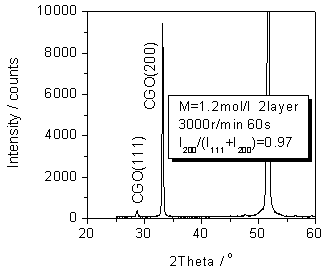

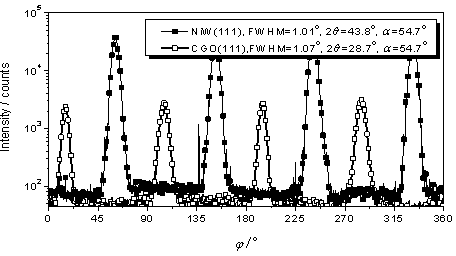

Cubic texture Ce1-sigmaGdsigmaO2 film on NiW alloy substrate and preparation method thereof

InactiveCN103236319AReduce crackingMerit orientation is goodSuperconductors/hyperconductorsSuperconductor devicesYttrium barium copper oxideAlloy substrate

The invention belongs to the technical field of the superconducting material, and particularly relates to a cubic texture Ce1-sigmaGdsigmaO2 film on a NiW alloy substrate and a preparation method thereof. The Ce1-sigmaGdsigmaO2 film is grown on the Ni-5%W alloy substrate of the cubic texture, has the thickness of 200-500nm and has a (200) preferred orientation and face-centred cubic crystal structure, and the texture is {100}(001), wherein sigma is more than or equal to 0.1 and less than or equal to 0.2. The preparation method comprises the following steps of: dissolving (CH3CO2)3Ce(III) and GdN3O9 into C2H5OOH to obtain Ce1-sigmaGdsigmaO2 precursor liquid, coating the precursor liquid onto the Ni-5%W alloy substrate in a spinning mode, and sending the spin coating substrate into a furnace tube for thermal treatment. The CGO (Ce1-sigmaGdsigmaO2) buffer layer disclosed by the invention has the face-centred cubic crystal structure, the a and b axis lattice constants of YBCO (yttrium barium copper oxide) are almost same with the semi-diagonal length of the CGO(001) surface; after a YBCO(001) surface and after the CGO(001) surface are relatively rotated for 45 degrees in an in-plane mode, good lattice match can be formed; and the epitaxial growth of a YBCO superconducting film can be realized, thereby providing a great significance for improving the superconducting performance of the superconducting material prepared with a chemical method.

Owner:NORTHEASTERN UNIV

A wide temperature thin film energy storage capacitor modified by rare earth elements and its preparation method

ActiveCN109545548BExcellent epitaxyImprove energy storage characteristicsThin/thick film capacitorFixed capacitor dielectricRare-earth elementRadio frequency magnetron sputtering

The invention relates to the field of energy storage thin film materials, and discloses a rare earth element modified wide temperature film energy-storage capacitor and a preparation method thereof. The preparation method is characterized by adopting an ultrahigh vacuum radio frequency magnetron sputtering technology, in the high temperature and high oxygen pressure environment, by performing bombardment on a target material through a plasma to enable the particles of the target material to be deposited on a substrate, realizing epitaxial growth, and then obtaining a BHT epitaxial film. Due tocharacteristics of the radio frequency magnetron sputtering technology, the growing speed of the film is slower relatively, so that the film prepared by the preparation method is uniform in the crystal grain size, is flat in the surface of the film, has high degree of crystallization, and further enhances the energy storage feature of the ceramic target material taken as the BT-base energy storage material.

Owner:XI AN JIAOTONG UNIV

Nano doping structure and preparation method thereof

ActiveCN102953048BGood extension relationshipPrecise thickness controlMaterial nanotechnologyChemical vapor deposition coatingDopantReaction temperature

The invention provides a nano doping structure and a preparation method thereof. The preparation method comprises the following steps of: 1) placing a nano material into a reaction chamber of an atom layer depositing system; 2) utilizing an atom layer depositing method to deposit a dopant material with the thickness of 1-2 cycles; 3) depositing a base material of a nano material with the thickness of X cycles; and 4) alternatively and circularly depositing dopants and substrate material layers obtained in the steps 2) and 3) with the thickness of Y cycles, wherein the selection of the X is determined according to an actual doping ratio; when the X is smaller, a doping ratio is larger; and the selection of the Y is determined according to the thickness of an actually-needed doping layer, and the doping layer is thicker when the Y is greater. According to the nano doping structure and the preparation method thereof, an in-situ atom layer depositing technology is adopted, a process is simple and is easy to realize, a reaction temperature is low and an applicable material range is wide.

