Method for preparing transition metal chalcogenide/two-dimensional layered material interlayer heterogeneous structure through two-step chemical vapor deposition method

A chemical vapor deposition, chalcogenide technology, applied in the field of materials, can solve the problems of interface pollution, poor quality of transition metal chalcogenides, material damage, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

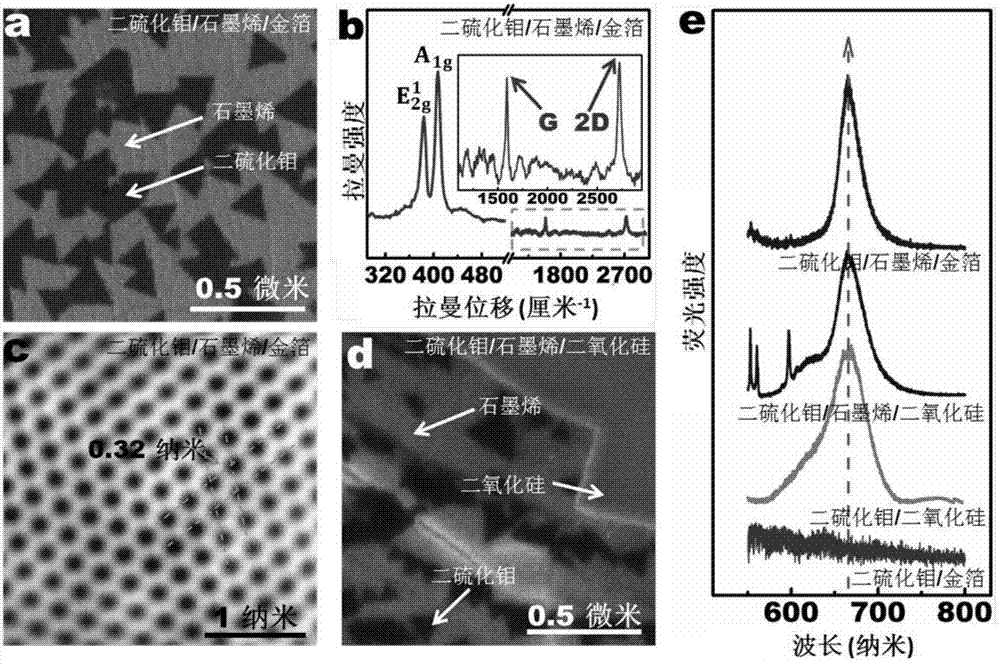

Embodiment 1

[0079] Purchased commercial gold foils (area 1 cm × 1 cm) were washed in sodium hydroxide (0.5 mol / l) solution and deionized water for 5 minutes, then ultrasonically cleaned in acetone for 10 minutes, and dried with nitrogen. Put the cleaned gold foil into a high-temperature annealing furnace at 1000°C for pre-annealing treatment, and the annealing time is 3 hours. Long-term high-temperature pre-annealing is beneficial to the reconstruction of the surface of gold foil, thereby obtaining a larger crystal plane size. The annealed gold foil is placed in a high-temperature tube furnace, and argon (200 sccm) and hydrogen (100 sccm) are introduced into the reaction chamber to clean the high-temperature tube furnace reaction chamber and discharge residual air in the chamber. The cleaning time is 20 minutes. Then reduce the flow rate of argon (100 sccm) and hydrogen (10 sccm), and raise the temperature of the reaction chamber to 970° C., open the methane gas valve after the temperatu...

