Lithium cobalt oxide positive electrode material of lithium ion battery with voltage of 4.45 V or above and preparation method of lithium cobalt oxide positive electrode material

A battery lithium cobalt oxide and positive electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of positive electrode material capacity influence, etc., and achieve the effect of balancing conductance and structural stability, structural stability, and ensuring capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

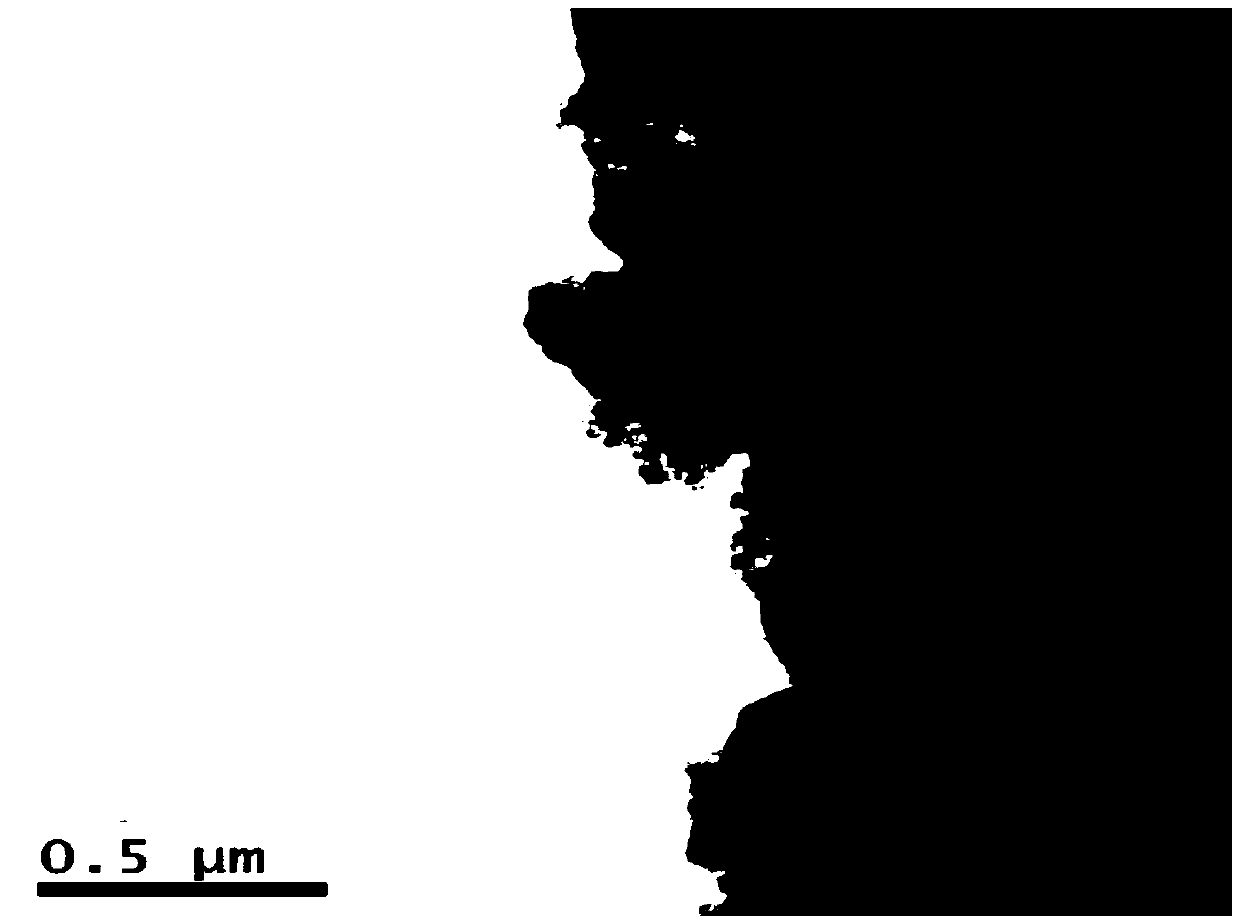

[0038] A kind of 4.45V lithium ion battery lithium cobaltate cathode material of the present invention, comprises cobaltate lithium substrate and the coating layer that is coated on substrate surface, and cobaltate lithium substrate is the lithium cobaltate of doping Mg, Ti, Al ( Molecular formula is Li 1.05 co 0.997 Mg 0.001 Ti 0.001 Al 0.001 o 2 ), the cladding layer is lithium cobalt oxide doped with elements Y and Ti, and its molecular formula is Li 0.60 co 0.97 Y 0.02 Ti 0.01 o 2 .