Owner:青岛艾斯达特新材料科技有限公司

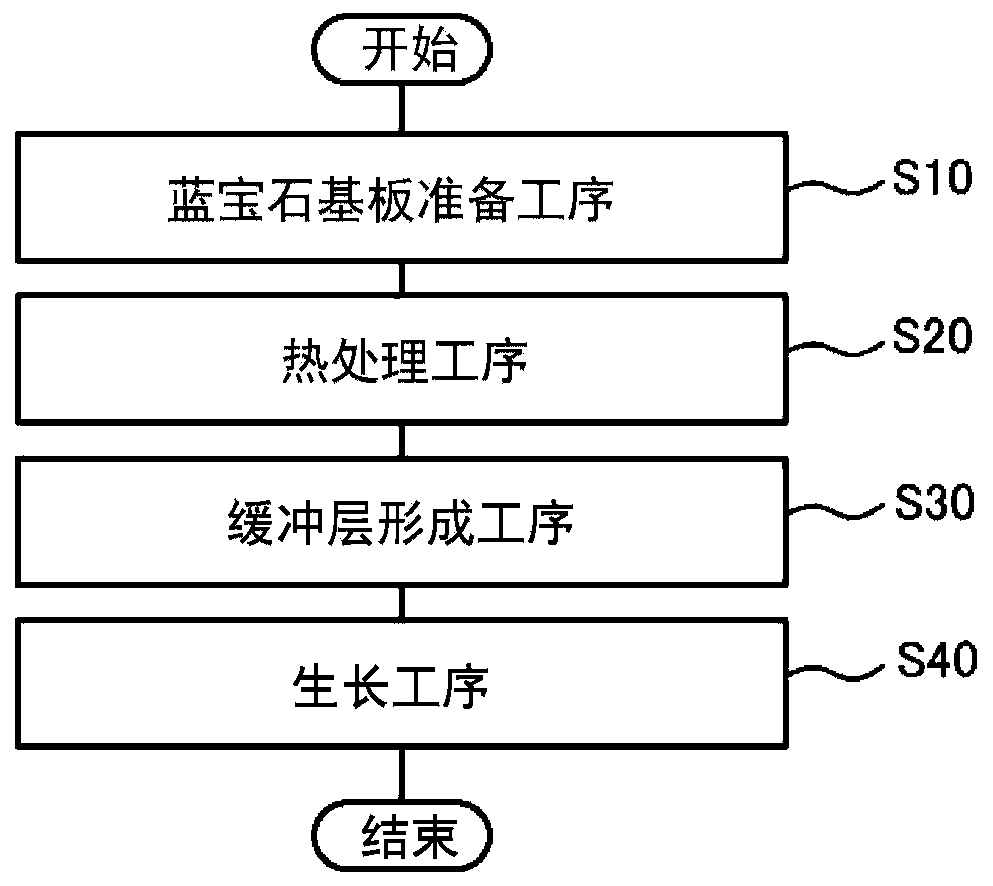

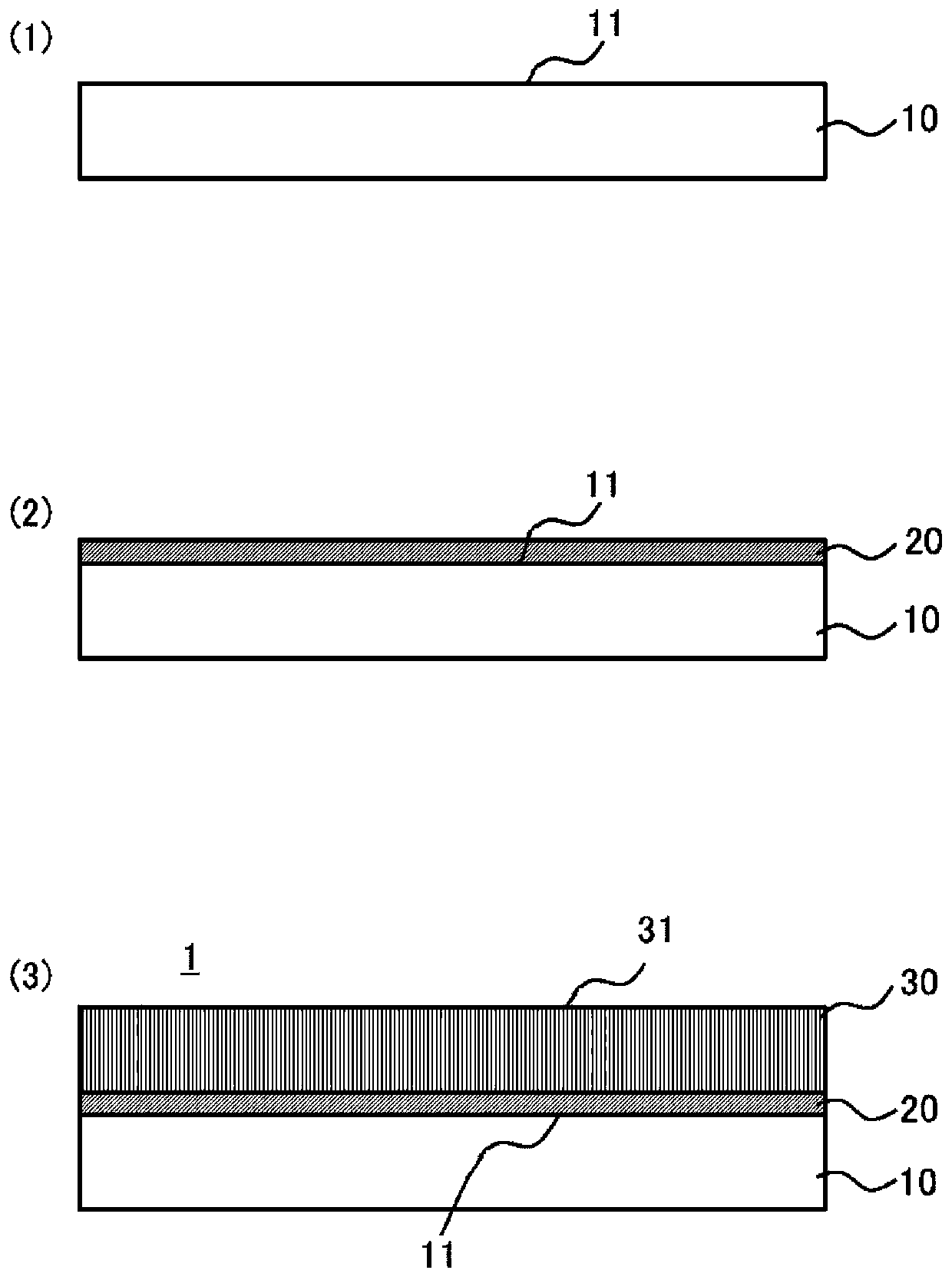

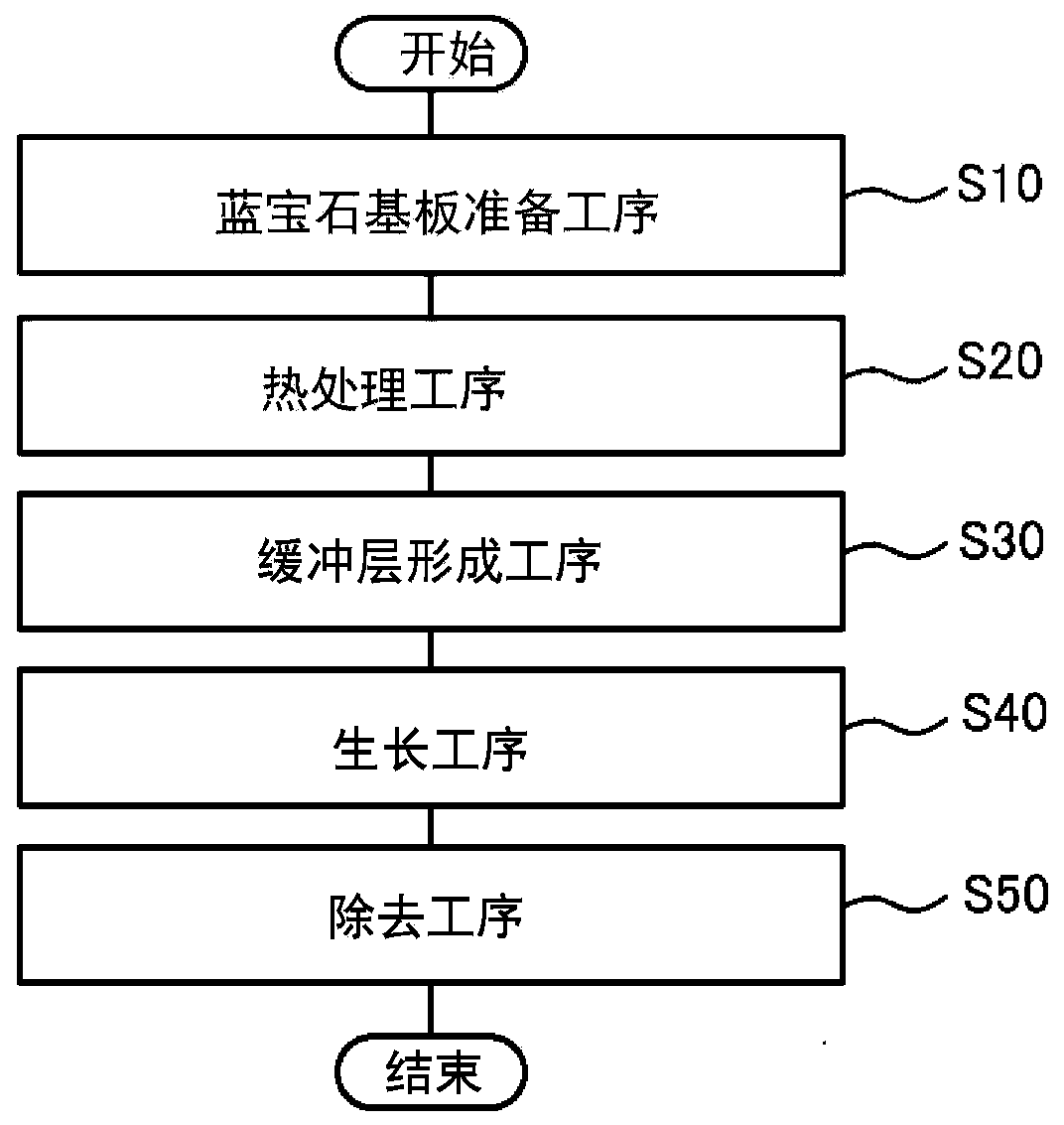

Group iii-nitride semiconductor substrate, and method for manufacturing group iii-nitride semiconductor substrate

PendingCN110168701AAchieve epitaxial growthPolycrystalline material growthSemiconductor/solid-state device manufacturingCrystallographyNitride semiconductors

Provided is a method for manufacturing a group III-nitride semiconductor substrate, the method comprising: a sapphire substrate preparation step S10 of preparing a sapphire substrate that has, as a principal surface, a {10-10} plane or a surface tilted a predetermined angle in a predetermined direction from the {10-10} plane; a heat treatment step S20 of heat treating the sapphire substrate whileperforming or not performing a nitriding treatment; a buffer layer forming step S30 of forming a buffer layer on the principal surface of the sapphire substrate after the heat treatment; and a growingstep S40 of forming, on the buffer layer, a group III-nitride semiconductor layer having a growth surface oriented in a predetermined plane direction, wherein at least one among the plane direction of the principal surface of the sapphire substrate, whether or not to perform the nitriding treatment during the heat treatment, and the growth temperature in the buffer layer forming step is adjustedso that the growth surface of the group III-nitride semiconductor layer is oriented in the predetermined plane direction.

