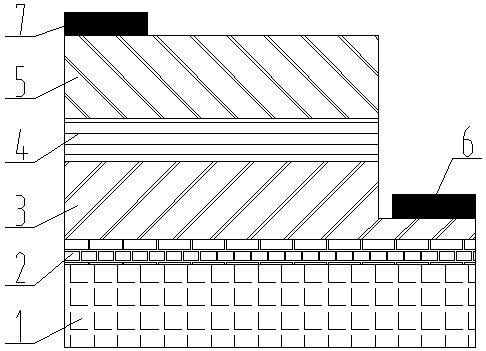

MoS2-based thin-layer ultraviolet light-emitting diode and manufacturing method thereof

A light-emitting diode, thin-layer technology, applied in nanotechnology, electrical components, nanotechnology, etc. for materials and surface science, which can solve multiple threading dislocations, poor quality of n-AlGaN, limiting GaN-based deep ultraviolet LEDs development and other issues to achieve the effect of high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention also provides a MoS-based 2 The preparation method of the thin-layer ultraviolet light emitting diode includes the following steps:

[0037] (1) On the substrate, use CVD process to grow MoS with a thickness of 2-5nm 2 The process conditions are: the temperature of the reaction chamber is 650-850°C, the pressure of the reaction chamber is maintained at 20-75 Torr, and nitrogen gas with a flow rate of 250-300sccm is introduced into the reaction chamber at the same time, and a drop of reduced graphene oxide solution is suspended before growth On the substrate surface of the substrate, then dry at 50 ℃, the MO 3 Put the powder into the CVD ceramic boat, and install the substrate face down on the top of the boat, and place the ceramic boat with a separate sulfur powder on the MO 3 Next to the powder.

[0038] (2) MoS covered with substrate 2 On the layer, use the MOCVD process to grow an n-type graded Al composition AlGaN layer with a thickness of 100-120nm by linea...

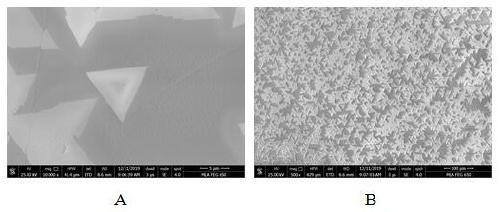

Embodiment 1

[0048] Embodiment 1. The preparation of a MoS2 thin-layer ultraviolet light emitting diode with a luminous wavelength of 320nm on a c-plane sapphire substrate includes the following steps:

[0049] Step 1: Pre-treat the substrate

[0050] After cleaning the c-plane sapphire substrate, it is placed in a chemical vapor deposition CVD reaction chamber, and the vacuum degree of the reaction chamber is reduced to 1×10 -1 Torr: Pour hydrogen into the reaction chamber, and when the pressure in the CVD reaction chamber reaches 200 Torr, heat the substrate to a temperature of 800°C and keep it for 15 minutes to complete the heat treatment of the substrate substrate;

[0051] Step two, grow MoS 2 Floor

[0052] On the treated substrate, a drop of reduced graphene oxide solution was suspended on the surface of the substrate substrate, and then dried at 50 ℃, the MO 3 The powder is placed in a CVD ceramic boat, and the substrate is mounted on the top of the boat with the substrate face down. Plac...

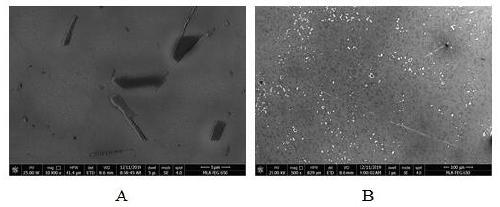

Embodiment 2

[0062] Example 2. Preparation of MoS with 295nm emission wavelength on c-plane sapphire substrate 2 The thin-layer ultraviolet light emitting diode includes the following steps:

[0063] Step 1: Pre-treat the substrate

[0064] After cleaning the c-plane sapphire substrate, it is placed in a chemical vapor deposition CVD reaction chamber, and the vacuum degree of the reaction chamber is reduced to 1×10 -1 Torr: Pour hydrogen into the reaction chamber, and when the pressure in the CVD reaction chamber reaches 200 Torr, heat the substrate to a temperature of 800° C. and keep it for 15 minutes to complete the heat treatment of the substrate substrate.

[0065] Step two, grow MoS 2 Floor

[0066] On the treated substrate, a drop of reduced graphene oxide solution was suspended on the surface of the substrate substrate, and then dried at 50 ℃, the MO 3 The powder is placed in a CVD ceramic boat, and the substrate is mounted on the top of the boat with the substrate face down. Place a separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com