Heterotopic multi-metal oxide film epitaxial growth and continuous preparation method

A technology of oxide film and multi-element metal, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of uneven component structure, easy deterioration of structure, holes, etc., and achieve rapid long-range preparation of high High-quality epitaxial film, crystallization and epitaxial growth, fast growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

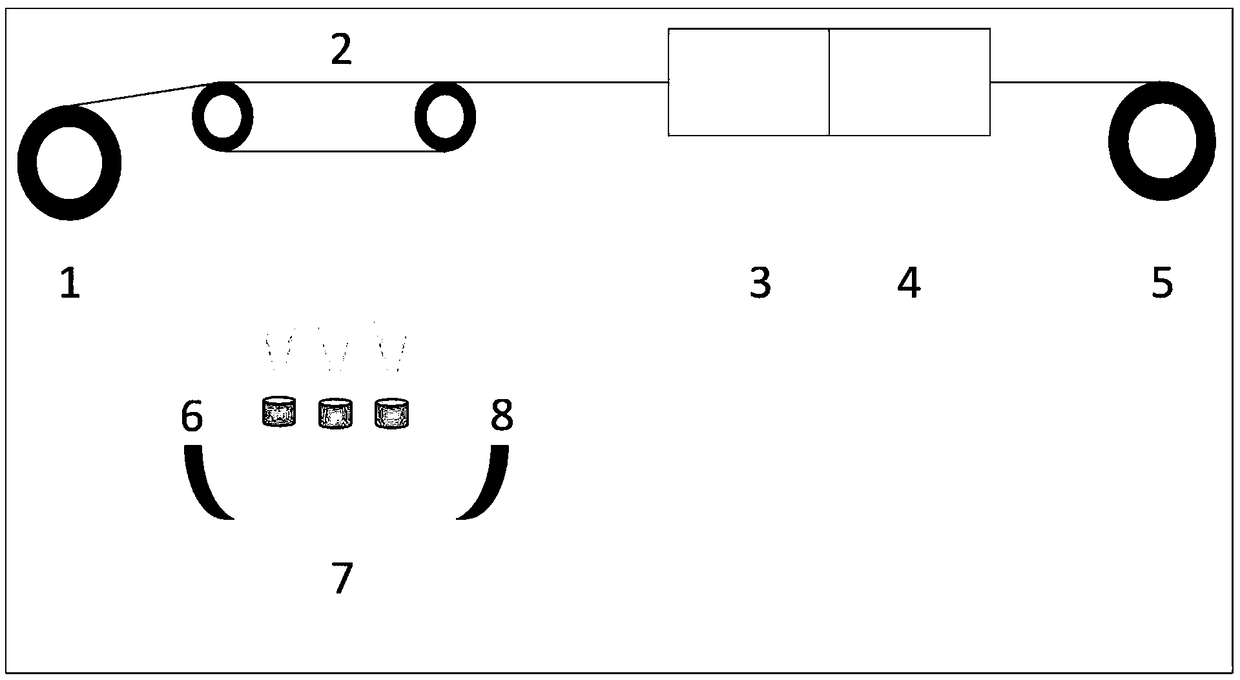

[0037] In this example, see figure 1 , an ectopic co-evaporation instrument, the names of each part are as follows: unwinding wheel 1, bidirectional multi-strand tape transport system 2, low oxygen pressure chamber 3, high oxygen pressure chamber 4, rewinding wheel 5, electron beam evaporation 6, thermal Evaporation 7, electron beam evaporation 8, taking the second-generation high-temperature superconducting tape as an example and combining figure 1 , which describes in detail the method of ex-situ continuous preparation of multi-element metal oxide epitaxial thin films. This process is always kept at 10 -5 under Torr vacuum conditions.

[0038] In this example, see figure 1 , a method for the epitaxial growth of heterotopic multi-element metal oxide film and its continuous preparation, comprising the steps of:

[0039] Step 001. Start the main power supply, start the compressor, start the water cooler, start the computer, open the backfill valve to backfill nitrogen and o...

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, especially in that:

[0053] In this embodiment, a method for the epitaxial growth of heterotopic multi-element metal oxide film and its continuous preparation includes the following steps:

[0054] Step 001. This step is the same as Embodiment 1;

[0055] Step 002. This step is the same as Embodiment 1;

[0056] Step 003. This step is the same as Embodiment 1;

[0057] Step 004. At the same time as vapor deposition, turn on the superconducting base tape conveying system, adjust the tension of the tape, the distance of the tape and the speed of the tape, and adopt the two-way multi-strand control of the strip to operate the multi-element metal on the multi-strand superconducting base tape. Co-dynamic deposition to prepare superconducting strip precursor film on superconducting substrate;

[0058] Step 005. This step is the same as Embodiment 1;

[0059] Step 006. This step is the same as Embodiment 1;

[0060] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com