Owner:FURUKAWA COMPANY

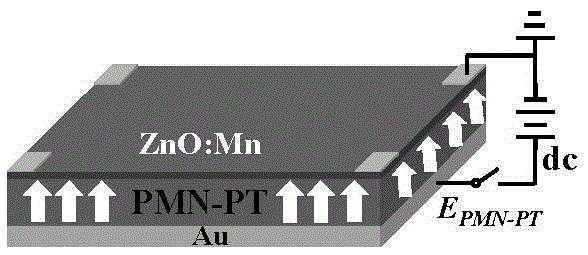

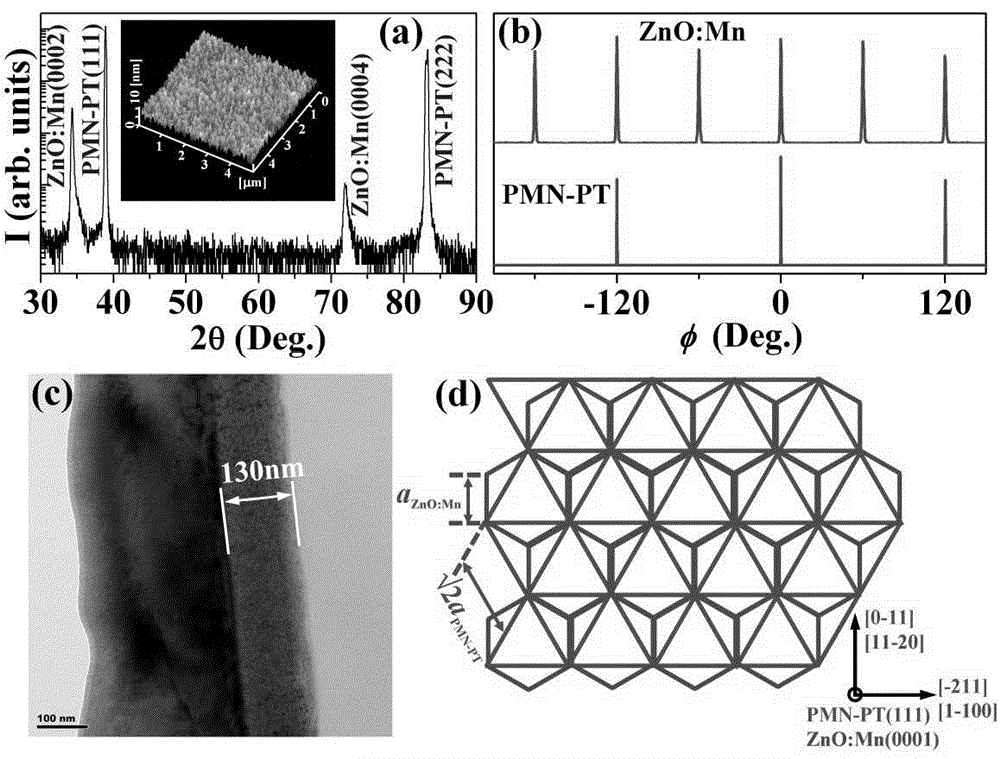

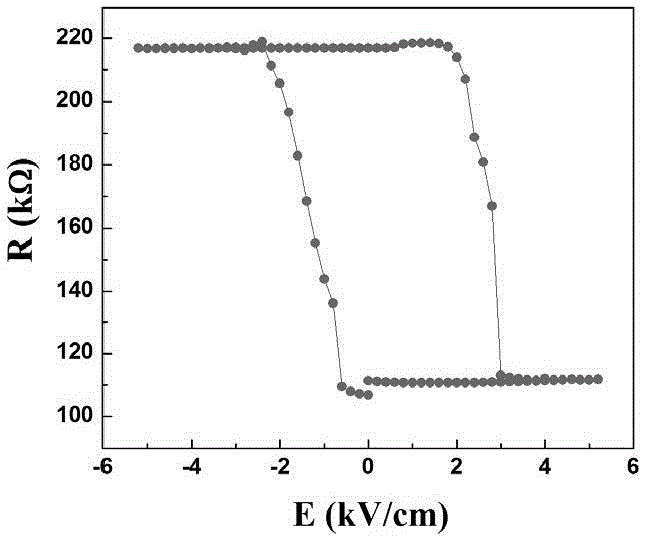

Preparation method of ZnO-based dilute magnetic semiconductor film and its in-situ regulation method of charge concentration

ActiveCN104480427BAchieve epitaxial growthVacuum evaporation coatingSemiconductor/solid-state device manufacturingMagnetic semiconductorSingle crystal substrate

The invention relates to a preparation method of a zinc oxide based diluted magnetic semiconductor thin film and an in-situ regulation and control method of charge concentration of the zinc oxide based diluted magnetic semiconductor thin film. A composition chemical formula of the zinc oxide based diluted magnetic semiconductor thin film is Zn1-xMnxO, wherein x is more than or equal to 0 and is less than or equal to 0.75. The preparation method comprises the following step: by taking a Zn1-xMnxO ceramic block as a target material, depositing Zn1-xMnxO on a ferroelectric single crystal substrate by adopting a pulsed laser deposition technique to obtain the zinc oxide based diluted magnetic semiconductor thin film.