[0039] The preparation method of lithium cobalt oxide cathode material above 4.45V of the present invention comprises the following steps:

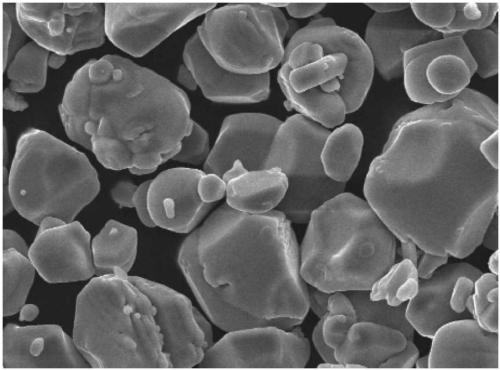

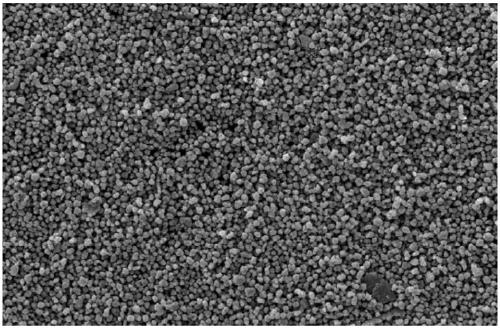

[0040] (1) Will Li 2 CO 3 、Co 3 o 4 (Spherical regular structure, D 50 =16.0~17.0μm), MgO, TiO 2 、Al 2 o 3 According to the molar ratio of Li, Co, Mg, Ti and Al elements of 1.05: 0.997: 0.001: 0.001: 0.001, fully mix in a high-speed mixer, and then carry out high-temperature solid-state sintering at 1070 ° C for 12 hours, Then the sint...

Embodiment 2

[0048] A kind of 4.45V lithium ion battery lithium cobaltate cathode material of the present invention, comprises cobaltate lithium substrate and the coating layer that is coated on substrate surface, and cobaltate lithium substrate is the lithium cobaltate of doping Mg, Ti, Al ( Molecular formula is Li 1.07 co 0.995 Mg 0.0015 Ti 0.0015 Al 0.002 o 2 ), the cladding layer is lithium cobalt oxide doped with elements Sn and Nb, and its molecular formula is Li 0.55 co 0.96 sn 0.02 Nb 0.02 o 2 .

[0049] The preparation method of lithium cobalt oxide cathode material above 4.45V of the present invention comprises the following steps:

[0050] (1) LiOH, Co(OH) 2 (spherical structure, D 50 =16.0~17.0μm), MgO, TiO 2 、Al 2 o 3 According to the molar ratio of Li, Co, Mg, Ti and Al elements of 1.07: 0.995: 0.0015: 0.0015: 0.002, fully mixed in a high-speed mixer, and then sintered at 1050 ° C for 20 hours at high temperature, and then The sintered product is pulverized to...

Embodiment 3

[0057] A kind of 4.45V lithium ion battery lithium cobaltate cathode material of the present invention, comprises cobaltate lithium substrate and the coating layer that is coated on substrate surface, and cobaltate lithium substrate is the lithium cobaltate of doping Mg, Ti, Al ( Molecular formula is Li 1.1 co 0.994 Mg 0.002 Ti 0.002 al 0.003 o 2 ), the cladding layer is lithium cobalt oxide doped with elements Mn and Nb, and its molecular formula is Li 0.60 co 0.98 mn 0.01 Nb 0.01 o 2 .

[0058] The preparation method of lithium cobalt oxide cathode material above 4.45V of the present invention comprises the following steps:

[0059] (1) LiNO 3 、Co 3 o 4 (Spherical regular structure, D 50 =16.0~17.0μm), MgO, TiO 2 、Al 2 o 3 According to the molar ratio of Li, Co, Mg, Ti and Al elements of 1.1: 0.994: 0.002: 0.001: 0.003, they were fully mixed in a high-speed mixer, and then sintered at 1030 ° C for 8 h at high temperature, and then The sintered product is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com