Embodiment 2

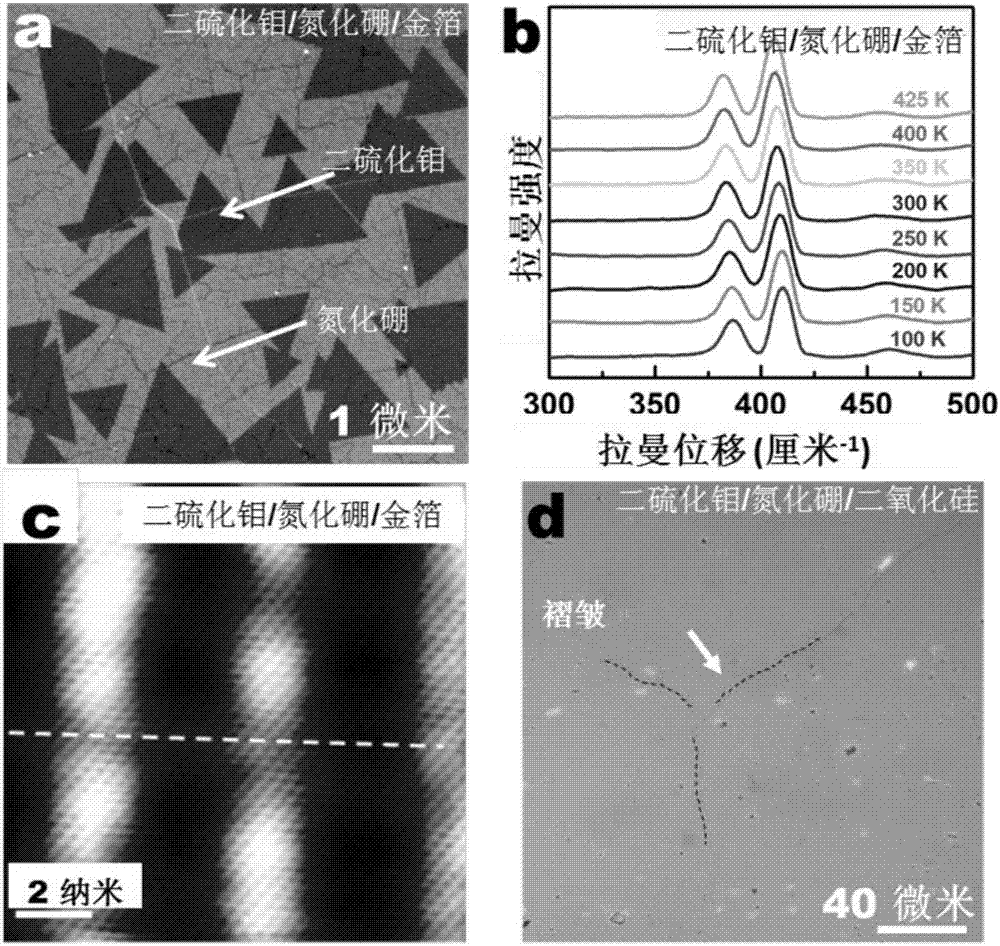

[0082]Purchased commercial gold foils (area 1 cm × 1 cm) were washed in sodium hydroxide (0.5 mol / l) solution and deionized water for 5 minutes, then ultrasonically cleaned in acetone for 10 minutes, and dried with nitrogen. Put the cleaned gold foil into a high-temperature annealing furnace at 1000°C for pre-annealing treatment, and the annealing time is 3 hours. Long-term high-temperature pre-annealing is beneficial to the reconstruction of the surface of gold foil, thereby obtaining a larger crystal plane size. The annealed gold foil was placed in a high-temperature tube furnace, and the borane ammonia and the gold foil were placed in sequence according to the sequence of the gas route from upstream to downstream, and the mass of borane ammonia was 5 mg. Turn on the vacuum pump to evacuate the vacuum in the reaction chamber to below 1Pa, and discharge the residual air in the chamber. Then argon (80sccm) and hydrogen (200sccm) were introduced into the reaction chamber, and ...

Embodiment 3

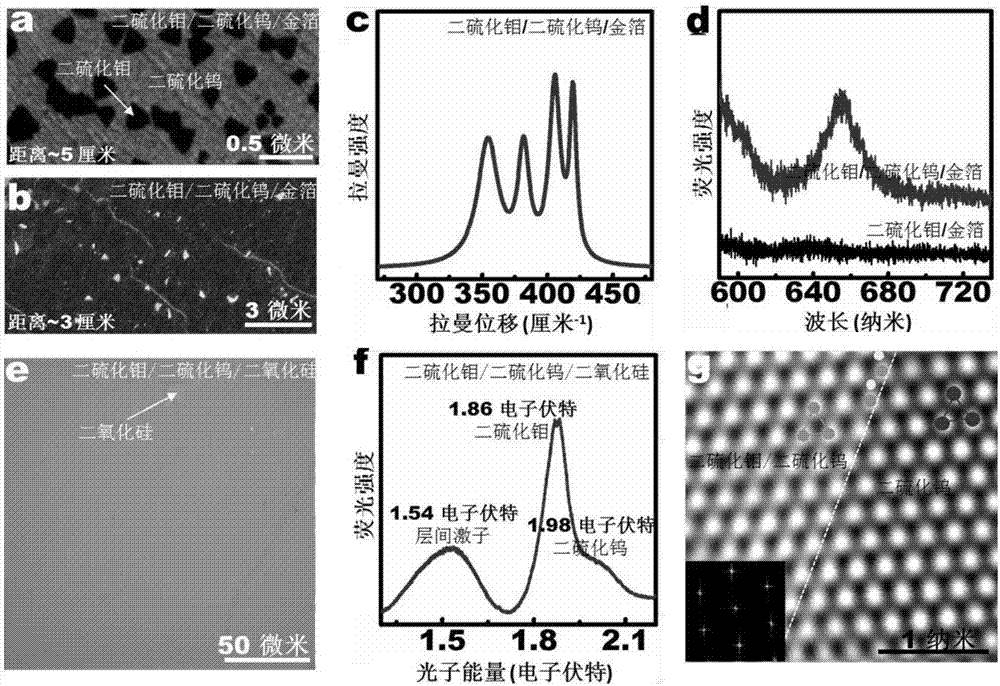

[0085] Purchased commercial gold foils (area 1 cm × 1 cm) were washed in sodium hydroxide (0.5 mol / l) solution and deionized water for 5 minutes, then ultrasonically cleaned in acetone for 10 minutes, and dried with nitrogen. Put the cleaned gold foil into a high-temperature annealing furnace at 1000°C for pre-annealing treatment, and the annealing time is 3 hours. Long-term high-temperature pre-annealing is beneficial to the reconstruction of the surface of gold foil, thereby obtaining a larger crystal plane size. The annealed gold foil is placed in a high-temperature tube furnace, and sulfur powder, tungsten oxide and gold foil are placed in sequence in the order of the gas route from upstream to downstream. The masses of sulfur powder and tungsten oxide are 100 mg and 3 mg, respectively. The distance between the tungsten oxide and the gold foil is in the range of 3 cm. Turn on the vacuum pump to evacuate the vacuum in the reaction chamber to below 1Pa, and discharge the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com