Owner:江苏先进无机材料研究院

MoS2-based thin-layer ultraviolet light-emitting diode and manufacturing method thereof

InactiveCN111146318AReduced crystal qualityImprove uniformityMaterial nanotechnologySemiconductor devicesQuantum wellUltraviolet lights

The invention provides a MoS2-based thin-layer ultraviolet light-emitting diode and a preparation method thereof. The MoS2-based thin-layer ultraviolet light-emitting diode comprises a substrate, an MoS2 layer, an n-type gradient Al component AlGaN layer, an AlGaN quantum well layer, a p-type gradient Al component AlGaN layer and a p electrode which are sequentially arranged from bottom to top; ann electrode is arranged on the lateral upper portion of the n-type gradient Al component AlGaN layer, and the MoS2 layer is made of a multilayer tiled MoS2 material. According to the invention, no dangling bond exists on the heteroepitaxy surface of MoS2, and the crystal quality is high. The epitaxial mode of the invention is Van der Waals epitaxy, and epitaxial growth can be realized on varioussubstrates. The MoS2-based thin-layer ultraviolet light-emitting diode is smaller in overall thickness and wide in application field.

Owner:江苏晶曌半导体有限公司

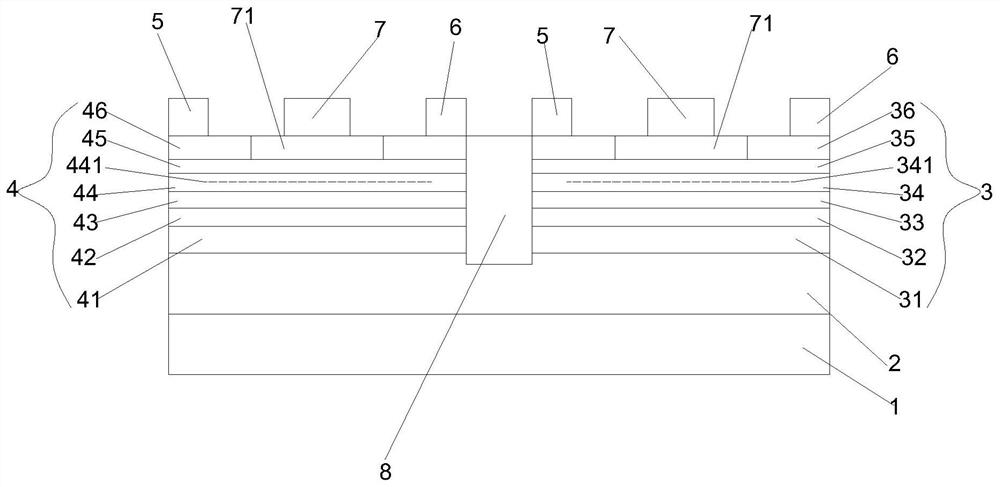

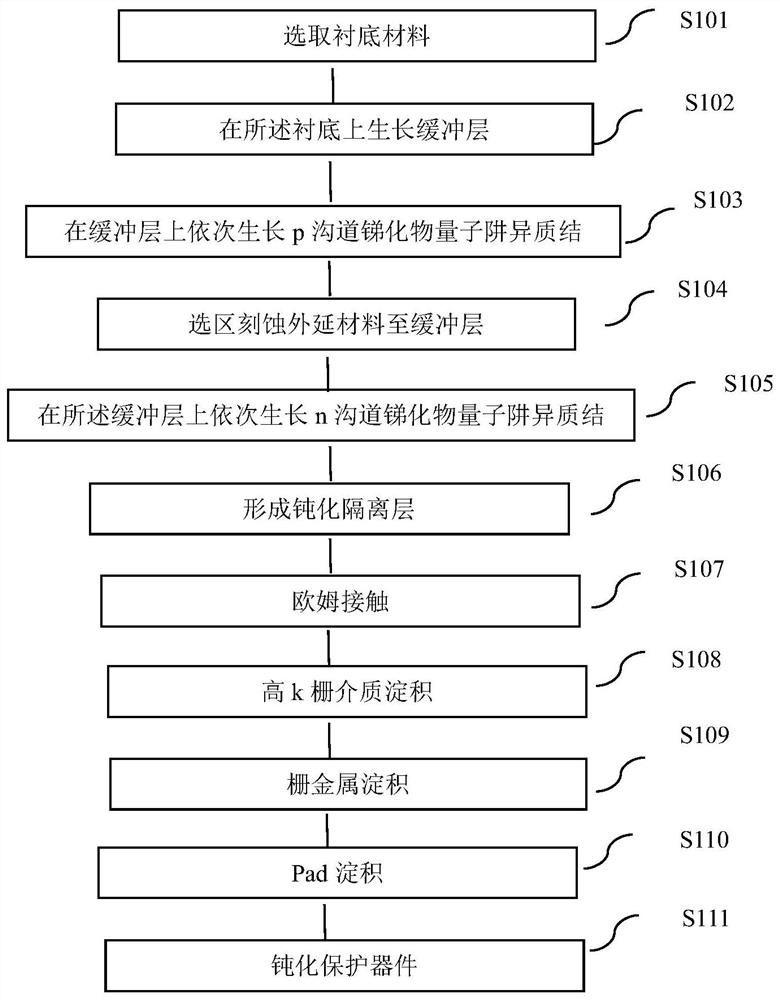

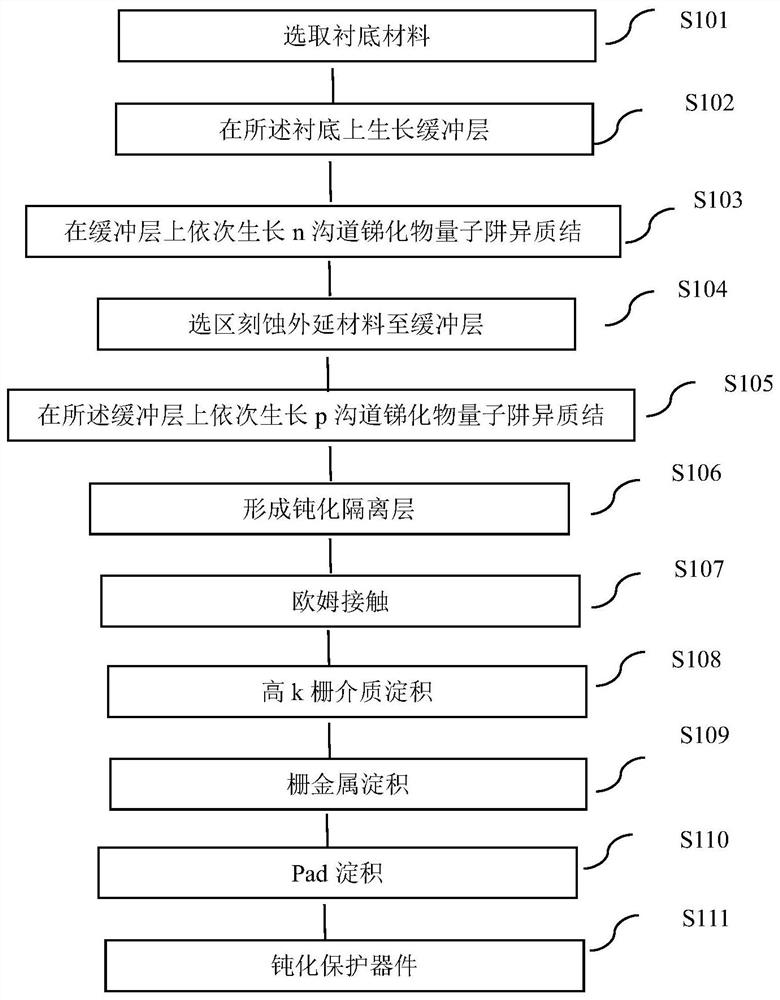

Structure of antimonide quantum well CMOS device and preparation method thereof

