Method for epitaxial growth of monocrystalline barium titanate film on germanium substrate

A single crystal barium titanate, epitaxial growth technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of easy oxidation, complicated process, high cost, etc., to achieve clear interface, smooth film surface, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Use acetone, alcohol, and deionized water to ultrasonically clean the Ge(001) substrate in sequence;

[0042] 2) Load the cleaned Ge(001) substrate into the chamber of the pulsed laser deposition system, and pump the chamber to the back vacuum;

[0043] 3) heating the substrate to 800°C;

[0044] 4) annealing for 30 minutes;

[0045] 5) Maintain the air pressure at 5×10 -4 Pa, temperature 800°C;

[0046] 6) Turn on the pulse laser and control the laser energy density to 1.77J / cm 2 , the growth frequency is 2Hz, and the film is grown;

[0047] 7) End the growth, pass air into the cavity, and take out the sample.

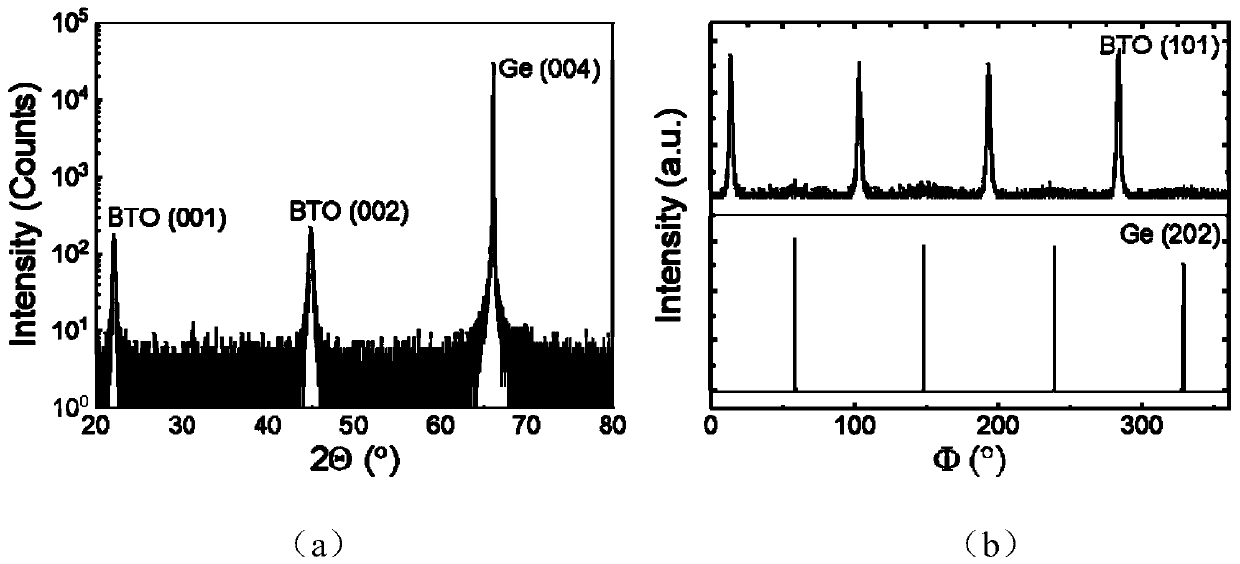

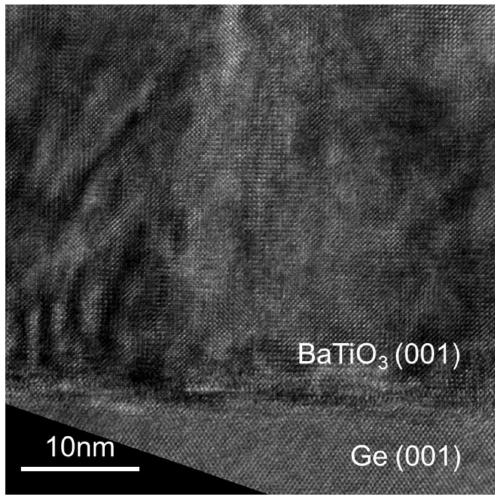

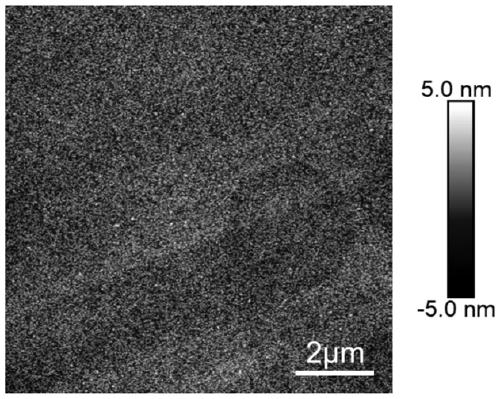

[0048] Such as figure 1 , the TEM image of the interface of the grown film, it can be seen that the interface is clear and there is no interdiffusion of atoms. Such as figure 2 , the crystallization XRD pattern of the film obtained after growth, it can be seen that the film grows epitaxially. Such as image 3 , the AFM image of the surface morphol...

Embodiment 2

[0050] 1) Use acetone, alcohol, and deionized water to ultrasonically clean the Ge(001) substrate in sequence;

[0051] 2) Load the cleaned Ge(001) substrate into the chamber of the pulsed laser deposition system, and pump the chamber to the back vacuum;

[0052] 3) heating the substrate to 800°C;

[0053] 4) annealing for 30 minutes;

[0054] 5) Maintain the air pressure at 5×10 -4 Pa, temperature 500°C;

[0055] 6) Turn on the pulse laser and control the laser energy density to 1J / cm 2 , with a growth frequency of 1 Hz, for film growth;

[0056] 7) End the growth, pass air into the cavity, and take out the sample.

Embodiment 3

[0058] 1) Use acetone, alcohol, and deionized water to ultrasonically clean the Ge(001) substrate in sequence;

[0059]2) Load the cleaned Ge(001) substrate into the chamber of the pulsed laser deposition system, and pump the chamber to the back vacuum;

[0060] 3) heating the substrate to 800°C;

[0061] 4) annealing for 30 minutes;

[0062] 5) Maintain the air pressure at 5×10 -4 Pa, temperature 650°C;

[0063] 6) Turn on the pulse laser and control the laser energy density to 5J / cm 2 , the growth frequency is 10Hz, and the film is grown;

[0064] 7) End the growth, pass air into the cavity, and take out the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com