Low-temperature type lithium iron phosphate anode material and preparation method thereof

A technology of lithium iron phosphate and cathode material, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as high cost, unfavorable industrial production, complex process, etc., to improve electrical conductivity, facilitate de-intercalation, and reduce diffusion paths. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

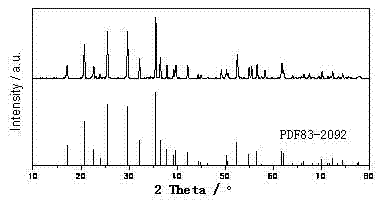

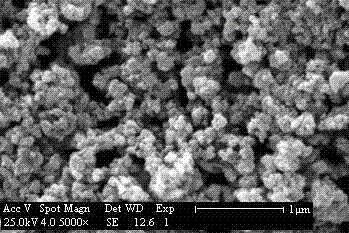

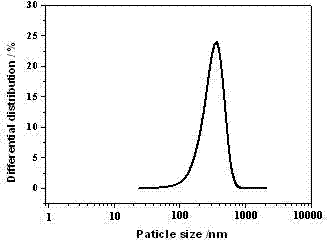

Embodiment 1

[0033] The ratio of lithium carbonate, magnesium oxide, iron phosphate and glucose is based on the molar ratio of Li:Mg:Fe:P:C=1.09: 0.01:1:1:0.8 (C is C in glucose) and then directly mixed with the above mixture Anhydrous ethanol with a mass of 2.5 times is ball milled in a planetary ball mill for 10 hours. Both the ball mill pot and the balls are made of zirconia, the diameter of the balls is 10 mm, and the weight ratio of the mixed wet material to the balls is 1:0.8. The speed of revolution is 100r / min, and the speed of rotation is 800r / min. After ball milling, the slurry is dried, pulverized, granulated, and calcined in an inert atmosphere furnace at 300°C for 5h in a loose state, and cooled to room temperature. Put the powder on the surface with a pressure of 10kg / cm3 In the compacted state, calcined at 800°C for 8 hours in an inert atmosphere furnace, and the synthesized material was subjected to airflow crushing and classification. The median particle size was controlled...

Embodiment 2

[0038] The ratio of lithium carbonate, magnesium oxide, iron phosphate and glucose is based on the molar ratio Li:Mg:Fe:P:C=1.08: 0.02:1:1:0.8 (C is C in glucose) and then directly mixed with the above mixture Anhydrous ethanol with a mass of 2.5 times is ball milled in a planetary ball mill for 10 hours. Both the ball mill pot and the balls are made of zirconia, the diameter of the balls is 10 mm, and the weight ratio of the mixed wet material to the balls is 1:2. The speed of revolution is 200r / min, and the speed of rotation is 800r / min. After ball milling, the slurry is dried, pulverized and granulated. In a loose state, it is calcined in an inert atmosphere furnace at 500°C for 2 hours and cooled to room temperature. Put the powder on the surface with a pressure of 10kg / cm 3 In the compacted state, calcined in an inert atmosphere furnace at 700°C for 10 hours, and the synthesized material was subjected to airflow crushing and classification. The median particle size was co...

Embodiment 3

[0040] The ratio of lithium carbonate, magnesium oxide, iron phosphate and glucose is based on the molar ratio of Li: Mg:Fe:P:C=1.07:0.03:1:1:0.8 (C is C in glucose) and directly mixed with the above mixture Anhydrous ethanol with a mass of 2.5 times is ball milled in a planetary ball mill for 10 hours. Both the ball mill pot and the balls are made of zirconia, the diameter of the balls is 10 mm, and the weight ratio of the mixed wet material to the balls is 1:3. The speed of revolution is 300r / min, and the speed of rotation is 600r / min. After ball milling, the slurry is dried, pulverized, granulated, and calcined in an inert atmosphere furnace at 400°C for 3h in a loose state, and cooled to room temperature. Put the powder on the surface with a pressure of 10kg / cm 3 In the compacted state, calcined in an inert atmosphere furnace at 600°C for 12 hours, and the synthesized material was subjected to airflow crushing and classification. The median particle size was controlled at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com