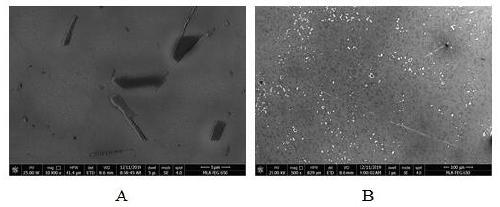

PendingCN113193041AImprove performanceReduce dislocation densityTransistorSolid-state devicesGate dielectricLattice mismatch

The invention discloses a structure of an antimonide quantum well CMOS device and a preparation method thereof, and belongs to the technical field of microelectronics. The device structure comprises a substrate; a buffer layer arranged on the substrate; a p-channel antimonide quantum well layer and an n-channel antimonide quantum well layer which are relatively independently arranged on the buffer layer; wherein a passivation isolation layer is arranged between the p-channel antimonide quantum well layer and the n-channel antimonide quantum well layer. According to the antimonide quantum well structure provided by the invention, on one hand, the dislocation density caused by lattice mismatch can be reduced through component regulation and control, and on the other hand, the channel and the high-k gate dielectric are effectively isolated through the barrier layer, and a two-dimensional electron / hole gas is formed on the surface of the channel, so that the mobility is improved, and the performance of a device is improved. The invention further provides the preparation method of the antimonide quantum well CMOS device, and epitaxial growth of n channel and p channel materials of the same system is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

