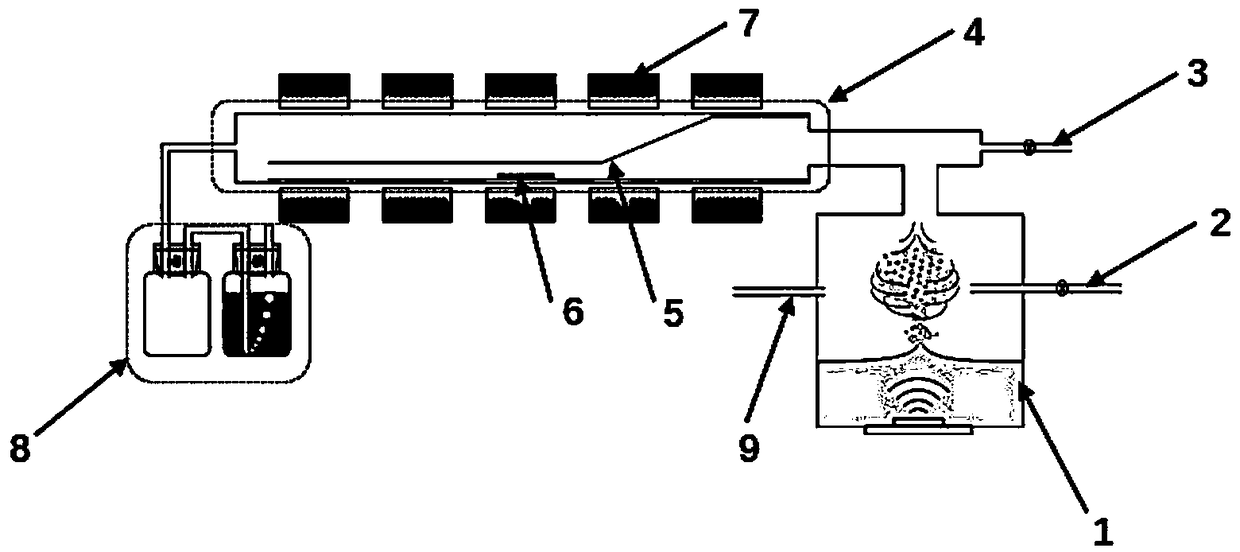

System for growth of gallium oxide by means of ultrasound-assisted fog-phase transport chemical vapor deposition

A chemical vapor deposition, ultrasonic-assisted technology, applied in the field of material growth of chemical vapor deposition, to achieve the effect of convenient doping and alloying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Epitaxial gallium oxide on sapphire

[0022] 1. Substrate cleaning, etching and annealing.

[0023] 2. Select a quartz holder with a suitable thickness, place the substrate horizontally on the quartz holder, put the quartz holder into the airflow constriction device, and then put the airflow constriction device into the growth chamber so that the substrate is located close to the growth chamber. The position of the front end of the cavity.

[0024] 3. Set the growth temperature to 600°C. When the temperature in the growth chamber reaches the set temperature, turn on the ultrasonic atomizer, and the solution added therein is 0.05mol / L gallium acetylacetonate solution. At the same time, open the dilution gas, the gas is oxygen, and the flow rate is 100 sccm. After the growth chamber was kept warm for 5 minutes, the carrier gas was turned on to start growth. The carrier gas was nitrogen, the flow rate was 700 sccm, the peristaltic pump was turned on, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com