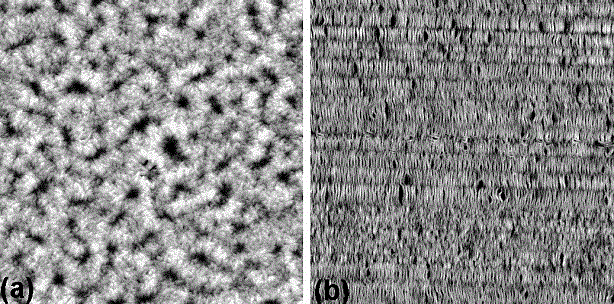

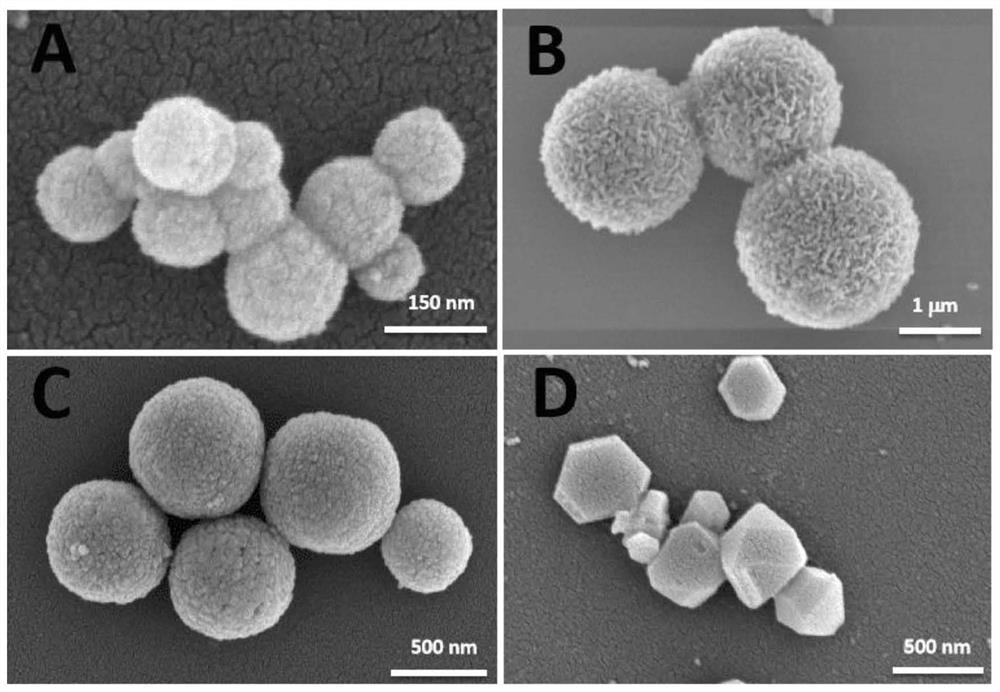

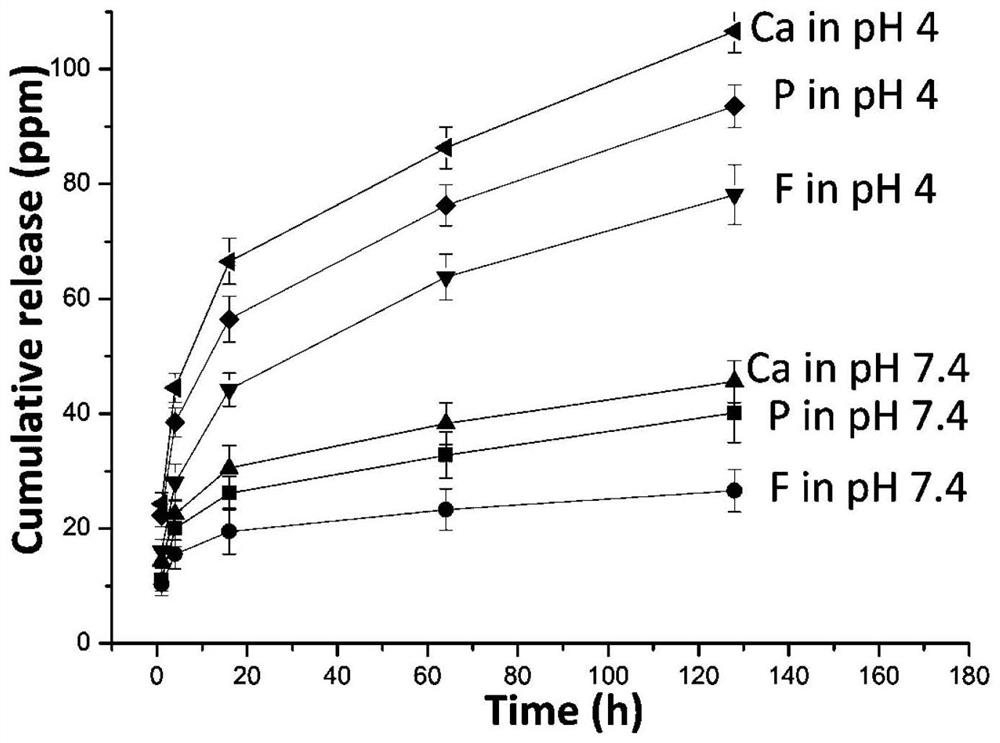

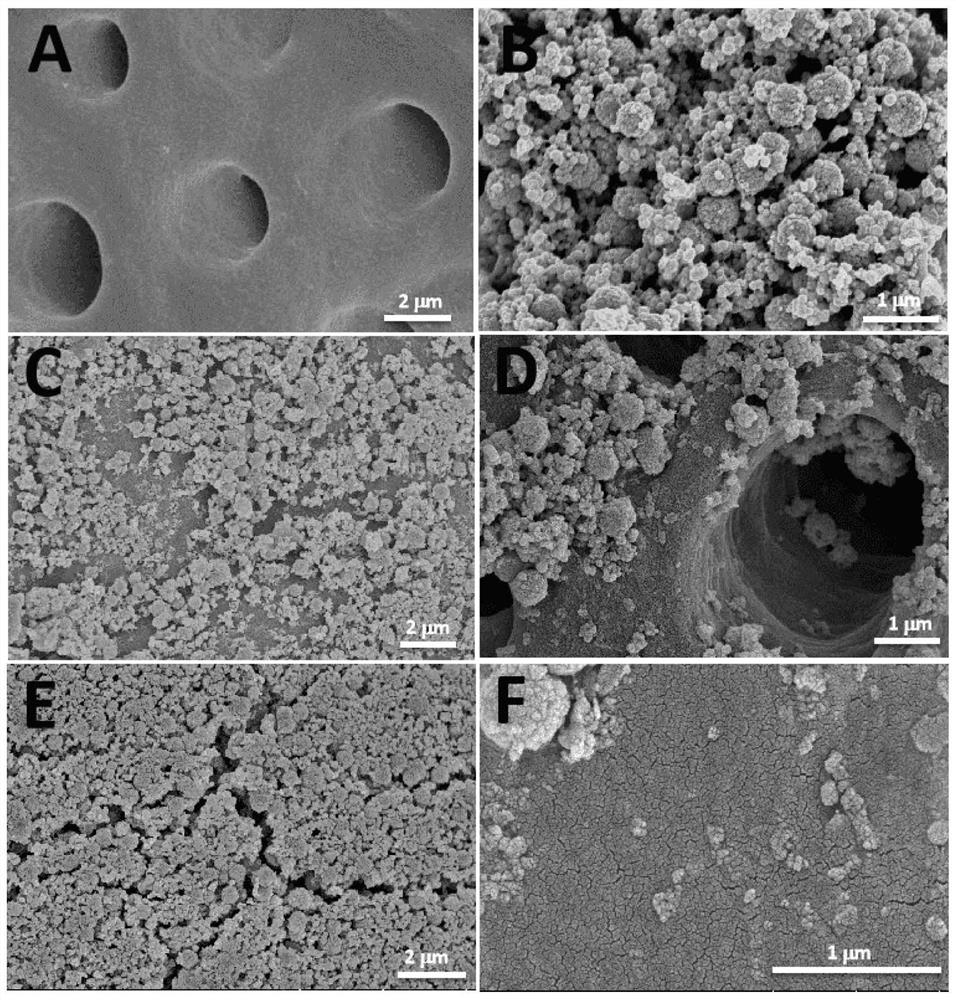

Composite micro-nano particle formula and application thereof

InactiveCN111714385AAchieve epitaxial growthPromote remineralizationCosmetic preparationsToilet preparationsEnamel mineralizationMicrosphere

The invention provides a composite micro-nano particle formula applied to the fields of dental restoration and toothpaste formulas. A composite micro-nano particle material consists of multiple particles, including calcium phosphate nanospheres (nano-CaP), calcium phosphate microspheres (micro-CaP), calcium fluoride microspheres (CaF2) and calcium hydroxide particles (Ca(OH)2). The multi-particlesystem can adapt to various oral environments caused by acid beverages. Under a damp tooth surface microenvironment, the composite micro-nano particle material can release calcium, phosphate, fluorineions and hydroxide ions so as to promote remineralization of teeth. Exposed dentinal tubules can be sealed, and enamel caries can be restored by epitaxial crystal growth after remineralization. Microstructural analysis conducted through focused ion beam (FIB) cutting and transmission electron microscopy (TEM) examination indicates that the treatment can cause seamless growth of enamels, so that the composite micro-nano particle material can have good effects on enamel mineralization and restoration.

Owner:WENZHOU MEDICAL UNIV

A high-temperature large-area silicon carbide epitaxial growth device and processing method

ActiveCN102747418BKeep constantAchieve epitaxial growthPolycrystalline material growthFrom chemically reactive gasesGraphiteUltimate tensile strength

The invention discloses a high-temperature large area silicon carbide epitaxial growth device and a treatment method. The high-temperature large area silicon carbide epitaxial growth device comprises a closed working chamber made of stainless steels, a graphite reaction cavity chamber arranged in the working chamber and a heating component arranged at the periphery of the reaction cavity chamber, wherein a tray groove is arranged in the reaction cavity chamber, a tray which bears a silicon carbide substrate is arranged in the tray groove, the reaction cavity chamber is provided with a penetrating channel, and a gas inlet device and a gas outlet device are respectively arranged at two ends of the channel. During treatment, the silicon carbide substrate is put into the reaction cavity chamber and then vacuumized and heated, reaction gas is introduced into the reaction cavity chamber so as to allow epitaxial growth of the silicon carbide, and then the silicon carbide taken out. Compared with the traditional quartz tube structure, the high-temperature large area silicon carbide epitaxial growth device has a simple structure, is relatively easy to manufacture, is convenient to process and can be used for treating the silicon carbide with a larger area. In addition, according to the high-temperature large area silicon carbide epitaxial growth device disclosed by the invention, the working chamber is in a water-cooling stainless steel structure, has higher strength and is not easy to damage.

Owner:DONGGUAN TIANYU SEMICON TECH

Germanium multi-junction solar cell and preparation method thereof

PendingCN114649437ABest current matchingTake advantage ofPhotovoltaic energy generationSemiconductor devicesEngineeringBattery cell

The invention discloses a germanium multi-junction solar cell and a manufacturing method thereof. The germanium multi-junction solar cell comprises a Ge sub-cell, an InGaAs sub-cell, an InGaAsP sub-cell and an InAlGaP sub-cell which are sequentially arranged in a stacked mode. According to the germanium multi-junction solar cell and the manufacturing method thereof disclosed by the invention, the manufacturing cost of the germanium multi-junction solar cell can be reduced, the photoelectric conversion efficiency of the germanium multi-junction solar cell can be improved, and the thin film and flexibility of the germanium multi-junction solar cell can be realized.

Owner:DR TECH CO LTD YIXING JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com